Lifting Chains

Lifting chains take on heavy lifts where fabric slings fall short. We forge alloy steel lifting chains in-house for heat resistance, cut resistance, and strength you rely on at the jobsite. You choose Grade 100 or 120 with confidence. Get a fast lifting chains quote from Powerful Machinery.

Built with defined load ratings and safety factors to support lifts with confidence and control.

Produced to meet Grade 80, Grade 100, and industry standards for consistent jobsite acceptance.

Each product supports traceability and compliance to reduce risk and simplify inspections.

Factory-controlled output supports bulk orders, stable lead times, and predictable pricing.

Featured Partners

We work with industry leaders to provide dependable lifting chains supply.

Lifting Chain

Our lifting chains support heavy lifting and load control across a wide range of applications. Our selection includes:

A 1 leg chain lifting sling handles simple vertical lifts with a single lifting point. It offers steady load control, clear working load limits, and dependable strength for daily lifting work.

A 2 leg chain lifting sling uses two chain legs connected to a master link to balance loads at two lift points. It helps control load movement and keeps off-center lifts more level and predictable.

3 leg lifting chain slings use three chain legs to support large or uneven loads. They distribute weight across multiple lift points to keep bulky lifts stable and controlled.

A 4 leg lifting chain sling uses four chain legs to support large or uneven loads. It keeps heavy lifts balanced across multiple lifting points for stable, controlled handling.

Adjustable Lifting Chains

An adjustable lifting chain sling uses shortening clutches or hooks to adjust leg length. It allows better load balance and correct lift angles for different load sizes.

Endless Lifting Chains

Endless lifting chains form a continuous loop for choker or basket hitches. They work well for pipes, bundles, and round loads that need flexible wrapping and even load support.

Lifting Chain Parts

Our lifting chain components handle heavy loads and precise control across varied lifting applications. Our lineup includes:

Master Links

Master links (Oblong Link) sit at the top of a lifting chain assembly and connect directly to crane or hoist hooks. They provide a strong connection point and help spread the load evenly during lifting.

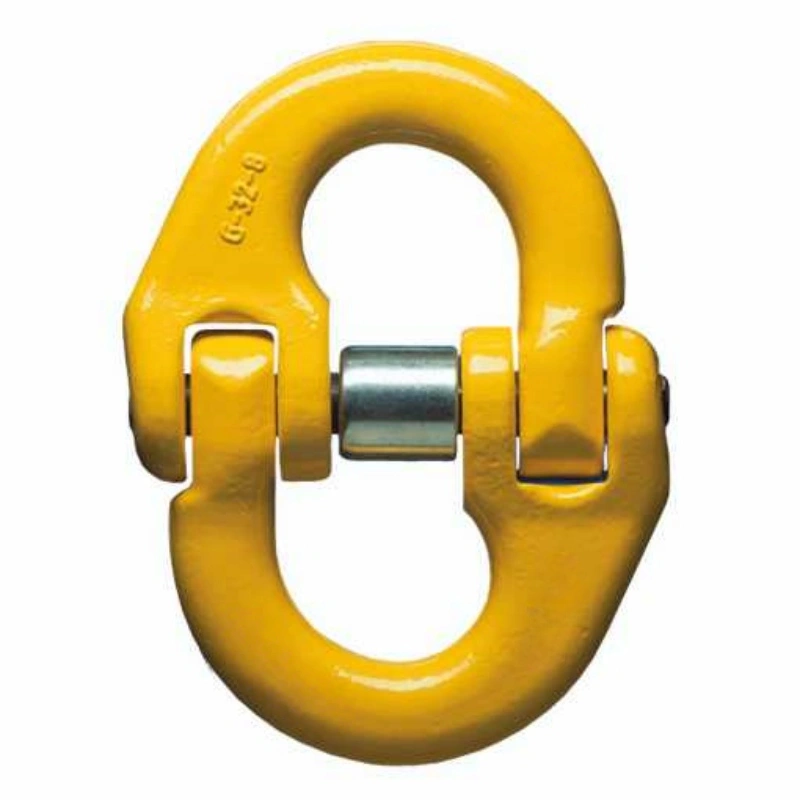

Coupling Links

Coupling links connect lifting chains to master links or hooks. Their load pin and sleeve design creates a secure, rated connection for safe and dependable lifting setups.

Hooks attach lifting chains directly to the load. Latch hooks help prevent unhooking, self-locking hooks secure automatically under weight, and grab hooks allow chain shortening and quick adjustment.

NEED HELP WITH YOUR ORDER?

Let us help! Reach out today and get recommendations on materials and sizing from our experts.

LIFT CHAINS GUIDE

Lift chains selection impacts safety and efficiency. Explore our guide to understand where each hardware type works best.

What is a Lifting Chain?

A lifting chain is a heat-treated alloy steel chain designed for overhead lifting, load suspension, and controlled positioning of heavy equipment. Lifting chains perform reliably under shock loads, elevated temperatures, and demanding industrial environments where wire rope or synthetic slings fail faster.

Types of Lifting Chains

Lifting chains are designed in several configurations, grades, and capacities to meet the demands of specific lifting tasks. The right selection depends on factors such as load symmetry, lifting angle, frequency of use, and environmental conditions. Below are the primary types of lifting chains, each serving a distinct purpose in overhead lifting and material handling operations.

Single-Leg Chain Slings

Ideal for straight vertical lifts, single-leg chain slings are used when simplicity and strength are required for direct, straightforward lifting.Two-Leg Chain Slings

These provide stability and load balance for more complex lifts, offering control over load positioning and distribution.Three-Leg Chain Slings

Common for lifting irregular or asymmetrical loads, three-leg chains offer additional control, balancing both load and lift points efficiently.Four-Leg Chain Slings

Suitable for heavy-duty lifts, four-leg chains provide superior stability and control for large, unstable, or critical loads.Adjustable Chain Slings

These slings offer adjustable lengths, enabling fine-tuning of the lift and reducing delays in fabrication. Ideal for custom lifts that require frequent adjustments.Endless Chains

Primarily used in hoist mechanisms, endless chains are designed for smooth, continuous operation where dimensional accuracy is essential for efficient load movement.

Chain Lifting Capacity / Lifting Chain Capacity Calculation

Lifting chain capacity is determined by factors such as chain diameter, grade, the number of legs, and sling angle. The working load limit (WLL) stamped on each component should always be referenced, not guessed.

Chain capacity under straight-pull conditions, and the capacity is reduced when leg angles decrease. Dynamic loading, shock, and load symmetry should also be considered when calculating capacity.

Factors Affecting Capacity

Chain grade rating

Nominal chain diameter

Number of active legs

Sling angle from vertical

Load balance and symmetry

How to Lift an Engine with a Chain?

Lifting an engine with a chain requires selecting the correct chain grade, verifying its capacity, and ensuring balanced lift points. Attach the chains to rated lifting eyes or engineered brackets, and avoid wrapping chains around sharp edges.

Proper preparation prevents shock loading and rotating, minimizing the risk of equipment damage or injury.

Engine Lifting Best Practices

Confirm engine weight, including fluids

Use two-leg or four-leg chains for balance

Maintain sling angles above 60 degrees

Protect contact points from abrasion

Lift slowly and monitor load behavior

How to Measure Lifting Chain?

Measuring lifting chains is an essential part of routine maintenance and ensuring the safety and reliability of your lifting operations. Accurate measurements help detect wear, fatigue, and potential failure points that can compromise the chain’s performance. This tutorial will guide you through the steps to measure a lifting chain properly, highlighting the key areas to inspect and the tools needed to do so.

Tools Required

Calipers: Precision calipers are essential for accurately measuring the chain’s diameter and inside length. Ensure the calipers are calibrated and in good working condition.

Measuring Tape or Ruler: For overall length measurements, a measuring tape or ruler may be useful in certain scenarios.

Magnifying Glass: For inspecting small markings and signs of wear in detailed areas such as the hook throat or master link.

Step-by-Step Process for Measuring Lifting Chains

1. Measure the Link Diameter at the Wear Zone

The diameter of each link is crucial for determining the chain’s capacity and performance under load. The wear zone typically forms in the areas that experience the most friction and contact during operation, such as the link’s contact points with lifting devices or hoists.

How to Measure: Use calipers to measure the outer diameter of the chain link at the wear zone. Be sure to check multiple links, as wear can be uneven. If the diameter has reduced significantly, it may indicate wear and tear that reduces the chain’s strength.

What to Watch For: Diameter reduction of more than 10% of the original measurement usually signals a need for replacement.

2. Measure the Inside Link Length

The inside link length refers to the distance between the inside edges of two adjacent links. This measurement is important because it ensures proper engagement of the chain in the lifting mechanism, whether it’s a hoist, crane, or winch.

How to Measure: Measure the internal length between the inside surfaces of adjacent links. This ensures that the chain will fit snugly within the hoist system without undue slack or excessive tightness.

What to Watch For: A change in the internal length due to elongation could indicate stretching of the chain from overloading or wear. If elongation exceeds the manufacturer’s specifications, it may be time to replace the chain.

3. Inspect the Hook Throat Opening

The hook throat opening is where the chain connects to the hoist or lifting mechanism. It’s critical to inspect this area for deformation or excessive wear that could cause the chain to slip out or fail during lifting.

How to Measure: Use calipers to measure the throat opening of the hook, which should match the dimensions specified by the manufacturer for a secure fit. Check for any elongation or widening that could compromise the hook’s grip.

What to Watch For: If the hook throat is deformed or excessively worn, it might be unable to hold the chain securely, leading to a higher risk of failure.

4. Check for Master Link Deformation

The master link is the primary connector of the lifting chain assembly, typically linking the chain to the hoist or crane. It’s vital to inspect for signs of deformation, cracks, or elongation.

How to Measure: Measure the master link using calipers and compare the measurements with the original specifications. Look for any elongation or changes in the link shape, such as cracking or bending. Deformation may occur under heavy load or due to shock loading.

What to Watch For: Deformation of the master link can severely compromise the integrity of the entire chain system. Any elongation, distortion, or visible cracking should be taken seriously and may warrant replacement.

5. Verify Tag Readability and Identification

Every lifting chain should have a clearly visible identification tag. This tag contains essential information, such as the chain’s grade, working load limit (WLL), and manufacturer details. The readability of this tag is critical for ensuring compliance with safety and inspection regulations.

How to Measure: Simply inspect the tag for legibility. The information should be clear and easy to read, even after extensive use. Use a magnifying glass if necessary.

What to Watch For: If the tag is illegible or missing, it’s important to replace the tag to ensure that all necessary information is available for regulatory compliance.

How to Use Lifting Chains?

Using lifting chains safely and effectively is critical for the success of your lifting operations. Proper use not only ensures the safety of your team but also maximizes the lifespan of your lifting equipment. In this tutorial, we will guide you through the key steps to use lifting chains correctly and provide important tips on preventing damage and ensuring safety.

Step-by-Step Instructions for Using Lifting Chains

1. Match the Chain with the Required Capacity

Before using a lifting chain, always ensure that it has the correct capacity for the load being lifted. Each lifting chain is rated for a specific working load limit (WLL), which indicates the maximum weight it can safely lift.

How to Check Capacity: Look for the identification tag on the chain, which will have the grade and working load limit stamped on it. Never exceed this limit.

What to Watch For: Using a chain that is not rated for the load you intend to lift can cause the chain to stretch, weaken, or break, leading to dangerous accidents.

2. Inspect the Chain’s Condition

Before using a lifting chain, conduct a thorough inspection to check for any signs of damage, wear, or deformation.

What to Check: Look for visible signs of wear, such as reduced link diameter, elongation, cracks, or rust. Make sure all components, including hooks, links, and slings, are intact and secure.

What to Watch For: If any part of the chain appears damaged or excessively worn, do not use it. Replace it with a new chain to ensure safety.

3. Control the Lift Geometry

The geometry of the lift plays a crucial role in the safety and effectiveness of using lifting chains. This refers to the angle at which the chain is positioned during the lift.

Proper Lift Angles: Always ensure that the chain is used in a way that the load is lifted vertically whenever possible. Avoid using a lifting chain at extreme angles, as this increases the load on the chain and can cause failure.

What to Watch For: Using a chain at an angle greater than 60° can increase the load on the chain and cause excessive wear or failure. Always adjust the length of the chain or use additional slings to ensure the load remains vertical.

4. Avoid Side-Loading Hooks or Twisting Chains

When lifting, side-loading the hooks or twisting the chains can put additional stress on the equipment and lead to premature wear or damage.

How to Prevent Twisting or Side-Loading: Make sure the hooks are properly aligned with the load and that the chain is not twisted or bent during the lift. The hooks should always sit securely in their designated positions.

What to Watch For: Misalignment or twisting can cause the hooks to fail, potentially leading to accidents. Always ensure hooks are seated properly before loading.

5. Use Shortening Clutches Properly

Shortening clutches are designed to adjust the length of the chain, making it easier to control the position of the load.

How to Use: Only use the shortening clutch to adjust the length of the chain to suit the load and the required lifting position. Never use the clutch to compensate for incorrect chain setup or angles.

What to Watch For: Improper use of shortening clutches can lead to uneven load distribution and reduce the chain’s effectiveness. Always follow the manufacturer’s instructions for correct usage.

6. Store Chains Clean and Dry

Proper storage of lifting chains is just as important as how they are used. Storing them in a clean, dry environment helps prevent rust and degradation, ensuring they remain in good condition for future use.

How to Store: After each use, clean the chains to remove dirt, debris, or chemicals, and store them in a dry area away from moisture and corrosive substances.

What to Watch For: Avoid storing lifting chains in wet or damp areas, as this promotes rust and shortens their lifespan. Always store them off the ground and hang them to prevent tangling or deformation.

Correct Usage Guidelines

To ensure safe and effective use of lifting chains, follow these key guidelines:

Load Vertically Whenever Possible: Always try to lift the load as close to vertical as possible. This reduces the stress on the chain and ensures an even distribution of weight.

Avoid Shock Loading: Never allow the chain to suddenly take the full weight of the load in a short burst. Shock loading can cause the chain to stretch or break. Lift the load slowly and gradually to avoid this.

Maintain Proper Sling Angles: Ensure that the lifting angle remains within the manufacturer’s recommended range (typically not exceeding 60 degrees from the vertical). This helps prevent overstressing the chain.

Use Shortening Clutches Properly: Only use shortening clutches to adjust the chain length as needed. Incorrect use of the clutches can create uneven loading and unnecessary strain.

Store Chains Clean and Dry: After each use, clean the lifting chains thoroughly and store them in a dry, clean environment. This will help maintain the chain’s strength and prevent premature wear.

Lifting Chain Certification

Lifting chain certification proves compliance with load testing, material grade, and inspection standards. It includes test certificates, batch numbers, and traceability records.

Certification ensures reliable performance, especially during audits and site inspections, providing confidence in product quality.

Certification Documents to Request

Proof load test report

Material chemical composition

Heat treatment records

Serial number traceability

Inspection criteria reference

Lifting Chain Grades

Lifting chains are available in different grades, with Grade 80 being the industry standard for most overhead lifting applications. Grade 100 offers higher capacity with reduced weight, while Grade 120 supports high-performance systems for specialized lifting needs.

Manufacturers recommend higher grades when weight reduction and efficiency are a priority.

Grade Insights

Grade 80 offers standard reliability

Grade 100 increases capacity without increasing size

Grade 120 supports high-performance rigging designs

Lifting Chain Inspection Checklist

Lifting chains should be inspected before every use and during scheduled audits to identify wear, deformation, or heat damage. Early detection is essential to prevent catastrophic failure, ensuring safety and equipment reliability.

Inspection Checklist

Measure link diameter reduction

Check for cracks or nicks

Inspect hooks for throat spread

Verify proper function of safety latches

Confirm legibility of identification tags

Lifting Chain Safety Factor

The safety factor of a lifting chain is the ratio between breaking strength and the working load limit. This safety margin absorbs shock loads and prevents misuse. Chains are designed with a safety factor that aligns with international standards, protecting both personnel and assets.

Why the Safety Factor Matters

Absorbs dynamic loading

Reduces risk of fatigue failure

Tolerates real-world misuse

Enhances long-term reliability and safety

Lifting Chain Sizes

Lifting chain size is determined by the required load capacity and compatibility with lifting hardware. Larger diameters increase capacity but also add weight, so selecting the appropriate size optimizes efficiency and handling. Proper sizing also enhances crane utilization by reducing unnecessary weight.

Common Industrial Sizes

6mm for light machinery

8mm for standard lifting operations

10mm for heavy-duty equipment

13mm and larger for extreme loads

Lifting Chain Sling Parts

A lifting chain sling comprises several load-bearing and connection components. It is critical that each part matches the required grade and size for safe operation. A well-engineered sling system ensures optimal load distribution and reliability.

Key Sling Components

Master link

Chain legs

Shortening devices

Hooks with safety latches

Identification tags for traceability

Lifting Chain vs Tie Down Chain

Lifting chains are designed for overhead lifting, while tie down chains are used for securing loads during transport. Tie down chains do not have the design safety factors necessary for lifting heavy loads. Proper product categorization ensures safety and prevents misuse.

Critical Differences

Lifting chains support suspended loads

Tie down chains are for load restraint

Different safety factor requirements

Varying inspection criteria for each type

Have More Questions?

Understanding the specific applications of each type of lifting chain and their compatibility with different lifting equipment enables informed decision-making. This ensures the selection of the right components for your lifting requirements. For assistance or more information on choosing the appropriate hardware, reach out to us today.