You rely on lifting accessories to move heavy loads efficiently and protect workers on the job site. Industry standards define lifting accessories as equipment or elements that facilitate lifting work while meeting strict legislative requirements for worker health and safety.

You must select and use these components according to the load and always follow the manufacturer’s instructions. In construction, marine, transportation, and cargo handling, understanding safe lifting practices and safety considerations helps you prevent accidents and improve productivity.

Choosing certified products from trusted brands like Powerful Machinery ensures you meet safety standards and support reliable lifting operations.

Key Takeaways

Choose the right lifting accessories based on load weight and type. This ensures safety and efficiency during lifting operations.

Regularly inspect lifting equipment before each use. Daily checks help catch potential issues early and prevent accidents.

Invest in operator training for safe lifting practices. Proper training reduces risks and builds a strong safety culture on the job site.

Select certified products from trusted brands like Powerful Machinery. This guarantees compliance with safety standards and reliable performance.

Understand the specific uses of lifting accessories. Knowing how to use chains, slings, shackles, and hooks correctly enhances safety and productivity.

Main Types of Lifting Accessories

When you work with heavy loads, you need the right lifting accessories to ensure safety and efficiency.

International safety organizations recognize a wide range of lifting equipment, but the most essential accessories include chains, slings, shackles, hooks, lifting beams and spreaders, eyebolts, karabiners, and other hardware. Each plays a unique role in lifting operations.

Powerful Machinery manufactures certified lifting accessories that meet or exceed global standards, giving you confidence in every lift.

Chains

Chains are among the most robust lifting accessories you can use. They handle heavy-duty lifting in construction, marine, and industrial settings. You will find chains in various grades, each designed for specific working load limits and applications.

Chain Grade | Working Load Limit (WLL) Characteristics |

|---|---|

Grade 80 | Known for strength and toughness, with a 4:1 safety factor. |

Grade 100 | Offers roughly 25% higher WLL than Grade 80, allowing for smaller chains. |

Grade 120 | Features advanced geometry for even load distribution, enhancing durability and service life. |

The material of the chains affects their performance and suitability for different environments.

Material | Properties | Applications |

|---|---|---|

Carbon Steel | Basic durability, cost-effective, suitable for moderate loads | General lifting applications |

Alloy Steel | Higher tensile strength, ideal for heavy-duty applications | Infrastructure projects |

Stainless Steel | Excellent corrosion resistance, withstands harsh environments | Outdoor and industrial applications |

Powerful Machinery produces high-tensile chains in Grade 80 and Grade 100, ensuring you get reliable lifting accessories for demanding jobs.

Slings

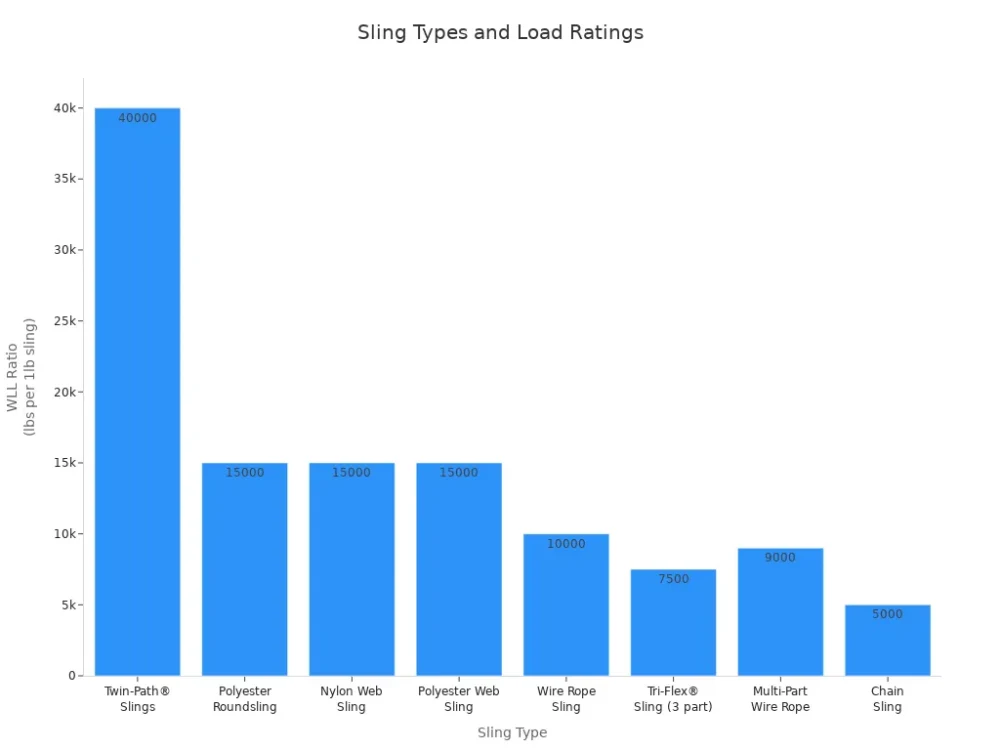

Slings are versatile lifting accessories that connect loads to cranes or hoists. You can choose from several types of slings, each with unique properties and load ratings. The main types of slings include chain slings, wire rope slings, synthetic web slings, and roundslings.

Sling Type | Approx. Weight to WLL Ratio | Max Temp | Flexibility | Design Factor | Proof Tested | Repairable |

|---|---|---|---|---|---|---|

Twin-Path® Slings | 1lb/40,000lbs | 180 | Very Flexible | 5:1 | Yes | Yes |

Polyester Roundsling | 1lb/15,000lbs | 180 | Very Flexible | 5:1 | No | No |

Nylon Web Sling | 1lb/15,000lbs | 180 | Very Flexible | 5:1 | No | No |

Polyester Web Sling | 1lb/15,000lbs | 180 | Very Flexible | 5:1 | No | No |

Wire Rope Sling | 1lb/10,000lbs | 400 | Low | 5:1 | No | No |

Tri-Flex® Sling (3 part) | 1lb/7,500lbs | 400 | Flexible | 5:1 | No | No |

Multi-Part Wire Rope | 1lb/9,000lbs | 400 | Flexible | 5:1 | No | No |

Chain Sling | 1lb/5,000lbs | 400 | Flexible | 4:1 | Yes | Yes |

You must inspect slings before every lift. Never exceed the rated capacity. Powerful Machinery offers a full range of slings, including custom-engineered solutions for unique lifting needs.

Shackles

Shackles are essential lifting accessories for connecting chains, slings, and other hardware. You will encounter several types, each suited for specific tasks:

Anchor Shackles: Feature a rounded bow, ideal for multi-leg slings.

Chain Shackles (Dee Shackles): Compact, perfect for single-leg slings and tight spaces.

Wide Body Shackles: Extra-wide bow for heavy lifting and reduced wear.

Round Pin Shackles: Secured with a cotter pin, best for straight-line pulls.

Screw Pin Shackles: Quick to connect and disconnect, great for temporary jobs.

Bolt-Type Shackles: Most secure, used for permanent installations.

Shackles must display clear identification markings for safe working load. Powerful Machinery’s shackles meet international certification requirements, ensuring your lifting operations remain compliant and safe.

Hooks

Hooks are critical lifting accessories that attach slings or chains to loads. You will find several hook designs, each with a specific purpose:

Eye Hooks: Durable and secure, ideal for lifting heavy machinery and steel beams.

Clevis Hooks: Allow quick reconfiguration, common in construction and cargo handling.

Swivel Hooks: Rotate for precise load positioning, useful in shipbuilding and manufacturing.

Sling Hooks: Designed for use with slings, providing a secure grip.

Grab Hooks: Grip irregular shapes, often used in forestry and salvage.

Safety Feature | Description |

|---|---|

Automatic Hooks | A fail-safe mechanism prevents accidental release during lifting. |

Elimination of Accidents | Reduces risk when operating at heights. |

Injury Reduction | Minimizes repetitive movements and manual handling. |

Hand Injury Prevention | Reduces the need to manipulate accessories by hand. |

Hazardous Material Handling | Protects operators from exposure to dangerous materials. |

Temperature Exposure | Limits direct contact with extreme temperatures. |

Hooks from Powerful Machinery comply with ASME, EN, and ASTM standards, giving you peace of mind during every lift.

Lifting Beams & Spreaders

Lifting beams and spreaders help you manage loads that are wide, heavy, or awkwardly shaped. These lifting accessories distribute weight and reduce stress on the load and rigging.

Lifting beams have a single attachment point and convert lifting loads into bending forces.

Spreader beams use two lifting points and convert loads into compressive forces, making them ideal for wide or heavy loads.

Spreader beams distribute weight evenly, reducing the risk of damage.

Some spreader beams can support up to 170 tons at a length of 20 meters, but you must always consider the configuration and available height. Powerful Machinery offers custom lifting beams and spreaders for specialized lifting challenges.

Eyebolts

Eyebolts are threaded lifting accessories that provide secure anchor points for hoisting. You use lifting eyebolts to attach slings, hooks, or chains directly to machinery or structures.

Specification | Value |

|---|---|

Material | Carbon Steel |

Heat Treat | Quench and draw |

Tensile Strength | 65,000 PSI MIN – 90,000 PSI MAX |

Yield Strength | 30,000 PSI MIN |

Elongation | 30% MIN |

Rated Capacity | Refer to Eyebolt Dimensions & Rated Capacities |

You must always use lifting eyebolts according to the manufacturer’s guidelines. Improper configuration or planning can lead to failure. Powerful Machinery’s eyebolts meet strict quality standards, ensuring reliable performance in every lift.

Karabiners

Karabiners, also known as carabiners, are quick-connecting lifting accessories. You use them for temporary connections in rigging and lifting. Only use karabiners rated for lifting, as not all are suitable for overhead loads.

Type of Carabiner | Minimum Breaking Strength (MBS) | Working Load Limit (WLL) | Safety Factor Ratio |

|---|---|---|---|

Steel Carabiner | 25,000 lbs | 5,000 lbs | 5:1 |

Aluminum Carabiner | 12,500 lbs | 2,500 lbs | 5:1 |

Heavy Duty Carabiner | 23-30 kN (5,170-6,740 lbs) | Varies by application | Varies |

ANSI standards require karabiners used in lifting to meet strict classifications. Powerful Machinery supplies industrial-grade karabiners for safe, compliant lifting.

Other Accessories (Cable Clamps, Tensioners, Thimbles)

You will also need other lifting accessories to complete your rigging system. Cable clamps secure wire rope ends. Tensioners keep cables taut and maintain structural integrity. Thimbles protect the eye or loop of a wire rope, preventing kinking and wear.

Component | Function |

|---|---|

Cable Thimbles | Protect and support the eye or loop of a wire rope, preventing kinking, fraying, and crushing. |

Cable Tensioners | Keep cables taut, ensuring safety and structural integrity. |

Powerful Machinery offers a full range of these accessories, all manufactured to the highest standards for safety and durability.

Tip: Always select lifting accessories that match your load requirements and environmental conditions. Certified products from Powerful Machinery help you maintain safety and compliance in every lifting operation.

Lifting Uses & Selection Criteria

Typical Applications

You encounter a wide range of lifting tasks in construction, marine, and industrial environments. Chains and slings handle heavy lifting and hoisting, especially when you need durability and flexibility. You use chain slings in single, double, or quad leg configurations for lifting steel beams, machinery, or containers.

These chains stretch and elongate under load, which increases safety during lifting work. Slings, including wire rope and synthetic types, help you move fragile or irregularly shaped items. Shackles and hooks connect slings to cranes or anchor points, making securing loads efficient and reliable.

Lifting beams and spreaders distribute weight for wide or awkward loads, while eyebolts and karabiners provide secure attachment points for lifting and hoisting in tight or temporary setups. You must always use certified lifting accessories to ensure safe lifting operations.

How to Choose Accessories?

Selecting the right lifting accessories requires careful evaluation of your lifting needs. You must consider the type of load, the environment, and the required safety standards. The table below outlines the most common criteria you should review:

Criteria | Description |

|---|---|

Load Requirements | Assess the weight and size of the objects being lifted, including any special requirements. |

Workplace Environment Considerations | Consider whether the lifting will occur indoors or outdoors, and the conditions of the environment. |

Material and Construction | Evaluate the strength and durability of the materials used in the lifting accessories. |

Load Capacity | Ensure the accessory can handle loads greater than the weight being lifted for safety. |

Safety Standards | Choose accessories that meet regulatory safety standards, such as OSHA and ANSI. |

Powerful Machinery offers custom-engineered solutions for unique project needs, ensuring you always have the right equipment for securing loads in any environment.

Key Selection Factors (Load, Center of Gravity, Angles, Environment)

You must understand several key factors before you select lifting accessories. The table below summarizes these factors:

Factor | Description |

|---|---|

Load Weight | The total weight of the load being lifted, which must be known to select appropriate rigging. |

Center of Gravity (CG) | The point where the load’s weight is balanced, crucial for stability during lifting operations. |

Sling Angle | The angle of the sling affects the tension and force on the rigging; lower angles increase tension. |

Rigging Configuration | The arrangement of slings (e.g., single-leg vs. two-leg) impacts load stability and safety. |

The center of gravity affects the tilt angle during lifting. You must keep the center of gravity as low as possible to minimize excessive tilt and prevent instability.

Environmental factors play a major role. Outdoor or marine lifting exposes accessories to moisture, salt, and temperature changes. You should select materials that resist corrosion and withstand extreme conditions. Regular maintenance helps prevent equipment failure and ensures safe securing loads.

Tip: Always match your lifting accessories to the load, environment, and safety requirements. Consult with Powerful Machinery for expert guidance and custom solutions for your lifting and hoisting challenges.

Regulations Related to Lifting Accessories & Safety

Required Markings & Documentation

You must ensure that all lifting accessories display clear markings and come with proper documentation. Markings indicate the maximum load each accessory can safely handle. This information helps you select the right equipment for your rigging applications and prevents overloading.

The table below shows common marking requirements for different accessories:

Type of Accessory | Marking Requirement | Standard |

|---|---|---|

Eyebolts | Maximum mass authorized to sustain along the centerline axis | EN 3266 |

Shackles | Maximum mass authorized to sustain in general service | EN 13889 |

Flat Webbing Sling | Maximum mass designed to sustain in a straight pull | EN 1492-1 |

Roundsling | Maximum mass designed to sustain in a straight lift | EN 1492-2 |

Wire Rope Sling | Maximum mass authorized to sustain in general service | EN 13414-1 |

Chain Sling | Maximum mass authorized to be sustained in the general lifting service | EN 818-4 |

In Europe, the Machinery Directive requires an EC Declaration of conformity. You also need a manufacturer’s certificate for most lifting accessories. Initial certification depends on local regulations related to lifting accessories.

Powerful Machinery provides full documentation and markings for all chains, slings, and rigging hardware, supporting your compliance needs.

LOLER & International Standards

You must follow the Lifting Operations and Lifting Equipment Regulations (LOLER) and other international standards to ensure safe lifting operations. These regulations related to lifting accessories set strict rules for planning, equipment use, and thorough examinations. The table below highlights key provisions:

Key Provision | Description |

|---|---|

Proper Planning and Management | Lifting operations must be properly planned and managed. |

Safe Use of Equipment | Lifting equipment must be used in a safe manner. |

Regular Inspections | Lifting equipment must be thoroughly inspected at suitable intervals by a competent person. |

LOLER covers a wide range of lifting equipment, including chains, slings, hooks, and spreader beams. Compliance with these regulations ensures safety and reduces the risk of accidents. Powerful Machinery’s products meet or exceed ISO, EN, and OSHA standards, giving you confidence in every lift.

Inspection Intervals & Legal Compliance

You must inspect lifting accessories regularly to maintain compliance and prevent failures. Daily checks by operators help you spot visible damage before each shift. Monthly inspections focus on wear and integrity for wire rope, chains, and hooks.

OSHA and ASME require documented, thorough examinations at least every twelve months. For harsh environments, you may need quarterly or monthly inspections. Always keep records of each inspection to prove compliance during audits or investigations.

Tip: Schedule thorough examinations of all rigging hardware and lifting accessories to ensure ongoing safety and legal compliance.

Risks of Non-Compliance

Ignoring regulations related to lifting accessories can lead to serious consequences. You risk fines, penalties, and even prison sentences for failing to follow lifting operations and lifting equipment regulations. Non-compliance increases the chance of preventable accidents and injuries.

In recent years, the construction industry has seen a sharp rise in workplace fatalities. Delays from safety investigations and equipment failures can disrupt your operations. Your company’s reputation may suffer, leading to lost customers and damaged partnerships.

You protect your team and your business by prioritizing compliance and thorough examinations in all rigging applications.

Inspection, Maintenance & Training Best Practices

Daily Visual Checks

You must start every shift with a daily visual inspection of your lifting accessories. This process helps you catch problems before they lead to accidents. Follow these steps for effective inspections and checks on lifting accessories:

Prepare for inspection. Gather your checklist, flashlight, and personal protective equipment.

Review the operational manual for your slings and other lifting gear.

Conduct a general overview. Look for visible damage, loose parts, or anything unusual.

Check all protective features, including emergency stops and interlocks.

Examine electrical connections for fraying or damage.

Verify fluid levels and look for leaks if your equipment uses hydraulics.

Document your findings on the checklist.

Report any concerns and arrange for repairs or maintenance.

You must always perform an inspection in case of an accident, even if the equipment looks fine.

Scheduled Inspections

You need to schedule regular inspections to keep your lifting operations safe. These checks go beyond daily visual inspection and include detailed reviews of slings, chains, hooks, and other lifting accessories. Monthly and annual inspections help you find wear, corrosion, or deformation.

You should always keep records of these inspections for compliance and traceability. Powerful Machinery recommends following industry standards for periodic maintenance of lifting accessories to ensure reliability.

Maintenance Procedures

You extend the life of your slings and lifting equipment with proper maintenance. Periodic maintenance of lifting accessories includes:

Lubricate and clean all moving parts to prevent rust and wear.

Repair or replace damaged components right away.

Test the equipment to confirm it can handle the loads required.

Schedule regular inspections to catch issues early.

Well-maintained lifting accessories improve safety and efficiency. You reduce the risk of accidents and keep your lifting operations running smoothly when you follow these maintenance steps.

Operator Training

You must invest in training for everyone who handles lifting accessories. Slinger signaller training teaches you how to attach and detach slings, signal crane operators, and recognize hazards. You need sling signaller training to understand load weights, angles, and safe lifting practices.

Slinger signaller training also covers how to inspect and maintain equipment. Industry standards require that you receive both formal and practical instruction.

The employer must provide each operator-in-training with sufficient training, through a combination of formal and practical instruction, to ensure that the operator-in-training develops the skills, knowledge, and ability to recognize and avert risk necessary to operate the equipment safely for assigned work.

The operator-in-training must be continuously monitored on-site by a trainer while operating equipment. The employer may only assign tasks within the operator-in-training’s ability.

You should only source lifting accessories from certified suppliers like Powerful Machinery. This ensures your training matches the equipment you use and supports a culture of safety.

Conclusion

You improve safety and efficiency when you understand the main types of lifting accessories and their uses. You must follow regulations, inspect your lifting equipment, and keep up with maintenance. Choose certified products from trusted brands like Powerful Machinery.

Review your current lifting practices and invest in training. Training helps you recognize hazards, use lifting gear correctly, and keep your team safe. Training also builds confidence and supports a strong safety culture. Make training a priority for every lifting operation.

Take action today: Review your lifting procedures and schedule regular training for your team.

FAQ

What is the most important factor when choosing lifting accessories?

You must always consider the load weight and type. Check the working load limit and ensure the accessory matches your lifting needs. Proper selection helps you avoid accidents and keeps your lifting operations safe.

How often should you inspect lifting accessories?

You should inspect lifting accessories before each use. Schedule regular, detailed inspections monthly or annually, depending on usage and environment. Frequent checks help you spot wear or damage early and prevent equipment failure.

Why is operator training essential for safe lifting?

Operator training teaches you how to use lifting accessories correctly. You learn to identify hazards, follow safety procedures, and perform inspections. Proper training reduces accidents and improves workplace safety.

Can you use any sling or hook for all lifting jobs?

No, you cannot use any sling or hook for every job. Each lifting task requires specific accessories. You must select equipment based on load, environment, and safety standards. Training helps you make the right choice.

How does training impact compliance with safety regulations?

Training ensures you understand legal requirements and industry standards. You learn how to document inspections, use certified equipment, and follow best practices. Ongoing training keeps your team compliant and reduces the risk of violations.