You need to select shackle sizes that match the working load limit of your load and meet strict safety standards. Using certified, high-quality shackles from trusted brands like Powerful Machinery helps you lift safely and efficiently.

Always check that your shackles comply with recognized standards such as ASME B30.26, RR-C-271, EN 13889, and AS 2741. Understanding shackle markings and following manufacturer guidelines protects you from accidents and ensures a secure lift every time.

Key Takeaways

Select shackles with a working load limit (WLL) higher than your load to ensure safety during lifting.

Always inspect shackles for damage or wear before each use to prevent accidents.

Understand shackle markings, including size and WLL, to choose the right equipment for your lifting needs.

Follow manufacturer guidelines and international standards to maintain safety and compliance in lifting operations.

Regularly schedule inspections and consult experts for customized shackle solutions to enhance lifting efficiency.

Understanding Shackle Sizes

What Are Shackle Sizes?

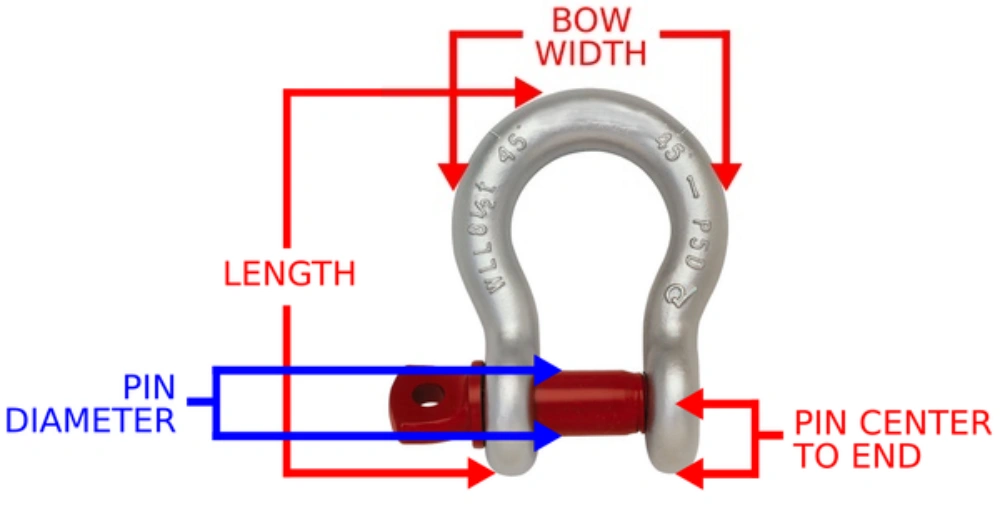

Shackle sizes refer to the specific dimensions of a shackle, which is a key component in lifting and rigging. You will find that shackle sizes are not just about the overall length. They include the diameter of the body, the width between the jaws, and the diameter of the pin.

Each measurement affects how the shackle fits with other equipment and how much weight it can safely handle. Powerful Machinery offers a wide range of certified shackle sizes, ensuring you can find the right fit for any lifting task.

How Shackle Sizes Are Measured?

You measure shackle sizes by looking at several main parts:

The diameter of the shackle body (the curved part).

The diameter of the pin (the straight bar that closes the shackle).

The inside width between the jaws.

The overall length from end to end.

Tip: Always check the manufacturer’s specifications for each shackle size. This helps you match the shackle to your lifting needs and ensures you stay within safe working limits.

International standards guide these measurements. For example, ASME B30.26 and RR-C-271 G set clear rules for how shackles should be sized and tested.

Standard Code | Description |

|---|---|

RR-C-271 G | Federal specification for chains and attachments, including screw-pin shackles. |

ASME B30.26 | Standards for selection, use, and maintenance of rigging hardware. |

Why Size Matters?

Choosing the correct shackle sizes is critical for safety. The size directly affects the working load limit (WLL), which is the maximum weight you can safely lift. Larger shackles have higher WLLs, letting you handle heavier loads.

You must always select a shackle with a WLL greater than your actual load. This safety margin protects you from unexpected stresses during lifting.

The total weight of your load determines the shackle size you need.

Always allow for a safety margin by choosing a shackle with a higher WLL than your load.

Regular inspections help keep your lifting operations safe.

Powerful Machinery uses high-strength steel and rigorous testing to meet international safety and quality standards. This commitment ensures every shackle delivers reliable performance in demanding environments.

Common Shackle Sizes and Types

Standard Shackle Sizes

You will find that shackle sizes cover a wide range to fit different lifting needs. Most manufacturers offer shackles from as small as 3/16 inch up to 2-1/2 inches or more. Each size comes with a specific working load limit (WLL), which tells you the maximum weight the shackle can safely handle.

For example, a 3/8-inch shackle from Columbus McKinnon has a WLL of 0.75 tons, while a 1-1/4-inch shackle from Crosby can handle up to 24,000 pounds. Always check the WLL before you select a shackle for your job.

Manufacturer | Shackle Size | Working Load Limit | Description |

|---|---|---|---|

Crosby | 1 1/4 inches | 24,000 lbs | Bolt and cotter type, carbon steel, meets ASME B30.26 standards. |

Columbus McKinnon | 3/8 inches | 0.75 ton | Micro-alloy steel, shows major deformation before failure, meets RR-C-271 performance requirements. |

You should always match the shackle size to your load and application. This helps you avoid overloading and keeps your lifting operation safe.

Shackle Types by Powerful Machinery

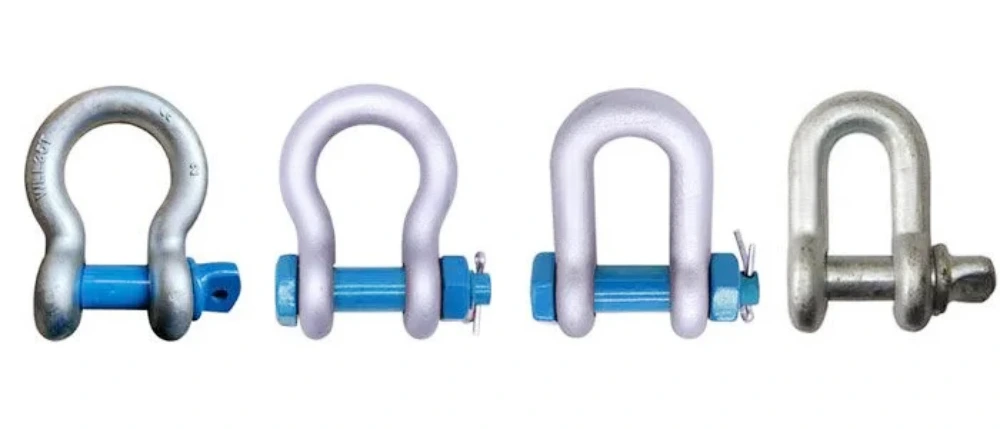

Powerful Machinery offers a full range of shackles to meet your lifting and rigging needs. You can choose from:

G2150 Bolt-Type Shackles: Made from 304 stainless steel, ideal for permanent or long-term use.

G209 Screw Pin Anchor Shackles: Easy to connect and disconnect, perfect for temporary setups.

G210 Screw Pin Chain Shackles: Best for straight-line pulls and marine environments.

G2130 Safety Pin Shackles: Provide extra security with a locking pin, great for critical lifts.

Stainless Steel Shackles: Resist corrosion, suitable for marine and outdoor use.

Stainless Steel Screw Pin D Shackles: Designed for straight-line loads and easy adjustments.

Each type comes in multiple sizes and meets strict international standards. You can find detailed specifications for each product on the Powerful Machinery website.

Typical Applications

You will see shackles used in many industries. In construction, workers use anchors and D-shackles to connect lifting slings and hoist heavy beams. Marine crews rely on stainless steel shackles for mooring, towing, and securing loads on ships.

Industrial sites use galvanized and high-strength shackles for moving machinery and cargo.

Shackle Type | Typical Load Rating (WLL) | Common Use Cases |

|---|---|---|

D-shackles | 0.5t to 85t | Construction, rigging |

Anchor shackles | 2 tons (1/2″ size) | Marine, lifting slings |

Bow shackles | Varies | Slacklining, multi-directional |

Galvanized shackles | Not specified | Industrial, outdoor |

Note: Always select shackles based on the load, environment, and safety requirements. Using the right shackle type and size helps you achieve safe and efficient lifting every time.

Choosing Shackle Sizes

Selection Steps

Selecting the right shackle size is a step-by-step process that helps you lift safely and efficiently. Follow these steps to make sure you choose the correct shackle for your job:

Inspect the shackle before each use. Look for any signs of damage, wear, or corrosion.

Check the working load limit (WLL) marked on the shackle. Never exceed this limit.

Make sure the shackle fits your lifting equipment and aligns properly with the load. Avoid side loading, which can reduce strength.

Tighten the pin securely. Do not overtighten, as this can damage the threads.

Replace the shackle if you see any deformation, cracks, or other defects.

Tip: Always compare the body diameter, pin diameter, and inside width to the manufacturer’s chart. Powerful Machinery provides clear specifications and certifications for every product, so you can trust the safety and quality of your shackles.

Factors to Consider

When you choose a shackle, you need to think about more than just the size. The type of material, the environment, and the way you plan to use the shackle all play a role. The table below shows how different materials perform in various conditions:

Material Type | Strength Characteristics | Suitable Applications | Environmental Suitability |

|---|---|---|---|

Carbon Steel | High strength, good toughness, economical | General construction, manufacturing | Best in dry, controlled environments |

Alloy Steel | Superior strength-to-weight, fatigue resistance | Heavy lifting, overhead cranes | Good in temperature extremes |

Galvanized Steel | Corrosion resistance via zinc coating | Outdoor, marine, humid environments | Prevents rust from moisture/rain |

Stainless Steel | Corrosion and chemical resistance | Saltwater, chemical plants, food processing | Excellent for corrosive/hygienic needs |

Environmental factors can affect shackle performance. Low temperatures may make some steels brittle, while high-quality alloy steels stay tough in the cold. Corrosion resistance is important in wet or salty environments. Always check the angle of your lift, as side loading can lower the WLL and increase the risk of failure.

Note: Powerful Machinery shackles meet strict international standards and come with clear markings for WLL and manufacturer identification. This helps you select the right shackle sizes for your specific needs.

Mistakes to Avoid

Many lifting incidents happen because of simple mistakes. You can prevent accidents by avoiding these common errors:

Choosing the wrong sling or shackle for the job.

Attaching the load incorrectly or using the shackle in the wrong orientation.

Exceeding the working load limit.

Using shackles with bent pins, deformed bodies, or missing markings.

Forcing or hammering shackles into position.

Using screw pin shackles that can unscrew if the load shifts.

These mistakes can lead to equipment failure, injuries, or even fatalities. Only trained and competent people should handle lifting operations. Supervisors should watch the process closely and never join in the lifting. Everyone must stay alert and avoid standing in the line of fire.

Always use shackles that match your load and environment. Consult the manufacturer’s data and follow all safety guidelines to keep your lifting operations safe.

Shackle Markings and Safety

Reading Markings

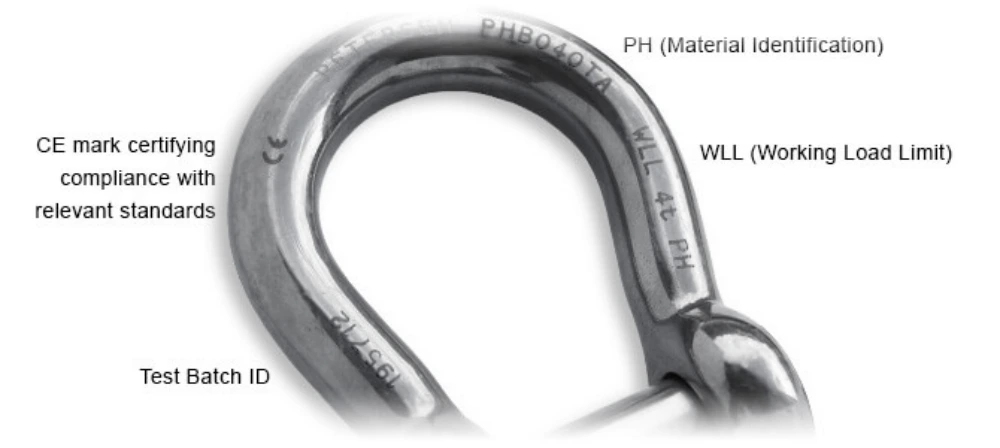

You need to read shackle markings before every lift. Markings tell you the size, working load limit (WLL), and manufacturer information. These details help you choose the right shackle and avoid mistakes. Powerful Machinery shackles display clear markings that meet international standards.

You will see the size stamped on the body, the WLL, and the brand name or logo. Some shackles also show angle indicators to help you check hitch angles quickly.

Marking Type | What It Means | Why It Matters |

|---|---|---|

Size | Diameter of body or pin | Ensures correct fit for your rigging |

WLL | Maximum safe load | Prevents overloading |

Manufacturer Info | Brand, logo, or batch number | Tracks quality and certification |

Angle Indicators | Forged marks for hitch angles | Helps reduce risk in side loading |

Tip: Always use shackles with legible markings. If you cannot read the WLL or manufacturer info, remove the shackle from service.

Understanding WLL

The working load limit (WLL) tells you the maximum weight a shackle can safely lift. Manufacturers determine WLL by testing the material strength, design, and safety factors. Powerful Machinery shackles undergo rigorous static and dynamic tests to ensure reliability.

You must never exceed the WLL stamped on the shackle. If you use shackles for side loading, reduce the WLL as recommended.

Material strength, shape, and size affect WLL.

Safety factors protect you from unexpected stresses.

Testing ensures each shackle meets strict standards.

Note: Always check the WLL before every lift. Using shackles with a higher WLL than your load keeps your operation safe.

Inspection Tips

You should inspect shackles regularly to maintain safety. Start with an initial inspection when you buy new shackles or after repairs. Before each use, check for distortions, cracks, or missing markings. Conduct thorough examinations every six months and annual inventory checks.

Inspection Type | Frequency/Details |

|---|---|

Initial Inspection | When new or repaired shackles are acquired |

Pre-Use Inspection | Visual check before each use |

Thorough Examination | At least every 6 months |

Periodic Inventory Inspection | Annual check considering usage and environment |

If you find distorted jaws, bent pins, or missing WLL markings, remove the shackle from service immediately. Shackles with visible damage or missing tags must not be reused.

The average lifespan of a well-maintained shackle is 5 to 10 years.

Remove any damaged or unmarked shackles from service to prevent accidents.

Regular inspections and proper use of marked shackles help you maintain a safe lifting environment every day.

Powerful Machinery Shackle Solutions

Product Highlights

You want shackles that deliver strength, safety, and reliability. Powerful Machinery offers a wide selection of certified shackles for every lifting need. You can choose from models like G2150, G209, G210, G2130, and various stainless steel shackles. Each product stands out for its robust construction and advanced features.

Here is a quick overview of some key shackles:

Shackle Model | Size (inches) | Working Load (Tons) | Material | Certifications | Features |

|---|---|---|---|---|---|

1/2″~4″ | 2 to 150 | Carbon Steel, Alloy Steel | ISO, CE, SGS, BV | Drop forged, heat-treated, anti-corrosion | |

N/A | N/A | N/A | N/A | US Type | |

N/A | N/A | N/A | N/A | US Type | |

N/A | N/A | N/A | N/A | US Type Bow Shackle |

You get shackles that resist corrosion, handle heavy loads, and meet strict safety standards. Powerful Machinery shackles work well in construction, marine, and industrial settings. You can rely on their solid structure and precise engineering for every lift.

Note: Powerful Machinery shackles undergo drop forging and heat treatment. These processes increase strength and durability, so you can trust your equipment in demanding environments.

Customization and Support

You may need shackles with special sizes, coatings, or features. Powerful Machinery provides customization options to match your exact requirements. You can request different pin types, materials, or finishes for unique projects.

The company works with you from consultation to production, ensuring every detail meets your needs.

You also benefit from strong after-sales support. The team helps you with product selection, technical questions, and warranty services. You get clear guidance on installation, inspection, and maintenance.

Here is how Powerful Machinery ensures product reliability:

Certification Aspect | Description |

|---|---|

International Standards | Products meet or exceed major international safety and quality standards. |

Quality Control Process | Rigorous quality control is embedded in every stage, from raw material inspection to final testing. |

Testing Procedures | Comprehensive testing, including chemical analysis, dimensional verification, and proof-load testing. |

Traceability | Full traceability from steel to shipment ensures certified products. |

You can trust Powerful Machinery to deliver shackles that meet global standards. You get peace of mind knowing your lifting hardware is safe, certified, and backed by expert support.

Tip: For more details on shackle models, specifications, and customization, visit the Powerful Machinery website. You will find complete product information and support for your lifting projects.

Conclusion

Choosing the right shackle size keeps your lifting operations safe and efficient. Follow these steps for every lift:

Respect the working load limit (WLL) on each shackle.

Avoid side loading by keeping pulls straight.

Calculate sling angles to select the correct shackle.

Inspect shackles before every use.

Certified shackles from Powerful Machinery offer lasting value:

Feature | Benefit |

|---|---|

Strength and Durability | Withstand extreme lifting conditions. |

Compliance with Standards | Guarantee safety and reliability. |

Long Product Life | Reduce replacement costs. |

Traceability and Certification | Provide safety verification for every product. |

Versatility | Suit a wide range of lifting needs. |

Schedule regular inspections and consult with lifting experts for custom solutions. Explore Powerful Machinery’s full range of shackle solutions to support your next project.

FAQ

What size shackle should you use for lifting?

You should select a shackle with a working load limit (WLL) higher than your load. Always check the size and WLL stamped on the shackle. Refer to manufacturer charts for exact sizing.

How do you know if a shackle is safe to use?

Inspect the shackle for cracks, bends, or missing markings. Make sure the WLL and manufacturer information are clear. Remove any damaged or unmarked shackles from service.

Can you use stainless steel shackles in marine environments?

Yes, stainless steel shackles resist corrosion and work well in marine settings. You should choose AISI 316 stainless steel for the best performance in saltwater.

What is the difference between a screw pin and a bolt-type shackle?

A screw pin shackle allows quick connections for temporary use. A bolt-type shackle provides extra security for long-term or permanent installations. Choose based on your application needs.

Where can you find shackle specifications and certifications?

You can find detailed specifications and certifications on the Powerful Machinery website. Always review product data sheets before making a selection.