When you select crane wire rope manufacturers, you want strength, safety, and trust. The top choices in the industry include:

PowerFul Machinery

Bridon-Bekaert Ropes Group

WireCo WorldGroup

Usha Martin

Kiswire

Teufelberger

The global market for crane wire ropes stands at $1.2 billion in 2024 and continues to grow. You face challenges like corrosion, poor maintenance, and rope loosening. See how the main reliability issues compare:

Reliability Issue | Causes |

|---|---|

Corrosive Environments | Frequent contact with chemicals, saltwater, or industrial fumes accelerates corrosion. |

Lack of Maintenance | Failure to clean and lubricate the wire rope regularly allows dirt and moisture to stay trapped. |

High Humidity | Constant exposure to damp air or water promotes oxidation on steel surfaces. |

Arc Burning | Occurs when the rope touches an electrical source, causing localized melting. |

Rope Loosening | Defects in manufacturing or torsional stress can lead to slack or deformation of the rope. |

Severe Wave Deformation | Unreleased torsion or inadequate tension management leads to uneven stress distribution. |

You want reliable products that protect your crew and investment. These manufacturers stand out for their commitment to quality and innovation.

Key Takeaways

Choose crane wire rope manufacturers based on their quality certifications, like ISO 9001:2015, to ensure safety and reliability.

Look for manufacturers with a strong reputation and years of experience in the industry to guarantee dependable products.

Consider the range of products and innovative technologies offered by manufacturers to meet your specific lifting needs.

Always check customer feedback and testimonials to gain insights into the quality and service of the manufacturer.

Request inspection records and maintenance guides to ensure the longevity and safety of your wire ropes.

Top Criteria for Crane Wire Rope Manufacturers

When you choose crane wire rope manufacturers, you want to make sure they meet strict standards. Here are the top criteria you should consider:

Quality & Certifications

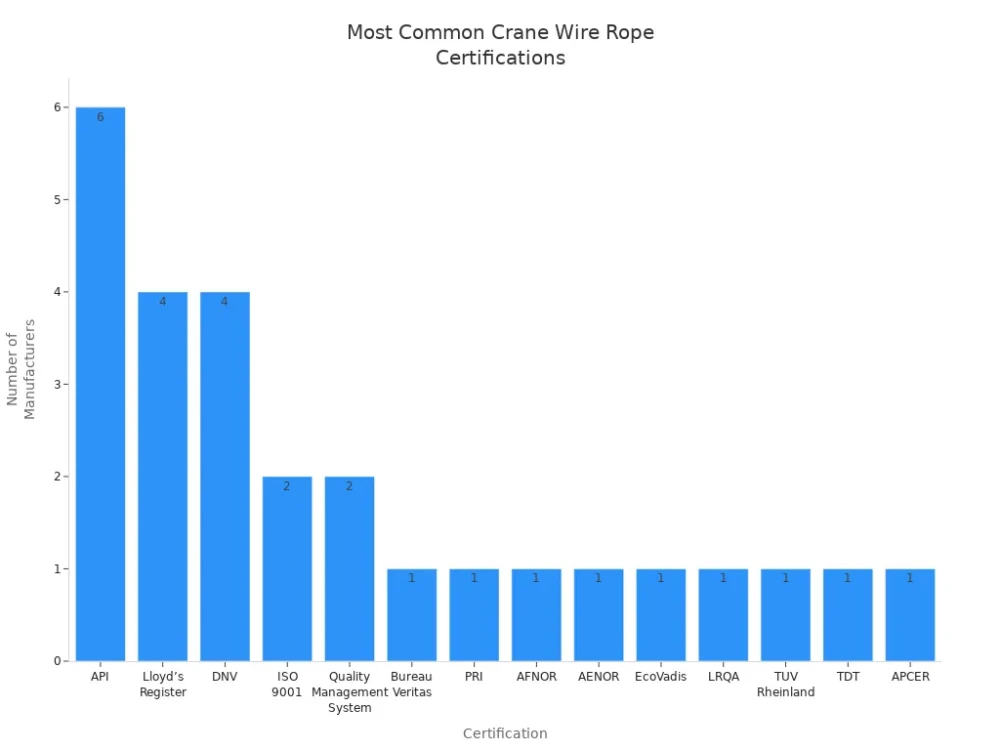

You need products that pass international safety and quality checks. Leading manufacturers hold certifications that prove their commitment to excellence. These certifications include:

Certification | Description |

|---|---|

ISO 9001:2015 | Quality management system certification |

ABS | Manufacturing assessment certification |

DNV-GL | Manufacturing assessment certification |

Lloyds | Manufacturing assessment certification |

Manufacturers also follow important ISO standards:

ISO Standard | Description |

|---|---|

ISO 13001 | General design requirements for cranes |

ISO 13411 | Safety standards for terminals of steel wire ropes |

You can look for a digital quality certificate, which tracks every step of the process. Regular inspections by authorized staff help keep products safe and reliable.

Reputation & Experience

You want a manufacturer with a strong history and a good name in the industry. Companies with decades of experience often win awards and earn trust from customers. Their long track record shows they know how to deliver safe and reliable products.

Product Range & Innovation

Top crane wire rope manufacturers offer a wide range of products. They invest in new technology and design features that improve performance. For example, some ropes have triple-core construction or special coatings for extra strength and durability.

Customer Feedback

You should always check what other buyers say. Customer reviews and testimonials give you real-world insight into product quality and service. Positive feedback means you can trust the manufacturer to meet your needs.

Tip: Always ask for inspection records and certificates before making a final decision.

1. PowerFul Machinery

Company Overview

You find PowerFul Machinery at the forefront of lifting and rigging solutions. With over 20 years of experience, this company delivers high-performance chains, steel wire ropes, and rigging hardware.

Powerful Machinery serves industries like construction, marine, transportation, and cargo handling. You benefit from their direct-from-manufacturer approach, which helps you save on costs and ensures you receive products straight from the source.

Products & Tech

PowerFul Machinery offers a wide range of products, including Grade 80 and G100 lifting chains, hooks, shackles, master links, and wire rope fittings. Their advanced manufacturing facility uses automated welding systems and precision forging presses. This technology ensures each product meets strict quality standards.

You can see their commitment to innovation in the following advancements:

Advancement Type | Description |

|---|---|

Advancements in Materials | High-strength synthetic fibers reduce weight and boost corrosion resistance. |

Increased Automation | Automated systems handle lifting and transport, improving efficiency and safety. |

Safety Improvements | Sensors detect early damage, helping you prevent accidents. |

Sustainability | Eco-friendly materials and optimized processes cut waste and energy use. |

Artificial Intelligence | AI predicts maintenance needs and spots hazards before they become problems. |

Reliability Factors

You can trust PowerFul Machinery for several reasons. Every product goes through rigorous testing to exceed international standards like ISO 9001:2015 and ISO 13411. Their in-house engineers work with you to design custom solutions for unique projects.

You also receive digital quality certificates and inspection records for peace of mind.

Note: PowerFul Machinery’s logistics team manages secure packaging and documentation, so your orders arrive safely and on time.

Projects & Clients

You see PowerFul Machinery’s products in action worldwide. They support major construction projects, marine operations, and cargo handling facilities. Their global export experience and strong logistics network help you get reliable products wherever your project takes you.

Many clients return for repeat business, showing high satisfaction and trust in the brand.

2. Bridon-Bekaert Ropes Group

Company Overview

You discover Bridon-Bekaert Ropes Group as a global leader in steel wire rope manufacturing. The company combines the expertise of Bridon and Bekaert, creating a powerhouse with decades of experience. You see their products in mining, construction, oil and gas, and industrial lifting.

Bridon-Bekaert focuses on innovation and sustainability, aiming to reduce environmental impact with energy-efficient equipment and recyclable wire rope solutions.

Products & Tech

You benefit from a wide range of advanced wire rope technologies. Bridon-Bekaert offers proprietary products that set them apart in the industry.

Product Name | Description |

|---|---|

Spiral Strand | Multiple layers of helically twisted steel wires, featuring the Bekaert blocking compound for reduced steel-steel contact and added corrosion resistance. |

Bridon Tiger® 6T Compound Bristar® | Used for shaft hoisting, this rope provides advanced diameter stability and longer lifetime with a Bristar® core. |

Redbak+® | A plastic-infused shovel rope that uses TUFF8 technology and engineered polymers for extended service life. |

You find these products deliver high performance in demanding environments, helping you tackle tough lifting and hoisting jobs.

Reliability Factors

You want reliability and safety in every wire rope. Bridon-Bekaert ensures this through strict quality checks, international certifications, and rigorous testing.

Quality Measure | Description |

|---|---|

Strict Quality Checks | Conducted at every stage of steel wire production. |

International Certifications | Holds ISO and API certifications to meet global safety standards. |

Rigorous Testing | Products undergo tests for load capacity, flexibility, and corrosion resistance. |

You also receive installation, inspection, and maintenance services, making sure your equipment stays in top condition.

Tip: Bridon-Bekaert’s commitment to sustainability means you get reliable products that also help protect the environment.

Projects & Clients

You see Bridon-Bekaert’s ropes in major projects around the world. Notable examples include:

Installation of overhead cranes and gantries for building movement.

Construction of substations with lighting and power supply.

Collaboration with ABB to provide integrated mine hoist services, boosting productivity.

Warehouse projects with overhead cranes, gantries, and structural steel fabrication, all completed while maintaining client access and production.

You can trust Bridon-Bekaert Ropes Group for proven expertise and reliable solutions in complex lifting operations.

3. WireCo WorldGroup

Company Overview

You find WireCo WorldGroup as one of the largest wire rope manufacturers in the world. The company has a long history of serving industries like construction, mining, oil and gas, and marine.

WireCo operates production facilities in North America, Europe, and Asia. You benefit from their global reach and strong supply chain. Their focus on research and development helps you access advanced lifting solutions for your toughest jobs.

Products & Tech

WireCo offers a wide range of wire rope and synthetic rope products. You can choose steel wire ropes for heavy-duty lifting. These ropes give you durability and resist abrasion, so you can use them in harsh environments.

If you need lighter options, you can select synthetic ropes made from high-performance fibers like Dyneema and Aramid. These ropes provide strength, easy handling, and corrosion resistance.

Here are the main technological strengths of WireCo’s wire rope products:

Strengths | Description |

|---|---|

Durability | Products withstand harsh conditions and high loads. |

Resistance to Abrasion | Built to resist wear and tear for demanding applications. |

Technical Expertise | You benefit from unmatched technical knowledge in wire rope technology. |

Commitment to Innovation | WireCo invests in ongoing innovation for better performance. |

Quality Assurance | Products meet high standards with international certifications. |

Global Availability | You get a consistent supply and support worldwide. |

Reliability Factors

You can trust WireCo for reliable performance. The company uses strict quality assurance processes. Every product meets international standards, so you know you are getting safe and dependable wire ropes.

WireCo’s technical team supports you with expert advice and custom solutions. Their commitment to innovation means you always have access to the latest technology.

Tip: You can ask for product certifications and technical support to make sure your project runs smoothly.

Projects & Clients

You see WireCo’s ropes in action on major projects around the globe. Construction companies use their products for high-rise buildings and bridges. Mining operations rely on WireCo ropes for hoisting and hauling. Marine and offshore industries trust their ropes for mooring and lifting in tough sea conditions.

Many clients choose WireCo again and again because of their strong reputation and reliable service.

4. Usha Martin

Company Overview

You encounter Usha Martin as one of the largest wire rope manufacturers in the world. The company has built a strong reputation for delivering high-quality wire ropes to industries such as mining, construction, oil and gas, and maritime.

Usha Martin operates sales offices and distribution networks in several countries, which helps you access their products wherever your project is located. You find their presence in the United States, the United Kingdom, Dubai, Thailand, and Singapore.

India leads the world in exports of Martin and HSN Code 7312, with 1,612 shipments, showing the company’s global reach.

Usha Martin stands among the largest wire rope producers worldwide.

You can find their sales offices and distribution networks in:

United States

United Kingdom

Dubai

Thailand

Singapore

India ranks first in the exports of Martin wire ropes.

Products & Tech

You benefit from Usha Martin’s wide range of wire rope products. The company designs ropes for heavy-duty lifting, mining, and marine applications. You can choose from specialized ropes for cranes, elevators, and oilfield operations.

Usha Martin invests in advanced manufacturing technology, which ensures consistent quality and durability. Their products feature high-tensile steel and corrosion-resistant coatings, helping you tackle tough environments with confidence.

Usha Martin’s research and development team works to improve wire rope performance, so you get solutions that meet modern industry standards.

Reliability Factors

You want wire ropes that meet strict safety and reliability standards. Usha Martin holds important certifications that validate their commitment to quality and secure supply chains.

Certification Name | Description | Benefits |

|---|---|---|

AEO T-2 Certification | Authorized Economic Operator status under the WCO SAFE Framework | Validates compliance with global supply chain security standards, strengthens trade partner reliability, enables faster customs clearance, and aligns with WTO commitments |

You receive products that pass international inspections and meet industry requirements. This gives you peace of mind when choosing Usha Martin for critical lifting operations.

Projects & Clients

You see Usha Martin’s wire ropes in action across major industries. Their ropes support a significant service project for Fred. Olsen Windcarrier’s vessel, Blue Tern, which highlights their expertise in maritime applications.

You also find their products used in a major coal mine in Queensland, Australia, demonstrating reliability in mining operations. Usha Martin’s international subsidiary, De Ruiter Staalkabel, secured a major service project with Liebherr Maritime Benelux B.V. for the Blue Tern vessel.

These projects show that leading companies trust Usha Martin for demanding lifting and hoisting needs.

5. Kiswire

Company Overview

You recognize Kiswire as a key player in the global crane wire rope market. The company has built a strong reputation for delivering high-quality wire ropes to customers worldwide. Kiswire’s significant presence in the industry means you can rely on their products for demanding lifting operations.

You see their wire ropes used in many sectors, including construction, mining, oil and gas, and marine. Kiswire’s commitment to innovation and quality helps you meet your project goals with confidence.

Kiswire Ltd. stands out as a major supplier in the global wire rope market for cranes.

You benefit from their expertise and consistent product performance.

Products & Tech

Kiswire invests in advanced manufacturing technologies to ensure you get reliable and durable wire ropes. Their testing equipment covers a wide range of performance checks, so you know each product meets strict standards.

Testing Equipment | Description |

|---|---|

Tensile Test Machines | Quasistatic tensile test up to 2500kN |

Bending Fatigue Test Machines | Multizone bending fatigue test machine up to 198kN |

Torque Test Machine | Twist/Torque test machine up to 300kN |

Wire Testing Equipment | Wire reverse bending test, wire torsion test |

Non-Destructive Testing Equipment | FE-SEM for microstructure observation |

Micro Vickers Hardness Test | Determines material hardness |

Rockwell Hardness Tester | Determines material hardness |

You see Kiswire’s focus on quality and innovation in every wire rope they produce.

Reliability Factors

You want wire ropes that last and perform under pressure. Kiswire’s steel wire meets rigorous testing and strict quality control measures. You get products designed for reliability and durability, especially in hydraulic hose assemblies. The high tensile strength ensures long-lasting performance.

Kiswire wire ropes provide excellent protection against abrasion and corrosion. You can use them in tough environments, such as chemical processing and oil and gas, without worry.

Rigorous testing and strict quality control

High tensile strength for long-lasting performance

Excellent protection against abrasion and corrosion

Suitable for demanding environments

Tip: Kiswire’s wire ropes help you tackle heavy lifting jobs with confidence.

Projects & Clients

You find Kiswire wire ropes in many industries. Their products play a vital role in construction, mining, oil and gas, and marine applications. The following table shows how different industries use Kiswire’s crane wire ropes:

Industry | Usage Description |

|---|---|

Construction | Vital for lifting, rigging, and hoisting operations, especially in urbanization and infrastructure projects. |

Mining | Essential for various lifting and hoisting tasks in mining operations. |

Oil & Gas | Used for heavy lifting and rigging in oil extraction and processing. |

Marine | Important for lifting and securing loads in marine applications. |

You see the wire rope for cranes market growing at a CAGR of 8% from 2025 to 2032. Industrial automation and a booming construction sector drive this growth. Rising demand for heavy lifting solutions means Kiswire’s products remain in high demand across the globe.

6. Teufelberger

Company Overview

You find Teufelberger as a family-owned company with a long tradition in rope manufacturing. Founded in Austria in 1790, Teufelberger has grown into a global leader in steel wire ropes and synthetic ropes. The company operates production sites in Europe, the United States, and Asia.

You benefit from their focus on quality, safety, and sustainability. Teufelberger serves industries such as construction, cranes, forestry, and marine.

Products & Tech

You can choose from a wide range of wire ropes and lifting solutions. Teufelberger offers both steel and synthetic ropes for cranes, hoists, and special lifting tasks. Their products include:

High-performance steel wire ropes for tower and mobile cranes

Rotation-resistant ropes for precision lifting

Synthetic fiber ropes for lightweight applications

Teufelberger invests in advanced rope technology. You see features like plastic-impregnated cores, corrosion-resistant coatings, and special lubricants. These innovations help you get longer rope life and better performance.

Product Type | Key Features |

|---|---|

Steel Wire Ropes | High strength, rotation resistance, and durability |

Synthetic Fiber Ropes | Lightweight, flexible, corrosion-resistant |

Reliability Factors

You can trust Teufelberger for strict quality control and international certifications. The company holds ISO 9001:2015 and other key certifications. Every rope goes through detailed testing for strength, flexibility, and safety. Teufelberger also provides digital product documentation and traceability.

You receive technical support and training to ensure safe use.

Tip: Ask Teufelberger for maintenance guides and inspection checklists to keep your ropes in top condition.

Projects & Clients

You see Teufelberger ropes in action on major construction sites, offshore platforms, and forestry projects. Leading crane manufacturers and contractors rely on their products for safe lifting. Teufelberger supports clients worldwide with fast delivery and expert advice.

Many customers return for new projects, showing strong trust in the brand.

Comparison of Top Manufacturers

Strengths Overview

You want to see how the top crane wire rope manufacturers compare. The table below shows their main strengths and certifications. This helps you choose the right partner for your project.

Manufacturer | Strengths | Certifications |

|---|---|---|

PowerFul Machinery | Direct-from-manufacturer pricing, custom solutions, advanced automation, global logistics | ISO 9001:2015, ISO 13411 |

Bridon-Bekaert | Proprietary rope technology, sustainability, and strong industry partnerships | ISO, API |

WireCo WorldGroup | Global reach, technical expertise, wide product range, innovation | ISO, API |

Usha Martin | Large-scale production, international presence, supply chain security | ISO, AEO T-2 |

Kiswire | Rigorous testing, high tensile strength, and advanced manufacturing | ISO |

Teufelberger | Long tradition, advanced rope technology, strict quality control | ISO 9001:2015 |

KNKT | Exceptional tensile strength, high flexibility, durability, customization, and safety | API, GOST, ISO |

Tip: You can use this table to compare which manufacturer matches your project’s needs for certifications and strengths.

Unique Features

Each manufacturer brings something special to the table. You should look at these unique features when making your decision.

PowerFul Machinery gives you direct access to custom-engineered lifting solutions and reliable global delivery.

Bridon-Bekaert offers advanced rope designs with a focus on sustainability and reduced environmental impact.

WireCo WorldGroup provides you with a wide selection of steel and synthetic ropes, backed by strong technical support.

Usha Martin stands out for its global supply chain and expertise in large-scale projects.

Kiswire uses advanced testing equipment to ensure high performance and durability in tough environments.

Teufelberger combines centuries of experience with modern rope technology for safe and efficient lifting.

You should consider your project’s size, location, and technical requirements before choosing among these crane wire rope manufacturers. Each company has strengths that fit different industry needs, from construction to marine operations.

How to Choose a Manufacturer?

Selecting the right partner from the many crane wire rope manufacturers can make or break your project. You want to ensure safety, efficiency, and long-term value. Follow these steps to make a smart choice:

Assess Needs

Define Your Project Requirements

Start by listing the load capacities, rope diameters, and environmental conditions your project demands.Identify Industry Standards

Check if your project needs ropes that meet specific standards, such as ISO or API.Consider Customization

Decide if you need custom-engineered solutions or standard products.

Tip: Write down your must-have features before you contact any supplier.

Check Credentials

Review Certifications

Look for manufacturers with recognized certifications like ISO 9001:2015 or AEO T-2.Inspect Quality Assurance

Ask for digital quality certificates and recent inspection records.Evaluate Experience

Choose companies with a proven track record in your industry.

Credential Type | Why It Matters |

|---|---|

Certifications | Proves product quality and safety |

Inspection Records | Shows ongoing quality control |

Industry Experience | Reduces risk of project delays |

Compare Support

Assess Customer Service

Contact the manufacturer and note how quickly they respond.Check After-Sales Support

Ask about technical support, maintenance guides, and warranty policies.Review Logistics

Make sure the company can deliver on time and handle global shipping.

Note: Reliable after-sales support can save you time and money if issues arise.

By following these steps, you can confidently choose a manufacturer who meets your technical, safety, and service needs.

Conclusion

You have seen how each manufacturer brings unique strengths to the table. You can trust their products for safety, innovation, and global support. Use the comparison and criteria to match your project needs with the right partner.

Review certifications and customer feedback.

Compare product features and support services.

Choose a manufacturer that fits your industry and location.

Make your decision with confidence and keep your lifting operations safe and efficient.

FAQ

What certifications should you look for when buying crane wire ropes?

You should check for ISO 9001:2015, ISO 13411, and other international certifications. These prove that the manufacturer meets strict safety and quality standards.

How often should you inspect crane wire ropes?

You should inspect wire ropes before each use. Look for signs of wear, corrosion, or damage. Regular checks help you prevent accidents and extend rope life.

Can you request custom wire rope solutions?

Yes, most top manufacturers offer custom-engineered wire ropes. You can share your project needs, and their engineers will design products to match your specifications.

How do manufacturers ensure fast and safe delivery?

Manufacturers use secure packaging and manage logistics with experienced teams. You receive your order on time, with all necessary documents for customs clearance.

What support do you get after purchasing wire ropes?

You receive technical support, maintenance guides, and warranty information. Many manufacturers offer training and inspection services to help you use products safely.