You can join steel wire rope with simple tools such as rope clamps and splicing. These wire rope connection methods dominate industrial settings, with hand-tucked splices and mechanical splices used in 80–95% of cases, and wire rope clips in 80%.

The right method ensures safety and strength for your application. Always select tools and techniques that fit your project requirements. Powerful Machinery supplies certified steel wire rope and wire rope clips trusted by professionals worldwide.

Connection Method | Percentage Range |

|---|---|

Hand-Tucked Splices | 80–90% |

Mechanical Splices | 90–95% |

Wire Rope Clips | 80% |

Wedge Sockets | 75–90% |

Key Takeaways

Choose the right connection method based on your project needs. Rope clamps are great for quick, temporary connections, while splicing offers a strong, permanent bond.

Always prepare your steel wire rope properly before joining. Clean cuts and thorough inspections prevent issues and ensure safety.

Use the correct number and size of wire rope clips for secure connections. Follow manufacturer guidelines for spacing and torque to maintain strength.

Regularly inspect your wire rope connections for damage or wear. Early detection of problems can prevent accidents and extend the life of your rope.

Select high-quality materials and tools for your projects. Using certified products from trusted suppliers like Powerful Machinery enhances safety and reliability.

Wire Rope Connection Methods Overview

Rope Clamps vs Splicing

You have two main wire rope connection methods available for joining steel wire rope: rope clamps and splicing. Rope clamps, often called wire rope clips, use mechanical hardware to secure two rope ends together. This method works well for quick installations and temporary connections.

Splicing involves weaving or tucking the strands of wire rope together to form a strong, permanent bond. You can choose between hand-tucked splices and mechanical splices, depending on your skill level and the demands of your project.

Powerful Machinery supplies both high-quality steel wire rope and reliable wire rope clips. You can trust their products for lifting, rigging, and securing loads in construction, marine, and transportation industries.

Their wire rope connection methods meet strict safety standards and provide dependable performance in challenging environments.

Choosing the Right Method

Selecting the best wire rope connection methods depends on your application, required strength, and available tools. You should consider the following factors before making your choice:

Bending the rope beyond its minimum bend radius can damage internal strands and reduce strength. Always follow manufacturer guidelines.

Improper use of wire rope clips, such as installing them backwards, may cause slippage or failure. Use the correct installation method and number of clips.

Mismatched hardware can lead to wear and corrosion. Select fittings designed for your specific wire rope type.

Over-tensioning or under-tensioning weakens the rope or causes sagging. Use calibrated tools to achieve the recommended tension.

Neglecting end termination integrity can result in accidents. Inspect and test all end terminations.

Ignoring environmental factors may cause corrosion. Choose materials suitable for your environment.

Failure to pre-inspect the wire rope increases risk. Always inspect the rope before installation.

Incorrect winding onto drums or reels shortens lifespan. Wind evenly and under tension.

Lack of documentation and maintenance planning makes monitoring difficult. Document installation and set up a maintenance schedule.

You can avoid these common mistakes by following best practices and using certified products from Powerful Machinery. Their expertise in wire rope connection methods helps you achieve safe, strong, and long-lasting connections for any project.

Wire Rope Connection Methods: Rope Clamps

Selecting Powerful Machinery Wire Rope Clips

You need reliable hardware when you join two wire ropes for lifting, rigging, or securing loads. Powerful Machinery wire rope clips offer robust construction and certified performance. You can choose from several types of rope clamps, including malleable and drop-forged options.

Malleable clamps work well for lighter loads, while drop-forged clamps provide extra strength for demanding applications. Powerful Machinery wire rope clips resist corrosion and wear, making them suitable for construction, marine, and transportation industries.

You can select the right size and type for your steel wire rope, ensuring a secure and long-lasting connection.

Tip: Always match the wire rope clip to the diameter and material of your steel wire rope. This ensures maximum grip and safety.

Preparing Steel Wire Rope for Joining

Proper preparation is essential before you use rope clamps. Follow these steps to get your steel wire rope ready:

Select the correct rope clamps based on the diameter and type of your wire rope.

Cut both rope ends cleanly. Remove any frayed wires or debris.

Clean the rope surfaces to eliminate grease, dirt, or corrosion.

Align the two rope ends side by side. Make sure they butt together without overlapping.

Insert the rope ends into the clamp saddle. Position them so the clamp will grip both ropes evenly.

You can use these steps whether you plan a side splice, short splice, or long splice. Proper preparation helps you create a new rope connection that meets safety standards.

How to Join Two Wire Ropes with Rope Clamps?

You can join two wire ropes securely by following a systematic process. Rope clamps provide a mechanical bond that holds the ropes together under load. Here is a step-by-step guide:

Place the first rope clamp about one saddle width from the end of the ropes.

Position the U-bolt over the dead end and the saddle on the live end.

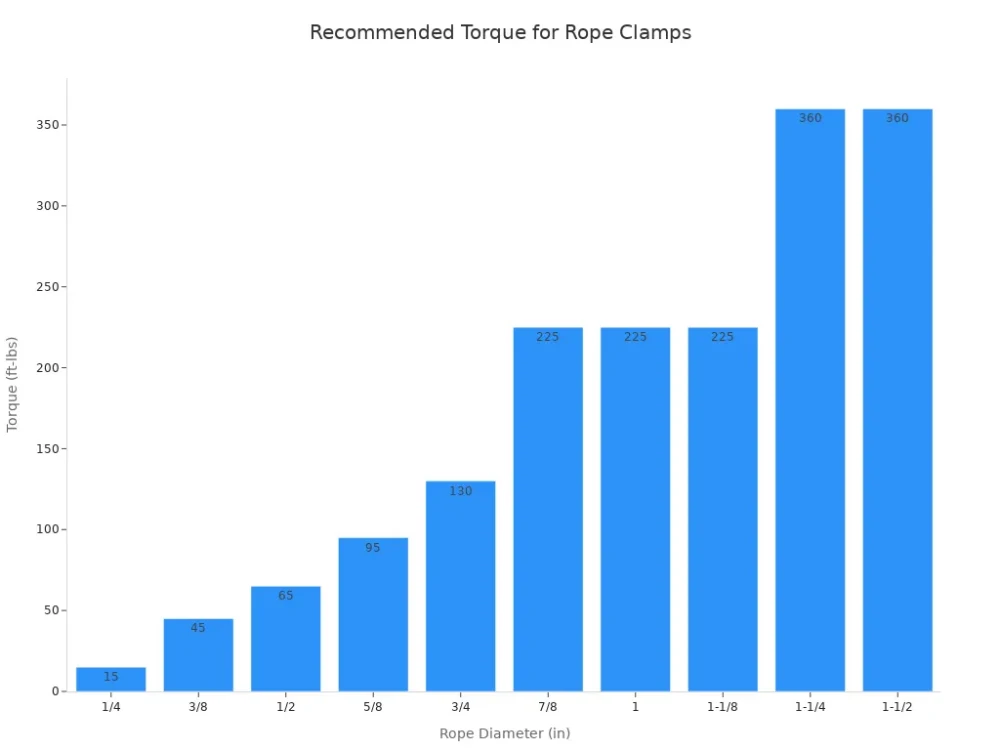

Tighten the nuts evenly using a wrench. Apply the recommended torque for your rope diameter.

Add additional clamps as required. Space them according to manufacturer guidelines.

Tighten each clamp to the specified torque. Use a calibrated torque wrench for accuracy.

Inspect the connection after tightening. Make sure the ropes are flush and the clamps are secure.

Rope Diameter (in) | Number of Clips | Clip Spacing (in) | Torque (ft-lbs) |

|---|---|---|---|

1/4 | 2 | 1-1/2 | 15 |

3/8 | 2 | 2-1/4 | 45 |

1/2 | 3 | 3 | 65 |

5/8 | 3 | 3-3/4 | 95 |

3/4 | 4 | 4-1/2 | 130 |

7/8 | 4 | 5-1/4 | 225 |

1 | 5 | 6 | 225 |

1-1/8 | 6 | 6-3/4 | 225 |

1-1/4 | 7 | 7-1/2 | 360 |

1-1/2 | 8 | 9 | 360 |

You can rely on Powerful Machinery rope clamps for consistent performance. Their clips meet international safety standards and work in harsh environments.

Inspecting the Connection

You must inspect the connection after installation to ensure safety and reliability. Use these inspection criteria:

Check for visible damage, corrosion, broken wires, or deformation.

Look for wire breakage. If you find 6 breaks in one lay or 3 in one strand, replace the rope.

Measure the rope diameter. A reduction of 5% or more signals internal wear or core collapse.

Watch for distortion, such as kinking, birdcaging, or crushing.

Perform regular inspections to catch severe corrosion or improper end connections.

Note: Always inspect the connection before each use. Early detection of problems prevents accidents and extends the life of your wire rope assembly.

Powerful Machinery wire rope clips help you maintain strong and safe connections. Their durability and precision engineering support critical operations in every industry.

Wire Rope Splicing Techniques

Types of Wire Rope Splicing

You can choose from several types of wire rope splicing when you need to join steel wire rope for industrial or marine applications. Each method offers unique benefits for strength and durability. The most common types of wire rope splicing include:

Hand-tucked splice: You pass the wire rope around a thimble or form an eye, then tuck the strands to secure the splice.

Back or end splicing: You splice the rope end strands directly without making a loop. This method prevents fraying and keeps the rope intact.

Eye splicing: You form a loop at the end of the rope by interweaving the unraveled strands back into the main length.

Side splice: You intertwine one rope’s end to the midsection of another rope.

Horseshoe splice: You splice two sides of a loop that are not equal in length.

Short splice and long splice: You join two rope ends together for a strong connection.

These types of wire rope splicing maintain almost 95% of the rope’s original strength. You can rely on splicing techniques for both temporary and permanent connections in demanding environments.

Note: Powerful Machinery steel wire rope is engineered for high tensile strength and non-rotating stability, making it ideal for all splicing applications.

Tools for Splicing Steel Wire Rope

You need the right wire rope tools to perform a safe and effective splice. The tools you select depend on the type of splicing you plan to use. Here are the essential wire rope tools for splicing:

Wooden mallet: You use this to shape and flatten strands.

Pliers: You grip and manipulate wire strands during splicing.

Wire cutters: You trim excess wire and prepare clean ends.

Metal spike or screwdriver: You separate strands and open the rope for tucking.

Press: You use this for larger wires to secure mechanical splices.

Cable clips or wire rope clips: You reinforce the splice and add extra security.

You should always match your wire rope tools to the diameter and construction of your steel wire rope. Powerful Machinery offers steel wire rope in multiple configurations, ensuring compatibility with all splicing methods.

Step-by-Step Wire Rope Splicing

You can perform wire rope splicing with simple tools and careful technique. Follow these steps for a practical and reliable splice:

Cut the wire rope ends cleanly. Remove any frayed wires.

Unravel the strands at each end for the length required by your chosen splicing method.

Align the rope ends or form a loop, depending on whether you are making a short splice, long splice, back or end splicing, or eye splicing.

Interweave the unraveled strands back into the main rope or into the other rope’s midsection.

Use pliers and a wooden mallet to tuck and flatten the strands securely.

Trim excess wire with wire cutters for a neat finish.

For added security, install cable clips or wire rope clips at the splice points.

Tighten all hardware to the recommended torque.

You should always use Powerful Machinery steel wire rope for splicing. Its non-rotating design and high-grade steel construction help you achieve a splice that retains approximately 90% of the rope’s original strength.

Tip: Practice your splicing techniques on scrap wire rope before working on critical applications. This helps you master the process and avoid mistakes.

Checking Splice Strength and Safety

You must inspect every wire rope splicing connection to ensure safety and reliability. Follow these safety checks after completing a splice:

Make sure all parts of the splice are visible and accessible.

Clean the splice area so you can see wires and fittings clearly.

Examine the entire splice, focusing on areas prone to wear.

Pay special attention to fittings and end attachments.

Check the weakest section against established criteria for wire rope splicing.

Label inspected splices and maintain inspection records.

Dispose of any spliced rope that does not meet safety standards.

You should also look for these signs of damage:

Broken wires in the splice.

Wear of one-third of the original diameter of the outside wires.

Kinking, crushing, or other physical damage.

Heat damage is indicated by discoloration.

Excessive stretch or reduction in diameter.

Safety Alert: A properly executed wire rope splicing retains about 90% of the original strength. If you notice any defects, replace the rope immediately to prevent accidents.

Powerful Machinery steel wire rope provides superior durability and performance for all splicing applications. You can trust its certified quality for lifting, rigging, and marine operations.

Best Practices for Joining Steel Wire Rope

Application, Safety, and Inspection

You must follow best practices to maximize the strength and longevity of your steel wire rope connections. Start by selecting the right wire rope for your application. Consider the grade, construction, and finish. Always inspect the rope before use. Look for kinks, broken wires, or signs of corrosion.

Use the correct tools for measuring and cutting. Clean cuts and sealed ends prevent fraying and make it easier to connect two steel cables.

When you prepare to join or repair a damaged wire rope, use compatible end fittings and install them with the recommended tools. Avoid sharp bends and kinks by maintaining the minimum bending radius. Proper tensioning is essential. Use calibrated tools to achieve the correct tension and avoid sagging or damage.

Secure anchor points with compatible materials. In high-friction or marine environments, apply lubricants to protect the rope.

Tip: Follow international standards and manufacturer guidelines for every application. Regular inspections and maintenance checks help you catch problems early.

You should inspect your connections frequently. Start with an initial inspection after installation. Perform daily visual checks for gross damage. Schedule periodic inspections based on rope life, environment, and how often you use the rope.

Look for distortion, broken wires, or corrosion. Address any issues immediately to maintain safety.

Task | Purpose | Frequency |

|---|---|---|

Cleaning | Removes abrasive debris | As needed |

Lubrication | Reduces friction and corrosion | During checks |

Storage check | Prevents moisture damage | Monthly |

When to Use Rope Clamps or Splicing?

Choosing between rope clamps and splicing depends on your application, required strength, and available tools. Rope clamps work well when you need to connect two steel cables quickly or for temporary setups. Use them with the correct number and size of clamps, and always follow torque recommendations with the right tools.

Splicing is ideal for permanent connections or when you need to maximize the efficiency of the joint. Each splice type offers different strength levels, so consider the rated capacity for your application. Splicing requires more skill and specialized tools, but it provides a strong, reliable connection.

Note: Never compromise on safety. Trained personnel should always handle installation and inspection. Use only certified tools and components for every job.

Regular maintenance, proper selection of tools, and adherence to safety standards ensure your steel wire rope connections perform reliably in any application.

Conclusion

You can join steel wire rope securely using either rope clamps or splicing, both effective with simple tools. Choose the method that matches your application, required strength, and available tools. Preparation is key for a safe, durable connection:

Match clip size to rope and ensure proper spacing.

Inspect for damage or wear before installation.

Gather all necessary tools and tighten clips to the specified torque.

Professionals in industries like automotive recovery and adventure parks trust Powerful Machinery steel wire rope and clips for reliable performance in demanding environments.

FAQ

How do you choose between rope clamps and splicing?

You should consider your application, required strength, and available tools. Rope clamps work best for quick or temporary connections. Splicing provides a stronger, more permanent bond. Always follow safety guidelines for your chosen method.

How many wire rope clips do you need for a secure connection?

You must match the number of clips to the rope diameter. Refer to manufacturer recommendations. For example, a 1/2-inch rope usually requires three clips. Proper spacing and torque are essential for safety.

Can you reuse wire rope clips after removal?

You should not reuse wire rope clips for critical applications. Deformation or wear can reduce holding strength. Always inspect clips before reuse and replace any that show damage.

What makes the Powerful Machinery steel wire rope ideal for joining?

Powerful Machinery steel wire rope features high tensile strength and a non-rotating design. You get reliable performance, long service life, and compatibility with all major joining methods. The rope resists corrosion and abrasion in tough environments.