Types of D Rings and Their Uses Explained Simply

Types of D rings include dorsal, sternal, side, weld-on, bolt-on, and more—each designed for specific safety, lifting, or cargo control uses.

Welcome to the Powerful Machinery resource center. Here, our experts share deep insights into the science of lifting, rigging, and mooring. Explore technical guides on everything from wire ropes to anchor chains and hardware, helping you engineer safer, more reliable solutions.

Types of D rings include dorsal, sternal, side, weld-on, bolt-on, and more—each designed for specific safety, lifting, or cargo control uses.

What is a d ring? A D-ring is a secure metal loop for anchoring, lifting, or connecting. Learn how to select the right D-ring for your project needs.

See the top 10 D ring manufacturers worldwide for 2026, featuring leaders in quality, certifications, and custom solutions for industrial applications.

Compare the top wire rope fittings suppliers worldwide in 2026 for quality, certifications, and global service to support your infrastructure projects.

Wire rope fittings guide: types, materials, applications, and tips for proper selection, installation, and maintenance to ensure safety and reliability.

Chain binder storage tips help prevent rust, damage, and ensure safety. Keep binders organized and protected for longer life and reliable performance.

Master pallet jack adjustment with step-by-step handle and lift height tips, essential tools, troubleshooting, maintenance, and sourcing quality parts.

Not all pallet jacks have brakes. Some models include hand, foot, or automatic brakes for added safety and control in warehouse settings.

How to loosen a ratchet chain binder safely in 3 steps: prep your tools, release tension, and remove the binder with simple, effective techniques.

Pallet jack storage keeps equipment safe, extends lifespan, and ensures compliance. Learn best practices for organization, safety, and maintenance.

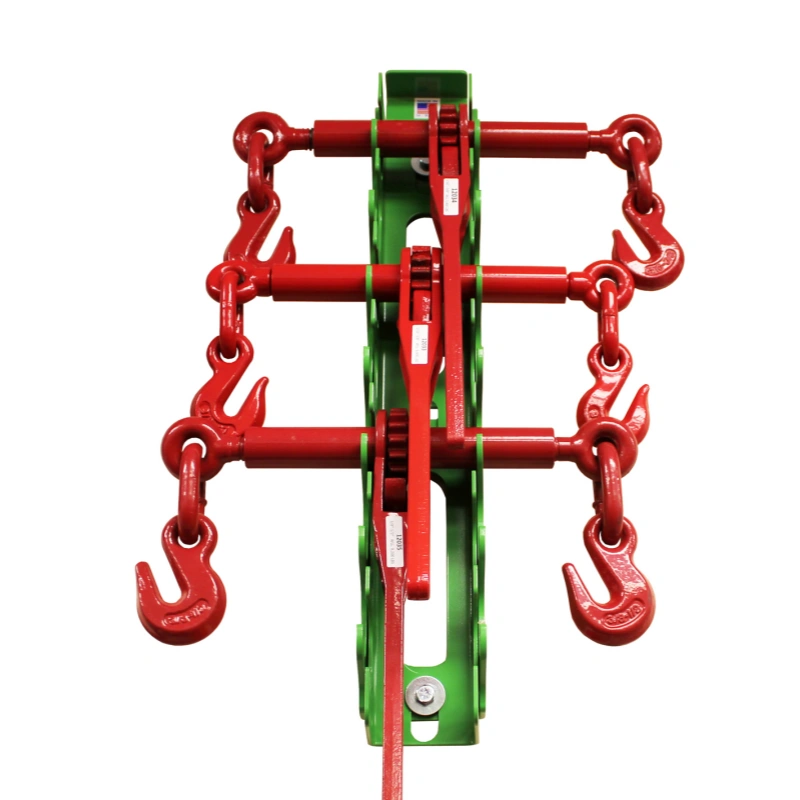

Chain binders secure heavy loads during transport. Compare types, uses, safety tips, and selection criteria with step-by-step instructions.

Moving storage sheds with a pallet jack is possible if the shed fits weight limits and the terrain is smooth. Review safety tips and equipment options.

After downloading the product catalogue, our dedicated technical experts will provide you with one-on-one service.