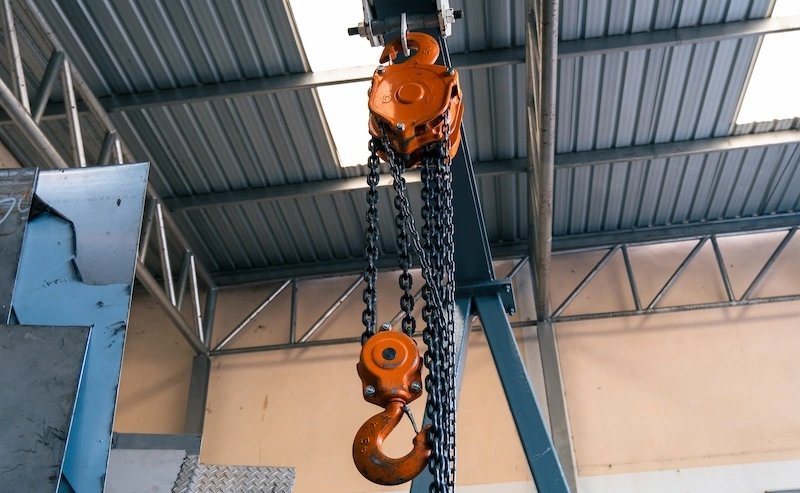

If you want to know how to use a chain block safely and effectively, start by following every step with care. Powerful Machinery’s Chain Block offers reliability and ease of use, making your lifting tasks straightforward. Always follow manufacturer guidelines and safety standards.

Prevent equipment failure by following instructions.

Enhance operational efficiency during lifting.

Minimize risks when handling heavy loads.

Conduct regular inspections and maintenance.

Ensure proper installation and operator training.

Following these practices helps you create a safer and more efficient work environment.

Key Takeaways

Always inspect the chain block before use. Check for damage, wear, and proper lubrication to ensure safe operation.

Secure the chain block to a strong anchor point. This prevents accidents and ensures stability during lifting.

Use proper lifting techniques. Lift vertically and avoid exceeding the rated capacity to prevent equipment failure.

Conduct regular maintenance and inspections. This helps identify issues early and extends the lifespan of your chain block.

Follow safety guidelines and receive proper training. This enhances safety and efficiency when operating the chain block.

Inspect Before Use

Check Chain Block Condition

Before you operate the Powerful Machinery Chain Block, always perform a thorough inspection. This step protects you, your team, and your equipment. Start with a visual sweep.

Walk around the chain block and check for any obvious damage, missing labels, or fluid leaks. Examine every angle to confirm the structural integrity.

Follow these steps for a complete inspection:

Visual Sweep: Walk around the chain block and check for cracks, dents, or missing parts. Confirm that all labels are readable.

Load Chain: Inspect the chain for proper lubrication, signs of wear, stretching, twists, kinks, or corrosion.

Hook and Latch: Check the hook for deformation or cracks. Test the safety latch to ensure it locks securely.

Control System: Test the control pendant and buttons for smooth operation.

Limit Switches: Activate the upper and lower limit switches to confirm they work correctly.

You should also look for common defects. The table below summarizes what to check:

Defect Type | Inspection Criteria |

|---|---|

Load Chain | Look for elongation, reduced diameter, stiff links, and surface damage. |

Pocket Wheel/Sprocket | Inspect for worn teeth, cracks, or deformation. |

Hooks and Swivel Assemblies | Measure throat opening and check for cracks or wear. |

Gearing, Bearings, Frame | Listen for unusual noise and check for cracks or loose fasteners. |

Brake System | Test the function and check the disc thickness. |

Overload Protection | Confirm the friction clutch works and check for tampering. |

Trolleys and Suspension | Inspect wheel tread and side plates for wear or elongation. |

Tip: Regular inspections help you comply with safety standards and prevent costly downtime.

Assess Work Area Safety

Inspect the work area before you begin lifting. Remove any obstacles or debris that could interfere with the operation. Check for environmental hazards such as dust, moisture, chemicals, or extreme temperatures. These factors can affect the performance and safety of your chain block.

Dust and grit can cause premature wear.

Water or moisture may lead to corrosion.

Chemicals or salt can damage metal components.

High heat or cold can affect material strength.

Heavy shock loads or constant vibration may reduce equipment life.

Make sure the floor is stable and level. Confirm that lighting is adequate so you can see all parts of the chain block and load. Always keep unauthorized personnel clear of the lifting area. By taking these precautions, you create a safer environment for every lift.

How to Use a Chain Block: Setup Steps

Secure to Anchor Point

You must start every lift by securing your chain block to a strong anchor point. This step forms the foundation for safe operation and prevents accidents. When you learn how to use a chain block, you need to select an anchor that can handle the intended load and meets industry standards.

Recommended anchor points include:

Fixed overhead beam clamps

Gantry or jib cranes

Properly rated ceiling mounting points

Structural I-beams with appropriate beam clamps

Tripod stands are designed for hoisting

Before you attach the hoist to the load, inspect the anchor for wear, corrosion, or defects. Confirm that the anchor is stable and will not shift during lifting. Use certified shackles or hardware from Powerful Machinery for best results. Always choose the correct size and type of shackle or hook for your load.

Tip: Routine inspections of anchorage points help prevent accidents and ensure reliable performance.

Follow these steps to secure your chain block:

Attach your block and tackle system to a fixed anchor point.

Select an immovable structure that can handle the intended load.

Use certified shackles or hardware from Powerful Machinery.

Ensure the anchor point meets industry standards.

Inspect the anchor for wear, corrosion, or defects before use.

Confirm that the anchor is stable and will not shift during lifting.

Use the correct size and type of shackle or hook for your load.

Conduct routine inspections of your anchorage points.

Twisted or knotted chains during operation often lead to damage and failure of the chain link. Insufficient headroom can cause excessive force on the chain, contributing to its failure. When you understand how to use a chain block, you avoid these common errors and maintain a safe work environment.

Attach Load Properly

Once you secure the chain block, you must attach the hoist to the load with care. This step ensures balance and prevents accidents. Knowing how to use a chain block means you always select stable lifting points and balance the load before starting.

Best practices when you attach the hoist to the load:

Select stable lifting points and balance the load before starting.

Never exceed the rated capacity of the chain block to prevent overloading.

Lift vertically to avoid dangerous side loads.

Use tag lines to guide and control the load if necessary.

Before you attach the hoist to the load, inspect all lifting points. Rig the load correctly and distribute the weight evenly. Use only engineer-certified spreader bars for telehandlers and forklifts. Always inspect the forklift attachment to ensure it is in good condition.

Maintenance Task | Importance |

|---|---|

Lubricating the load chain | Reduces friction and wear. |

Checking gearbox oil levels | Ensures gears are properly lubricated and cooled. |

Inspecting and cleaning the brake | Removes dust and ensures positive engagement. |

Testing safety functions | Verifies the operation of overload clutches and limit switches. |

You must attach the hoist to the load with the safety latch engaged. Confirm that the chain hangs straight and is not twisted or knotted. When you learn how to use a chain block, you prevent accidents by following these steps and maintaining proper balance.

Note: Always lift vertically. Side loads can cause dangerous stress and lead to equipment failure.

If you attach the hoist to the load incorrectly, you risk damaging the chain block and endangering personnel. Proper setup is essential for safe and effective lifting. Understanding how to use a chain block helps you achieve reliable results every time.

Operate the Chain Hoist Safely

Lift and Lower Loads

You must use a chain hoist with precision to achieve a secure lifting operation. Begin by evaluating the load and confirming that the rigging is correct. Attach the lifting hook to the load, making sure the safety latch is engaged. Stand in a stable position and wear proper personal protective equipment.

Follow these steps to use a chain hoist:

Secure the load to the chain by attaching the lifting hook properly.

Pull the hand chain in the designated direction to lift the load. Maintain steady pressure and avoid jerking movements.

Monitor the load as it rises. Keep the area beneath the load clear to prevent injury.

To lower the load, release the chain slowly and maintain control. Never let the load drop suddenly.

Test the brakes before and during the operation to ensure they hold the load securely.

Tip: Always lift the load vertically. Side pulls can cause the chain hoist to fail or the load to swing dangerously.

You must never exceed the rated capacity of the chain hoist. Overloading increases the risk of equipment failure and accidents. Use a chain hoist only after proper training and regular inspection.

Monitor Operation

During operation, you must stay alert and watch for signs of unsafe conditions. Listen for unusual noises such as grinding or squealing, which may indicate worn components or inadequate lubrication. Observe the load for drifting or slipping, as this can signal brake failure.

Check for overheating in the chain hoist motor or parts.

Inspect for control or circuit failures that disrupt operation.

Monitor load stability to prevent tipping or swinging.

Maintain clear communication with your team throughout the operation. Balance the load to avoid tipping and ensure even distribution. If you notice any abnormal behavior, stop the operation immediately and inspect the equipment.

Note: Routine training and hands-on practice help you use a chain hoist safely and confidently. Always follow safety regulations and manufacturer guidelines.

Safety Tips and Common Mistakes

Essential Precautions

You must follow strict safety guidelines when operating a hand chain hoist. Proper training and education for all operators improve safety and efficiency. Inspect the lifting area for hazards before you begin. Always check the safety latch on the hook and confirm that the chain is not twisted.

You need to secure the load with care and use correct lifting techniques to maintain control and reduce accident risks. Regularly review and update your safety procedures to match current standards.

Receive proper training before using a hand chain hoist.

Inspect the work area for hazards to ensure safety.

Check the safety latch and confirm the chain hangs straight.

Secure the load at stable lifting points.

Use correct lifting techniques with the hand chain hoist.

Update safety procedures as standards change.

You must never exceed the load capacity of your hand chain hoist. Overloading leads to equipment failure, accidents, and serious injuries. Always secure the load and lift vertically to avoid dangerous side pulls.

Tip: Routine inspections and proper handling help you prevent accidents and extend the life of your equipment.

Avoiding Errors

Many users make mistakes that compromise safety and damage the hand chain hoist. You must recognize these errors and take steps to prevent them. The table below highlights common mistakes and their consequences:

Mistake | Consequence |

|---|---|

Overloading the Hoists | Strain on the hook, potential damage to commodities, and loss of usability of the CPB. |

Improper Handling | Damage to internal components, potential for equipment failure. |

Modifications | Voiding of warranty, unsafe lifting practices, and increased risk of equipment failure. |

Twisting the Chain | Jamming of the chain, potential damage to the load, and internal machinery. |

Applying Excessive Force | Detachment of the chain from the hoist, stretching of chain links, and damage to loads. |

You must avoid improper storage and modifications. Store your hand chain hoist in a dry, clean area after use. Never alter the equipment or use it for tasks outside its intended purpose.

By following these safety tips and avoiding common mistakes, you create a safer work environment and ensure reliable performance every time you secure the load.

After Use: Detach and Store

Remove Load Safely

You must detach the load with care to protect both the equipment and your team. Begin by lowering the load slowly until it rests securely on the ground or a stable surface. Release tension from the chain block before unhooking the load. Inspect the hook and safety latch to confirm they remain intact.

Stand clear of the load during detachment to avoid injury. Remove the lifting hook from the load, making sure the chain hangs straight and untangled. Check the chain for signs of wear or damage after each use. You prevent accidents and maintain the chain block’s reliability by following these steps.

Tip: Always inspect the chain block after detaching the load. Early detection of damage helps you avoid costly repairs.

Store Chain Block

Proper storage extends the lifespan of your Powerful Machinery Chain Block. You need to clean the chain block after every use. Remove dust, grime, and debris using a non-corrosive cleaner. Lubricate moving parts to reduce friction and prevent rust.

Store the chain block in a dry, clean environment to avoid moisture damage and corrosion. Avoid placing the chain block on the floor where it can collect dirt or become tangled.

Best practices for storing your chain block:

Clean the chain block thoroughly after each use.

Lubricate moving parts regularly to prevent mechanical failure.

Inspect for wear, frayed chains, or damaged components.

Store in a dry, clean area away from moisture and harmful chemicals.

Keep the chain untangled and off the ground.

Improper storage exposes your chain block to dirt and moisture, which leads to corrosion and mechanical failure. Neglecting to clean and lubricate the chain increases wear and tear. You maintain optimal performance by following these storage guidelines.

Usage Intensity | Recommended Inspection Interval |

|---|---|

High-use (daily) | Every 1-3 months |

Moderate use | Every 6 months |

Low-use or standby | Annually |

Note: Routine inspections and proper storage keep your chain block ready for safe operation. You protect your investment and ensure reliable lifting every time.

Conclusion

You ensure safe and effective chain block use by following each step with care. Regular inspections and proper operation help you spot defects early and keep every part working safely.

Pre-use checks and scheduled maintenance prevent failures.

Industry standards require clear markings, regular inspections, and prompt removal of worn chains.

Modern chain blocks, like those from Powerful Machinery, feature innovations that boost safety and efficiency:

Feature | Benefit |

|---|---|

Load Limiting Mechanism | Prevents overload and equipment failure |

Automatic Brake System | Enhances load control and user confidence |

Ergonomic Design | Reduces strain and improves handling |

Stay updated on safety standards, participate in emergency drills, and report any concerns. For more details or support, visit Powerful Machinery’s official website.

FAQ

How do you determine the working load limit for a chain block?

You check the manufacturer’s specifications for the chain block. You must never exceed the working load limit. This ensures safe lifting and prevents equipment failure. Always verify the load weight before you lift.

What steps should you follow to keep the load under control during lifting?

You position yourself safely. You use tag lines if needed. You lift slowly and steadily. You lower the load gradually. You monitor the load and keep the load under control at all times.

Can you use a manual chain hoist for heavy lifting tasks?

You can use a manual chain hoist for heavy lifting if the load does not exceed the rated capacity. You must inspect the lifting equipment before every lift. You keep the load under control and follow safety protocols.

What is the best way to lower a load safely with a chain block?

You lower the load slowly. You keep the load under control. You check the area below for hazards. You use smooth movements. You never let the load drop suddenly.

How do you choose between an electric chain hoist and a manual chain block for lifting equipment?

You assess the lifting frequency and load weight. You select an electric chain hoist for frequent or heavy lifting. You choose a manual chain block for occasional lifts. You always keep the load under control and follow safety protocols.

Tip: You must inspect all lifting equipment before every lift and lower operation.

Task | Action Required |

|---|---|

Lifting | Check load, use proper equipment, lift vertically |

Lower | Lower slowly, keep the load under control, and monitor the area |

Equipment Selection | Match lifting equipment to the task, inspect before use |