You need to trust your lifting equipment every time you use it. Proof load testing for lifting equipment checks if your gear can handle the loads you expect. This process keeps you, your team, and your property safe.

It also ensures your equipment meets strict compliance rules. When you use certified lifting solutions from Powerful Machinery, you get products that go through tough proof load tests.

Proof testing shows how equipment reacts under stress and confirms its reliability.

It helps you know the real performance and lifespan of your gear.

Proof loading keeps sensors accurate and protects your operations in safety-critical jobs.

Key Takeaways

Proof load testing ensures your lifting equipment can handle expected loads safely, reducing the risk of accidents.

Regular testing and inspection of lifting gear help maintain compliance with safety standards and protect your team.

Always check proof load test records before using lifting equipment to avoid unexpected failures and ensure safety.

Using certified lifting equipment from trusted suppliers like Powerful Machinery guarantees reliability and adherence to international standards.

Following a clear testing process and maintaining documentation supports long-term equipment safety and performance.

Proof Load Testing for Lifting Equipment

What Is Proof Load Testing?

You need to know that your lifting equipment will perform safely every time you use it. Proof load testing for lifting equipment is a process that checks the strength and reliability of your gear.

During a proof load test, you apply a controlled load that is higher than the equipment’s normal working load limit. This test helps you confirm that the equipment can handle stress and will not fail during regular operations.

International standards define proof load testing as a method to verify the load capacity and structural integrity of lifting equipment. You use hydraulic cylinders and load cells to measure the force applied.

The process involves holding the load for a set period to see how the equipment reacts. This step ensures that your lifting equipment meets safety standards and can operate within its specified limits.

Proof load testing for lifting equipment is systematic. You subject the equipment to a weight greater than its working load limit. This approach lets you assess the power, performance, and structural integrity of your gear. You can trust that your equipment will remain safe and reliable in demanding environments.

Tip: Always check that your lifting equipment has passed a proof load test before using it for critical tasks. This step protects you and your team from unexpected failures.

Why Is Proof Load Testing Important?

Proof load testing for lifting equipment plays a key role in keeping your workplace safe. You reduce the risk of accidents and equipment failure by verifying that your gear can handle the required load.

Industries like construction, marine, and logistics rely on certified proof load testing because lifting operations are common and safety is a top priority.

You face several risks if you skip proof load testing:

System overload can cause equipment failure.

Equipment exhaustion may lead to early breakdowns.

Safety vulnerabilities can result in dropped loads or injuries.

Proof load testing for lifting equipment helps you avoid these problems. You ensure that your equipment meets international safety guidelines, such as IS, ASME, BS, and OSHA. These standards require proof load testing, especially after repairs or modifications.

You also protect your workers by reducing the chance of equipment failure during lifting operations. Regulatory compliance is another benefit. You meet legal requirements and avoid penalties by following proof load testing procedures.

Powerful Machinery takes quality and compliance seriously. You get lifting equipment that has passed rigorous proof load tests. The company follows strict international standards and uses advanced testing methods. You can rely on Powerful Machinery for certified products that keep your operations safe and efficient.

Note: Regular proof load testing for lifting equipment is not just a legal requirement. It is a smart way to protect your investment and ensure long-term reliability.

Lifting Equipment and Accessories Tested

Types of Lifting Equipment

You use many types of lifting equipment in industrial settings. Each piece plays a key role in safe and efficient material handling. Proof load testing applies to a wide range of equipment. You often see the following items tested:

Cranes

Hoists

Load-bearing structures

Slings

Clamps

Wire rope pulling hoists

You rely on these tools to move heavy loads in construction, marine, and logistics environments. Proof load testing checks that each item can handle the stress of daily operations. You protect your team and your workplace by making sure every piece of lifting machinery passes these tests.

Powerful Machinery’s Certified Products

You want lifting equipment that meets the highest standards. Powerful Machinery offers a full range of certified lifting machinery for your toughest jobs. You can choose from wire rope pulling hoists, ratchet pullers, chain pulley blocks, hand chain hoists, and I Beam Hoist Clamps.

Each product goes through strict proof load testing before it reaches you.

You find that Powerful Machinery’s lifting equipment stands out for its strength and reliability. The I Beam Hoist Clamp, for example, gives you a secure grip on beams and supports loads up to 2 tons.

Chain pulley blocks and hand chain hoists help you lift and position heavy items with ease. Wire rope pulling hoists and ratchet pullers give you control and safety in demanding environments.

You can trust that every piece of equipment from Powerful Machinery meets or exceeds international standards. You get products that work in harsh conditions and deliver consistent performance. When you choose certified lifting machinery, you invest in safety, efficiency, and long-term value for your operations.

Tip: Always check the certification and proof load test records before using any lifting equipment. This step helps you avoid accidents and ensures compliance with safety regulations.

How Proof Load Test Conducted?

Testing Methods and Tools

You use several methods and tools to carry out a proof load test on lifting equipment. Each method helps you verify that your gear can handle the required load without failure. The most common tools include hydraulic cylinders, load cells, and water bags.

Hydraulic cylinders apply controlled force to your equipment. You can measure the exact load using independent load cells.

Load cells or dynamometers give you accurate readings of the force applied during load testing. These devices help you monitor the load in real time.

Water bags offer a flexible solution for large lifting equipment. You fill the bags with water to reach the desired load. This method lets you adjust the load precisely and reduces shock compared to solid weights. Water bags are easy to transport and store, making them a cost-effective choice for many sites.

You often see these methods used in crane testing, tension load link checks, and compression tests. Each approach ensures your equipment can handle loads above its working limit for a set period. You follow local laws and standards to make sure your proof load testing meets compliance requirements.

Tip: Always use calibrated tools and certified accessories during load testing. This step ensures accurate results and keeps your team safe.

Step-by-Step Load Testing Process

You need a clear process to conduct a proof load test. Following each step helps you confirm the strength and reliability of your lifting equipment.

Preparation

Start by reviewing design drawings and previous test reports. Check your equipment for signs of corrosion, cracks, or deformation. This inspection helps you spot problems before you begin load testing.Equipment Setup

Choose certified slings, shackles, and other accessories. Set up your test weights or water bags. Make sure the load is balanced and the equipment is secure.Conducting the Load Test

Attach the lifting beam or hardware to your test rig. Apply the load in stages, increasing it gradually. Watch for any deflection, unusual noises, or movement. Hold the load at the required level for the specified time.Post-Test Inspection

Remove the load and check your equipment again. Look for any permanent deflection, cracks, or microfractures. This step ensures your gear remains safe for future use.Documentation and Sign-Off

Record all details in a test report. Include the description of the equipment, applied loads, working load limit, deflection measurements, and a unique identification number. If your equipment passes, you receive a certificate. If it fails, you get a defect report explaining the reasons.

Note: Careful documentation of each proof load test supports compliance and helps you track the history of your lifting equipment.

Certification and Inspection

You must certify your lifting equipment after each proof load test. Certification proves that your gear meets safety standards and is ready for use. The certificate usually includes:

A description of the equipment

The applied load during testing

The safe working load or working load limit

Deflection measurements

A unique identification number

If your equipment does not pass, you receive a defect report. This report explains why the equipment failed and what you need to fix.

Regular inspection is just as important as the initial proof load test. International standards recommend periodic proof load testing and inspection to keep your equipment safe and reliable. The table below shows how often you should inspect your lifting gear:

Inspection Frequency | Conditions |

|---|---|

Yearly | Everyday use |

Monthly/Quarterly | Severe service or conditions |

Customized | Special services |

You should follow these guidelines to maintain compliance and protect your team. Regular load testing and inspection help you catch problems early and extend the life of your equipment.

Alert: Never skip periodic proof load testing. Regular checks keep your workplace safe and ensure your lifting equipment always meets the highest standards.

Working Load Limit and Safety Factor

What Is Working Load Limit (WLL)?

You need to know the safe working load for every piece of lifting equipment you use. The working load limit is the maximum load that your equipment can safely support during normal operations. Manufacturers determine this value by testing the equipment and considering its material strength and design.

The working load limit helps you avoid workplace accidents and keeps your team safe when handling heavy loads. You should always check the WLL before lifting anything in your workplace.

Calculating WLL in Load Testing

You calculate the working load limit by looking at several important factors:

Material strength, such as tensile and yield strength, affects how much load your equipment can handle.

The design of the equipment, including its shape and size, plays a role in the working load limit.

Rigorous testing, including both static and dynamic tests, ensures the equipment can withstand the required load.

Manufacturers apply a safety factor to the calculated limit to account for unexpected stresses or misuse.

The working load limit is not just the breaking point. It is the safety limit that you must follow to prevent workplace accidents and injuries. Site engineers use failure testing data and specific designs to set the right safety factor.

Controlled tests, often using hydraulic cylinders, confirm that your equipment can safely exceed the minimum allowable working load.

Safety Factor and Compliance

You rely on the safety factor to protect your workplace from accidents. The safety factor is a number that shows how much stronger your equipment is compared to the load it will carry. Industry standards recommend different safety factors for different types of lifting equipment:

Equipment Type | Safety Factor Range |

|---|---|

Rigging Equipment | 4:1 to 7:1 |

Hoisting Devices | 2:1 to 3:1 |

Proof load testing checks that your equipment meets these safety factor requirements. You verify that your gear can safely handle heavy loads and exceed the minimum working load.

This process helps you maintain safety, prevent workplace accidents, and comply with legal standards. Regular proof load testing is crucial for keeping your workplace safe and reducing the risk of injuries.

Tip: Always follow the recommended safety factor and never exceed the safe working load. This habit protects your team and your equipment.

Standards and Compliance in Proof Load Testing

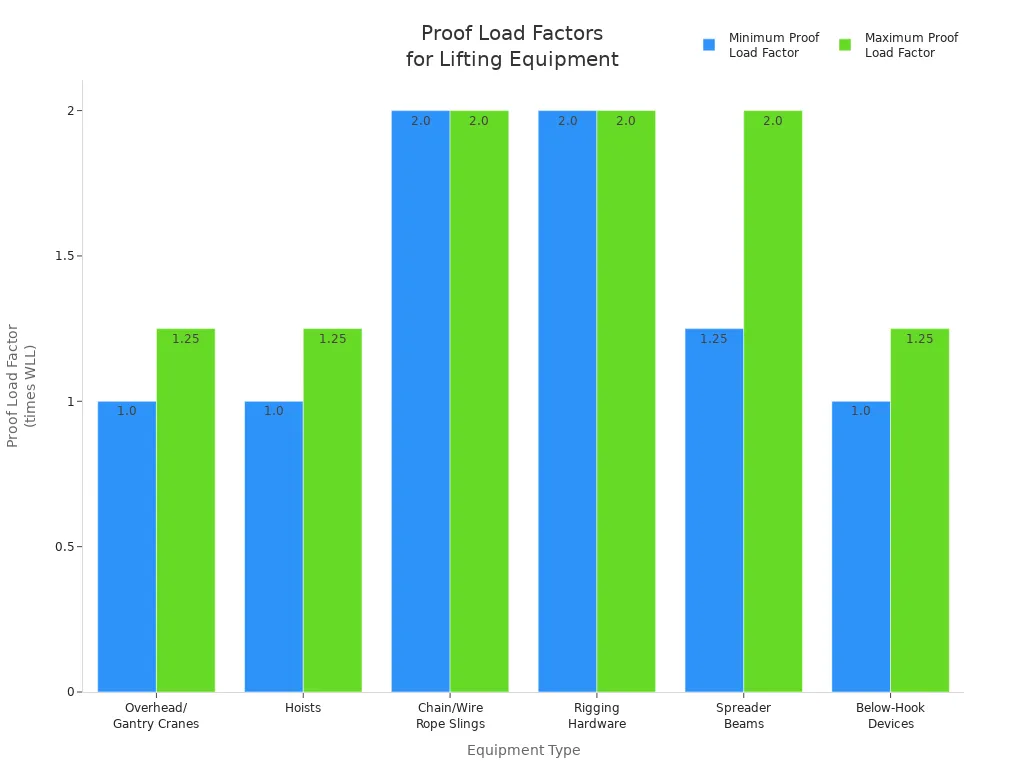

Key Standards (OSHA, ASME, ISO)

You need to follow strict standards when you test lifting equipment. The Occupational Safety and Health Administration sets rules for load testing in the United States.

The American Society of Mechanical Engineers and the American National Standards Institute also publish safety standards for lifting equipment. These standards help you keep your workplace safe and avoid accidents.

Here is a table showing the main standards and testing requirements:

Equipment Type | Testing Requirement | Standard |

|---|---|---|

Overhead/Gantry Cranes | 1.0 to 1.25 times WLL | 29 CFR 1910.179 |

Hoists | 1.0 to 1.25 times WLL | ASME B30.16 |

Chain/Wire Rope Slings | 2.0 times WLL | ASME B30.9 |

Rigging Hardware | 2.0 times WLL | ASME B30.26 |

Spreader Beams | 1.25 to 2.0 times WLL | ASME BTH-1 |

Below-Hook Devices | 1.0 to 1.25 times WLL | ASME B30.20 |

You must test new, repaired, or modified equipment at 100% to 125% of its rated load. These rules help you meet safety standards and protect your team.

Powerful Machinery’s Certifications

You want equipment that meets global safety standards. Powerful Machinery holds ISO 13854:2017 certification. This certification shows that the equipment meets or exceeds international safety standards. You can trust Powerful Machinery to deliver equipment that is safe and reliable for your operations.

Testing Frequency and Legal Requirements

You must test and inspect your equipment regularly. The law requires you to follow strict schedules for proof load testing and inspections. Here is a table showing how often you need to test and inspect your equipment:

Testing Type | Frequency Requirement |

|---|---|

Unit proof tests | Every 4 years (mandatory) |

Annual testing | Best practice (not always mandatory) |

Daily/pre-shift inspections | Before each use (mandatory) |

Monthly inspections | Required by competent individuals |

Annual inspections | Must be performed by qualified personnel |

You need to keep records for every test and inspection. You must retain reports for as long as the equipment is in use. If you do not follow these rules, you risk legal penalties and safety hazards. You protect your team and your business by following all safety standards and keeping your equipment in top condition.

Tip: Always check the latest regulations and keep your records up to date. This habit helps you avoid fines and keeps your workplace safe.

Conclusion

You protect your team and your business when you choose certified lifting equipment and follow regular proof load testing.

Certified gear reduces accidents and injuries. Almost 40% of serious workplace injuries come from lifting mistakes or using the wrong tools. OSHA reports over 20,000 lifting-related injuries each year.

Regular proof load testing brings long-term benefits:

Benefit | Description |

|---|---|

Enhanced Safety | Finds hidden defects and prevents failures. |

Reliability | Keeps your operations running and avoids costly repairs. |

Compliance | Meets safety standards and lowers legal risks. |

Minimizes Risks and Downtime | Detects problems early and reduces downtime. |

Prolongs Equipment Lifespan | Supports timely maintenance for longer use. |

Safety experts recommend you inspect and test your lifting equipment often:

Testing Type | Frequency | Notes |

|---|---|---|

Unit proof tests | Every 4 years | Mandatory |

Annual testing | Annually | Best practice |

Daily/pre-shift inspections | Before each use | By operators |

Monthly inspections | Monthly | By competent individuals |

Annual inspections | Annually | By qualified personnel |

Stay safe and keep your operations strong by choosing Powerful Machinery and following international standards.

FAQ

What is the difference between proof load and working load limit?

You use the proof load to test equipment strength. The working load limit (WLL) is the maximum safe load you can lift during normal use. Proof load is higher than WLL to ensure safety.

How often should you perform proof load testing?

You should test your lifting equipment at least every four years. Some industries require annual tests. Always check your local regulations and follow the manufacturer’s recommendations.

Can you use lifting equipment right after proof load testing?

Yes, you can use your equipment immediately if it passes the test and shows no damage. Always check the certification and inspection report before use.

What happens if lifting equipment fails a proof load test?

If your equipment fails, you must remove it from service. You need to repair or replace it before using it again. Never use damaged equipment.

Does Powerful Machinery provide proof load test certificates?

Yes, you receive a proof load test certificate with every certified product from Powerful Machinery. This certificate shows your equipment meets international safety standards.