Chain slings must be constructed of certified, high-tensile alloy steel to ensure maximum safety in lifting operations. Certified materials mean the steel has passed strict quality checks and earned approval from recognized organizations like ISO, ASME, or OSHA.

You can trust Powerful Machinery to use only certified materials that meet international standards for strength and reliability. This commitment helps prevent accidents and ensures that every chain sling performs as expected during critical lifts.

Key Takeaways

Always use certified alloy steel for chain slings to ensure safety and reliability during lifting operations.

Check for compliance with international standards like OSHA and ASTM to guarantee the quality of your lifting equipment.

Inspect chain slings before each use, looking for legible identification tags and documented inspection records.

Understand the differences between Grade 80 and Grade 100 alloy slings to choose the right equipment for your lifting needs.

Using uncertified slings can lead to accidents and costly downtime; prioritize safety in all lifting operations.

Chain Slings Must Be Constructed of Certified Alloy Steel

When you select lifting equipment for critical operations, you need to know that chain slings must be constructed of certified alloy steel. Certification means the steel has passed rigorous tests and meets international standards for safety and performance. You cannot compromise on this requirement.

Certified alloy chain slings protect you, your team, and your assets during every lift.

International standards set strict requirements for the materials used in alloy chain slings. You should look for compliance with these key standards:

OSHA (Occupational Safety and Health Administration)

Federal NACM (National Association of Chain Manufacturers)

ASTM (American Society for Testing and Materials)

ISO (International Organization for Standardization)

ASME B30.9.1 (American Society of Mechanical Engineers)

These standards ensure that chain slings must be constructed of materials with high tensile strength, proper ductility, and consistent quality. The working load limits for alloy chain slings are based on a 4:1 design factor, which means the chain can handle four times the rated load before breaking.

Proofloading is also mandatory for new and repaired alloy chain slings, so you can trust their reliability.

Powerful Machinery uses only certified alloy steel for all alloy chain slings. Every batch undergoes strict quality checks and traceability procedures. You receive products that meet or exceed ISO9001, ISO14001, TUV Rheinland, EURO CERT, EAC, Geprufte Sicherheit, OSHA, ASTM, and other international certifications.

This commitment guarantees that your lifting equipment will perform safely in the most demanding environments.

Commonly Used Sling Materials in Powerful Machinery Chain Slings

You will find that chain slings must be constructed of the best alloy steel grades available. The most commonly used sling materials in the industry are Grade 80 and Grade 100 alloy steels. These grades offer the ideal combination of strength, toughness, and resistance to wear.

Grade 80 alloy chain slings are the most widely used for overhead lifting. They provide excellent energy absorption and durability.

Grade 100 alloy chain slings are gaining popularity because they deliver higher working load limits and improved strength-to-weight ratios.

Both grades meet the latest NACM and ASTM guidelines for alloy chain slings.

The commonly used sling materials in Powerful Machinery chain slings ensure you get consistent performance and long service life. You can rely on these sling materials for safe and efficient lifting operations.

Alloy Steel Grades: Grade 80 and 100

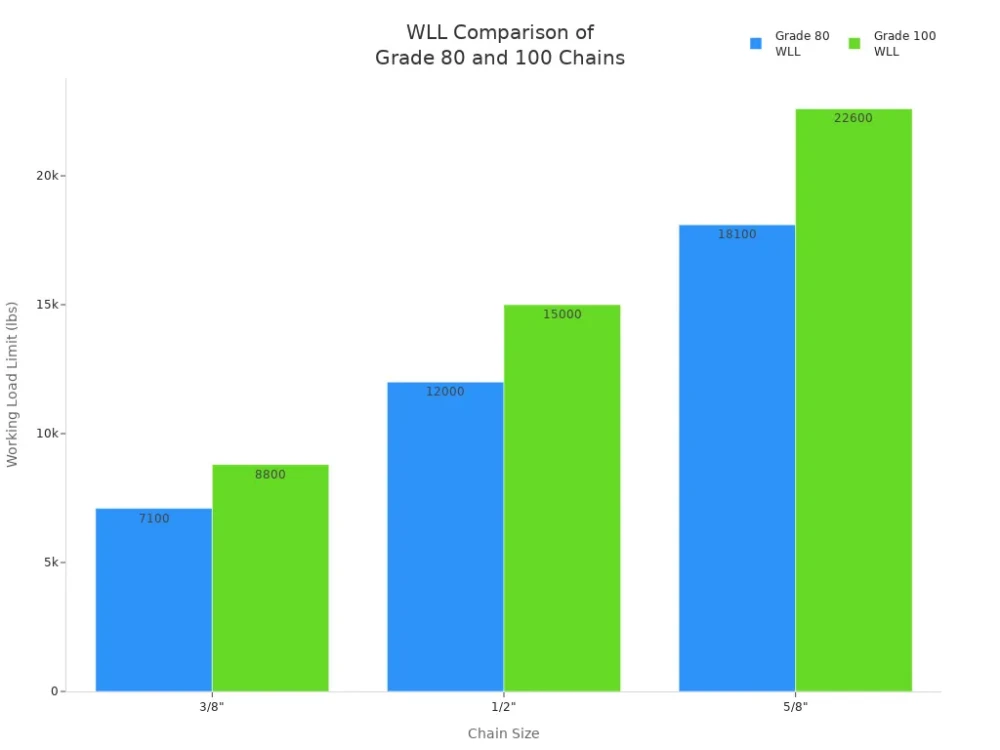

You need to understand the differences between Grade 80 and Grade 100 alloy chain slings when choosing lifting equipment. The table below shows how working load limits compare for different chain sizes:

Chain Size | Grade 80 WLL (lbs) | Grade 100 WLL (lbs) |

|---|---|---|

3/8″ | 7,100 | 8,800 |

1/2″ | 12,000 | 15,000 |

5/8″ | 18,100 | 22,600 |

Grade 100 alloy chain slings provide a 25% increase in tensile strength compared to Grade 80. You can handle greater loads with the same chain size or use a smaller diameter to achieve the same working load limit.

This advantage comes from advanced alloy compositions and precise heat treatment processes that improve the steel’s grain structure.

When you use Grade 100 alloy chain slings, you benefit from:

Reduced manual handling fatigue and lower risk of strain injuries.

Faster attachment and removal during rigging.

Improved crane efficiency because less lifting capacity is consumed by rigging weight.

Easier mobility for workers handling multiple assemblies.

You should always remember that chain slings must be constructed of certified alloy steel to guarantee safety, reliability, and compliance with international standards. Powerful Machinery delivers only the highest quality alloy chain slings, giving you confidence in every lift.

Working Load Limit and Chain Sling Safety

How Working Load Limit Is Determined?

You must understand the working load limit before you begin any lifting operation. The working load limit tells you the maximum weight a chain sling can safely lift. This value depends on the strength of the material, the number of sling legs, and the angle at which you rig the sling.

For example, when you use a two-legged chain sling, the working load limit changes based on the angle between the legs. If you rig the sling at a 120-degree angle or greater, you use the full working load limit. If the angle is less, you must reduce the limit.

For instance, a ½-inch grade 80 chain can lift 9,600 pounds at a vertical choke. When you set the angle to 60 degrees, you multiply 9,600 pounds by the sine of 60 degrees, which gives you about 8,314 pounds per leg. With two legs, the total working load limit becomes 16,628 pounds.

International safety standards guide how you determine the working load limit for chain slings. These standards include OSHA, ASME B30.9, NACM, and ASTM. Each standard sets rules for strength, material quality, and proofloading. You must follow these standards to ensure safe lifting every time.

Importance of Certification for Chain Sling Safety

Certification plays a key role in lifting safety. You need to use only certified chain slings that meet strict industry standards. Powerful Machinery ensures every chain sling has accurate working load limit markings and passes all required tests. The company follows these certification standards:

Certification Standard | Description |

|---|---|

ASME B30.9 | Requires annual certification for chain slings to ensure safe usage in lifting operations. |

WSTDA | Requires a written record of the most recent inspection for valid certifications. |

RS-1 | Requires a written record of the most recent inspection for valid certifications. |

You should always check the identification markings on your chain slings. These markings must be permanent and easy to read. They show the safe working load, sling type, angle, and number of legs. Never use a chain sling without these markings.

Employers must not load a sling beyond the recommended working load limit. By following these rules, you protect your team and equipment during lifting.

Tip: Always inspect your chain slings before each use. Look for clear markings and check that the material and strength match your lifting needs.

How to Identify Certified Chain Sling Materials?

Markings, Documentation, and Compliance

You must check for specific markings and documents when you identify certified chain sling materials. Every chain sling should have a permanent identification tag or label. This tag must stay attached to the sling at all times. If the tag is missing or unreadable, you need to remove the sling from service.

The tag shows important information, such as the chain grade, rated load limits, and the type of sling. These details help you confirm the sling ratings and ensure you use the right equipment for your job.

You should also look for written records of inspections. International standards like ASME B30.9, WSTDA, and RS-1 require you to keep these records. Inspection intervals depend on how often you use the sling. For normal service, inspect at least once a year.

For severe service, inspect monthly or quarterly. Always keep these documents available for review.

Here are common compliance issues found during inspections:

Compliance Issue | Description |

|---|---|

Damage to Slings | Broken wires, corrosion, or deformation require immediate removal from use. |

Improper Rigging Hardware | Missing latches or bent hardware can cause failures. |

Legible Tags | Illegible or missing tags mean the sling is not compliant. |

You must understand the different grades of alloy chain slings and select the right type for your lifting needs. Options include single-leg chain sling, double-leg chain sling, and multi-leg chain sling. Each type suits different loads and lifting angles.

Verifying Powerful Machinery Chain Slings

You can trust Powerful Machinery to provide certified chain slings that meet strict international standards. The company certifies every batch and supplies documentation for each product. You receive proof of chemical analysis, dimensional checks, and proof-load testing. These steps ensure the highest quality and safety.

Powerful Machinery works with recognized third-party organizations for inspection and certification. Hercules Crane and Lifting Supplies also provides trusted certification services. Both organizations help you meet legal requirements and reduce risk.

Recent advancements in chain sling certification focus on material strength, fatigue resistance, and improved inspection protocols. Automated inspection systems and AI-based predictive maintenance now help you detect faults early and extend sling life.

When you verify a Powerful Machinery chain sling, always check for:

A permanent, legible identification tag

Up-to-date inspection records

Certification documents from trusted organizations

These steps help you confirm compliance and keep your lifting operations safe. You should always match the types of alloy steel chains to your application for the best results.

Conclusion

You must use only certified materials for chain slings to protect your team and equipment. Certified chain slings enhance safety, reduce hazards, and ensure efficient lifting operations. Powerful Machinery stands behind every product with strict adherence to international standards.

Using uncertified slings can cause accidents, legal issues, and costly downtime.

To verify certification and compliance, follow these steps:

Inspect slings before each use.

Check for legible identification tags.

Review documented inspection records.

Replace damaged components immediately.

Stay vigilant and keep your lifting operations safe.

FAQ

What makes alloy slings better than nylon or polyester slings?

You get higher strength and durability with alloy slings. They handle heavy loads and resist abrasion. Nylon slings and polyester slings work well for lighter tasks, but alloy slings offer superior performance in demanding environments.

How often should you inspect your slings?

You should inspect your slings before each use. Schedule a thorough inspection at least once a year. Increase inspection frequency if you use slings in harsh conditions or for critical lifts.

Can you use alloy slings in extreme temperatures?

You can use alloy slings in both high and low temperatures. They maintain strength and flexibility where nylon or polyester slings might fail. Always check the manufacturer’s guidelines for safe temperature ranges.

What information must appear on a chain sling identification tag?

You must see the grade of alloy, the number of legs, the working load limit, and the manufacturer’s details. This tag helps you confirm the sling’s specifications and compliance with safety standards.

Are alloy slings suitable for all lifting applications?

You can use alloy slings for most heavy-duty lifting. For delicate or finished surfaces, choose nylon or polyester slings to prevent damage. Select the right sling based on your load and environment.