Selecting the right chain for your operation requires a clear understanding of chain grades, materials, and application needs. You must consider the safety risks—load drops from poor rigging practices cause 27% of industrial incidents.

Powerful Machinery stands as a trusted source for certified heavy-duty chains, delivering products that meet international standards. When choosing among the various types of heavy-duty chains, focus on safety and compatibility.

Common mistakes include overlooking the load’s structural integrity, underestimating weight, using the wrong slings, or relying on untrained workers. Your decisions directly impact jobsite safety and efficiency.

Key Takeaways

Always check the chain grades guide before selecting a chain. The grade affects the chain’s working load limit and safety.

Select the right chain type for your application. Use lifting chains for overhead tasks and transport chains for securing loads.

Regularly inspect your chains for wear and damage. Frequent checks help maintain safety and prevent accidents.

Choose the appropriate material based on your environment. Alloy steel offers strength, while stainless steel provides corrosion resistance.

Document inspections and maintenance. Keeping records helps track the chain condition and ensures timely replacements.

Types of Heavy Duty Chains

Powerful Machinery offers a comprehensive selection of heavy-duty steel chain solutions for industrial, construction, and transport applications. You can choose from alloy steel and stainless steel chains, each designed for maximum durability and performance.

The product range covers the most common types of heavy-duty chains used worldwide, ensuring you find the right fit for your project.

Chain Grades Guide

When you explore the types of heavy-duty chains, you encounter several chain grades guide options. Powerful Machinery manufactures chains that meet strict international standards, including NACM2010, DIN, UK, and Australian requirements.

These standards guarantee that every heavy-duty steel chain delivers reliable strength and safety.

Tip: Always check the chain grades guide before selecting a chain for your application. The grade determines the chain’s working load limit and suitability for lifting or securing loads.

You will find three main types of heavy-duty chains in industrial use:

Standard Roller Chains

Engineering Class Chains

Leaf Chains

Standard Roller Chains handle power transmission and heavy loads efficiently. You see these chains in conveyor systems and machinery, with tensile strengths ranging from 1,000 to 150,000 pounds.

Engineering Class Chains offer superior strength and durability, making them ideal for environments with high stress and impact, such as material handling equipment. Leaf Chains feature an interlocking design that boosts strength and reliability, perfect for demanding lifting tasks.

Powerful Machinery’s heavy-duty steel chain products come in grades like G43, G70, G80, and G100. Each grade serves a specific purpose.

G43 and G70 chains are commonly used for transporting and securing cargo. G80 and G100 chains are engineered for lifting and rigging, meeting OSHA and ASME standards for overhead lifting.

Heavy Duty Steel Chain Options

You need to understand the difference between lifting chains and transport chains when selecting types of heavy-duty chains. Lifting chains, such as those in grades G80 and G100, are made from alloy steel and designed for overhead lifting, load suspension, and precise positioning.

These heavy-duty steel chain options undergo rigorous testing to ensure they meet workplace safety regulations.

Transport chains, often found in grades G43 and G70, secure loads during transit. These heavy-duty steel chain products must comply with DOT standards, which require a sufficient working load limit for the cargo.

Powerful Machinery’s transport chains are built for reliability and safety, making them a trusted choice for logistics and cargo handling.

The table below summarizes key international standards that define and differentiate heavy-duty steel chain types:

Standard | Main Focus | Critical Rules |

|---|---|---|

NACM | Product quality, classification, and performance standards | Defines chain grades, testing methods, and provides guidelines for marking chains. |

DOT | Load safety in road transport | Requires chains to have a sufficient Working Load Limit (WLL) for the secured load. G70 chains are typically mandated. |

OSHA | Workplace safety and health | Prohibits the use of general-purpose chains for lifting; requires regular inspections. |

ASME | Design and testing of lifting equipment | Standardizes WLL definitions and safety factors for chains. |

You benefit from Powerful Machinery’s commitment to international standards. Every heavy-duty steel chain is manufactured to exceed the requirements for quality, safety, and traceability.

You can select from short, medium, or long link configurations, as well as alloy steel or stainless steel materials, depending on your operational needs.

Note: Lifting chains and transport chains serve different functions. Never use a transport chain for overhead lifting. Always refer to the chain grades guide to confirm the correct application.

When you choose Powerful Machinery, you gain access to a full spectrum of types of heavy-duty chains. The product lineup includes heavy-duty steel chain options for lifting, securing, and transporting, all backed by certifications and industry-leading expertise.

You ensure safety and efficiency by matching the right chain grade and type to your specific job requirements.

Choosing the Right Chain Grade

Selecting the correct chain grade is essential for safety and efficiency in any heavy-duty operation. You must consider the specific task—whether you need to lift, secure, or transport loads.

Each application demands a different level of strength and durability. Choosing the right chain grade ensures you meet safety standards and avoid costly mistakes.

Different Grades of Chain Explained

You will encounter several different grades of chain in industrial settings. Each grade has unique properties and load capacities. The table below summarizes the most widely used chain grades and their typical applications:

Chain Grade | Description | Typical Load Capacity |

|---|---|---|

General-purpose economical chain; low tensile strength. | Light construction, agricultural applications. | |

Grade 43 | Stronger than Grade 30; better wear resistance. | Container securement, logging, and towing. |

Grade 70 | Higher strength, heat-treated carbon steel; 20% higher load rating than Grade 43. | Load securement for truckers and loggers. |

Grade 80 | Economical for overhead lifting; high-strength alloy chain. | Heavy-duty tow chain and sling component. |

Grade 100 | High-strength, heat-treated alloy; 25% stronger than Grade 80. | Overhead lifting in construction and manufacturing. |

Grade 120 | Ultra-premium chain for overhead lifting; 50% stronger than Grade 80. | Rigorous overhead lifting applications. |

When choosing the right chain grade, always match the grade to your application. Use Grade 43 or Grade 70 for securing and transporting loads. For overhead lifting, you must select Grade 80, 100, or 120 chains. These grades offer the strength and reliability required for lifting heavy loads safely.

Tip: If you want to know how to identify chain grade, look for stamped markings on the chain links. Manufacturers like Powerful Machinery clearly mark each chain with its grade for easy identification.

Powerful Machinery Grade 80, 100, and 120 Chains

Overhead lifting demands the highest level of safety and performance. OSHA regulations require you to use only approved chain grades for lifting above people or valuable equipment.

Grade 80 and Grade 100 chains meet these requirements and have become the industry standard for overhead lifting. Grade 120 chains provide even greater strength for the most demanding jobs.

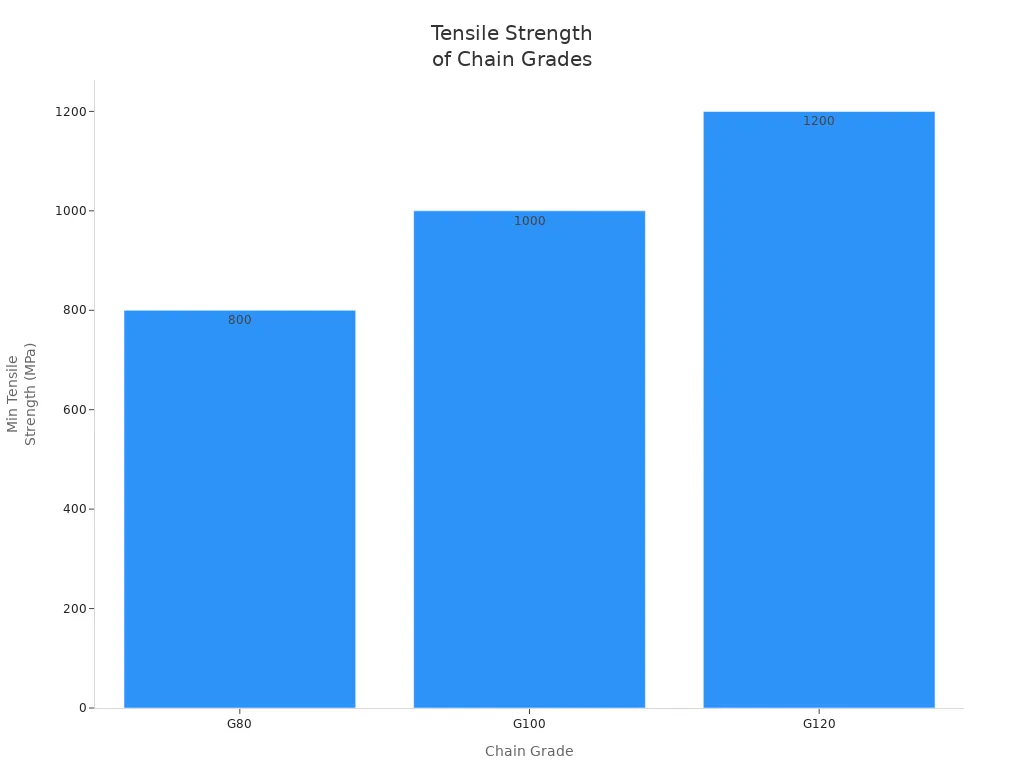

The table below highlights the mechanical properties and performance differences between these top lifting chain grades:

Grade | Minimum Tensile Strength (MPa) | Base Material | Heat Treatment | Key Alloying Elements |

|---|---|---|---|---|

G80 | 800 | Medium-carbon steel | Quenching & Tempering | C (0.25-0.35%), Mn |

G100 | 1,000 | High-strength low-alloy (HSLA) steel | Controlled quenching | Cr, Mo, V |

G120 | 1,200 | Advanced HSLA steel | Precision tempering | Cr, Ni, Mo, Nb/V |

Grade 80 chains deliver reliable performance for most overhead lifting tasks. Grade 100 chains offer about 25% more lifting capacity than Grade 80, making them ideal for construction and manufacturing. Grade 120 chains, with their square links, provide up to 50% more strength than Grade 80.

You should use Grade 120 for the most rigorous overhead lifting applications.

Powerful Machinery’s certified lifting chains stand out for their quality and safety. You benefit from:

Advantage | Description |

|---|---|

Compliance with safety standards | Certified chains meet international safety standards, ensuring user safety. |

Reliability | They are tested for performance in demanding environments, ensuring durability. |

Quality control | Certification involves strict quality control measures for peace of mind. |

You can trust Powerful Machinery’s lifting chains for every overhead lifting job. Each chain is fully traceable and certified, giving you confidence in both safety and performance.

Note: OSHA requires frequent and periodic inspections for all lifting chains. Always check for missing tags, stretched links, cracks, or signs of wear before use. Proper inspection and documentation keep your operation compliant and safe.

Choosing the right chain grade protects your team and your investment. By understanding the different grades of chain and selecting certified products from Powerful Machinery, you ensure every lift meets the highest standards.

Chain Materials and Environmental Suitability

Alloy Steel vs. Stainless Steel Chains

You face many choices when selecting heavy-duty chains for your operation. The material you choose directly impacts durability, abrasion resistance, and performance in challenging environments.

Alloy steel chains offer high strength and excellent abrasion resistance, making them ideal for lifting, rigging, and transport tasks. These chains handle heavy loads and resist wear from repeated use.

Stainless steel chains provide a different set of advantages. You benefit from outstanding corrosion resistance, especially in wet or chemical-rich environments. Stainless steel forms a protective oxide layer that prevents rust and maintains structural integrity.

This feature ensures reliable operation and reduces maintenance needs. Grades like 304 and 316 stainless steel deliver high mechanical strength and abrasion resistance, even under stress. You can trust these chains for both indoor and outdoor applications where exposure to moisture or chemicals is a concern.

Powerful Machinery supplies both alloy steel and stainless steel chains. You can select the right material for your specific environment, knowing each option meets international standards for safety and performance.

Material Type | Corrosion Resistance Rating | Notes |

|---|---|---|

Stainless Steel 316 | High | Superior in marine environments due to increased molybdenum content. |

Alloy Steel | Moderate | More prone to corrosion, especially in chloride-rich environments. |

Selecting Chain Finish for Outdoor Use

You must consider environmental factors that can lead to premature chain failure. Dust, moisture, and fluctuating temperatures often cause rust and abrasion. Protective finishes and proper material selection help slow down wear and extend chain life.

For outdoor or marine environments, you should choose chains with the highest corrosion resistance. Grade 316 and 316L stainless steel chains are ideal for these conditions. These chains can last for decades without significant corrosion, making them a smart investment for long-term use.

You also gain superior abrasion resistance, which is essential when chains face constant movement or contact with rough surfaces.

To further protect your chains, use environmental control systems like enclosures and seals. Regular inspections and maintenance keep your chains in top condition, preventing unexpected failures.

Powerful Machinery offers a full range of chain finishes and materials designed for harsh environments. You can rely on their expertise to match the right chain to your application, ensuring safety, durability, and maximum abrasion resistance.

Safety and Compatibility Factors

Working Load Limit and Inspection

You must always check the working load limit before using any chain for lifting or securing. The load-bearing capacity of a chain defines the maximum weight it can safely handle. This limit protects you from equipment failure and serious accidents.

Exceeding the load-bearing capacity can cause dropped heavy loads, property damage, or injury. OSHA and ASME stress that improper handling and overloading are leading causes of workplace incidents.

Tip: Always follow the working load limit guidelines. Ignoring them can compromise the structural integrity of your equipment.

Several factors can affect the load-bearing capacity of your chains:

Wear and tear, such as cuts or rust, can weaken chains even if they look fine.

Sling angles can increase the stress on the chain, reducing its safe load.

Extreme temperatures or chemicals can lower the chain’s load-bearing capacity.

Regular inspection is a key part of safety considerations. You should inspect your chains at least once every 12 months. In harsh environments, increase inspection frequency to quarterly or even monthly. Look for signs of wear, deformation, or corrosion. Replace any chain that does not meet safety standards.

Powerful Machinery’s certified chains include full traceability features. Each chain has unique identifiers, certifications, and markings. These features help you track the chain’s history and ensure compliance with regulations.

Feature | Description |

|---|---|

Certifications and markings | Chains carry official certifications and markings for traceability. |

History tracking | You can track the condition and the history of each chain. |

Unique identifiers | Each chain has a unique code to verify its load-bearing capacity and status. |

Chain Compatibility with Attachments

You need to match your chains with the right attachments to maintain safety and performance. Compatibility issues can arise if you overlook key factors. Use this checklist to avoid common problems:

Check the load’s weight, size, and center of gravity. Choose attachments that match the load-bearing capacity required.

Select the correct chain grade for your application. Grade 80 and Grade 100 chains have different load limits.

Pick the right sling configuration. Single-leg, double-leg, or multi-leg slings affect stability and compatibility.

Consider environmental factors. Temperature, chemicals, and moisture can impact both chains and attachments.

Note: Always use attachments that are rated for the same or higher load-bearing capacity as your chain. This ensures your system can handle heavy loads without risk.

Powerful Machinery’s products make it easy to maintain safety compliance. Every chain and attachment comes with clear markings and documentation. You can trust these features to support your safety considerations and operational efficiency.

Maintenance and Longevity Tips

Proper care extends the life and performance of your heavy-duty chains. You can prevent unexpected failures and maximize efficiency by following proven maintenance tips. Powerful Machinery supports you with product traceability and expert guidance, making chain care straightforward.

Inspection and Cleaning Best Practices

Regular inspection and cleaning keep your chains in top condition. You should always clean the chain before inspecting it. This step removes dust and rust that can hide signs of wear. Use these steps to maintain optimal performance:

Clean the chain surface to remove rust and dust.

Lubricate the chain regularly to reduce friction and prevent wear.

Check chain tension to avoid loosening and excessive wear.

Inspect for twisted or bent links and remove damaged chains from service.

Look for nicks, gouges, or corrosion, and measure worn sections against the minimum allowable dimensions.

Clean and lubricate sprockets and gears to ensure smooth power transmission.

Tip: Document each inspection. Consistent records help you track chain condition and schedule timely replacements.

You should never skip cleaning before inspection. Always measure wear instead of guessing. Understand the difference between normal wear and actual damage to make informed decisions.

Storage and Replacement Guidelines

Proper storage prevents corrosion and degradation. After cleaning, apply a rust inhibitor or protective coating to all metallic parts. Store chains in a dry, well-ventilated area away from chemicals and moisture. Lubricate chains before storage to maintain performance and prevent rust.

When you notice excessive wear or damage, replace the chain immediately. The average lifespan of heavy-duty chains ranges from 10,000 to 30,000 hours of operation, depending on the application. Lighter power transmission tasks may allow for longer use, while heavy lifting requires more frequent replacement.

Powerful Machinery offers full product traceability and expert support. You can schedule professional servicing, consult with specialists, and receive ongoing training. These services help you maintain compliance, reduce downtime, and ensure peak performance.

Note: Choosing the right equipment and following a strict maintenance schedule protects your investment and keeps your operation running smoothly.

Conclusion

You improve safety and efficiency when you select the correct chain type, grade, and material. Consider load-bearing capacity, working environment, and certifications to avoid costly mistakes. Powerful Machinery’s rigorous manufacturing and adherence to international standards guarantee reliability.

Factor | Description |

|---|---|

Load-Bearing Capacity | Calculate the required Working Load Limit (WLL) for your application. |

Working Environment | Select materials suited for humidity or extreme temperatures. |

Certifications | Ensure compliance with G80, G100, and other standards for safety. |

You can consult Powerful Machinery’s experts for tailored solutions and chain strength guides. Visit Powerful Machinery’s website for more information.

FAQ

What factors should you consider when choosing a chain grade for different applications?

You should evaluate the load weight, environment, and safety requirements. Each chain grade suits specific applications. For lifting, select a higher chain grade. For securing cargo, use a chain grade designed for transport applications. Always match the chain grade to your applications.

How do you identify the correct chain grade for your applications?

Manufacturers stamp the chain grade on each link. You can check these markings before using chains in your applications. Powerful Machinery provides clear identification, making it easy to select the right chain grade for your applications.

Can you use the same chain grade for all applications?

You should not use one chain grade for every application. Each chain grade has unique properties. For overhead lifting applications, choose a chain grade with higher strength. For transport applications, select a chain grade that meets DOT standards.

Why is chain grade important for safety in different applications?

Chain grade determines the working load limit and durability. You protect your team by selecting the correct chain grade for your applications. Using the wrong chain grade in critical applications can lead to accidents or equipment failure.

How does Powerful Machinery support you in selecting the right chain grade for your applications?

Powerful Machinery offers expert guidance and certified products. You can consult specialists to match the chain grade to your applications. The company provides traceable chains, ensuring you use the correct chain grade for all applications.