You need to schedule annual servicing for most hoists, but the frequency changes based on hoist type, usage, and legal requirements. Daily visual checks, weekly lubrication, and periodic maintenance tasks help keep your equipment safe and reliable.

Safety should always be the top priority, so you must comply with regulations and manufacturer guidelines. High-risk environments require monthly or quarterly inspections. Powerful Machinery delivers certified hoist solutions that support your commitment to safety and professional hoist maintenance.

Key Takeaways

Schedule annual servicing for most hoists, but increase frequency based on usage and environment.

Perform daily visual checks and monthly functional tests to ensure safety and reliability.

Follow manufacturer guidelines for maintenance to comply with safety regulations and extend equipment life.

Document all inspections and maintenance tasks to support compliance and track equipment history.

Train staff regularly on safety procedures and proper hoist operation to reduce risks and enhance workplace safety.

How Often Do Hoists Need to Be Inspected?

General Service Recommendations

You need to follow a structured approach for hoist maintenance to ensure safety and reliability. Start by assessing how often you use your hoist. If you operate it daily or in demanding environments, you must schedule more frequent inspections.

You should check critical components like cables, brakes, and chains during routine inspections. Create a tailored maintenance schedule based on your usage patterns. Powerful Machinery’s certified hoists, including manual chain hoists and electric wire rope hoists, require regular maintenance to maintain peak performance.

Tip: Always use manufacturer-approved parts for replacements and keep detailed records of every inspection and maintenance task.

Here is a quick overview of safety regulations and best practices:

Safety Regulation | Description |

|---|---|

OSHA Compliance | Routine inspections and maintenance are required to prevent accidents. |

Load Capacity Limits | Operators must adhere to the rated load capacity to avoid overloads. |

Regular Inspections | Daily checks and periodic inspections help identify potential issues. |

Proper Labeling | Clear labels on hoists provide quick reference for capacity and instructions. |

Certified Training | Workers should be trained by certified professionals for safe operation. |

Scheduled Maintenance | Regular maintenance schedules help reduce wear and extend machinery life. |

Use of Genuine Parts | Manufacturer-approved components ensure safety and performance. |

Documentation | Detailed maintenance records are essential for audits and inspections. |

Emergency Procedures | Clear emergency procedures must be established for unsafe conditions. |

Factors Affecting Service Intervals

You must consider several factors when determining how often to schedule hoist maintenance and inspections. The intensity of use plays a major role. If you frequently lift loads near the maximum capacity, you need to perform thorough examinations more often.

Environments with dust, moisture, or corrosive chemicals demand increased inspection and lubrication. Legal requirements may also require you to schedule examinations every three to six months, especially in high-risk settings.

High-intensity use requires quarterly maintenance and inspections.

Harsh environments, such as those with dust or chemicals, demand more frequent lubrication and checks.

Annual servicing is standard, but you may need to increase the frequency based on compliance with regulations and lifting regulations.

Note: Powerful Machinery’s hoists are engineered for durability, but you must adjust your maintenance schedule if you operate in extreme conditions.

Manufacturer Guidelines

You need to follow the manufacturer’s recommendations for hoist maintenance and inspections. Most manufacturers advise daily visual inspections and lubrication. Monthly checks should include testing brakes and inspecting the electrical system.

In harsh environments, you should schedule a full examination every six months. Annual comprehensive servicing by a certified technician is essential for all hoists.

Interval | Task |

|---|---|

Daily | Visual inspection, chain lubrication |

Monthly | Check the electrical system, test the brakes |

Every 6 months | Full inspection in harsh environments |

Annually | Comprehensive service by a technician |

Major international standards, such as ISO and FEM, classify hoists based on load capacity and operating conditions. ISO standards range from M2 (light) to M7 (very heavy), while FEM standards rate hoists from 1Dm to 5m.

Both standards aim to ensure a minimum theoretical lifespan for hoists under specific load conditions. You must always align your maintenance and examination schedule with these standards to guarantee compliance and safety.

Powerful Machinery’s certified products meet ISO and OSHA requirements, supporting your commitment to compliance with regulations and safe operation.

You should visually inspect your hoist before each use for any obvious damage or loose pieces. Monthly inspections must include a thorough check of the framework, wiring, and controls. This approach ensures your hoist remains reliable and safe for every lifting task.

Inspections and Compliance

Regulatory Standards (LOLER, OSHA, ASME)

You must follow strict safety regulations when operating hoists. The main standards include the Lifting Operations and Lifting Equipment Regulations (LOLER), the Occupational Safety and Health Administration (OSHA), and the American Society of Mechanical Engineers (ASME).

These organizations set clear requirements for hoist maintenance, inspections, and documentation.

Powerful Machinery’s products meet international certifications such as ISO, CE, OSHA, and ASME. These certifications show that your equipment meets the highest safety requirements and supports your compliance with regulations.

You can trust that every hoist from Powerful Machinery has passed rigorous tests for quality and reliability.

Here is a summary of the main regulatory requirements:

Regulation | Inspection Requirement |

|---|---|

OSHA | Regular inspections and proper documentation are required. Initial inspections before use, followed by periodic and frequent inspections. |

LOLER | Thorough examination by a competent person is required every 6 months for equipment lifting people and annually for other lifting devices. |

You must understand your legal obligations under these standards. OSHA requires routine inspections to enhance safety. LOLER mandates a thorough examination by a competent person every six months for hoists that lift people and annual inspections for other lifting devices.

ASME standards also require you to keep detailed records of every examination and maintenance task.

Note: Following the provision and use of work equipment regulations ensures your workplace meets all safety regulations and legal obligations.

Inspection Intervals and Competent Person

You need to schedule examinations based on the service class and usage of your hoist. The frequency of inspections depends on how often you use the equipment and the environment where you operate it. You must arrange for a competent person to carry out each scheduled examination.

This person should have the training and experience to identify potential hazards and ensure compliance with all safety requirements.

The table below outlines typical intervals for frequent and periodic inspections:

Service Class | Frequent Inspection Frequency | Periodic Inspection Frequency |

|---|---|---|

Class A | Monthly | Annually |

Class B | Monthly | Annually |

Class C | Weekly to Monthly | Semi-Annually |

Class D | Weekly to Monthly | Semi-Annually |

Class E | Daily to Weekly | Quarterly |

Class F | Daily to Weekly | Quarterly |

You must perform routine inspections before each use. For normal service, schedule monthly examinations. For heavy or severe service, increase the frequency to weekly or even daily.

OSHA mandates monthly inspections for running ropes, hoist chains, end connections, and hooks. You must document every examination and keep records for audits and compliance checks.

Professional inspections play a key role in hoist maintenance. A competent person will conduct thorough examinations, identify wear or damage, and recommend repairs or replacements. You should never skip scheduled examinations, as they are essential for safety and compliance with regulations.

Healthcare and Specialized Hoists

Specialized hoists, such as those used in healthcare, require even stricter compliance. You must follow additional standards like OSHA 1910.184, ASME B30.9, and ANSI Z359. These standards require periodic inspections of slings, rigging hardware, and lifting devices.

You must document these inspections every 12 months, or more often in severe conditions.

Healthcare hoists often lift people, so LOLER requires a thorough examination every six months by a competent person. You must ensure all operators complete certified training courses.

For example, the “Cranes, Derricks, Hoists, Elevators, and Conveyors Course” provides an official certificate of completion and covers all safety requirements.

Powerful Machinery’s hoists meet all relevant certifications, including ISO, CE, and OSHA. These certifications guarantee that your equipment is suitable for specialized environments and meets the highest safety standards.

Tip: Always keep inspection records up to date and ensure only trained personnel operate healthcare and specialized hoists.

You must prioritize hoist maintenance, routine inspections, and scheduled examinations to protect both operators and those being lifted. Proper documentation and professional oversight ensure you meet every legal obligation and maintain compliance with all safety regulations.

Types of Hoists

You encounter several types of hoists in industrial settings. Each type has unique maintenance and inspection requirements. Understanding these differences helps you keep your equipment safe and reliable.

Manual Chain Hoist

Manual chain hoists use hand-operated mechanisms to lift smaller loads. You need to inspect these hoists regularly for wear and tear. Daily visual checks and monthly lubrication are essential. Annual servicing ensures long-term reliability. In severe service conditions, schedule inspections monthly or quarterly.

Inspection Type | Frequency |

|---|---|

Frequent Inspection | Daily to monthly |

Normal Service | Annually |

Severe Service | Monthly or quarterly |

Manual chain hoists from Powerful Machinery carry certifications such as CE Marking, ISO 9001, ASME B30.16, and EN 13157. These certifications guarantee compliance with international safety standards. You benefit from improved workplace safety and reduced accident risks.

Tip: Always check the chain and hooks for signs of damage before each use.

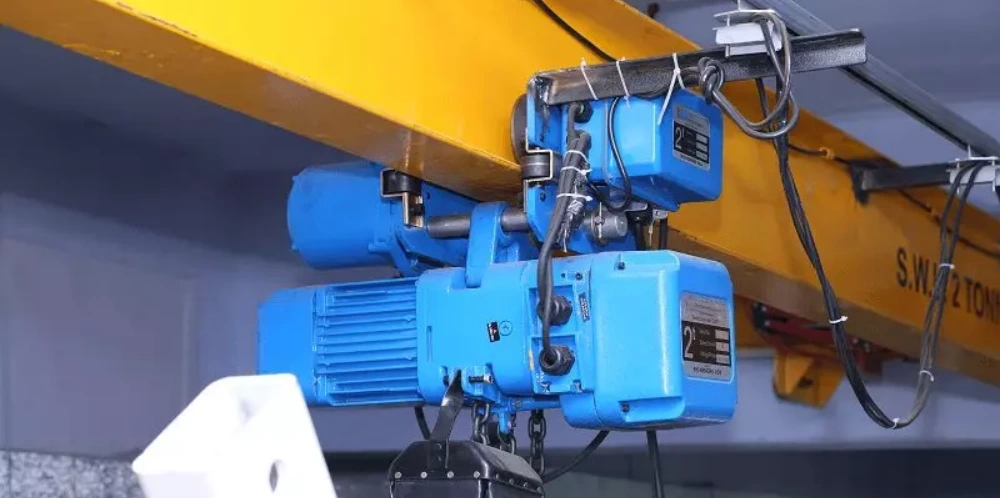

Electric Chain Hoist

Electric chain hoists lift heavy loads quickly and efficiently. You must perform routine checks on electrical components and load limits. These hoists require more frequent maintenance by qualified technicians because of their complex motors and electrical systems.

Daily inspections and monthly testing of brakes and limit switches are recommended.

Feature | Advantage |

|---|---|

Motor Performance | Reliable operation reduces danger and downtime. |

Built-in Safety Features | Limit switches and dual brake systems enhance safety. |

Electric chain hoists reduce manual handling, automate lifting, and minimize strain injuries. Powerful Machinery’s electric chain hoists include overload protection and emergency stop buttons. Certifications such as CE, ISO 9001, and OSHA ensure you meet industry standards.

Electric Wire Rope Hoist

Electric wire rope hoists offer efficient lifting for larger loads. You need to inspect these hoists daily and lubricate moving parts monthly. Quarterly checks of electrical connections and periodic testing of load brakes and limit switches are necessary.

Maintenance Task | Frequency |

|---|---|

Daily Inspection | Daily |

Lubrication and Cleaning | Monthly |

Testing Load Brakes and Limit Switches | Periodically |

Electrical Connections Inspection | Quarterly |

Powerful Machinery’s electric wire rope hoists meet certifications such as ASME B30.17, OSHA 1926.1400, CE, and ISO 9001. These certifications confirm the hoists’ safety and reliability for industrial applications.

Note: Consistent hoist maintenance extends equipment lifespan and ensures safe operation.

Safety Benefits and Warning Signs

Safety Advantages of Regular Maintenance

You protect your workplace and your team when you prioritize regular maintenance. Powerful Machinery stands behind enhanced safety and reliability, ensuring every hoist stays in good working condition.

Industry reports show that regular maintenance lowers the risk of accidents, keeps operations efficient, and helps you stay compliant with legal requirements.

Benefit | Description |

|---|---|

Legal Compliance | Avoid fines and legal action by staying compliant. |

Risk Reduction | Lower the chance of accidents and injuries. |

Operational Efficiency | Prevent downtime and keep operations running smoothly. |

Routine inspections help you spot hazards early and meet OSHA and ASME standards. Proactive replacement of worn parts reduces the risk of failures during operation. You extend the lifespan of your equipment and create a safer environment for everyone.

Early Detection and Prevention

You need to identify issues before they become safety concerns. Daily checks and routine inspections focus on critical components like brakes and electrical systems.

Early detection lowers mechanical failure rates by up to 40% and extends hoist lifespan by about 20%. You avoid sudden breakdowns and keep your hoist in good working condition.

Evidence Type | Description |

|---|---|

Regular Inspections | Help identify potential issues early, reducing the risk of accidents. |

Routine Checks | Vital for safe and efficient hoist operation, focusing on critical parts. |

Maintenance Impact | Lowers failure rates and extends equipment lifespan. |

You must perform specific maintenance tasks such as checking chains, lubricating moving parts, and testing brakes. These actions prevent unexpected failures and support enhanced safety.

Warning Signs for Immediate Service

You must act quickly when you notice warning signs that indicate your hoist needs immediate servicing:

Hard to start or shakes when starting

Loud banging or humming during lifting

Frayed or rusty wire ropes

Cage slowly drops after stopping

Cage sways during lifting

Floor buttons don’t respond

Frequent power trips or shutoffs

Limit switches not working or overload allowed

Visible swaying between towers

Brake failure or slipping cage

Frequent circuit breaker trips

Safety limits not triggering or overload not detected

You should never ignore these signs. Immediate service prevents accidents and keeps your equipment in good working condition.

Consequences of Non-Compliance

Ignoring hoist maintenance regulations leads to serious consequences. You risk legal penalties, financial losses, and operational delays. Accidents can halt your operations and damage your reputation.

Consequence Type | Description |

|---|---|

Legal Implications | Non-compliance can lead to fines, penalties, and investigations, with fines now being unlimited. |

Financial Implications | Companies may incur high costs due to downtime and fines. |

Operational Impacts | Accidents can halt operations, leading to delays and increased costs. |

Reputational Damage | Publicized incidents can harm your reputation and affect customer trust. |

Preventable accidents and injuries are common risks. In recent years, the construction industry has seen a sharp rise in workplace fatalities. Non-compliance can cause downtime, delay projects, and make it harder to earn customer trust.

You must follow maintenance schedules and safety standards to protect your business and your team.

Best Practices for Hoist Maintenance

Structured Maintenance Schedules

You need a clear and consistent schedule to keep your hoist operating safely. A structured plan helps you prevent unexpected breakdowns and ensures you meet safety requirements.

Regular hoist servicing improves worker safety, extends equipment life, and reduces downtime. Use the table below as a guide for your maintenance routine:

Maintenance Task | Frequency |

|---|---|

Visual Inspection | Before each use |

Functional Test | Weekly |

Lubrication | Monthly or as recommended |

Load Test | Annually |

Full Preventive Maintenance | Every 3-6 months |

You should adjust these intervals based on how often you use your hoist, the environment, and the type of hoist. Annual servicing by trained professionals ensures your equipment meets safety standards and compliance requirements.

Critical Components to Inspect

You must check several key parts during every inspection. Focus on the following components to maintain safe operation:

Chains and load chain

Hooks and sheaves

Drums and wire rope assemblies

Crane and trolley wheels

Brakes and fasteners

Always perform a brake test to verify engagement and load-holding capacity. Look for corrosion, check lubrication, and inspect gears as needed. Schedule teardown inspections every few years for hoists used in critical applications. Load capacity verification should be part of your routine to ensure safe lifting.

Tip: Use only genuine parts and rely on certified technicians for repairs. This practice guarantees safety, reliability, and ongoing manufacturer support.

Documentation and Staff Training

You need to keep detailed records of every inspection, repair, and annual servicing. Proper documentation supports compliance with OSHA and other safety standards. Maintenance logs help you track issues and prove that you follow legal and insurance requirements.

Train your staff regularly so they understand emergency procedures and the safety features of your hoist. Powerful Machinery recommends ongoing training for all operators and maintenance staff. Well-trained professionals reduce risks and improve workplace safety.

Note: Up-to-date records and skilled staff are your best defense against accidents and compliance issues.

Conclusion

You must schedule service intervals based on your hoist type and usage. The table below shows recommended intervals:

Type of Hoist | Recommended Service Interval |

|---|---|

General Hoists | At least once a year |

Frequent Use Hoists | More frequent servicing as needed |

Inspections | Regular checks by trained professionals |

Frequent inspections help you identify issues early, maintain compliance, and extend equipment life. Professional inspections and certified products from Powerful Machinery ensure you meet industry standards and protect your team. Choose certified hoists for reliable performance and ongoing safety.

FAQ

How often should you schedule hoist inspections?

You should schedule inspections at least once a year. If you use your hoist frequently or in harsh environments, increase the frequency. Daily visual inspections and monthly functional tests help you maintain safety and reliability.

What is the difference between an inspection and an examination?

An inspection checks the hoist for visible damage or wear. An examination involves a deeper review of mechanical and electrical systems. You must perform both to ensure compliance and prevent accidents.

Who can carry out a hoist examination?

You need a competent person to conduct each examination. This person must have proper training and experience. Professional examinations identify hazards and confirm your equipment meets safety standards.

Why are regular examinations important for hoists?

Regular examinations help you detect issues early. You reduce the risk of accidents and extend the lifespan of your equipment. Scheduled examinations also ensure you comply with legal requirements and industry standards.

What records should you keep after inspections and examinations?

You must keep detailed records of all inspections and examinations. These logs support compliance and help you track maintenance history. Proper documentation protects your business during audits and reviews.