Rigging and slinging safety stands at the core of every successful lifting operation. You must follow clear guidelines to protect yourself and your team from unnecessary risk. Rigging and slinging safety relies on certified equipment, which trusted brands like Powerful Machinery deliver through rigorous testing and strict guidelines.

Industry data shows that certified manufacturers achieve a 22.6% drop in accident frequency and a 29.2% decrease in accident severity. Rigging and slinging safety depends on your commitment to these guidelines.

You create a safer work environment by making rigging and slinging safety your top priority and following all guidelines.

Key Takeaways

Prioritize sling safety by using certified equipment and following manufacturer guidelines to reduce accident risks.

Inspect slings before each use to catch damage early and ensure safe lifting operations.

Understand the working load limit (WLL) of slings to prevent overloading and potential failures.

Choose the right sling type and hitch for each lift to enhance safety and efficiency.

Provide ongoing training for your team to maintain awareness of rigging safety practices and compliance.

Rigging and Slinging Safety Essentials

Sling Safety Fundamentals

You play a critical role in maintaining rigging safety on every job site. Safe rigging starts with a clear understanding of sling safety. You must recognize the risks and follow best practices to protect yourself and your team.

Industry safety reports show that improper installations, overloading, and damaged slings are leading causes of accidents. You can see the most common causes in the table below:

Cause | Description |

|---|---|

Improper Installations | Rigging systems must be designed and installed by experts to prevent accidents. |

Overload | Exceeding the working load limit (WLL) of rigging equipment often leads to failures. |

Damaged Synthetic Slings | Rips and tears from environmental factors can cause synthetic slings to fail. |

Stretched or Bent Links | Misjudging the strength of chain slings can result in overloading and failure. |

You must always follow the manufacturer’s guidelines when selecting and using slings. This practice forms the foundation of superior sling safety. According to the U.S. Bureau of Labor Statistics, over 30% of rigging-related accidents result from incorrect sling usage.

You can prevent these incidents by choosing the right sling, inspecting it before each use, and never exceeding its rated capacity.

OSHA 1910.184(c) requires that slings must not be damaged, should not be shortened with makeshift devices, and must be securely attached to loads.

You should also remember these essential safety standards:

Know the load weight before lifting.

Guard against sharp edges to protect your slings.

Focus on the final moments—always conduct a last check before lifting.

You face several challenges in sling safety. These include improper sling selection, neglecting inspections, overloading, and failing to use proper protection and storage methods. You must address each challenge to achieve superior sling safety.

You should never use damaged or defective slings. You must keep all personnel clear of loads about to be lifted. You should not load slings beyond their rated capacities.

Superior sling safety depends on your commitment to these fundamentals. You must use the correct sling, device, and hitch for each lift. You must protect slings from sharp edges and understand the structural integrity of every load. When you follow these steps, you create a safer environment and reduce the risk of accidents.

Role of Powerful Machinery Products

You need equipment that meets the highest standards for rigging safety. Powerful Machinery delivers certified, high-performance lifting and rigging solutions trusted by professionals worldwide. Every product undergoes rigorous testing and meets or exceeds international safety standards.

You benefit from features such as machine guards, emergency stop buttons, safety interlocks, and warning lights. These controls protect you and your team during lifting and rigging operations.

Safety Features and Controls | Description |

|---|---|

Machine Guards | Protect you from moving parts. |

Emergency Stop (E-Stop) Buttons | Allow immediate shutdown in emergencies. |

Safety Interlocks | Prevent operation under unsafe conditions. |

Warning and Indicator Lights | Alert you to potential hazards. |

Lockout/Tagout Systems | Ensure machinery is properly shut down during maintenance. |

Safety Sensors | Detect unsafe conditions and prevent operation. |

You can trust Powerful Machinery to comply with all legal standards and regulations. The company implements risk assessments, regular maintenance, and inspections. You receive training and education for operators, and all safety practices are documented and reported.

This commitment ensures superior sling safety and reliable performance in every lifting and rigging scenario.

Superior sling safety is not just about the equipment. It is about your actions and your attention to detail. When you use Powerful Machinery products, you gain peace of mind knowing you have chosen equipment designed for maximum safety and efficiency.

You support a culture of rigging safety that protects everyone on site.

You must make superior sling safety your standard practice. You must follow the manufacturer’s guidelines, inspect your equipment, and use only certified products. You ensure safe rigging and lifting and rigging operations every time you step onto the job site.

Identifying Sling Types

Choosing the right sling type is essential for safe and efficient lifting. Powerful Machinery offers a complete range of solutions to match your specific needs. You must understand the unique features and benefits of each sling to use them safely and maximize performance.

Chain Slings for Heavy Loads

You rely on chain slings when you need to lift the heaviest loads in demanding environments. Powerful Machinery manufactures chain slings from high-grade alloy steel, ensuring you get unmatched strength and durability.

These slings perform well in construction, manufacturing, and shipping. You can trust them to handle extreme conditions and repeated use.

Key safety features of chain slings include:

Strength and longevity from Grade 100 or higher alloy steel, which provides about 25% more strength than Grade 80 slings.

Reliable performance in high temperatures, maintaining strength up to 400°F.

Resistance to cuts and abrasions, so you can depend on them in tough conditions.

Compliance with strict safety standards, including ANSI, NACM, ASTM, and OSHA.

You should select chain slings for heavy-duty lifting where safety and reliability matter most.

Slings & Tie Downs Versatility

You need versatile lifting solutions for a wide range of tasks. Slings & Tie Downs from Powerful Machinery offer flexibility and adaptability across many industries. You can use them for lifting, securing, and transporting loads in construction, logistics, and marine operations.

Sector | Applications | Advantages |

|---|---|---|

Industrial Production | Equipment installation and transport | High load capacity and tensile strength |

Logistics Transportation | Cargo lifting and securing | Lightweight and easy to operate |

Construction Engineering | Lifting materials and equipment | Quick task completion and improved efficiency |

Maritime Transport | Loading/unloading at ports | Long service life and low maintenance |

Air Transport | Aircraft maintenance and cargo handling | Broad applicability |

Other Fields | Fisheries, agriculture, and mining | Made from renewable materials for sustainability |

You benefit from their soft, lightweight design, which makes them easy to handle and reduces the risk of damage to delicate loads.

Round Webbing Sling Features

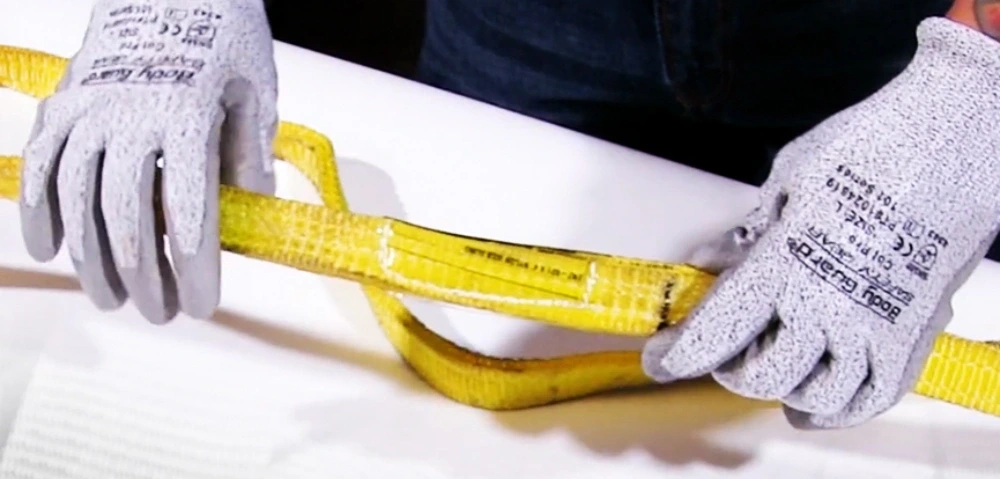

You should consider round webbing slings when you need to lift sensitive or irregularly shaped loads. Powerful Machinery’s round webbing slings use 100% polyester yarn for high strength and low stretch. The color-coded system helps you identify load capacity quickly, reducing the risk of overloading.

These slings feature a non-load-bearing tubular sleeve that protects the internal fibers from wear and dirt. You can customize the length and add company branding for easy identification. Their flexibility and gentle touch make them ideal for industries like steel, wood handling, and warehousing.

You must use proper sling types for each lifting scenario to ensure safety and efficiency. Understanding these options helps you make the best choice for your operation.

Inspect Slings Regularly

You must inspect slings regularly to ensure safe lifting operations and extend the life of your equipment. Routine visual inspections help you catch early signs of wear, damage, or misuse before they lead to accidents.

Industry standards recommend specific inspection intervals for each sling type. You can use the table below as a quick reference:

Sling Type | Inspection Frequency |

|---|---|

Alloy Steel Chain Slings | Daily visual inspection + thorough periodic inspection at least once every 12 months |

Wire Rope Slings | Daily visual inspection + additional based on use and conditions |

Synthetic Slings | Daily visual inspection + periodic inspection as recommended |

You should always follow the manufacturer’s guidelines and your company’s safety protocols. Powerful Machinery provides clear instructions and labels on every product, making it easy for you to stay compliant.

Inspection Steps for Chain Slings

You rely on chain slings for heavy-duty lifting, so you must check them carefully. Start with a visual inspection before each use. Look for stretched, bent, or cracked links. Examine hooks and connectors for deformation or missing safety latches.

Check for signs of corrosion or wear, especially at the contact points. If you find any of these issues, remove the sling from service immediately.

For a more thorough inspection, measure the length of each leg. Compare it to the original length. Any permanent stretch means the sling has been overloaded. You should also check the identification tag. Make sure it is readable and matches the sling’s configuration and grade.

Powerful Machinery’s chain slings feature high-tensile steel and corrosion-resistant finishes, but you must still inspect them regularly to maintain safety.

Checking Slings & Tie Downs

You use slings & tie downs for their versatility and ease of handling. These products require careful attention during inspections. Begin with a visual check for cuts, tears, or abrasions on the webbing.

Look for chemical burns or discoloration, which can weaken the fibers. Examine the stitching for loose threads or broken seams. Inspect hardware such as hooks, rings, and buckles for deformation or missing parts.

Synthetic slings are especially vulnerable to chemical damage. Exposure to harsh chemicals can degrade the fibers and reduce the sling’s load-bearing capacity. If you notice any damage, remove the sling from service.

Powerful Machinery’s slings & tie downs come with color-coded labels and reinforced eyes, making it easier for you to spot problems quickly.

Round Webbing Sling Inspection

You depend on round webbing slings for lifting delicate or irregular loads. These slings require a detailed inspection routine. Start by feeling along the entire length of the sling.

Check for cuts, snags, or abrasion on the outer sleeve. Look for exposed core yarns, which indicate serious damage. Inspect the identification label to confirm the working load limit and safety factor.

You should also check for chemical stains or burns. These signs mean the sling may have lost strength. Powerful Machinery’s round webbing slings feature a non-load-bearing tubular sleeve and PU impregnation for extra protection, but you must still inspect them before every lift.

Tip: Always keep a record of your inspections. Document the date, findings, and any actions taken. This practice helps you track sling condition and ensures compliance with safety standards.

The most frequent defects you may find during inspections include:

Broken or damaged rigging hardware, such as bent hooks or missing latches

Chemical damage to synthetic slings, which weakens the fibers

Cuts, abrasion, or deformation to the sling body

You protect your team and your investment when you inspect slings regularly. Consistent visual inspections help you prevent accidents, reduce downtime, and extend the service life of your Powerful Machinery lifting equipment.

Know Sling Capacities

Understanding sling capacity is essential for every lifting operation. You must know sling capacities before you start any lift. This knowledge helps you prevent overloading and ensures the safety of your team and equipment.

Understanding Working Load Limits

You determine the rated capacity of a sling by considering several factors. The working load limit (WLL) is the maximum load a sling can safely handle. Manufacturers calculate this limit through rigorous testing and engineering. You must check the following when assessing sling capacity:

Chain size and grade: Larger and higher-grade chains support heavier loads.

Number of legs: Multi-leg slings distribute weight and increase capacity.

Angle of lift: Narrower angles increase tension and reduce the rated capacity.

Type of hitch: Basket, choker, and vertical hitches affect the load a sling can carry.

Material strength and design factor: These influence the final WLL.

Wear, damage, and environmental conditions: Corrosion or extreme temperatures lower the safe limit.

Never exceed the rated capacity. Overloading can cause sling failure and serious accidents.

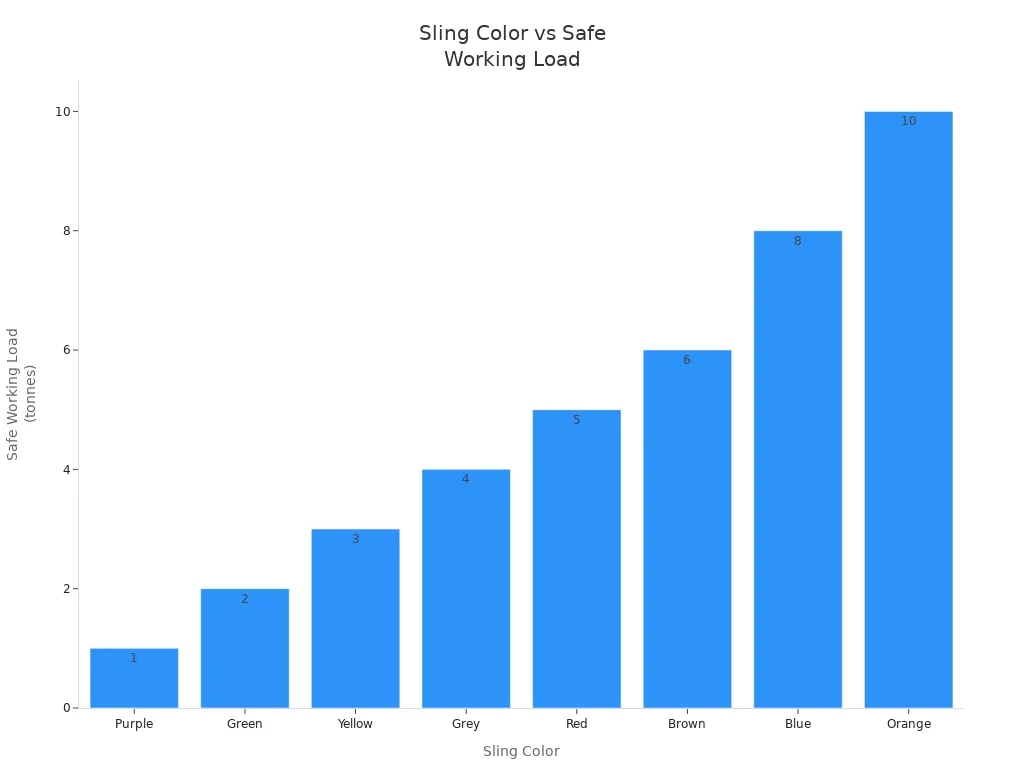

Capacity Labels and Color Coding

You can quickly identify the rated capacity of synthetic slings by checking their color coding and labels. Each color represents a specific safe working load. This system helps you select the right sling for each job and reduces the risk of mistakes.

Color | Safe Working Load (SWL) |

|---|---|

Purple | 1 tonne |

Green | 2 tonnes |

Yellow | 3 tonnes |

Grey | 4 tonnes |

Red | 5 tonnes |

Brown | 6 tonnes |

Blue | 8 tonnes |

Orange | 10 tonnes and above |

Labels on each sling provide critical information, including the working load limit, inspection status, and manufacturer details. You should always verify this information before every lift.

Tip: Use color coding and clear labeling to match the sling to the load. This practice prevents overloading and keeps your operation safe.

Powerful Machinery Certification

You can trust Powerful Machinery to provide certified slings with accurate capacity markings. Every product undergoes strict testing and meets international standards. You receive slings with clear labels, color coding, and documentation.

This commitment ensures you always know the rated capacity and can rely on your equipment for every lift.

Selecting the Right Sling and Hitch

Choosing Sling Length and Configuration

You must approach sling selection with careful attention to detail. Proper rigging techniques start with evaluating the load and the environment. You need to consider several factors before you choose the right sling length and configuration:

Load Weight: Confirm the sling’s Working Load Limit matches your requirements.

Headroom: Use shorter slings when space is limited.

Load Type: Assess whether the load is fragile or exposed to high temperatures.

Worksite Environment: Select slings that resist corrosion if you work in harsh conditions.

Cost Effectiveness: Balance durability and usability with your budget.

Polyester round slings offer durability and flexibility. Nylon web slings provide strength and resilience. Round slings work well for irregular loads. Web slings protect surfaces from damage. You must match the sling to the job for safe lifting.

Powerful Machinery recognizes that every lifting project is unique. You benefit from customizable solutions that adjust sling length, width, and safety factors to fit your specific needs. The company collaborates with you to design slings that address your lifting challenges and optimize safety.

Feature | Description |

|---|---|

Customization | Solutions can be adjusted in length, width, and safety factors. |

Unique Handling | Tailored slings manage various load shapes and sizes, enhancing efficiency. |

Vertical, Choker, and Basket Hitches

You must use proper rigging techniques when selecting the correct hitch for each lift. The hitch type determines how the sling supports the load. You have three main options:

Vertical hitch: Use this for direct lifting. The sling attaches straight to the load.

Basket hitch: Distribute the load weight across two sling legs. This method increases stability.

Choker hitch: Secure the sling tightly around the load. This hitch provides a firm grip.

You must select the correct hitch for each scenario. The hitch type affects load balance and safety.

Matching Sling to Load Type

You need to match the sling and hitch to the load type for safe lifting. Proper rigging techniques require you to assess the load’s shape, weight, and fragility. Round slings work best for irregular or delicate loads.

Web slings suit smooth surfaces and protect against scratches. Chain slings handle heavy, rugged loads in tough environments.

Powerful Machinery offers personalized recommendations to help you select the right sling and hitch. You receive expert guidance that improves safety, efficiency, and cost-effectiveness. You ensure every lift meets your project’s demands.

Tip: Always review the load and environment before you choose your sling and hitch. This step supports safe lifting and reduces risk.

Avoid Twisting or Kinking Slings

Twisting, kinking, or knotting slings can put your entire lifting operation at risk. You must avoid twisting or kinking slings to maintain their rated strength and ensure safe handling.

When you twist or knot a sling, you change how the load distributes across the fibers or links. This action weakens the sling and increases the chance of sudden failure.

Using a twisted or knotted sling can lead to uneven weight distribution and potential failure during lifting operations.

Proper Sling Handling Techniques

You need to handle slings with care from the moment you pick them up. Lay the slings flat before attaching them to the load. Never pull a sling from under a load if it is snagged. Always untwist and straighten slings before use. If you see a kink or knot, remove the sling from service until you can inspect and correct the issue.

You should train your team on proper lifting techniques. Make sure everyone knows how to protect slings from sharp edges and avoid improper handling. Regular refresher training helps your crew stay updated on best practices and safety standards.

Ensure all personnel involved in rigging receive thorough training.

Schedule refresher training sessions to keep everyone updated on safety practices.

Teach correct lifting techniques to protect slings from sharp edges.

Maintaining Sling Integrity

You must inspect slings before every lift. Look for signs of twisting, kinking, or knotting. If you find any damage, do not use the sling. Powerful Machinery’s durable sling designs help resist damage from everyday use, but you still need to follow proper handling and inspection routines.

Regular inspections keep your equipment compliant and safe. The table below shows how often you should inspect slings based on service conditions:

Service Condition | Inspection Frequency |

|---|---|

Normal Service | Yearly (Annual Inspection) |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified Person |

Inspecting slings before each use helps you catch defects early and prevent accidents. Powerful Machinery chain slings are built for strength and reliability, but your attention to detail ensures their long service life.

Protective Measures for Sling Safety

Guarding Against Sharp Edges

You face sharp edges on many loads. These edges can cut or damage your slings quickly. You must always protect slings from sharp edges to prevent accidents and extend equipment life.

All sling types, especially synthetic ones, need extra care when lifting loads with sharp corners. Even slings with edge guard coatings benefit from added cut protection.

Protective Equipment | Description |

|---|---|

Corner Guards | Protects slings from sharp edges and corners. |

Sleeves | Adds a protective layer around the sling. |

Reinforced Eyes | Strengthens the sling’s attachment points. |

Wear Pads | Prevents cuts and abrasions on the sling. |

Tip: Always inspect the load for sharp edges before rigging. Use the right protective gear every time.

Using Wear Pads and Corner Guards

You can extend the lifespan of your slings by using wear pads and corner guards. These accessories create a barrier between the sling and the load. Wear pads, also called protective sleeves, that shield both sides of the sling from abrasion.

Corner guards prevent direct contact with sharp corners. You find wear pads in different lengths and materials, such as nylon or Cordura® fabric.

Wear pads reduce abrasion by shielding slings from rough surfaces.

Corner guards create a tunnel of protection where the sling meets the load.

Both options prevent fibers from wearing down over time.

You should always wear edge protection when lifting heavy or abrasive loads. This practice keeps your slings strong and safe.

Compatible Hardware Selection

You need to choose hardware that matches your sling and load. Select hooks, shackles, and links that fit your sling’s width and type. Powerful Machinery offers a full range of certified hardware accessories designed for compatibility and safety.

Reinforced eyes and proper connectors help distribute force evenly and prevent damage at attachment points.

Note: Using the right hardware reduces stress on your slings and lowers the risk of failure.

You improve safety and efficiency when you combine quality slings with the right protective measures and hardware.

Load Management and Control

You must master load management and control to keep every lift safe and efficient. Accurate calculations and careful planning help you prevent accidents and protect your team. Powerful Machinery provides detailed product specifications, so you can make informed decisions for every lift.

Calculating Load Weight and Center of Gravity

You should always determine the load weight before starting any lift. This includes the weight of all items below the hook. Use a lift scale to measure each side of the load.

Divide the heaviest end weight by the total weight to find the ratio. Measure the span between pick points and apply the ratio to locate the center of gravity. This process helps you balance the load and avoid tipping.

Best practices for proper load control include:

Inspect all rigging equipment before lifting.

Choose the correct sling style and hitch type.

Calculate the sling-to-load angle for each lift.

Account for environmental factors that may affect load weight.

Lift the load only as high as necessary.

You should conduct practice tests to confirm stability before the main lift. These steps help you achieve precise load control and reduce risk.

Maintaining Proper Sling Angles

You must ensure a proper sling angle to maintain load stability. The sling-to-load angle affects the tension on each sling leg. Smaller angles increase tension and can overload the sling. Always keep sling angles above 30 degrees to avoid excessive tension and possible failure.

Check the sling-to-load angle during setup and adjust as needed. Powerful Machinery’s slings come with clear angle charts and capacity ratings to guide your selection.

Tip: Use a protractor or angle indicator to verify the sling-to-load angle before lifting.

Test Lifts and Taglines

You should perform a test lift by raising the load a few inches off the ground. This allows you to check the balance and sling-to-load angle. If the load shifts, lower it and adjust your rigging.

Use taglines to guide and control the load during movement. Taglines help you keep the load steady and prevent rotation or swinging. Proper use of taglines and test lifts ensures safe and controlled lifting operations.

You improve safety and efficiency when you follow these load management and control practices. Powerful Machinery’s certified slings and hardware support you in every step, giving you confidence in your lifting operations.

Training and Compliance

Rigging Safety Training

You must prioritize ongoing training to keep your team safe and effective. Rigging safety training gives you the skills to recognize hazards and follow best practices on every job. You should cover all critical topics in your training program. These include:

Comprehensive training on equipment operation, safety procedures, and emergency protocols.

Clear written safety policies that everyone understands.

Regular risk assessments and hazard identification.

Proper use and inspection of personal protective equipment.

Routine equipment maintenance and inspection.

Job-specific procedures and checklists for each task.

Effective communication using standardized signals.

Emergency response and rescue plans.

Substance abuse policies to maintain a safe environment.

Continuous improvement and a strong safety culture.

You must train personnel regularly and update their knowledge as standards evolve. This approach helps you build a team that follows best practices and responds quickly to any situation.

Adhering to Industry Standards

You need to comply with international standards to ensure safe lifting operations. Powerful Machinery meets or exceeds all major requirements for rigging and slinging. You can see the most important standards in the table below:

Standard | Description |

|---|---|

ASME B30 | Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and Slings. It outlines safety practices and compliance requirements for rigging and slinging operations. |

OSHA | Occupational Safety and Health Administration regulations that ensure workplace safety, including rigging operations. |

You should always follow these standards as part of your daily rigging practice. This commitment protects your team and your equipment.

Keeping Documentation Accessible

You must keep all safety documentation organized and easy to access. Store inspection records, training certificates, and compliance documents in a central location. This habit supports best practices and helps you pass audits or inspections without delay.

You should review your records often to make sure they stay current. When you keep documentation accessible, you show your commitment to safety and compliance.

Tip: Review your safety documents at the start of each project. This step ensures you meet all requirements and follow best practices from day one.

Final Safety Checks and Communication

PPE and Personnel Clearance

You must complete a series of final safety checks before any lift begins. Start with a walk-around inspection of your equipment. Confirm that all components are in proper working order. Test safety devices to ensure they function as designed.

Secure attachments and auxiliary devices according to the manufacturer’s guidelines. Never exceed the rated load-capacity limits. Always check for overhead clearance, including ceilings and power lines. Set outriggers on pads or a level, solid surface.

Analyze the work area for stability hazards. Make sure all systems are operational, and safety devices are active.

Tip: Always verify that every team member wears the correct personal protective equipment (PPE). Clear all personnel from the lift zone before you start the operation.

Signal Person and Hand Signals

You rely on clear communication to keep lifting operations safe. Assign a qualified signal person to maintain contact with the crane operator. The signal person uses standardized hand signals to guide the operator, especially in noisy environments. These signals prevent misunderstandings and reduce the risk of accidents.

Establish all signals before crane operations begin. If communication breaks down, instruct the operator to stop all movement until contact is restored.

The signal person maintains communication with the operator at all times.

Standardized hand signals keep everyone informed during the lift.

Operations pause immediately if communication is interrupted.

Environmental Considerations

You must assess environmental factors before lifting. Check for wind, rain, or poor visibility that could affect safety. Monitor ground conditions to ensure stability. Adjust your lifting plan if the weather changes or hazards appear.

Powerful Machinery’s commitment to safety and reliability means you receive equipment designed to perform in challenging environments. You protect your team and your investment by following these final safety steps and maintaining clear communication throughout every lift.

Storing and Maintaining Slings

Proper storage and maintenance of your Powerful Machinery slings play a vital role in maximizing their lifespan and ensuring safe lifting operations. You need to follow best practices to keep your equipment in top condition and ready for every job.

Proper Storage Conditions

You should always store slings correctly to prevent deterioration and damage. The right storage environment protects your investment and supports safety on site.

Keep slings in a clean, dry, and temperature-controlled area.

Hang or lay slings flat on racks or hooks to avoid tangling or crushing.

Store slings off the ground to prevent moisture absorption and damage from vehicles.

Organize slings in lockers or rigging boxes to shield them from dirt and sunlight.

Avoid exposure to direct sunlight, rain, or extreme temperatures, which can weaken materials.

Choose a cool, dark space to maintain sling strength and flexibility.

Tip: A well-organized storage area helps you quickly find the right sling and reduces the risk of using damaged equipment.

Maintenance for Longevity

You extend the life of your slings through regular maintenance and inspection. This routine not only prevents costly accidents but also ensures compliance with safety standards like OSHA and ASME.

Inspect each sling before every use to catch early signs of wear or damage.

Clean slings after use to remove dirt, chemicals, or moisture that can degrade materials.

Document all inspections and repairs to track sling condition and support safety audits.

Train your team on proper handling, inspection, and storage procedures.

Implement a sling management system to organize records and schedule maintenance.

By making maintenance a priority, you reduce equipment costs and downtime. You also create a safer work environment for your team. Remember, investing time in sling care pays off with enhanced safety, reliability, and productivity.

Conclusion

You strengthen workplace safety and operational success by following rigging and slinging best practices. Regular inspections, proper sling selection, and ongoing training help you prevent accidents and maintain efficiency.

Certified products from Powerful Machinery deliver reliability and lower liability risks compared to non-certified alternatives.

Aspect | Certified Products | Non-Certified Alternatives |

|---|---|---|

Safety | Meet safety benchmarks | Higher risk of failures |

Efficiency | Reduce downtime and maintenance | Increased operational disruptions |

Routine maintenance and careful handling extend sling lifespan and protect your team. You build a safer, more productive environment with every lift.

FAQ

What is the most important step before using any sling?

You need to inspect the sling for damage, wear, or missing labels. Always check the working load limit and confirm the sling matches your lifting requirements. This step protects you and your team from accidents.

How do you identify the correct sling for your load?

Tip: Use color coding and capacity labels on each sling. Powerful Machinery slings display clear markings, making selection easy. Always match the sling’s working load limit to your load weight.

Can you use a sling with a damaged label or unreadable capacity marking?

No. You must not use any sling with a missing or unreadable label. Remove it from service immediately. Labels provide critical safety information and help you avoid overloading.

How often should you inspect your slings?

Sling Type | Inspection Frequency |

|---|---|

Chain Slings | Daily and annually |

Synthetic Slings | Daily and periodically |

Wire Rope Slings | Daily and as needed |

You should document each inspection for safety compliance.