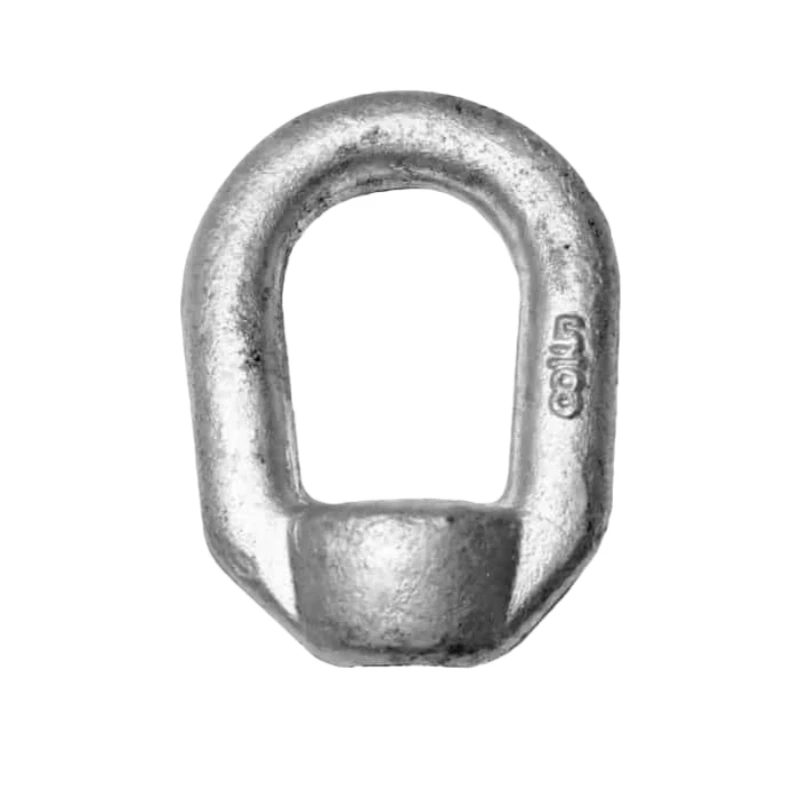

Eye Nuts

Eye nuts provide strong, reliable lifting points for rigging and industrial projects. We manufacture galvanized, stainless steel, and self-colored eye nuts in inch and metric sizes. Quote your rigging hardware from Powerful Machinery today.

We manufacture eye nuts from durable materials that meet strict industrial and rigging safety standards.

Our eye nuts feature precise load ratings, thread sizes, and inch/metric specs for every project.

We supply bulk orders reliably with flexible quantities for all industrial and rigging applications.

Our experts provide trusted guidance and full manufacturing support for your rigging hardware needs.

Powerful Machinery - Your Trusted Eye Nut Manufacturer

We supply work provide dependable eye nuts for industry leaders.

EYENUT BY MATERIAL

Our Galvanized, stainless steel, brass, and steel eyenuts provide strong, durable lifting points for safe and reliable rigging applications.

Stainless steel eye nuts resist corrosion and deliver reliable strength, designed to meet DIN 582 standards for lifting and rigging use.

Galvanized Eye Nuts

Galvanized eye nuts feature a zinc coating that resists corrosion and provides reliable strength for lifting and rigging applications.

Brass Eye Nut

Brass eye nuts offer corrosion resistance, non-sparking performance, and a smooth finish, suitable for light lifting, marine, and rigging applications.

Bronze Eye Nut

Bronze eye nuts provide excellent seawater corrosion resistance and long service life, making them ideal for marine rigging and offshore applications.

EYENUTS BY APPLICATION

Eyenuts create secure lifting and attachment points for rigging, construction, marine, and industrial handling applications.

Lifting Eye Nut

Eye nuts create secure lifting points for machinery and equipment. We supply M8, M10, M12, M16, and M20 sizes for safe, reliable handling.

Thimble Eye Nut

Thimble eye nuts provide a reinforced anchor point that protects wire rope and cables from wear, widely used in utility lines and pole line construction.

Forged Eye Nut

Forged eye nuts form under high pressure to deliver a solid, high-strength design for heavy-duty lifting and industrial rigging.

EYE NUTS BY SHAPE

Eye nuts come in round, oval, and collared shapes to fit different lifting angles and rigging space requirements.

Collared Eye Nut

Collared eye nuts feature a built-in collar that sits flush on the surface, improving load distribution and stability for safer lifting and rigging connections.

Oval Eye Nut

Oval eye nuts feature an elongated eye shape that allows smoother load alignment and easier attachment, making them suitable for controlled lifting and rigging applications.

Shoulder Eye Nut

Shoulder eye nuts include a reinforced shoulder beneath the eye, providing better load support and stability for lifting and rigging applications with angled pulls.

NEED HELP WITH YOUR EYE NUTS ORDER?

Let us help! Reach out today and get recommendations on materials and sizing from our experts.

Guide to Eyenut

Our guide to eyenuts explains types, materials, sizes, applications, and selection tips to help you choose safe, reliable rigging connections.

What is the lifting capacity of eye nuts?

The lifting capacity of an eye nut depends on its material, size, and thread type. Typically, eye nuts are rated based on their workload limit, which ensures they are safe for heavy-duty rigging applications. As a manufacturer, we ensure our eye nuts meet rigorous standards like DIN 582 for load-bearing strength. To calculate the capacity, consider the thread size and material strength. Always verify with the manufacturer before use.

How do I determine the right size of an eye nut?

Selecting the right size of an eye nut depends on the thread size, load requirements, and the type of application. We provide detailed specifications for each product, including metric and inch sizes. Ensure that the diameter of the eye nut fits the lifting equipment or rod you’re using. Consider the thread length as well, which should match the depth of the receiving stud or bolt. Always use the correct size to ensure safe lifting.

What materials are commonly used for eye nuts?

Eye nuts are made from various materials, each offering specific benefits depending on the application. The material you choose impacts both corrosion resistance and strength. Here’s a breakdown of common materials used for eye nuts:

Steel: Provides strength for general lifting applications.

Stainless Steel: Offers enhanced corrosion resistance, ideal for marine or outdoor environments.

Brass: Non-sparking, making it perfect for sensitive environments.

Galvanized Steel: Provides rust resistance, suitable for harsh outdoor applications.

Tip: Choose the right material based on the environment and load requirements to ensure maximum performance and safety.

What are the applications of eye nuts?

Eye nuts are used for a wide range of lifting and rigging applications. They provide secure attachment points for lifting ropes, slings, cables, or chains in construction, marine, and industrial settings. Eye nuts are commonly used to attach rigging to heavy machinery or to suspend equipment. Depending on the material and design, eye nuts are suitable for applications where load distribution is critical, such as hoisting, lifting platforms, and pulley systems.

How do eye nuts compare to eye bolts?

Eye nuts and eye bolts both serve similar purposes in lifting and rigging, but they differ in design and application. Here’s a comparison to help you choose the right one for your needs:

Eye Nuts:

Threaded onto a bolt or stud to create a lifting point.

More versatile and can be easily removed and reused.

Ideal for temporary or adjustable rigging setups.

Have an integral eye that is threaded directly into a structure.

More permanent once installed.

Best for permanent or fixed lifting applications.

Tip: Choose eye nuts for flexibility and temporary setups, and eye bolts for permanent or structural lifting solutions.

How do I install an eye nut correctly?

Proper installation of an eye nut is crucial for safety and performance in lifting and rigging applications. Follow these steps to install an eye nut correctly:

Step 1: Match the Threads

Ensure the thread on the stud or bolt matches the thread of the eye nut.Step 2: Screw the Eye Nut

Thread the eye nut onto the stud and ensure it is tight and secure.Step 3: Align Properly for Rigging

For rigging, align the eye nut to distribute the load evenly during lifting.Step 4: Avoid Over-tightening

Do not over-tighten the eye nut, as it could damage the threads.Step 5: Follow Manufacturer Guidelines

Always refer to the manufacturer’s installation guidelines for safety and proper usage.

Can eye nuts be used with lifting slings?

Yes, eye nuts are ideal for use with lifting slings. The eye of the nut provides a secure attachment point for connecting the sling. When using eye nuts with slings, ensure the size and load capacity match the weight of the load being lifted. We offer custom eye nuts designed to work with various sling types, including wire ropes and webbing slings. Always verify the capacity and compatibility before use to avoid failure.

What is the load rating for eye nuts?

The load rating of an eye nut is determined by its material, size, and thread type. For example, stainless steel eye nuts tend to have higher load ratings compared to brass eye nuts due to the strength of the material. We provide detailed load capacity tables for each eye nut type, indicating safe working loads and break strength. Always refer to these ratings to ensure that the eye nut you use is capable of handling the required load without failure.

Are custom eye nuts available?

Yes, we offer custom eye nuts tailored to meet specific requirements. Whether you need a different size, material, or thread type, we can produce eye nuts that fit your precise needs. Our team can also work with you to design eye nuts for specialized applications, ensuring they meet industry standards like DIN 582 or other certifications. Customization options allow you to create the ideal solution for heavy-duty lifting or unique rigging applications.

Have More Questions of Eye Nuts?

Got more questions about eye nuts? From sizes and materials to installation tips, our experts are here to assist. Contact us today for personalized support and to ensure your rigging setup is safe and reliable!