Wire rope assemblies play a vital role in lifting, rigging, and industrial operations. When you select the right assembly, you protect your team and equipment from potential hazards. Global industries depend on these solutions, with annual usage exceeding 1.2 million metric tons in marine and oil & gas applications.

You need to consider rope strength, bending fatigue, abrasion resistance, and corrosion susceptibility to achieve safe and reliable outcomes. Powerful Machinery provides certified wire rope assemblies trusted by professionals worldwide.

Key Takeaways

Choose the right wire rope assembly based on load weight and environmental conditions to ensure safety and efficiency.

Regularly inspect wire rope assemblies for wear, corrosion, and damage to maintain their reliability and extend their lifespan.

Follow proper handling and installation techniques to prevent kinks and damage during use, ensuring safe operations.

Utilize galvanized steel wire ropes for outdoor applications to benefit from their corrosion resistance and durability.

Consult with experts for custom solutions to meet specific project needs, enhancing safety and performance in rigging tasks.

What Are Wire Rope Assemblies?

Key Functions and Uses

Wire rope assemblies serve as essential tools in many industries. You rely on them for tasks that demand high strength and durability. These assemblies consist of multiple steel wire strands twisted together, which gives them superior flexibility and abrasion resistance.

You can use wire rope assemblies to lift heavy objects, support structures, and secure equipment.

Here is a table showing how different industries use wire rope assemblies:

Industry | Primary Functions and Uses |

|---|---|

Construction | Used for lifts, window cleaning equipment, supporting utility equipment, and securing shafts. |

Lifting | Essential for cranes and hoists to lift, position, and move heavy loads safely. |

Mining | Used in lift shafts, mineral extraction, and securing equipment underground. |

Manufacturing | Integral in assembly lines, conveyor belts, and robotics for moving goods efficiently. |

Transportation | Utilized in automotive, aerospace, and rail industries for various mechanical applications requiring strength. |

You see wire rope assemblies in cranes, elevators, and conveyor systems. These assemblies help you move goods, secure loads, and maintain safety in your workplace.

Importance of Rigging and Lifting

Wire rope assemblies play a critical role in rigging and lifting operations. You depend on their strength and durability to handle high load capacities. In construction, you use them for crane cables and hoists, which ensure safe lifting of heavy objects.

Wire rope assemblies enhance safety and efficiency in lifting tasks.

You must perform regular maintenance and inspection to keep these assemblies reliable.

Load testing confirms that wire rope assemblies can withstand the demands of your projects.

When you choose the right wire rope assemblies for rigging, you protect your team and equipment. You also improve operational efficiency and reduce risks in demanding environments.

Types of Cable Assembly and Components

You encounter many cable assembly types in industrial settings. Each cable assembly design serves a specific purpose, whether you need to lift, secure, or connect heavy loads.

The most common cable assembly includes coaxial cable assemblies for digital audio and Ethernet connections, steel wire rope assemblies for lifting and rigging, and specialized assemblies for marine and construction projects.

Steel Wire Rope

Steel wire rope stands out as a core component in cable assembly design. Powerful Machinery offers steel wire rope that meets strict ISO and ASTM standards. You benefit from high tensile strength, durability, and advanced manufacturing techniques. The table below highlights what sets Powerful Machinery apart:

Distinguishing Factor | Description |

|---|---|

Product Quality | Durability, tensile strength, and compliance with ISO/ASTM standards |

Pricing & Cost Efficiency | Competitive pricing and volume discounts |

Global Reach & Supply Chain | Reliable logistics across multiple regions |

Innovation & R&D | Investment in new alloys and coatings |

Customer Support & Service | Technical assistance and training programs |

Certifications & Compliance | Safety certifications and environmental policies |

Track Record & Reputation | Client testimonials and case studies |

Flexibility & Customization | Tailored products for specific applications |

You can request a custom cable assembly design for unique projects. Powerful Machinery also invests in innovations such as multi-layer wire rope and eco-friendly coatings.

Wire Rope Clips and Fittings

Wire rope clips and fittings play a vital role in cable assembly termination. You use wire rope clips, U-bolt clips, double saddle clips, and forged or malleable variations to secure wire rope ends. Standards like ASME B30.9, ASME B30.26, and relevant EN standards guide safe installation and use.

You also rely on wire rope thimbles and eyebolts for additional support and secure connections. Proper termination ensures your cable assembly performs safely under load.

Tip: Always follow ASME and OSHA guidelines when installing wire rope clips and fittings. This practice helps prevent accidents and equipment failure.

Galvanized Steel Wire Rope Options

Galvanized steel wire rope offers excellent durability and corrosion resistance. You choose this option for outdoor and marine environments. The zinc coating protects the steel core from oxidation and environmental damage. Galvanized wire ropes are more affordable and slightly stronger than stainless steel ropes.

The zinc layer acts as a sacrificial barrier, extending the wire’s life and reducing maintenance costs. You find galvanized wire rope suitable for many outdoor applications, including those requiring eyebolts and robust cable assembly termination.

Note: The latest innovations include customized high-hardness terminal technology and PVC/TPU nylon coatings for enhanced wear and weather resistance.

Guides for Selecting the Right Wire Rope Assemblies

Choosing the right wire rope assemblies is essential for safe and efficient rigging operations. You need to consider several factors, from load requirements to environmental conditions. These guides will help you make informed decisions and ensure your assemblies perform reliably in every application.

Assessing Load and Application

You should always start with a clear understanding of your load and application needs. Follow this step-by-step assembly build process to select the best wire rope sling for your project:

Determine Load Weight

Calculate the exact weight of the load. This ensures your wire rope sling can handle the task safely.Consider Wire Rope Characteristics

Assess the diameter, construction, and core type. These features affect strength and flexibility.Choose Appropriate End Fittings

Select fittings that match your load and are compatible with your lifting equipment.Select Sling Length

Make sure the sling length provides stability and safety during lifting.Assess Environmental Conditions

Check for temperature extremes, moisture, or corrosive substances that could impact performance.Check for Wear and Tear

Inspect your wire rope sling regularly. Proper maintenance prevents failures and extends service life.

Tip: Always document your step-by-step assembly process. This practice helps you track inspections and ensures compliance with safety standards.

Material and Construction Choices

Selecting the right material and construction is crucial for both performance and longevity. Environmental factors play a significant role in your decision:

Coastal areas with saltwater require corrosion-resistant materials.

Exposure to chemicals, such as acids or bases, can degrade standard wire ropes.

Humidity and heat can shorten the lifespan of your assemblies.

Temperature swings may cause steel wire ropes to expand or contract, affecting tension.

Cold environments can make steel brittle, increasing the risk of fractures.

Polymer-coated ropes offer extra protection in extreme temperatures.

You must also match product features to your specific rigging requirements. The table below summarizes key considerations:

Consideration | Description |

|---|---|

Load Capacity | Ensure the rope meets or exceeds the minimum breaking force for your equipment. |

Rotation Resistance | Use rotation-resistant ropes if your application demands stability under load. |

Bending Fatigue | Select ropes with smaller wires for applications with frequent bending. |

Abrasion Resistance | Choose ropes with larger outer wires if abrasion is a concern. |

Corrosion Protection | Opt for plastic impregnation or lubricants to minimize corrosion. |

Flexibility | Evaluate strand count and wire size for the right balance of flexibility and wear resistance. |

Operating Environment | Use stainless steel or galvanized wire rope in corrosive or outdoor settings. |

Attachment Method | Make sure your attachment method matches working conditions and load requirements. |

When you select high-quality wire rope slings, you improve safety and reduce downtime. Always align your design choices with the demands of your application.

Custom Solutions from Powerful Machinery

Every project has unique challenges. Sometimes, standard products do not fit your needs. Powerful Machinery offers custom solutions for wire rope assemblies, ensuring you get the right fit for your rigging tasks.

Benefit | Description |

|---|---|

Product Quality | You receive certified products that guarantee strength and safety. |

Certifications | Powerful Machinery holds ISO9001, ISO14001, and OSHA certifications. |

Global Reach | You benefit from fast shipping and consistent availability worldwide. |

Customer Support | The team provides ongoing support and custom solutions tailored to your needs. |

Cost-Value Balance | You access high-grade steel and advanced designs at competitive prices. |

You can consult with Powerful Machinery’s experts to discuss your requirements. The team will guide you through the step-by-step assembly build process, from initial design to final production. This approach ensures your high-quality wire rope slings meet the highest standards for safety and performance.

Note: Custom assemblies from Powerful Machinery are ideal for complex lifting, marine, or construction projects where standard solutions fall short.

By following these guides and working with a trusted partner, you can confidently select, design, and implement wire rope assemblies that deliver reliability and safety in every application.

Wire Rope Handling and Installation

Safe Unreeling and Cutting

You must follow best practices for wire rope handling to maintain the integrity and safety of your wire rope assemblies. Start by storing your wire ropes on racks or reels in a dry, well-ventilated area. This prevents corrosion and extends the lifespan of your equipment.

Always check the rope diameter before use. Refer to a diameter reference guide and ensure you are measuring wire rope diameter accurately. Using the correct size prevents increased stress and potential failure.

When you prepare for installation, use proper unreeling procedures. The right way to unravel involves holding the end of the rope and rolling the coil along the floor. This allows the rope to uncoil naturally and avoids twisting. Never pull the rope straight off a flat coil.

Doing so can cause spirals and kinks, which weaken the rope. The right way to uncoil is to let the rope rotate freely as you remove it from the reel. Avoid dragging the rope over obstacles or around corners. Keep the wraps tight on the drum and maintain tension to prevent crushing damage.

Before cutting, always secure the ends of the rope. This process, known as seizing, is critical. Seizing prevents the core from slipping and the strands from unraveling. Use at least two seizings on each side of the cut.

For proper seizing and cutting, wrap the rope tightly with wire or tape, then cut between the seizings using a suitable tool. Treat rotation-resistant ropes with extra care. Handle them gently to prevent core slippage and overload.

Here is a quick checklist for unreeling and uncoiling:

Store wire ropes properly.

Check the diameter using a diameter reference guide.

Use proper unreeling procedures.

Avoid large fleet angles and obstacles.

Keep wraps tight on the drum.

Secure the ends with seizing before cutting.

Use a cable snake with a swivel when replacing lines.

Tip: Never let the rope go slack during unreeling and uncoiling. This prevents kinks and maintains rope strength.

Attaching Clips and Fittings

Correct installation procedures for wire rope clips and fittings ensure a secure assembly. Begin by inspecting your wire rope for wear, corrosion, or broken wires. Only use ropes that meet the standards shown in your wire rope breaking strength chart. Select the right type and size of clip for your application.

Follow these steps for attaching clips:

Position the first clip one base width from the dead end of the rope. The ‘U’ part of the clip should cover the dead end.

Tighten the nuts evenly.

Place the second clip near the loop or thimble, again tightening the nuts evenly.

Add additional clips as needed, spacing them equally and tightening after applying tension.

Seizing remains essential during this process. Always seize the ends before installing clips to prevent the strands from loosening. Use the correct number of clips for the rope diameter. Refer to the manufacturer’s installation procedures for specific guidance.

Wire rope clips from Powerful Machinery offer easy assembly. You do not need special tools. The zinc-coated finish enhances strength and durability, providing corrosion resistance for long-term use. These clips come in various designs and finishes, making them versatile for different environments.

Safety tips for wire rope slings: Always double-check the tightness of all fittings after initial load application. Re-tighten as necessary to maintain security.

Inspection and Maintenance Tips

Routine inspection and maintenance keep your wire rope assemblies safe and reliable. Begin with regular visual checks for broken wires, corrosion, or deformation. Increase inspection frequency in harsh environments, such as areas with high humidity or dust.

Lubricate your wire rope every three months. In more demanding conditions, increase the frequency. Lubrication reduces friction and prevents internal wear. Keep a detailed maintenance log. Record all inspections, repairs, and replacements. This log helps you track the condition of your equipment and plan for timely maintenance.

Conduct annual load testing to verify that your assemblies can handle the maximum rated load. Use the wire rope breaking strength chart as a reference during these tests. If you notice any signs of excessive wear or damage, replace the rope immediately.

Seizing plays a role in ongoing maintenance. After each inspection, check the condition of the seizings. Reapply or replace them if they show signs of loosening or wear.

Note: Well-maintained wire rope assemblies reduce downtime and improve workplace safety. Consistent care extends the service life of your equipment.

By following these best practices for wire rope handling, installation, and maintenance, you ensure the long-term performance and safety of your assemblies.

Troubleshooting and Maintenance Guides

Common Installation Mistakes

You often encounter mistakes during wire rope installation that can compromise safety and performance. The table below highlights frequent errors, their consequences, and solutions. You should always follow best practices to avoid these issues.

Mistake | Consequence | Solution |

|---|---|---|

Bending the rope beyond its minimum bend radius | Damages internal strands, reducing strength and flexibility | Follow manufacturer guidelines for minimum bending radius—usually no less than 10 times the rope diameter. |

Improper Use of Wire Rope Clips | Poor grip on the rope, slippage, or complete failure under load | Remember the phrase ‘never saddle a dead horse’. Place the saddle on the live end and the U-bolt on the dead end. |

Mismatched Hardware | Accelerated wear, galvanic corrosion, or improper load distribution | Select hardware designed specifically for stainless steel wire rope. |

Over-Tensioning or Under-Tensioning | Over-tensioning can stretch and weaken the rope, while under-tensioning may cause sagging | Use calibrated tensioning tools to achieve the recommended tension. |

Neglecting End Termination Integrity | Common failure points that can lead to catastrophic accidents | Ensure all end terminations are correctly installed and inspected. |

Ignoring Environmental Factors | Localized corrosion or stress cracking in harsh environments | Choose the appropriate stainless steel grade and consider coatings or lubricants. |

Failure to Pre-Inspect Wire Rope | Risk of using a rope that may have been damaged | Always inspect the wire rope for kinks, corrosion, or broken wires before installation. |

Incorrect Winding onto Drums or Reels | Uneven wear, crushing of lower layers, and reduced rope lifespan | Wind the wire rope evenly and under tension onto drums and reels. |

Lack of Documentation and Maintenance Planning | Harder to monitor wear, tension, and safety over time | Document installation specifications and set up a maintenance schedule. |

Tip: You should always apply proper seizing before and after installation to prevent strand separation and maintain rope integrity.

Identifying Wear and Damage

You need to inspect wire rope assemblies regularly to ensure safe rigging operations. Look for these signs of wear and damage:

Broken wires indicate fatigue and require immediate attention.

Corrosion often appears as pitting and can weaken the rope.

Abrasion shows as shiny or worn spots, reducing strength.

Kinking, birdcaging, or looping misaligns strands and lowers load capacity.

Flattening or crushing signals excessive pressure.

Core protrusion points to internal damage.

Reduced diameter suggests wear or damage.

Stretching or elongation decreases load-bearing ability.

You should also check for abrasive wire breaks, fatigue breaks, and mechanical abuse. Always inspect seizing for tightness and effectiveness. Proper seizing helps prevent further damage and keeps the rope safe for use.

Note: You must include seizing in your inspection routine to maintain the design and strength of your wire rope assemblies.

When to Replace Assemblies?

You must know when to replace wire rope assemblies to keep your rigging safe. Use these criteria:

Replace the rope if you see too many broken wires on the outside.

Remove any rope with signs of pitting or corrosion.

Take out ropes with kinks or permanent distortion.

Remove assemblies with severe doglegs or birdcaging.

Replace ropes with core protrusion or continuous pounding damage.

You should always check the design and sealing of your assemblies during inspections. If you find any issues with seizing, replace or repair it immediately. Proper seizing ensures the rope maintains its original design and load capacity.

Alert: Never ignore damaged seizing. You risk failure in rigging operations if you do not address it promptly.

Best Practices for Rigging with Wire Rope Assemblies

Routine Inspections

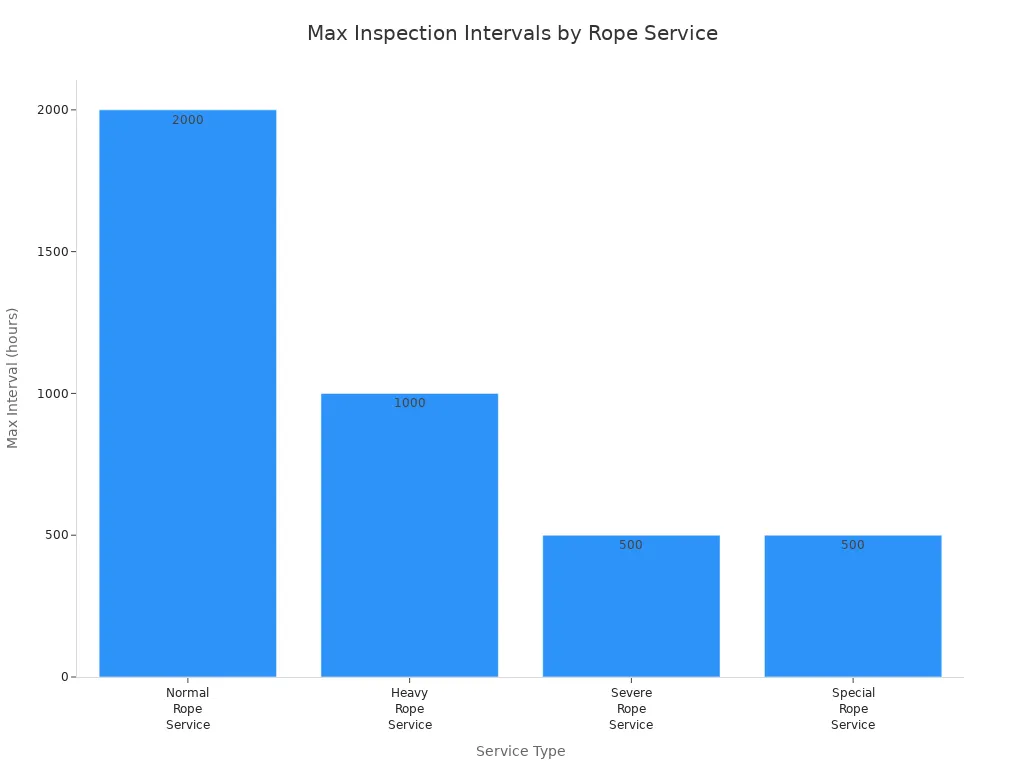

You must inspect wire rope assemblies before every rigging operation. Look for signs of wear, corrosion, or deformation on slings, shackles, hoists, and ropes. Inspection frequency depends on service type. The table below shows recommended intervals:

Service Type | Inspection Frequency |

|---|---|

Normal Rope Service | Not to exceed 12 months or 2,000 hours |

Heavy Rope Service | Not to exceed 6 months or 1,000 hours |

Severe Rope Service | Not to exceed 3 months or 500 hours |

Special Rope Service | Less than 500 hours |

You should rotate slings and lubricate wire ropes regularly. Use protective padding on sharp-edged loads to prevent damage. Staff training ensures everyone follows OSHA and ASME regulations.

Storage and Handling

You extend the lifespan of wire rope assemblies when you provide proper storage. Store equipment in a clean, dry, and well-ventilated area. Keep ropes off the floor by using pallets. Shield ropes from moisture, sunlight, and extreme temperatures. Avoid acids and chemicals in storage areas.

Apply high-quality lubricant to maintain flexibility and prevent corrosion. Identify each rope clearly and keep the manufacturer’s certificate with it. Use a ‘first in, first out’ approach to minimize storage time and reduce deterioration.

Tip: Protect ropes from accidental damage during handling. Always check for corrosion risk and loss of lubricant.

Compliance and Safety Standards

You must follow industry standards for safe rigging. The table below lists key regulations:

Standard | Description |

|---|---|

ISO 2307 | Specifies the fiber rope’s physical and mechanical properties. |

OSHA 1910.184 | Governs slings, wire ropes, and lifting practices in industrial environments. |

EN 1891 | Covers low-stretch kernmantle ropes for rope access and rescue. |

IMO & ABS | Guidelines for marine and offshore mooring and towing lines. |

ANSI | Standards for construction and rigging, including fall protection ropes. |

You should always follow manufacturer specifications for rigging equipment. Ensure clamps are installed by experts and inspected for damage. Maintain prescribed torque limits for clamps to guarantee safety.

Note: Adhering to these standards protects your team and equipment during every rigging operation.

Conclusion

You improve safety and efficiency in rigging by following essential steps for wire rope assembly selection and installation.

Choose the right wire rope for your application.

Handle and store assemblies properly to prevent damage.

Inspect for wear, corrosion, and broken wires before installation.

Use correct installation tools and techniques.

Maintain tension and avoid sharp bends.

Lubricate regularly and document inspections.

Regular inspection and certified products protect your team and equipment. Powerful Machinery offers expert advice and custom solutions for installation needs. Visit Powerful Machinery’s official website for more information or to request a quote.

FAQ

How do you choose the right wire rope assembly for your project?

You should assess your load requirements, environment, and application. Review product specifications and certifications. Consult Powerful Machinery’s experts for custom solutions that match your safety and performance needs.

What maintenance steps keep wire rope assemblies in top condition?

You need to inspect assemblies regularly for wear, corrosion, and broken wires. Lubricate every three months. Replace damaged components immediately. Keep a maintenance log to track inspections and repairs.

Can you use galvanized steel wire rope outdoors?

Yes. Galvanized steel wire rope resists corrosion and performs well in outdoor and marine environments. The zinc coating protects against moisture and extends the rope’s lifespan.

What certifications do Powerful Machinery wire rope products carry?

Certification | Description |

|---|---|

ISO9001 | Quality management |

OSHA | Safety standards |

TUV Rheinland | International compliance |

You can trust these certifications for safety and reliability.