You must consider several key factors that affect the steel wire rope strength, including material, construction, core type, diameter, lay, termination, loading, bending, environment, maintenance, and manufacturing quality.

Understanding the factors affecting strength helps you ensure safe and reliable operations in demanding industries. When you choose certified Steel Wire Rope solutions from Powerful Machinery, you gain confidence in every lift, rig, or hoist.

Key Takeaways

Choose high-grade steel wire rope for maximum strength and durability in tough environments.

Select the right diameter; larger diameters support heavier loads and improve safety.

Understand the importance of core type; steel cores enhance load capacity, while fiber cores offer better fatigue resistance.

Regularly inspect and maintain your wire rope to ensure safety and extend its lifespan.

Look for certified wire ropes to guarantee quality and compliance with safety standards.

Material and Construction Impact on Steel Wire Rope Strength

Material Composition and Grades

You must pay close attention to material composition when selecting steel wire rope for demanding tasks. The chemical makeup of the steel directly influences tensile strength, durability, and corrosion resistance.

Powerful Machinery uses high-grade steel in its wire rope construction, ensuring that each product delivers maximum performance in harsh environments.

The table below shows the typical material composition found in steel wire rope:

Element | Percentage (%) |

|---|---|

Fe | 94.18 |

Zn | 4.53 |

C | 0.87 |

Si | 0.38 |

Mn | 0.03 |

Ni | 0.01 |

S | N/A |

P | N/A |

The high percentage of iron (Fe) provides strength, while zinc (Zn) improves corrosion resistance. Carbon (C) and silicon (Si) contribute to hardness and toughness.

Manganese (Mn) and nickel (Ni) enhance flexibility and longevity. You benefit from these properties when you choose wire rope construction from Powerful Machinery.

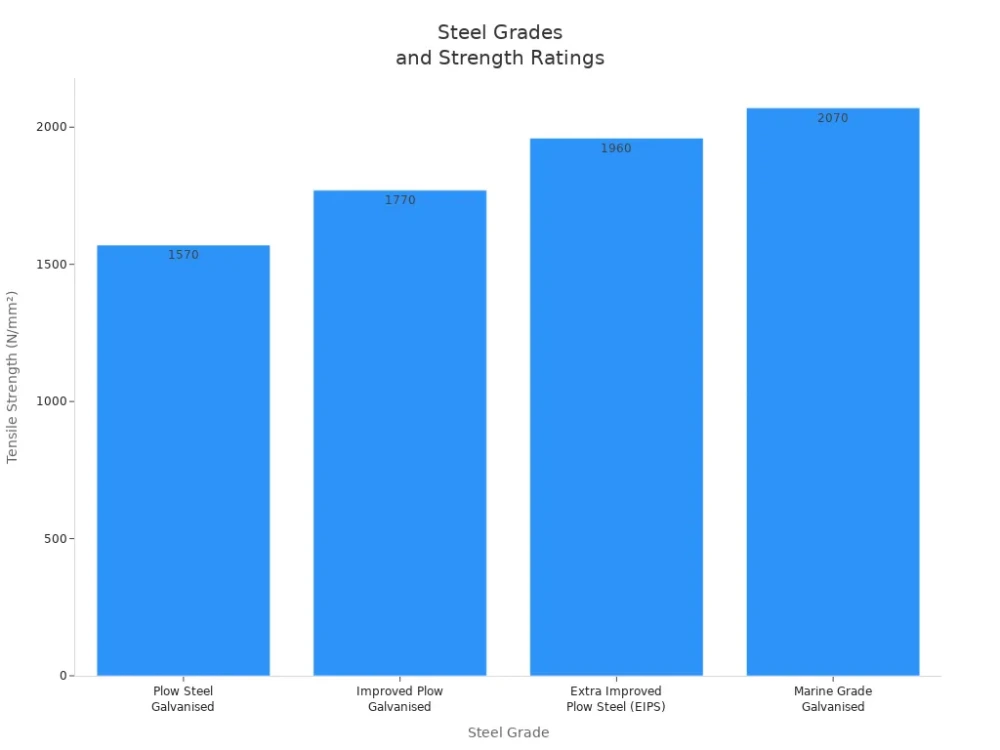

The grade of steel also matters. Different grades offer varying tensile strengths, which affect how much load the wire rope can handle. The table below compares common steel grades used in wire rope construction:

Steel Grade | Tensile Strength (N/mm²) |

|---|---|

Plow Steel Galvanised Wire Rope | 1570 |

Improved Plow Steel Galvanised Wire Rope | 1770 |

Extra Improved Plow Steel (EIPS) | 1960 |

Marine Grade Galvanised Wire Rope | 2070 |

You should select the material composition and grade that match your application’s requirements. Marine-grade wire rope construction offers the highest tensile strength, making it ideal for heavy-duty lifting and marine environments.

Powerful Machinery provides certified wire ropes with advanced material composition, ensuring you get the best balance of strength and durability.

The type of stainless steel used affects mechanical strength.

Corrosion resistance is influenced by the chemical composition.

Longevity of the wire rope is directly related to its material properties.

Rope Construction and Strand Types

Wire rope construction involves arranging wires and strands in specific patterns to achieve desired properties. The construction type determines flexibility, abrasion resistance, and fatigue life.

Powerful Machinery offers multiple construction type options, such as 35W×7, 18×19, and 8×55SWS, each designed for unique applications.

You must understand how strand configuration affects performance. For example:

6×19 ropes focus on abrasion resistance, making them suitable for wear-prone environments.

6×36 ropes are designed for fatigue resistance, with more wires per strand enhancing flexibility.

The 8×55SWS configuration provides superior flexibility and strength for specialized lifting tasks.

Wire rope construction type also includes the weaving method. The weaving method refers to how wires are twisted and layered. A non-rotating design uses strands wound in opposing directions, balancing torque and minimizing load rotation.

This construction type prevents spinning under load, which is critical for safety during vertical hoisting.

Tip: Non-rotating wire ropes maintain alignment during lifting, reducing the risk of dangerous shifts in load position. You gain precise control and improved safety for both equipment and personnel.

The weaving method and construction type you choose should match your operational needs. Powerful Machinery’s wire rope construction uses advanced weaving method and construction type to deliver optimal performance in every application.

Core Type and Its Role

The core is the central part of the wire rope construction. You can choose between fiber core and steel core, each offering distinct advantages. The core type impacts load-bearing capacity, flexibility, and fatigue resistance.

Feature | Fiber Core | Steel Core |

|---|---|---|

Load Capacity | Lower | Higher |

Fatigue Resistance | High | Moderate |

Steel core wire rope construction enhances load capacity by about 15% compared to fiber core. You should select a steel core for heavy lifting tasks where maximum strength is required. Fiber core provides higher fatigue resistance, making it suitable for dynamic environments with frequent bending and vibration.

The weaving method and construction type of the core also affect overall performance. Powerful Machinery engineers wire rope construction with both core types, allowing you to select the best option for your project.

The advanced material composition and weaving method ensure that each wire rope delivers superior reliability and longevity.

Note: Choosing the right core type and weaving method helps you maximize safety and efficiency in your lifting and rigging operations.

You must evaluate material composition, construction type, weaving method, and core type when selecting steel wire rope.

Powerful Machinery’s certified products combine advanced material composition, innovative construction type, and precise weaving method to meet the toughest demands in construction, marine, and transportation industries.

Diameter, Lay, and Tensile Strength of Steel Wire Rope

Diameter and Load-Bearing Capacity

You must consider the diameter of the rope when selecting stainless steel wire rope for any lifting or rigging task. The diameter directly affects the breaking strength and the tensile strength of steel wire rope.

Larger diameters support heavier loads and provide greater safety margins. Powerful Machinery offers a wide range of diameters to match your specific load requirements, ensuring you always have the right tool for the job.

The tensile strength of steel wire rope increases as the diameter grows, allowing you to handle more demanding applications.

Tests show that if you use a sheave with a small diameter compared to the rope, the breaking strength can decrease by 4% to 6%.

When you select wire ropes with more outer wires, you improve resistance to bending fatigue, especially in applications with repeated bending over sheaves or drums.

Manufacturers like Powerful Machinery use high-strength alloy steels to maximize both the tensile strength of steel wire rope and its durability. You benefit from ropes that maintain their performance even under heavy and dynamic loads.

Lay Direction and Weaving Methods

The lay direction and weaving method play a crucial role in the performance of stainless steel wire rope. Lay direction refers to the way wires and strands twist around the core.

Right-hand lay ropes are common in lifting because they align with most machinery, providing superior stability and reducing unwanted rotation. This alignment can extend the rope’s service life by up to 25% in rotating systems.

Right-hand lay ropes offer better torque balance and rotational stability, making them ideal for lifting.

Left-hand lay ropes work best in winching or applications where reverse rotation is needed.

Choosing the correct lay direction ensures you get the most out of your stainless steel wire rope, reducing stress and wear.

The weaving method also affects the rope’s resistance to abrasion and fatigue. The table below summarizes key aspects:

Aspect | Description |

|---|---|

Arrangement of Wires | Strands twisted and interwoven for strength and flexibility |

Wire Size | Larger wires resist abrasion; smaller wires improve flexibility |

Mechanical Properties | High-strength alloy steels provide excellent fatigue resistance |

Powerful Machinery designs stainless steel wire rope with advanced weaving methods and high-strength alloy steels, giving you the best combination of flexibility, abrasion resistance, and tensile strength of steel wire rope.

Termination and Installation Quality

Proper termination and installation are essential for maintaining the breaking strength and overall safety of steel wire ropes. Certified terminations, such as swaged or crimped ends, ensure secure connections and prevent slippage during operation. The table below compares common termination methods:

Termination Method | Advantages | Applications | Strength Effect |

|---|---|---|---|

Swaged Terminations | High strength, reliable | Overhead lifting, marine | Superior for critical applications |

Wire Rope Clips | Quick, adjustable, reusable | General rigging, construction | Less durable, needs regular inspection |

Spliced Terminations | Smooth finish, no extra parts | Yacht rigging, railings | Not as strong for high-load tasks |

Ferrule-and-Die Terminations | Secure, easy to install | Lifting slings, railings | Not as robust as swaged for heavy lifting |

Crimped Terminations | Quick, cost-effective | Guardrails, elevators | Good for light to medium loads |

You must follow proper installation practices to avoid fatigue and structural weaknesses. Improper coiling, sharp bends, or neglecting storage guidelines can lead to early failure of stainless steel wire rope.

Powerful Machinery provides certified terminations and expert guidance, helping you maintain the full tensile strength of steel wire rope in every application.

Tip: Always inspect terminations and installation quality before each use to ensure the safety and longevity of your stainless steel wire rope.

Loading, Bending, and Environmental Factors

Loading Conditions and Fatigue Resistance

You face many loading conditions in industrial environments. Each type affects the load-bearing capacity and lifespan of your steel wire rope. The most common causes of fatigue failure include:

Bending fatigue from the rope passing over sheaves or drums

Tensile fatigue from repeated lifting and lowering

Vibratory fatigue from constant vibrations, especially in long spans

Powerful Machinery engineers its steel wire rope for high performance in dynamic, static, and shock loading scenarios. You benefit from ropes that maintain their load-bearing capacity even under extreme stress. Manufacturers test fatigue resistance using ISO 6482:2017 standards.

These tests simulate real-world conditions and use high-precision sensors to monitor force and stress. You can trust that each rope meets strict requirements for working load limit and safety factor.

Aspect | Description |

|---|---|

Standard | ISO 6482:2017 |

Purpose | Tests fatigue resistance under dynamic and static loads |

Testing Environment | Simulates high-stress operational conditions |

Instrumentation | Sensors monitor force, elongation, and stress-strain behavior |

Bending Over Sheaves and Drums

Repeated bending over sheaves and drums reduces the load-bearing capacity of your wire rope. This process causes cyclic stress, leading to microscopic cracks and eventual fatigue. You also see fretting fatigue, where friction between wires increases wear.

Internal and external wear further reduce the rope’s operational lifespan. Corrosion can develop when bending damages protective coatings.

Degradation Mechanism | Description |

|---|---|

Fatigue | Cyclic stress creates cracks over time. |

Fretting Fatigue | Friction between wires causes localized failures. |

Wear | Bending leads to a gradual loss of load-bearing capacity. |

Corrosion | Damaged coatings allow corrosive agents to penetrate. |

You should always match the rope’s load-bearing capacity to the application and follow the recommended safety factor. This practice helps you avoid premature failure and maintain optimal load capacity.

Environmental Resistance and Maintenance

You need steel wire rope with high abrasion resistance and corrosion resistance for harsh environments. Powerful Machinery uses advanced coatings like polyurethane and PVC to enhance both abrasion resistance and corrosion resistance.

Polyurethane offers excellent corrosion resistance and superior abrasion resistance, making it ideal for construction, mining, and marine applications.

Coating Type | Corrosion Resistance | Abrasion Resistance | Temperature Stability | Applications |

|---|---|---|---|---|

Polyurethane | Excellent | Superior | Up to 150°C | Construction, Mining, Marine |

PVC | Good | Good | Moderate | Industrial Uses |

Regular inspection and maintenance are essential for safety and longevity. In marine environments, rinse and check for corrosion frequently. In construction, inspect and check the tension daily.

For elevators and hoisting, lubricate and test monthly. Always follow the recommended maintenance schedule to preserve the rope’s load-bearing capacity and safety factor.

Tip: Consistent maintenance ensures your wire rope delivers reliable performance and extends its service life, even in the toughest conditions.

Manufacturing Quality and Standards Compliance

Quality Assurance and Certifications

You need steel wire rope that meets strict quality assurance protocols. Powerful Machinery follows advanced processes to guarantee reliability in every product. You benefit from wire ropes tested in state-of-the-art laboratories.

These tests simulate tough real-world conditions, so you can trust the rope’s performance under extreme stress. Evaluations cover strength, flexibility, and resilience against heavy loads and harsh environments.

High-carbon steel wire ropes undergo rigorous testing before reaching you.

Testing replicates demanding scenarios to confirm durability and safety.

Evaluations include checks for strength, flexibility, and resistance to heavy loads.

Powerful Machinery’s steel wire ropes carry certifications from respected organizations. You see marks like ISO9001 and TUV Rheinland, which assure you of consistent quality and safety. These certifications mean you receive products that meet or exceed global standards.

Standard/Certification | Description |

|---|---|

ISO9001 | Quality management system certification |

TUV Rheinland | Independent safety and quality verification |

EURO CERT | European compliance for lifting equipment |

EAC | Eurasian Conformity for industrial products |

Tip: Always look for certified wire rope to ensure safety and reliability in your lifting operations.

Industry Standards and Testing

You rely on wire rope that complies with international standards. These standards set minimum requirements for breaking force, rotational resistance, and mechanical properties. Powerful Machinery designs products to meet or surpass these benchmarks, so you get dependable performance in every application.

Standard | Description |

|---|---|

EN 12385-1 | European standard for steel wire rope safety and testing |

ISO 3108 | Methods for determining breaking force |

ASTM A1023/A1023M | American standard for mechanical testing |

ASME B30.9 | U.S. safety standard for slings, including wire rope |

Lloyd’s Register | Marine and offshore classification protocols |

Industry standards also guide design factors, diameter tolerances, and performance characteristics. You avoid costly downtime and extend equipment life by choosing wire rope that complies with these requirements.

Minimum design factors are established for safe rope applications.

Diameter tolerances ensure proper fit and function.

Compliance with standards enhances equipment longevity.

Powerful Machinery’s commitment to manufacturing quality and standards compliance gives you confidence in every lift, rig, or hoist.

Conclusion

You must evaluate several factors when selecting steel wire rope for demanding environments. The table below highlights the most critical factors for safety and performance:

Factor | Description |

|---|---|

Strength-resistance to breaking | Handles maximum load to prevent breakage. |

Resistance to fatigue bending | Withstands repeated bending around sheaves and drums. |

Resistance to abrasion | Endures dragging over hard surfaces. |

Crushing resistance | Avoids distortion and permanent damage during operations. |

Resistance to vibrational fatigue | Absorbs energy at tangent points for optimal performance. |

Choosing certified wire rope from Powerful Machinery ensures you address these factors. You should consult experts and schedule regular inspections, cleaning, and lubrication. These practices help you avoid costly mistakes and extend the lifespan of your equipment.

Regular inspections detect corrosion and wear early.

Cleaning and lubrication protect against damage.

Using the correct wire rope type for each job maximizes safety.

Tip: Prioritize these factors and maintenance to achieve reliable, cost-effective results in every application.

FAQ

What factors should you consider when choosing steel wire rope?

You should evaluate load requirements, rope diameter, construction type, core material, and environmental conditions. Always select certified products that match your application for maximum safety and performance.

How often should you inspect your steel wire rope?

You should inspect your wire rope before each use. For critical applications, schedule detailed inspections weekly. Look for signs of wear, corrosion, broken wires, or deformation.

Why does the non-rotating design matter?

A non-rotating design prevents twisting and kinking under load. You gain better control and safety during lifting, especially in vertical hoisting or when handling heavy loads.

What certifications should you look for in steel wire rope?

Look for certifications such as ISO9001, TUV Rheinland, and EURO CERT. These ensure your wire rope meets international safety and quality standards.

How can you extend the lifespan of your wire rope?

Store your rope in a dry, clean area.

Lubricate regularly.

Avoid sharp bends and overloading.

Schedule routine inspections and maintenance.