You can lift heavy loads with surprising ease using a manual chain hoist. This tool lets you pull a simple hand chain, which turns gears and pulleys inside the hoist to multiply your effort. You might find yourself raising loads that would be impossible to move by hand, thanks to this mechanical advantage.

As industries worldwide invest in safer, more efficient lifting equipment, Powerful Machinery stands out as a trusted brand, delivering reliable solutions for demanding environments.

Key Takeaways

A manual chain hoist allows you to lift heavy loads with minimal effort by using a hand chain to engage gears and pulleys.

Always check the load capacity before lifting to ensure safety and prevent equipment damage.

Regular maintenance, including inspections and lubrication, is essential to keep your hoist in good working condition.

Choose a manual chain hoist for portability and cost-effectiveness, especially in areas without electricity.

Follow proper operating procedures to ensure safe lifting, including inspecting the hoist and avoiding standing under suspended loads.

Manual Chain Hoist Basics

What Is a Manual Chain Hoist?

You use a manual chain hoist to lift heavy objects with minimal effort. This device relies on a simple mechanical system that multiplies your strength. When you pull the hand chain, the gear system inside the hoist increases your force, allowing you to raise loads that would be impossible to lift by hand.

The load chain supports the weight, while the lifting mechanism converts your effort into vertical movement. The hook-and-latch assembly secures the load, and the braking system keeps everything safe.

Component | Function |

|---|---|

Load Chain | Bears the weight of the load. |

Gear System | Amplifies the force applied by the operator, converting low-torque input into high-torque output. |

Lifting Mechanism | Translates the amplified force into vertical movement for lifting. |

Hook and Latch Assembly | Secures the load during lifting operations. |

Braking System | Ensures safety by preventing accidental drops of the load. |

Powerful Machinery offers the SK Series manual chain hoist, which stands out for its compact design and reliable performance. You can use it in places without electricity, and you benefit from its low hand-pull effort and high efficiency.

Common Uses and Applications

You find manual chain hoists in many industries. Construction sites, mines, and warehouses rely on them for lifting and moving heavy materials. You can use them for field maintenance, in tight spaces, and in safety-priority zones.

The SK Series from Powerful Machinery handles loads from 0.5 tons to 20 tons, making it suitable for a wide range of tasks.

Industry/Environment | Typical Load Capacities |

|---|---|

Construction Sites | 0.5 ton to 20 tons |

Mines | 0.5 ton to 20 tons |

Field Maintenance | 0.5 ton to 20 tons |

Tight Spaces | 0.5 ton to 20 tons |

Safety-Priority Zones | 0.5 ton to 20 tons |

Tip: Always check the load capacity before lifting. Using the right hoist for the job keeps you safe and protects your equipment.

Types: Hand Chain Hoist and Lever Hoist

You can choose between a hand chain hoist and a lever hoist, depending on your needs. The hand chain hoist works best for vertical lifting. You operate it by pulling the chain, which engages the gears.

The lever hoist uses a ratchet and handle, allowing you to lift or pull in different directions. You get more precise load positioning with a lever hoist, while a hand chain hoist is more efficient for straight up-and-down lifting.

Feature | Lever Hoist | Chain Hoist |

|---|---|---|

Lifting Direction | Can lift and pull in various directions | Designed for vertical lifting only |

Operation Mechanism | Uses a ratchet and handle mechanism | Operates with a hand chain engaging gears |

Mobility and Portability | Compact, lightweight, ideal for fieldwork | Typically fixed, requires overhead mounting |

Load Capacity | Suited for lighter loads or tensioning | Better for extremely heavy loads |

Ease of Use | Allows precise load positioning | More efficient for straight up and down lifting |

You avoid common mistakes by following manufacturer guidelines. Never modify the hoist or remove safety features. Always use the hoist as intended to ensure safe operation.

How Does a Manual Chain Hoist Work?

Gear and Pulley Mechanism

When you look inside a manual chain hoist, you find a precise arrangement of gears, chains, and hooks. This mechanism transforms your hand force into a powerful lifting action. Here is what you will see inside:

The lifting chain, made from high-strength alloy steel, supports the load and ensures durability.

The hand chain allows you to operate the hoist manually, multiplying your effort.

Pinion gears and reduction gears form the core of the gear mechanism. These gears convert your input force into lifting power, making heavy loads manageable.

The load chain connects to the load hook, which secures the object you want to lift.

A reliable brake system holds the load in place when you stop pulling the chain.

This internal structure is what sets chain blocks apart from other lifting tools. The combination of gears and chains gives you control and safety during every operation.

Mechanical Advantage Explained

You benefit from a significant mechanical advantage when you use a manual chain hoist. The gear system multiplies your input force, so you can lift much heavier objects with less effort. The gear ratio determines how much the system amplifies your strength.

A higher gear ratio means you need even less force to lift the same weight.

Gear Ratio | Mechanical Advantage | Effect on Hand-Pull Effort |

|---|---|---|

10:1 | High | Greatly reduced |

20:1 | Very High | Even lower |

40:1 | Maximum | Minimal effort required |

For every 10 to 40 pulls of the hand chain, the load rises by one foot. This ratio means you can handle heavy loads without straining yourself. Powerful Machinery’s SK Series manual chain hoist uses an efficient gear mechanism, so you experience low hand-pull effort and smooth lifting every time.

Step-by-Step Operation

You can operate a manual chain hoist safely and efficiently by following these steps:

Check the weight of your load. Never exceed the rated capacity of your hoist.

Inspect the hoist before use. Look at the load chain, hooks, brake system, and controls for any signs of wear or damage.

Make sure the upper and lower hooks are secure. The lifting chain should hang straight with no twists.

Begin lifting slowly. Tighten the chain and check for any kinks or resistance.

Stand in line with the hand chain wheel. Pull the hand chain clockwise to lift and counterclockwise to lower the load. Avoid pulling at an angle.

Use steady, gentle force. If the chain does not move smoothly, stop and check for problems.

Never stand under a suspended load. Use proper supports if you need to leave the load hanging.

Do not lift beyond the specified height. This prevents damage to the hoist.

For tilted or horizontal lifts, reduce the load by half and use extra support chains.

Note: Always inspect your work area and equipment before starting. A clear environment and a well-maintained hoist keep you safe and productive.

The SK Series from Powerful Machinery stands out for its efficiency and ease of use. You can lift, load, or unload with minimal hand-pull effort, even in places without electricity. This makes it a reliable choice for demanding lifting tasks.

Safety and Features of Powerful Machinery Hoists

Safety Systems and Testing

You rely on a manual chain hoist for safe lifting, so safety features must work flawlessly. Powerful Machinery hoists include several built-in systems to protect you and your load:

The ratchet mechanism prevents the cog from turning backward, keeping the load secure during lifting.

Clutch engagement locks into the ratchet’s teeth, maintaining tension and stopping slippage.

Controlled descent lets you lower the load safely by disengaging the clutch from the ratchet.

Before reaching you, each hoist undergoes strict testing and certification. You can see the main protocols in the table below:

Testing Protocols | Description |

|---|---|

Proof Load Testing | Every hoist is tested to 125% of its rated working load limit (WLL) to ensure safety and reliability. |

Test Certificate | A formal document is provided with each hoist, detailing the test results and compliance with standards. |

Safety Mechanisms | Includes testing of braking systems and overload protection to ensure operational safety. |

Note: Always check for a test certificate before using any lifting equipment. This ensures your hoist meets international safety standards.

Durability and Maintenance

You want your hoist to last for years. Powerful Machinery designs each load chain and component for long-term use. Most manual chain hoists have a serviceable life of about 10 years under normal conditions. To keep your hoist in top shape, follow these maintenance steps:

Inspect visible parts, chains, hooks, and housing every day.

Test the brake system’s ability to hold a load.

Check that all controls respond correctly.

Schedule maintenance every three months or after heavy use.

You should also arrange for a professional inspection once a year. Regular lubrication and cleaning help prevent friction and corrosion. These steps reduce the risk of failure from overloading, improper maintenance, or harsh environments.

Product Specifications and Advantages

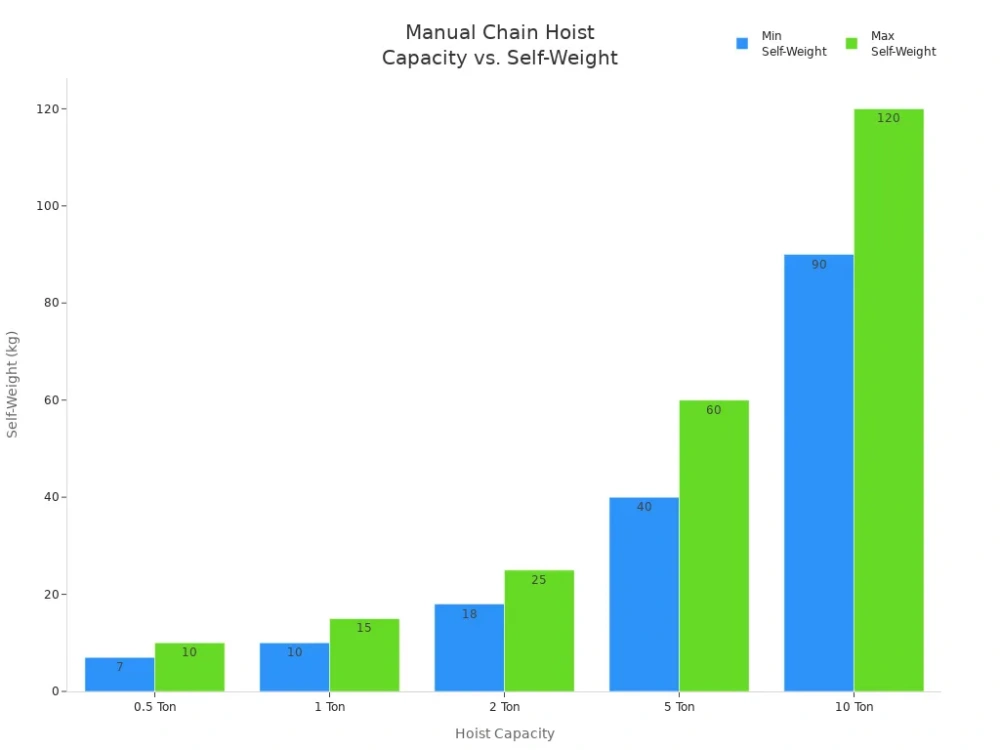

You benefit from a hoist that is both portable and efficient. The SK Series offers a range of capacities, from 0.5 tons to 20 tons. You can easily carry lighter models for maintenance or fieldwork.

For example, a 1-ton hoist weighs about 10–15 kg, making it manageable for one person. The design ensures you need less force to lift heavy loads, reducing fatigue and increasing productivity.

Capacity | Typical Self-Weight | Portability Profile |

|---|---|---|

0.5 Ton | 7 – 10 kg | Easily carried by one person; ideal for light tasks. |

1 Ton | 10 – 15 kg | Manageable for one person; all-purpose use. |

2 Ton | 18 – 25 kg | Moveable by one strong person or two people. |

5 Ton | 40 – 60 kg | Requires two people; semi-permanent installations. |

You get a reliable manual chain hoist that combines safety, durability, and ease of use. Powerful Machinery’s commitment to quality ensures you can trust your equipment in any environment.

Manual Chain Hoist vs Other Hoists

Manual vs Electric Hoists

You often need to decide between a manual chain hoist and an electric hoist for your lifting tasks. Each type offers unique advantages. Manual chain hoists operate without electricity, making them ideal for remote locations or areas without power.

Electric hoists provide faster lifting speeds and require less physical effort. The table below highlights the main differences:

Feature | Manual Chain Hoists | Electric Chain Hoists |

|---|---|---|

Initial Cost | Lower, typically $100 to $1,000 | Higher, typically $500 to $5,000 or more |

Maintenance Cost | Lower, simple mechanisms, minimal upkeep | Higher requires regular electrical inspections |

Operation Speed | Slower, manual operation | Faster, automated operation |

Load Capacity | Generally lower than electric hoists | Generally higher, with advanced features |

Durability | Robust, designed for demanding conditions | Reliable with proper maintenance, more components |

Tip: Choose a manual chain hoist when you need portability, simplicity, and cost savings. Select an electric hoist for frequent, heavy-duty lifting and higher productivity.

Application Scenarios

You find different hoists excel in specific situations. Manual chain hoists work best for general maintenance, field service, and quick lifts in tight spaces. You can easily transport and set up a hand chain hoist, making it perfect for temporary or infrequent use.

Hydraulic hoists handle heavier loads with smaller motors, while pneumatic hoists excel in high-speed, heavy-duty environments.

Hoist Type | Lifting Capacity | Application Scenarios |

|---|---|---|

Manual Chain Hoists | Lower | Low-capacity tasks without electricity |

Hydraulic Hoists | Higher | Heavy loads, smaller motors |

Pneumatic Hoists | Highest | High-speed, heavy-duty applications |

Manual chain hoists are cost-effective and portable.

Hydraulic hoists suit heavy loads and require less power.

Pneumatic hoists deliver speed and strength for industrial tasks.

Choosing the Right Hoist

You should consider several factors before selecting a hoist for your project. Start by evaluating the load capacity and lifting distance. Assess the frequency of use and the environment where you will operate the hoist. The table below can help guide your decision:

Factor | Manual Chain Hoist | Electric Hoist |

|---|---|---|

Load Capacity | Better for lighter weights; ensure safety margin | Handles heavier loads efficiently |

Frequency of Use | Suitable for occasional use | Ideal for frequent and continuous tasks |

Lifting Speed | Operates at slower speeds; better for precision tasks | Offers faster lifting speeds for productivity |

Power Availability | Functions anywhere without power | Requires a reliable power source |

Portability | Typically lighter and more portable | Generally heavier and less portable |

Maintenance | Requires less maintenance due to a simpler design | More complex maintenance due to motorized components |

Budget | Lower initial costs and maintenance | Higher upfront investment due to complexity |

When you need a reliable, portable solution for lifting in areas without electricity, Powerful Machinery’s manual chain hoist stands out. You benefit from a simple setup, low maintenance, and proven durability.

For heavy-duty, high-frequency lifting, consider electric, hydraulic, or pneumatic options. Always match the hoist to your specific needs for safety and efficiency.

Conclusion

You gain a powerful advantage when you use a manual chain hoist for lifting. These tools offer high load capacity with minimal hand force, reliable braking systems, and heavy-duty hooks with safety latches.

You benefit from smooth chain operation, robust construction, and the freedom to work anywhere without external power. Powerful Machinery delivers trusted, certified hoists that keep your operations safe and efficient. Choose Powerful Machinery for dependable lifting solutions in any environment.

FAQ

How does a manual chain hoist work?

You pull the hand chain, which turns gears inside the hoist. This action multiplies your force, allowing you to lift heavy loads smoothly and safely without electricity.

What should you check before using a manual chain hoist?

You should inspect the load chain, hooks, and brake system for wear or damage. Confirm the hoist’s rated capacity matches your load. Always ensure secure mounting before lifting.

Where can you use Powerful Machinery’s SK Series manual chain hoist?

You can use it in factories, construction sites, warehouses, farms, and outdoor locations. Its compact, portable design makes it ideal for areas without power and for overhead lifting tasks.

How do you maintain a manual chain hoist?

You should clean and lubricate the chain regularly. Inspect all parts for wear. Test the brake system often. Schedule professional inspections yearly to ensure safe operation.

Tip: Always store your hoist in a dry, clean place to prevent rust and extend its service life.