To lift an engine with a chain, you must select certified engine lift chains and use proper lifting equipment. Always check the weight of your engine and match it with the right chain type. In automotive workshops, you will find several common chain options, such as single-leg, adjustable, two-leg, and chains with latching hooks.

Each style offers unique features for different lifting needs. Prepare your workspace, attach the chain securely, and operate the engine hoist with care for safe results.

Type of Engine Lift Chain | Best For | Key Features |

|---|---|---|

Single-Leg Engine Lift Chain | Small engines, compact machinery | One chain leg with hooks, simple and economical |

Adjustable Engine Chain Sling | Uneven or offset engines | Allows length adjustment, improves balance |

Two-Leg Engine Chain Sling | Automotive and diesel engines | Two lifting points, better load distribution |

Engine Lift Chain with Latching Hooks | Enhanced safety requirements | Hooks with safety latches, prevent disengagement |

Key Takeaways

Always use certified engine lift chains to ensure safety and reliability during engine lifting.

Know the weight of your engine and choose a chain with a Working Load Limit that exceeds this weight for added safety.

Prepare your workspace by inspecting all equipment and clearing obstacles to prevent accidents during the lift.

Securely attach the engine lift chains to designated lifting points on the engine to maintain balance and prevent slippage.

Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect yourself while lifting.

Tools for Engine Lifting

Engine Lift Chains Overview

When you prepare to lift an engine, you need to choose the right engine lift chains. These chains are designed specifically for engine removal and installation. You will find that engine lift chains feature integrated hooks and manageable lengths, making them ideal for precise lifting tasks.

Unlike general crane chains, engine lift chains offer secure attachment points and reduce the risk of slippage.

Feature | Engine Lift Chain | Engine Crane Chain |

|---|---|---|

Purpose | Specifically for lifting engines | General lifting as part of the crane system |

Length | Short and manageable | Typically longer |

Hooks | Integrated hooks included | May need separate hooks |

Powerful Machinery supplies certified engine lift chains that meet international safety standards. You can rely on their products for consistent performance in demanding environments.

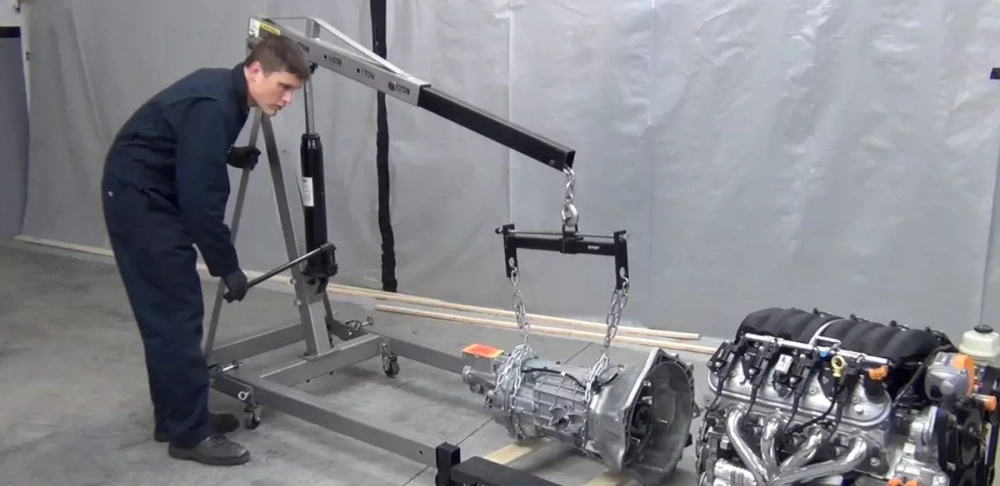

Engine Hoist and Attachments

You need an engine hoist to safely raise and lower the engine. Hydraulic hoists are the most common choice in professional garages. They offer quick lifting, high capacity, and minimal maintenance. Chain hoists provide a simple and inexpensive option, though they operate more slowly.

Electric hoists deliver fast and effortless lifting, ideal for frequent use.

Type of Hoist | Features and Considerations |

|---|---|

Hydraulic Hoists | Quick lifting, high capacity, easy operation, minimal maintenance |

Simple, inexpensive, slower operation, limited to loads under 6 tons | |

Electric Hoists | Fastest, easiest to use, requires a power source, ideal for frequent lifting |

You should use appropriate rigging, such as slings, shackles, or load balancers, to connect the engine lift chains to the hoist. Powerful Machinery offers a full range of certified lifting hardware for these tasks.

Safety Gear Essentials

Safety must be your top priority. You should wear gloves, safety glasses, and steel-toed boots when working with engine lift chains and heavy equipment. Always check that your lifting gear has a working load limit suitable for your engine. Use a mechanic’s tool set and an engine stand to support the engine after lifting.

Powerful Machinery’s certified products help you maintain a safe and efficient workspace.

Tip: Inspect all engine lift chains and attachments before each use. Replace any worn or damaged components immediately.

Understanding Engine Lift Chains

What Are Engine Lift Chains?

Engine lift chains are specialized lifting tools designed for removing and installing engines safely. You use these chains to connect the engine to a hoist or crane. Each chain features high-strength steel links and secure hooks that attach to engine lifting points.

Powerful Machinery manufactures engine lift chains that meet strict international standards, including ISO9001, TUV Rheinland, and OSHA. You can trust these chains to handle heavy loads without stretching or breaking. When you choose a certified engine lift chain, you protect yourself and your equipment.

Note: Always check for certification markings on your engine lift chain before use. Certified chains from Powerful Machinery display clear labels for easy identification.

Types of Engine Lift Chains

You will find several types of engine lift chains for different lifting needs:

Single-leg chains: Best for small engines or compact machinery.

Two-leg chains: Offer better load distribution for larger engines.

Adjustable chain slings allow you to change the length for uneven or offset engines.

Chains with latching hooks: Provide extra safety by preventing accidental disengagement.

Powerful Machinery offers all these types, each tested for strength and durability. You can select the right chain for your project, knowing it meets or exceeds international safety standards.

Engine Lift Chains vs General Chains

Engine lift chains differ from general-purpose chains in several important ways. You get enhanced safety, flexibility, and efficiency when you use a chain designed for engine lifting. The table below highlights the main advantages:

Advantage | Description |

|---|---|

Safety | Engine lift chains provide a secure area for technicians, reducing injury risks. |

Flexibility | You can customize them for different vehicle sizes and weights. |

Affordability | Engine lift chains are inexpensive and easy to purchase. |

Efficiency | They allow better access to hard-to-reach engine parts, improving workflow. |

When you choose Powerful Machinery’s certified engine lift chains, you ensure reliable performance and compliance with global safety standards.

Choosing the Right Chain

Determining Engine Weight

You must know the exact weight of your engine before you select an engine lift chain. Check your vehicle’s manual or look for the engine’s specifications online. If you plan to lift the engine with accessories attached, add their weight to your total. Always use the heaviest possible load as your reference.

This approach keeps your lifting operation safe and prevents overloading.

Identify the engine’s weight from reliable sources.

Add the weight of any attached components.

Use the highest total weight as your guide.

Load Capacity and Chain Grade

You should match the chain’s Working Load Limit (WLL) to your engine’s weight. Choose a chain with a WLL that meets or exceeds the load. For extra safety, select a chain with a comfortable margin above your engine’s weight.

Chain grade matters as well. Grade 80 and Grade 100 chains offer high strength and durability. Powerful Machinery provides both grades, ensuring you find the right fit for your project.

Chain Grade | Typical Use | Strength Level |

|---|---|---|

Grade 80 | Standard lifting | High |

Grade 100 | Heavy-duty lifting | Extra High |

Hook Types and Adjustability

You will find different hook types for engine lifting. Latching hooks prevent accidental slips. Clevis hooks offer quick attachment. Adjustable chain slings help you balance uneven loads.

Choose hooks and adjustability features that match your engine’s lifting points. Powerful Machinery offers a variety of hooks and adjustable options for every application.

Certification and Markings

Always check for certification markings on your engine lift chain. Look for labels or stamps that show compliance with international standards like ISO9001, TUV Rheinland, or OSHA. These markings guarantee the chain’s quality and safety.

Powerful Machinery’s chains display clear certification marks, so you can trust their reliability in demanding environments.

Tip: Never use a chain without visible certification markings. Certified chains protect you and your equipment.

How to Use an Engine Hoist?

Workspace Preparation

You must prepare your workspace before you lift the engine. This step ensures safety and efficiency during engine extraction. Follow these steps to set up the hoist and your work area:

Inspect the engine hoist for visible defects. Check for cracks, leaks, or damage. Examine the hydraulic system and confirm the fluid level is correct. Make sure wheels and casters move smoothly.

Check all lifting gear. Inspect chains and hooks for wear. Confirm that hooks have safety latches. Examine slings and straps for cuts or fraying.

Assess the load. Verify the engine’s weight does not exceed the hoist’s capacity. Identify secure lifting points on the engine to prevent slippage.

Prepare the work area. Clear all obstacles from the floor. Place the hoist on stable ground. Establish a safety zone around the lifting area.

Plan the lift path. Consider any obstacles and plan how you will move the engine. Communicate with your team and establish clear signals.

Equip yourself and others with personal protective equipment. Wear gloves, safety glasses, and steel-toed boots.

Tip: A well-prepared workspace reduces the risk of accidents and makes it easier to clear the engine of the car safely.

Attaching Engine Lift Chains

Proper attachment of engine lift chains is critical for safe lifting. Here’s how you should proceed:

Use angle iron pieces bolted to the engine block with head bolts for secure lifting.

Thread bolts through the lifting chain into the head bolt holes. You can also use the front block bolt holes if needed.

For extra stability, create an angle iron adapter that uses both front and rear head bolt studs.

Tighten all head bolts to avoid twisting or bending components during the lift.

Always use certified engine lift chains from Powerful Machinery. These chains provide the strength and reliability you need for lifting an engine.

Securing Hooks and Latches

You must secure all hooks and latches before you lift the engine. Choose hooks with safety latches, such as those found in Crosby S-314A, S-315A, or S-4088 latch kits. These hooks prevent accidental disengagement during lifting. Check that each latch closes completely and that the chain sits properly in the hook’s bowl.

If you use adjustable slings, confirm that all adjustment mechanisms are locked.

Hook Type | Safety Feature | Recommended Use |

|---|---|---|

Grade 80 Chain Hooks (3/8″, 5/8″) | Safety latch kits | General engine lifting |

Grade 8 Sling Hooks (1/2″, 3/4″) | S-4088 latch kits | Heavy-duty or industrial lifts |

Note: Only use hooks and latches that meet international safety standards. Powerful Machinery supplies certified hooks for all engine lifting applications.

Lifting and Moving the Engine

You are now ready to lift the engine. Follow these steps for a safe and controlled operation:

Double-check all connections. Inspect the chains, hooks, and attachment points.

Begin lifting slowly. Most engine hoists operate between 8 and 32 feet per minute. Use a slower speed for precise positioning.

Keep the engine level as you lift. Adjust the chain or sling if the engine tilts.

Pause after the engine clears its mounts. Check for any remaining connections or obstructions.

Move the engine along the planned path. Keep the load low to the ground for stability. Guide the hoist carefully to avoid sudden movements.

Callout: Never rush the process. Controlled lifting prevents damage and keeps everyone safe.

Lowering and Detaching

Lowering the engine requires as much care as lifting. Here’s how to finish the job safely:

Ensure the engine is secure before lowering it.

Disconnect any remaining hoses, wires, or mounts.

Use supports like 2x4s or pallets to protect the engine when resting it.

Lower the engine slowly and steadily. Avoid sudden drops.

Handle the engine gently to protect delicate components.

Store the engine in a clean, dry area. Shield it from dirt and moisture.

Label and organize all removed components for easy reinstallation.

Tip: Always use certified equipment from Powerful Machinery for every step. This ensures safety and reliability during engine extraction.

By following these steps, you will know how to use an engine hoist and lift the engine safely and efficiently. Certified chains and hardware from Powerful Machinery give you peace of mind for every engine lifting project.

Engine Lifting Safety Tips

Certified Chains and Hooks

You must use certified chains and hooks for every engine lifting operation. Certified lifting hardware reduces the risk of accidents and ensures consistent performance. Chains and hooks from Powerful Machinery meet international standards, including ISO9001 and OSHA.

These products feature high working load limits, excellent resistance to abrasion and weather, and heat-treated alloy construction for service longevity.

Feature | Description |

|---|---|

High Working Load Limits | Safely lifts heavy loads without risk of failure. |

Excellent Resistance | Durable against cutting, abrasion, and extreme weather. |

Flexible Use | Compatible with various hook styles and attachments. |

Service Longevity | Heat-treated alloy construction enhances safety and durability. |

Tip: Always inspect chains and hooks for visible certification markings before each use.

Avoiding Overload

You must prevent overload to maintain a safe lifting environment. Regularly test overload protection systems and verify limit switches to avoid catastrophic over-travel. Train your team on the location and use of emergency stop buttons.

Implement a strict inspection schedule for brakes, chains, and wire ropes. Select equipment with redundant safety features and consult experts to match hoist capabilities with job site hazards.

Test overload protection regularly.

Verify limit switches weekly.

Train personnel on emergency stop procedures.

Inspect lifting equipment on a strict schedule.

Choose hoists with multiple safety features.

Proper Chain Placement

Correct chain placement ensures balanced lifting and prevents engine damage. Attach a chain bracket under two head bolts at the center of the engine for easy balancing.

Use a short length of chain on valve cover studs with flat washers and hex nuts. Position the hook fore or aft to find the best balance point. Avoid sharp chain angles, which can cause severe bending loads and risk dropping the engine.

Note: Balanced lifting allows you to tilt the engine slightly for precise alignment during installation.

PPE and Common Mistakes

Personal protective equipment (PPE) is mandatory for engine lifting. You must wear a hard hat, safety footwear, eye and face protection, high-visibility clothing, and hand protection. These items shield you from falling objects, debris, and equipment accidents.

PPE Type | Function | When Required |

|---|---|---|

Hard Hat | Protects from overhead impact | Near cranes or lifting operations |

Safety Footwear | Shields toes from accidents | On active industrial sites |

Eye/Face Protection | Guards against debris and fluids | Risk of debris or pressurized fluids |

High-Visibility Clothing | Improves visibility | Around the moving equipment |

Hand Protection | Prevents cuts and impacts | When rigging or handling materials |

Common mistakes include misjudging load characteristics, ignoring hoist duty cycles, selecting the wrong lifting mechanism, and overlooking rigging importance. You must invest in quality equipment, proper training, and regular maintenance to prevent these errors.

Powerful Machinery’s commitment to safety and international standards helps you avoid these risks and ensures reliable engine lifting every time.

Applications and Professional Use

Automotive and Diesel Engines

You often need to lift engines in a car repair shop or during restoration projects. Engine lift chains from Powerful Machinery help you remove or install engines in a car with precision. You can use these chains for routine maintenance, engine swaps, or rebuilding a car’s powertrain.

Diesel engines in trucks and heavy-duty vehicles also require strong lifting solutions. When you work on a car, you must trust your equipment to handle the engine’s weight and keep the workspace safe.

Powerful Machinery’s certified chains give you confidence whether you are lifting a small car engine or a large diesel block.

Marine and Industrial Engines

You face unique challenges when lifting engines in marine and industrial settings. Boat engines and industrial machinery often weigh more than a typical car engine. You need chains that resist rust and corrosion because marine environments expose equipment to moisture.

Powerful Machinery designs chains for these tough jobs. You can lift engines from a car-sized boat or move heavy machinery in a factory. The rust-resistant surfaces and high-strength steel ensure that you can rely on these chains for every lift, even in harsh conditions.

Why Choose Powerful Machinery?

Professionals choose Powerful Machinery for engine lifting because of the advanced features and proven reliability. You get chains made from G80 manganese steel, rated for 6,600 pounds, and welded with automatic technology for uniform strength.

The butterfly-style buckle makes setup quick and easy. Spring-loaded latches on hooks reduce accidents and keep your car engine secure during lifting. You can see the main features in the table below:

Feature | Description |

|---|---|

Material | G80 manganese steel for high strength and durability |

Weight Capacity | Rated for 6,600 pounds, safe for heavy car engines |

Welding Technology | Automatic welding for uniform strength |

Rust Resistance | Rust-resistant surfaces for easy maintenance |

Setup Mechanism | Butterfly-style buckle for quick setup |

You gain confidence in load stability when moving a car engine.

You reduce accidents with spring-loaded latches.

You simplify the setup process, which boosts productivity in your car workshop.

Tip: Powerful Machinery’s certified chains and hardware help you complete every car engine lift safely and efficiently.

Conclusion

You ensure safe engine lifting by following best practices and using certified equipment. Always check load capacity, secure and balance the load, and operate the hoist smoothly. Certified engine lift chains offer key benefits:

Benefit | Description |

|---|---|

Overload Protection | Prevents excessive loads for safer lifting. |

Quality Hooks/Latches | Drop-forged for superior strength and reliability. |

Safety Standards | Meets strict international requirements for peace of mind. |

Choose trusted brands with strong reputations, clear certifications, and proven customer satisfaction—like Powerful Machinery—for every engine lifting project.

FAQ

What is the safest way to use an engine hoist?

You should always inspect your engine hoist before use. Check all chains, hooks, and lifting points. Make sure the hoist stands on a flat surface. Never exceed the rated capacity. Use certified equipment for every lift. Stay clear of the load while operating the hoist.

Can I lift any engine with a standard hoist?

You must check the weight of your engine before using an engine hoist. Not all hoists can handle every engine. Always match the hoist’s rated capacity to your engine’s weight. Use certified lifting chains for extra safety. Consult your hoist manual for specific limits.

How do I balance an engine when using an engine hoist?

You should attach the lifting chains to secure points on the engine. Adjust the chain length or use a load leveler if needed. Keep the engine level as you lift. A balanced load prevents swinging and makes it easier to move the engine with the hoist.

What maintenance does an engine hoist require?

You need to inspect your hoist regularly. Check for worn chains, damaged hooks, and leaking hydraulics. Lubricate moving parts as recommended. Store the hoist in a dry place. Replace any damaged components immediately. Proper maintenance keeps your hoist safe and reliable.

Why should I choose a certified engine hoist and lifting chain?

Certified engine hoists and chains meet strict safety standards. You reduce the risk of accidents and equipment failure. Certified products from trusted brands like Powerful Machinery give you peace of mind. Always look for certification markings on your hoist and lifting chains.