You encounter three main lifting sling configurations in the field: vertical, basket, and choker. Understanding sling configurations directly impacts safety. Industry studies show that selecting the right configuration maintains load stability and maximizes capacity.

Powerful Machinery offers certified products that support safe lifting practices. Pay close attention to angle impact and perform regular inspections.

Over 30% of rigging-related accidents are due to incorrect sling usage.

A study by Konecranes found 27% of load drops resulted from poor rigging practices.

The CDC reported 60% of crane-related fatalities stemmed from rigging failures.

Key Takeaways

Understand the three main sling configurations: vertical, basket, and choker. Each has unique benefits and limitations that impact safety and load stability.

Regularly inspect your lifting slings before each use. Look for signs of wear or damage to prevent accidents and ensure compliance with safety standards.

Choose the right sling configuration based on the load type and weight. Using the correct setup maximizes lifting capacity and reduces the risk of load failure.

Pay attention to sling angles during lifting. The angle affects the sling’s capacity; higher angles provide better support and reduce tension.

Use certified products from trusted manufacturers like Powerful Machinery. Certified equipment meets safety standards and enhances reliability in lifting operations.

Overview Of Lifting Sling Configurations

Why Sling Configurations Matter?

You face many choices when selecting lifting sling configurations for your worksite. Powerful Machinery stands out as a trusted provider of certified lifting solutions, including chain slings, webbing slings, and tie downs.

These products meet international safety standards and deliver reliable performance in demanding environments.

Selecting the correct configuration is critical for both safety and efficiency. Each setup—vertical, basket, or choker—offers unique advantages and limitations. The table below highlights the main differences in load capacity and application for each configuration:

Sling Configuration | Load Capacity | Application |

|---|---|---|

Vertical Hitch | Full lifting capacity | Basic connection to a load; not for loose or unbalanced loads |

Basket Hitch | Up to 200% of single-leg capacity | Distributes load equally; not for unbalanced loads |

Choker Hitch | 75-80% of single leg capacity | Provides greater load control; not for unbalanced or loose loads |

You must understand these differences to prevent accidents and maximize lifting efficiency. Improper rigging practices often lead to load instability and equipment failure.

Using incorrect slings or ignoring sling angles can increase stress and cause dangerous situations. Damaged slings and a lack of inspection also contribute to lifting accidents. Not using the correct sling or hitch for the application can result in injuries and failed lifts.

Tip: Always inspect your lifting slings before each use. Look for signs of wear, damage, or incorrect labeling. Replace any sling that does not meet safety standards.

Industry regulations emphasize the importance of proper sling configuration. For example, regulations such as §5042 and §5043 require safe operating practices and regular inspection. Figures S-4 and S-5 illustrate safe sling setups, including vertical legs and angled legs, to help you visualize correct practices.

Choosing The Right Configuration

You improve lifting safety and efficiency by choosing the right sling configuration for each task. Consider several criteria when making your selection:

Sling Types: Know the differences between chain, wire rope, synthetic, and multi-arm slings. Each type suits specific lifting needs.

Material Properties: Choose materials like nylon, polyester, or metal based on the load and environment.

Load Capacity: Check the maximum weight the sling can handle. Never exceed the rated capacity.

Size and Length: Select the appropriate size and length to match the load and lifting method.

Understanding the weight and strength of the load is essential. Identifying the center of gravity helps prevent load thrusting and damage. Using the right sling type, such as chain slings for sharp-edged loads, reduces the risk of accidents.

Certified lifting solutions from Powerful Machinery offer significant advantages over non-certified alternatives. These products follow strict quality management systems and safety standards. ISO-9001 certified manufacturers report fewer accidents and less severe injuries.

Choosing reputable manufacturers helps prevent mechanical failures and keeps your workplace safe.

Note: Inexperienced riggers may overlook critical details. Always follow manufacturer recommendations and use certified equipment for every lifting operation.

You protect yourself, your team, and your equipment by understanding sling configurations and making informed choices. Reliable products and proper practices ensure safe and efficient lifting every time.

Vertical Sling Configuration

Setup And Compatible Sling Types

You use the vertical sling configuration when you need to lift stable loads with a consistent center of gravity. This setup keeps the load upright and reduces the risk of swinging or shifting. Chain slings and polyester slings from Powerful Machinery work well for vertical lifts.

Chain slings offer durability and resist cuts, while polyester slings provide flexibility and allow for gentle load rotation. You should select the sling type based on the load’s shape and weight. The vertical sling configuration is less suitable for irregular or unbalanced loads, which may tilt and create hazards.

Sling Type | Key Features | Safety Benefits |

|---|---|---|

Chain Slings | Durable, temperature-tolerant, cut-resistant | Withstand extreme conditions, enhance safety |

Polyester Slings | Lightweight, flexible, allows for load rotation | Reduce risk of load damage, improve safety |

Applications In Industry

You find vertical sling configurations used in many industries. Construction sites rely on vertical lifting to move steel beams and concrete blocks. Manufacturing plants use vertical slings to handle machinery parts and raw materials. Shipping yards depend on vertical configuration to load and unload cargo containers.

Powerful Machinery’s certified chain slings and polyester slings support these operations by providing reliable performance and meeting strict safety standards. You benefit from using certified lifting slings, which help prevent accidents and ensure efficient lifting.

Safety Considerations

You must follow safety standards when using a vertical sling configuration. Always hitch slings to control the load. Pad sharp edges with a strong material to protect the sling. Adjust slings only with approved methods. Stay alert for snagging during lifting. Never shorten or lengthen a sling by knotting or twisting.

Avoid resting loads on the sling or pulling a sling from under a load. Do not drag slings over abrasive surfaces. Certified equipment from Powerful Machinery meets international safety requirements, giving you confidence in every lifting operation.

Tip: Inspect your lifting slings before each use. Replace any sling that shows signs of damage or does not meet safety standards.

Basket Sling Configurations

Load Distribution Benefits

You improve safety and efficiency when you use the basket sling configuration. This setup supports the load with two sling legs, which wrap under and around the object. You see the weight spread evenly across both legs. This method reduces stress on each sling and helps prevent damage to the load.

Powerful Machinery’s flat web slings and round webbing slings work well for basket applications. Flat web slings offer wide surface contact, which protects delicate or finished surfaces. Round webbing slings provide flexibility and adapt to irregular shapes.

The basket configuration increases the overall safety factor in lifting operations. The circular design of round man baskets gives you 360-degree access and stability. This feature protects workers and ensures that the equipment meets site conditions and regulatory standards.

You gain better control and reduce the risk of accidents in high-risk environments.

Sling Type | Basket Application Benefits | Typical Loads |

|---|---|---|

Flat Web Slings | Wide contact, reduced abrasion | Machinery, fragile items |

Round Webbing Slings | Flexibility, adapts to shapes | Pipes, steel beams |

Common Uses

You find basket sling configurations in many industries. Construction crews use baskets to lift beams, pipes, and panels. Manufacturing plants rely on baskets to move heavy machinery and large components. Shipping yards use basket setups for loading and unloading cargo.

You choose this configuration when you need to lift balanced loads that require extra stability. Powerful Machinery’s certified slings help you meet safety standards and handle demanding lifting tasks.

Safety Tips

Always follow these safety tips when using flat web slings and round webbing slings in basket configurations:

Use the correct hitch for the job. Basket hitches double the capacity of a vertical hitch, making them ideal for heavier loads.

Refer to the professional sling supplier’s guidelines. This ensures the hitch matches your web sling lifting needs and maintains stability.

Inspect slings before each lift. Look for cuts, abrasions, or damaged labels.

Avoid sharp edges. Use padding to protect the sling and the load.

Never exceed the rated capacity. Check the working load limit on the sling label.

You maintain safe lifting practices by following these guidelines. Certified products from Powerful Machinery give you confidence in every lifting operation.

Choker Sling Configurations

Choker Setup And Control

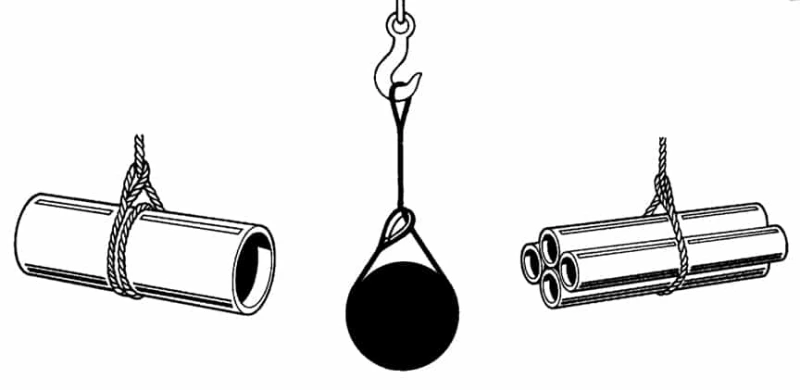

You use a choker sling configuration when you need to grip and control loads that might slip in a vertical lift. This setup works well for lifting pipes, poles, or bundles that require a secure hold.

Powerful Machinery’s chain slings and round webbing slings are excellent choices for choker configuration because they offer both strength and flexibility.

To set up a choker configuration safely, follow these steps:

Place the sling around the load, making sure the choke point touches only the sling body.

Thread one sling eye through the other and attach it to the crane hook. For extra grip, use a double wrap if needed.

Tighten the choke completely before lifting, and position the crane directly above the load’s center.

This method helps you maintain control and reduces the risk of the load slipping during lifting.

Angle Impact On Capacity

You must pay close attention to the angle in a choker sling configuration. The angle between the sling legs and the load affects the rated capacity. As the angle decreases, the lifting capacity drops.

Sling angles are critical because they increase compression and friction at the choke point, which can reduce the safe working load.

Note: Always check the manufacturer’s capacity charts for choker configurations. Never exceed the rated load, especially when working at low sling angles.

Best Practices

You can maximize safety and efficiency by following these best practices for choker configuration:

Position the headache ball over the load’s center of gravity.

Attach each choker securely and make sure the grip is tight before lifting.

Aim for a 60-degree angle between sling legs to balance the load.

Balance the basket hitches in the choker hitches to prevent slipping.

Stay alert for snags or shifting during the lift.

Keep clear of rigging equipment and suspended loads.

Inspect your sling before and after each use, and store it properly.

Tip: Place the choker directly below the headache ball and double-check the grip before starting the lift. Adjust the sling legs to distribute weight evenly.

Powerful Machinery’s certified slings help you maintain control and safety in every lifting operation. You protect your team and equipment by following these guidelines and using reliable products.

Sling Angles And Lifting Capacity

Effects Of Sling Angles

You must understand how sling angles affect lifting operations. Sling angles play a critical role in determining lifting capacity. When you use a basket hitch, the sling supports the load with two legs. A vertical angle provides maximum support.

As the angle between the sling legs and the horizontal decreases, tension increases, and the capacity to lift the load drops. In a choker hitch, the angle influences compression and friction. Lower angles increase stress on the sling and reduce the rated lifting capacity.

The following table shows how the sling angle impacts the capacity multiplier:

Sling Angle (degrees) | Capacity Multiplier |

|---|---|

60 | 1.73 |

45 | 1.41 |

30 | 1.00 |

You should always check the sling angle before lifting. Powerful Machinery’s product labeling and safety instructions help you identify the correct angle for each operation. You protect your team and equipment by following these guidelines.

Tip: Use the highest possible sling angle to maximize lifting capacity and reduce tension on the sling.

Practical Safety Warnings

You improve safety by following these practical warnings during lifting operations:

Balance the load evenly in a basket hitch to prevent shifting.

Know the working load limit of your sling and factor in the sling angle.

Lift slowly and evenly to avoid shock loads.

Avoid unequal leg lengths or angles, which can overload one leg.

Evaluate each sling leg individually for safety.

Remember that shallow angles dramatically increase tension.

You find clear safety instructions on Powerful Machinery’s product labels. Always refer to these guidelines before each lift. You reduce the risk of accidents and ensure safe lifting by staying alert to sling angles and load distribution.

Inspection And Maintenance For Safe Lifting

Importance Of Regular Inspections

You play a crucial role in keeping your workplace safe by inspecting your lifting slings regularly. Inspections help you spot early signs of wear, damage, or improper use before they lead to dangerous situations. International safety standards, such as ASME B30.9 and OSHA 1910.184, set clear guidelines for inspection frequency.

You should always perform a visual check before each use and schedule more thorough inspections based on how often and where you use your equipment.

Inspection Type | Frequency |

|---|---|

Initial Inspection | When you receive new rigging products to confirm ratings and condition |

Frequent Inspection | Before each use or shift change; more often in severe service conditions |

Periodic Inspection | At least every 12 months, monthly to quarterly for harsh environments |

Regular inspections ensure your slings remain in proper working condition. You catch small issues early, which prevents them from becoming major problems. This routine also extends the lifespan of your equipment and helps you comply with legal requirements.

When you follow these inspection routines, you create a safer environment for everyone on your team.

Tip: Always check for cuts, abrasions, broken stitching, or missing labels. Remove any sling from service if you find damage.

Equipment Rating And Certification

You must use only certified and properly rated equipment for every lifting operation. Powerful Machinery demonstrates a strong commitment to international safety standards by providing products that meet or exceed certifications like ISO9001, ASME B30.9, and CE.

These certifications guarantee that your equipment has passed strict tests for structural integrity, operational performance, and load-handling capability.

Certification Criteria | Description |

|---|---|

Structural integrity | Equipment can withstand intended loads |

Operational performance | Equipment operates as designed |

Load-testing compliance | Equipment handles specified loads safely |

Safety features and labeling | Proper safety features and clear labeling |

Documentation and identification | Complete records and identification tags |

You should always check the sling’s label for its working load limit and certification marks. This step ensures you use the right sling for the job and avoid overloading. Certified equipment gives you confidence that your lifting gear will perform as expected under pressure.

Preventing Accidents

You can prevent most lifting accidents by following a few essential strategies. Start with regular inspections and use only certified equipment. Make sure you know the weight of your load and never exceed the rated capacity of your slings or crane. Select the right rigging for each task and inspect it before every use.

Communicate clearly with your team and keep the work area free of obstacles and unauthorized personnel.

Inspect all equipment daily and before each lift.

Confirm the load matches the rated capacity of your lifting gear.

Use the correct sling and hardware for every application.

Train all operators and riggers thoroughly.

Plan each lift and review the process with your team.

Keep the area clear and never stand under a suspended load.

Mark and document all equipment for easy identification.

Powerful Machinery’s products come with clear safety instructions and proper documentation. When you follow these best practices, you reduce the risk of accidents and keep your lifting operations running smoothly.

You ensure every piece of equipment stays in proper working condition, which protects both your team and your investment.

Remember: Consistent inspection, certification, and safe practices form the foundation of every successful lifting operation.

Conclusion

You ensure safe lifting by understanding each sling configuration—vertical for direct lifts, basket for balanced load distribution, and choker for secure control. Regular inspection keeps your equipment reliable and ready for every job. Angle awareness protects you from capacity loss and accidents.

Choose certified products from Powerful Machinery for solutions that meet industry standards, provide practical recommendations, and offer specialized training. Consult Powerful Machinery for custom-engineered lifting solutions that support your team’s safety and efficiency.

FAQ

What is the safest sling configuration for most lifting tasks?

You should use the basket configuration for balanced loads. This setup distributes weight evenly and increases lifting capacity. Always check the load type and follow manufacturer guidelines to select the safest configuration for your task.

How often should you inspect your lifting slings?

You need to inspect slings before each use. Schedule frequent checks during heavy use or harsh conditions. Plan a thorough inspection at least once a year to ensure safety and compliance.

Can you use the same sling for different configurations?

You can use many slings in vertical, basket, or choker setups. Always check the sling’s label for compatibility and rated capacity. Never exceed the working load limit for any configuration.

Why choose certified products from Powerful Machinery?

Certified products from Powerful Machinery meet strict international standards. You gain peace of mind knowing your equipment has passed rigorous testing for strength, durability, and safety. This reduces risk and supports reliable lifting operations.