You rely on chain slings when you need to lift heavy loads safely and efficiently. Chain slings serve as essential tools in foundries, steel mills, and heavy machine shops, where durability and strength matter most.

Powerful Machinery manufactures certified chain slings and lifting chains that meet strict international standards. You gain confidence in your lifting operations by choosing products designed for demanding environments. Regular selection, safe use, inspection, and maintenance help you maximize safety and performance.

Key Takeaways

Chain slings are essential for safely lifting heavy loads in industries like construction and manufacturing. Choose the right type based on your lifting needs.

Regular inspection and maintenance of chain slings are crucial. Always check for wear, deformation, and ensure the identification tag is readable before each use.

Select the appropriate chain sling configuration to match your load type. Single-leg slings are for lighter loads, while multi-leg slings provide better stability for heavier items.

Understand the working load limit (WLL) of your chain sling. Never exceed this limit to prevent accidents and ensure safe lifting operations.

Consult with manufacturers like Powerful Machinery for expert advice on selecting the right chain sling for extreme environments or specific lifting challenges.

Chain Slings Overview

Chain Sling Definition

You use chain slings when you need a reliable tool for lifting heavy loads in industrial settings. Chain slings consist of high-strength steel chains connected with hooks, master links, and other fittings. You can choose from single-leg, double-leg, triple-leg, or quadruple-leg designs to match your lifting requirements.

Powerful Machinery stands out as a trusted manufacturer, offering certified chain slings that meet strict international standards. Each sling comes with a durable identification tag that shows its size, grade, rated capacity, and reach. This information helps you select the right sling for every job and ensures safe operation.

Industrial Applications

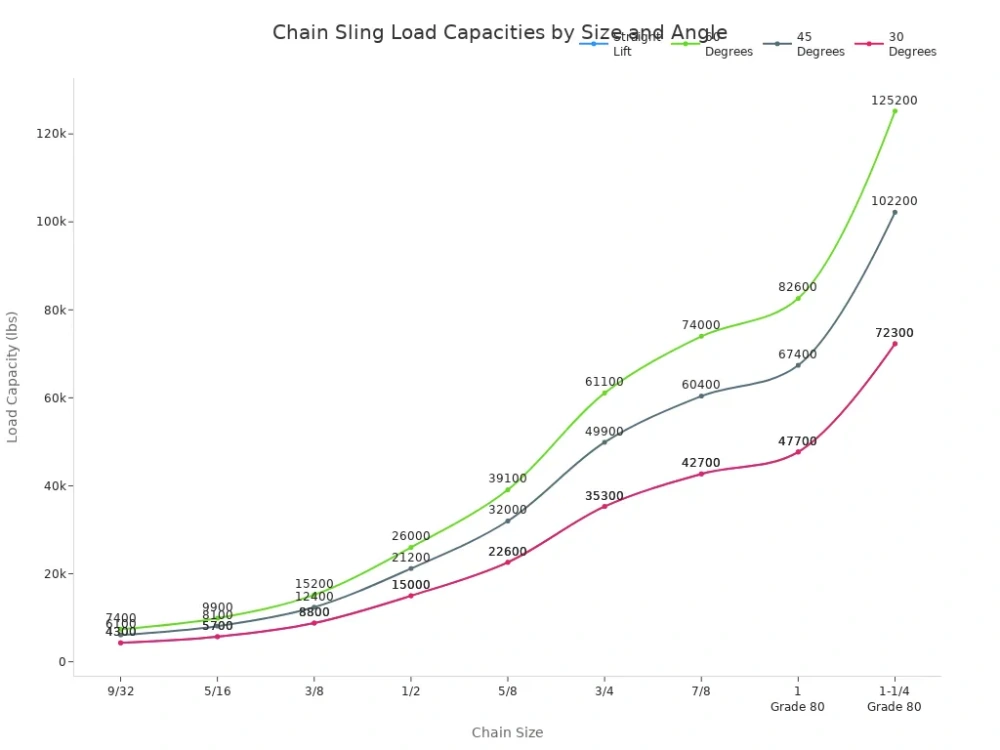

You find chain slings in many industries, including construction, manufacturing, shipping, and transportation. These slings handle a wide range of loads, from steel beams to heavy machinery. You can see how different chain sizes and lifting angles affect load capacity in the table below:

Chain Size in Inches | On Straight Lift | 60 Degrees | 45 Degrees | 30 Degrees |

|---|---|---|---|---|

9/32 | 4,300lbs. | 7,400lbs. | 6,100lbs. | 4,300lbs. |

5/16 | 5,700lbs. | 9,900lbs. | 8,100lbs. | 5,700lbs. |

3/8 | 8,800lbs. | 15,200lbs. | 12,400lbs. | 8,800lbs. |

1/2 | 15,000lbs. | 26,000lbs. | 21,200lbs. | 15,000lbs. |

5/8 | 22,600lbs. | 39,100lbs. | 32,000lbs. | 22,600lbs. |

3/4 | 35,300lbs. | 61,100lbs. | 49,900lbs. | 35,300lbs. |

7/8 | 42,700lbs. | 74,000lbs. | 60,400lbs. | 42,700lbs. |

1 Grade 80 | 47,700lbs. | 82,600lbs. | 67,400lbs. | 47,700lbs. |

1-1/4 Grade 80 | 72,300lbs. | 125,200lbs. | 102,200lbs. | 72,300lbs. |

You can also visualize these load capacities at different lifting angles in the chart below:

You rely on chain slings for their strength and adaptability. You can lift loads vertically or at an angle, but you must always check the rated capacity for your specific configuration. This helps you avoid overloading and ensures safe lifting operations.

Construction and Materials

You benefit from chain slings made with high-quality materials. Powerful Machinery uses alloy steel for its chain slings, which gives you high strength, durability, and corrosion resistance. The table below compares common materials used in sling construction and their impact on performance:

Material Type | Impact on Performance |

|---|---|

Alloy Steel | High strength, durable, resistant to corrosion, suitable for high temperatures. |

Synthetic Materials | Flexible, inexpensive, ideal for irregular loads, sensitive to heat and UV radiation. |

You achieve superior performance with alloy steel chain slings, particularly in harsh environments or when lifting at high temperatures. Powerful Machinery tests every sling to meet or exceed international standards.

You can trust their products because they hold certifications from organizations such as OSHA, NACM, ASTM, ISO, and ASME B30.9.1. These certifications guarantee that each chain sling meets strict safety and quality requirements.

Certification/Standard | Description |

|---|---|

OSHA | Compliance with Occupational Safety and Health Administration regulations. |

Federal NACM | Adherence to the National Association of Chain Manufacturers standards. |

ASTM | Compliance with American Society for Testing and Materials specifications. |

ISO | International Standards Organization requirements for design factors. |

ASME B30.9.1 | Specific requirements for alloy lifting chain assemblies, including proofloading and inspection protocols. |

Note: You must inspect your chain slings regularly and follow all safety guidelines. Proper inspection and maintenance help you extend the life of your equipment and keep your lifting operations safe.

Chain Sling Types

Powerful Machinery offers a complete range of chain sling configurations to match your lifting needs. You can select from single, double, triple, or quadruple leg designs, each engineered for specific applications and load capacities. Custom options are available to ensure you get the right solution for your project.

Single Leg Chain Sling

You use a single-leg chain sling for straightforward lifting tasks. This type handles lighter loads and works well when stability is not a major concern. You often see it in general material handling or when lifting items with a single attachment point.

2 Leg Chain Sling

A double-leg chain sling secures loads from two points. You gain better control and stability, especially when lifting heavy or oddly shaped items. You can adjust the angle of the legs to suit your lifting scenario, making this sling ideal for construction and manufacturing environments.

3 Leg Chain Sling

You choose a triple leg chain sling when you need to balance loads from three points. This design distributes weight more evenly, which helps stabilize heavy or irregularly shaped loads. You often use it for lifting large machinery or bulky components.

4 Leg Chain Sling

A quadruple leg chain sling is engineered for very heavy loads. You benefit from maximum stability and control, especially when handling extremely bulky or odd-shaped items. Industries such as construction, manufacturing, and transportation rely on this design for their toughest lifting challenges.

Tip: The more legs your chain sling has, the greater the load capacity and stability. Always check the rated capacity before lifting.

Type of Sling | Load Capacity Description | Applications Description |

|---|---|---|

Single Leg | Typically used for lighter loads; rated capacity varies based on the specific sling. | Suitable for general lifting tasks where stability is not a major concern. |

Double Leg | Designed to secure loads from two points, enhancing stability; rated for heavier loads. | Ideal for controlling heavy or oddly shaped loads, lifting at angles of 30°, 45°, and 60°. |

Triple Leg | Balances loads from three points, distributing weight effectively; higher load capacity. | Best for stabilizing heavy and odd-shaped loads, also lifting at angles of 30°, 45°, and 60°. |

Quadruple Leg | Engineered for very heavy loads, with a high load capacity, distributes weight across four points. | Perfect for extremely heavy, bulky, or odd-shaped loads, maximizing stability and control. |

Chain Sling Hook Types

You can equip your chain slings with a variety of hook types to suit different lifting tasks. Powerful Machinery provides options such as:

Slip hooks

Clevis shackles

Trigger kits

Swivel hooks

Weld-on hooks

Specialty rigging hooks

Chain hoist replacement hooks

Shank hooks

Hoist hooks

Foundry hooks

Grab hooks

Self-locking hooks

Sling hooks

Each hook type offers unique benefits for safety and usability. For example, self-locking hooks prevent accidental release, while grab hooks allow you to shorten the chain for precise load positioning. You should select the hook type based on your specific lifting requirements and safety standards.

Chain Slings Grades and Specifications

Grade 80 Chain Slings

You often choose Grade 80 chain slings for demanding lifting jobs. These slings use a special alloy steel that delivers high strength and durability. Powerful Machinery’s G80 Lifting Chain meets or exceeds major international standards, including ISO, ASTM, and OSHA.

You can trust these slings for overhead lifting, towing, and securing heavy loads. The black armor finish adds extra protection against wear and corrosion. Each sling comes with a certificate of conformity, so you know it meets strict safety requirements.

Grade 100 Chain Slings

When you need even more strength, you select Grade 100 chain slings. These slings are about 25% stronger than Grade 80. They use heat-treated alloy steel, which gives you better abrasion resistance and higher working load limits.

Grade 100 slings are ideal for hoisting and overhead lifting projects where safety and performance matter most. You benefit from lighter chains that still handle heavy loads.

Feature | Grade 80 | Grade 100 |

|---|---|---|

Strength | Standard for overhead lifting | Approximately 25% stronger than Grade 80 |

Material | Alloy mixture with black armor finish | Heat-treated alloy steel with better abrasion resistance |

Common Use | Towing, recovery, securing loads | Hoisting and overhead lifting projects |

Chain Sling Sizes

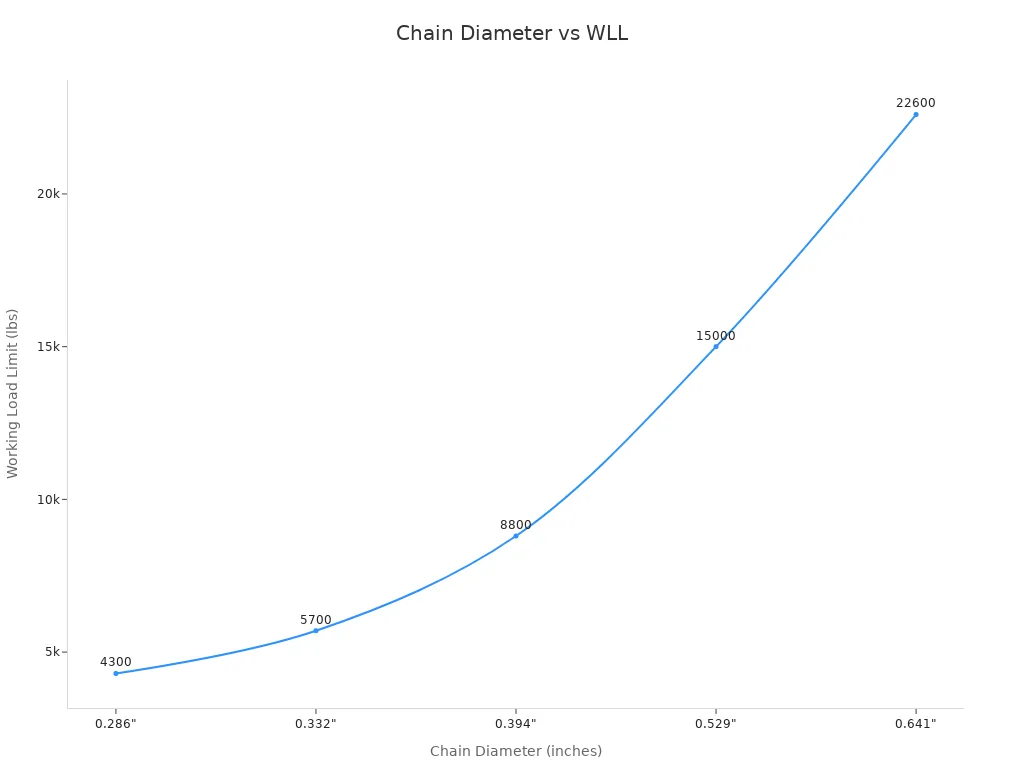

You must select the right chain sling size for your lifting task. The size, or diameter, of the chain directly affects its working load limit (WLL). Larger diameters support heavier loads. The table below shows how different sizes and grades impact WLL:

Chain Size | Material | Grade | Chain Diameter | WLL -lbs |

|---|---|---|---|---|

1/4″ | Alloy Steel | 100 | 0.286″ | 4,300 |

5/16″ | Alloy Steel | 100 | 0.332″ | 5,700 |

3/8″ | Alloy Steel | 100 | 0.394″ | 8,800 |

1/2″ | Alloy Steel | 100 | 0.529″ | 15,000 |

5/8″ | Alloy Steel | 100 | 0.641″ | 22,600 |

You can see from the chart below that as the chain diameter increases, the working load limit rises sharply:

Chain Sling Safety Factor

You always need to consider the safety factor when using chain slings. The safety factor is the ratio between the minimum breaking force and the working load limit. Powerful Machinery’s chain slings follow strict international standards, often using a 4:1 safety factor.

This means the chain can withstand four times its rated working load before breaking. You protect your team and equipment by never exceeding the working load limit and by choosing certified products.

Tip: Always check the identification tag for grade, size, and WLL before every lift. This simple step helps you avoid accidents and keeps your operation safe.

Advantages of Chain Slings

Strength and Durability

You rely on chain slings when you need unmatched strength and durability for heavy lifting. These slings use high-strength alloy steel, which resists wear and damage in tough environments. You can use them in steel mills, foundries, and other places where loads are heavy and conditions are harsh.

Chain slings do not stretch under load, so you maintain control and stability during every lift. If a chain sling gets damaged, you can repair and re-certify it, unlike wire rope slings that must be discarded. This repairability adds value and extends the life of your equipment.

Chain slings handle rugged conditions and maintain load integrity.

You can repair chain slings, which saves you time and money.

Chain slings excel in high-temperature and extreme applications.

Flexibility

You benefit from the flexibility of chain slings in your lifting operations. You can choose from single, double, triple, or quadruple leg designs to match your specific needs. Adjustable lengths and a variety of hook types allow you to lift loads of different shapes and sizes.

You can use chain slings for vertical lifts or at angles, giving you more options for complex tasks. This adaptability helps you work efficiently and safely.

Tip: Select the right configuration and hook type to maximize safety and performance for each lift.

Environmental Resistance

You gain confidence using chain slings in harsh environments. Powerful Machinery tests its chain slings for corrosion resistance using salt spray tests that last up to 600 hours. Zinc thermal diffused and powder-coated links achieve a rust rating of Ri0, showing no significant rust even after extended exposure.

You can use these slings outdoors or in areas with chemicals and moisture, knowing they will hold up over time.

Chain slings withstand extreme temperatures without losing effectiveness.

Advanced coatings protect against corrosion and rust.

Comparison with Other Slings

You see clear advantages when you compare chain slings to wire rope and synthetic slings. The table below highlights key differences:

Advantage | Chain Slings | Wire Rope Slings | Synthetic Slings |

|---|---|---|---|

Durability | Hold up in stressful climates | Susceptible to kinking and crushing | Lightweight, less durable |

Repairability | Easily repaired and re-certified | Must be discarded if damaged | Not repairable |

Longevity | Function in extreme temperatures | Can suffer from corrosion and heat | Not suitable for heavy-duty use |

Cost | Most expensive, but long-lasting | More economical, shorter lifespan | Least expensive, limited use |

You choose chain slings for their strength, adaptability, and resistance to environmental challenges. These features make them the preferred choice for demanding lifting tasks.

Selecting Chain Slings

Choosing the right chain sling ensures safe and efficient lifting. You need to consider several factors before making your selection.

Load Capacity

You must always match the sling’s capacity to your lifting needs. To determine the correct load capacity, follow these steps:

Consider the weight of the load.

Assess the shape of the load.

Evaluate the lift angle.

Choose a sling with a higher load capacity if you do not know the exact load weight.

Selecting a sling with the proper capacity helps you prevent accidents and equipment damage.

Configuration Choice

The configuration of your sling affects both stability and performance. Review the table below to compare the main options:

Sling Type | Benefits | Drawbacks |

|---|---|---|

Single-Leg | Simple for vertical lifts; versatile for securing | Limited stability for heavy loads |

Two-Leg | More stable; suitable for heavier objects | Requires more rigging knowledge |

Three-Leg | Most stable; ideal for heavy/irregular loads | Can be heavy; requires careful setup |

Four-Leg | Maximum stability; best for weighty objects | Heavier and bulkier; needs more space |

Adjustable | Versatile for different configurations | Complexity may lead to misuse |

You should select the configuration that matches your load type and lifting environment.

Sling Length

You need to choose the correct sling length for your application. Measure the distance from the lifting point to the load’s attachment point. The right length allows you to maintain safe lifting angles and avoid overloading any leg of the sling.

Attachment Points

You must identify secure attachment points on both the load and the lifting device. Proper attachment ensures balanced lifting and reduces the risk of shifting or dropping the load. Use hooks or connectors that fit your equipment and meet safety standards.

Certification and Tag Requirements

Regulations require that all chain slings have permanent identification tags. These tags provide essential information for safe use. Review the table below for key requirements:

Requirement | Description |

|---|---|

Identification Tags | All slings must have identification tags/labels permanently attached. |

Effective Date | This regulation has been in effect since June 8, 2011. |

Applicability | The regulation applies to slings sold and used in the United States. |

Employers must keep a record of the most recent inspection for each alloy steel chain sling. You should make these records available for examination when needed.

You can find detailed specifications and selection support for Chain Slings on Powerful Machinery’s product pages. This helps you make informed decisions and ensures compliance with industry standards.

Safe Use of Chain Slings

Powerful Machinery puts safety first in every product. You benefit from chain slings that meet strict international standards, including OSHA, ASME, and ISO. You must follow best practices to ensure safe lifting operations and protect your team.

Preparation

You start every lift with careful preparation. Inspect your chain slings for signs of wear, deformation, or corrosion. Check the identification tag for grade, size, and working load limit. Make sure all hooks, shackles, and connectors are secure and undamaged.

You select the right sling configuration for your load and confirm that the lifting equipment is rated for the task. You plan the lift path and clear the area of obstacles. You communicate with your team to coordinate each step.

Tip: Always inspect your equipment before each use. A quick check can prevent accidents and keep your operation running smoothly.

Load Handling

You handle loads with precision and care. Follow these best practices to minimize risk and ensure safety:

Choose stable lifting points to keep the load balanced.

Use padding or edge protectors to prevent chains from contacting sharp edges.

Select the appropriate hitch, such as vertical, choker, or basket, based on the load type.

Utilize tag lines to guide and control the load’s movement.

Inspect securement tools, including hooks and shackles, to ensure proper attachment.

Follow industry standards and ensure all personnel receive proper training.

You keep the load steady and avoid sudden movements. You never stand under a suspended load.

Connection Methods

You connect chain slings to loads using the right methods. Use hooks, shackles, or master links that match the load and sling configuration. Make sure each connection is secure and free from defects.

You avoid side-loading hooks, which can weaken the connection. You use self-locking hooks for added safety when needed. You double-check every attachment before lifting.

Connection Type | Best Use Case | Safety Note |

|---|---|---|

Hook | General lifting | Avoid side loading |

Shackle | Heavy or irregular loads | Ensure pin is tight |

Master Link | Multi-leg sling assemblies | Inspect for wear and cracks |

Sling Angles

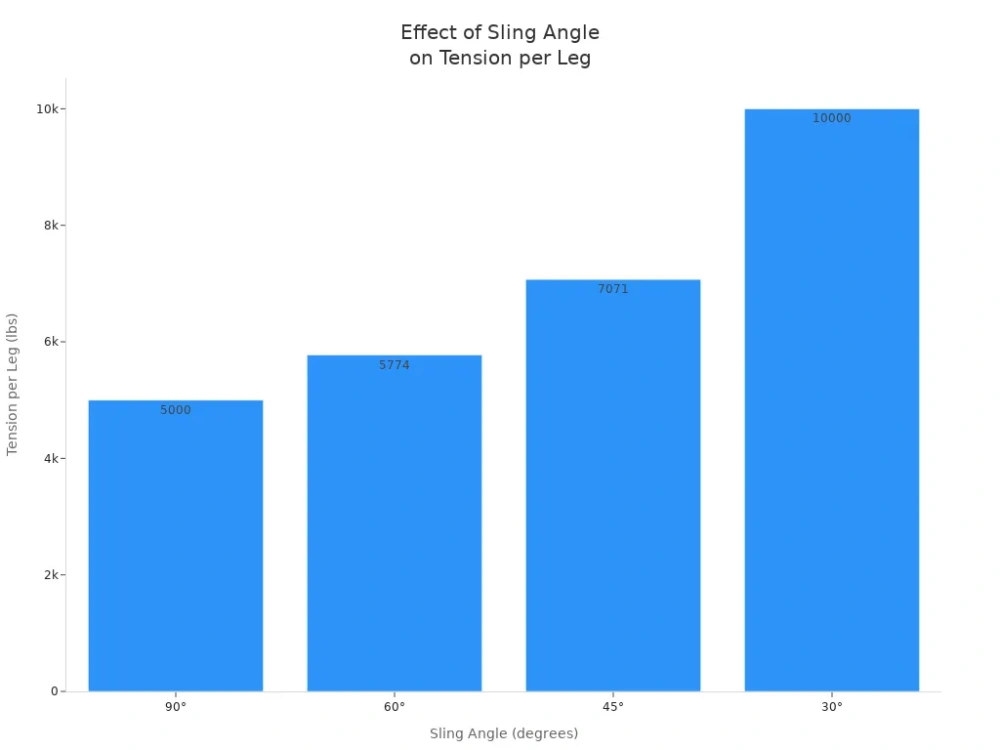

You pay close attention to sling angles during every lift. The angle between the sling legs and the vertical affects the tension on each leg. As the angle decreases, the tension increases sharply, which can create unsafe conditions. For example, at a 60° angle, the tension per leg is about 5,774 lbs.

At 30°, the tension jumps to 10,000 lbs per leg. You maintain sling angles of 60° or greater to keep the forces within safe limits.

Sling Angle | Tension per Leg (lbs) | Load Distribution |

|---|---|---|

90° | 5,000 | Half the load |

60° | 5,774 | 15% higher than vertical |

45° | 7,071 | More than 7,000 lbs |

30° | 10,000 | Whole load per leg |

You always check your sling angles before lifting. You adjust the sling length or attachment points to maintain safe angles.

Note: As the sling angle decreases from vertical, the tension on each leg increases. You must keep sling angles as large as possible to avoid dangerous conditions.

Working Load Limit

You respect the working load limit (WLL) of your chain slings at all times. The WLL is the maximum load the sling can safely handle. Exceeding this limit can lead to serious accidents, material damage, legal consequences, or even fatalities.

The WLL helps prevent overloaded equipment and reduces the chance of catastrophic failure. You never use equipment beyond its WLL to avoid sudden failure and injury.

Exceeding the WLL can cause sudden equipment failure.

You protect your team by staying within the rated limits.

You check the identification tag for WLL before every lift.

Safety Guidelines

You follow safety guidelines recommended by international standards to keep your lifting operations safe. Daily inspections by a competent person are required. Periodic inspections must occur at least once every 12 months, as specified by OSHA. You maintain records of all inspections for each sling.

You review rigger responsibilities and ensure everyone on your team understands their role.

Guideline/Change | Description |

|---|---|

New Appendix A | Nonmandatory guidelines for sling protection |

Rigger Responsibilities | Outlines the responsibilities of riggers |

Inspection Frequency | Inspect slings in severe service before each use |

Record Maintenance | Maintain records of periodic inspections |

Inspection Protocol | Daily and periodic inspections by competent persons |

You conduct daily inspections and record findings.

You schedule periodic inspections and keep records up to date.

You consult Powerful Machinery for advice on specific lifting scenarios or custom solutions.

Safety is your responsibility. You protect your team and equipment by following best practices and consulting experts when needed.

Inspection and Maintenance

Regular inspection and maintenance keep your chain slings safe and reliable. Powerful Machinery subjects every chain sling to rigorous testing and certification, ensuring you receive products that meet international safety standards.

You protect your investment and extend the lifespan of your equipment by following best practices for inspection and storage.

Inspection Checklist

You should use a detailed checklist during each inspection. This process helps you identify issues before they become hazards. Review the table below for essential inspection items:

Item Number | Inspection Item Description |

|---|---|

04 | Provide the sling identification number. |

05 | Note the load capacity of the sling. |

06 | Inspect for visible damage such as cuts, frays, or corrosion. |

07 | Check the sling’s hardware for any signs of damage. |

08 | Ensure that the sling is properly labeled. |

09 | Record any defects found during inspection. |

10 | Sign and date the record to confirm the inspection completion. |

Tip: Always document your inspection results. Accurate records help you track the condition of each sling.

Frequency

You must inspect chain slings at intervals based on service conditions. The table below outlines recommended inspection frequencies:

Service Condition | Inspection Frequency |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified Person |

You increase inspection frequency when slings operate in harsh environments.

Common Defects

During inspection, you look for defects that compromise safety. Common issues include:

Defective welds or weld spatter

Signs of deformation, breaks, or cracks

Excessive corrosion or pitting

Bent, twisted, or stretched links and fittings

Inability of the chain or fittings to articulate freely

Increased chain length

Evidence of heat damage

Cracked or opened hooks

Twisted hooks beyond safe limits

You remove any sling with these defects from service immediately.

Repair and Replacement

You must follow strict procedures when repairing or replacing chain slings:

Proof test new, repaired, or reconditioned slings before use.

Never use worn or damaged slings until they pass inspection and proof testing.

Avoid mechanical coupling links or low-carbon steel repair links for broken chain lengths.

Remove slings with cracked or deformed components from service.

Take out any chain with undersized links.

Professional repair services inspect and proof test each sling to verify strength and reliability.

Storage Best Practices

Proper storage extends the life of your chain slings. You should:

Store slings off the ground to prevent damage.

Keep slings in a cool, dry, and dark place.

Clean slings regularly to remove dust and moisture.

Avoid chemically active environments.

Use edge protection during lifting to prevent wear.

Note: Regular inspection and proper storage help you maintain safety and maximize the lifespan of your chain slings.

Environmental Considerations

Temperature Limits

You must consider temperature limits when using chain slings in demanding environments. Powerful Machinery designs chain slings to perform in extreme conditions. Many chain slings can withstand temperatures up to nearly 1000 degrees Fahrenheit.

This capability makes them suitable for steel factories, foundries, and heavy machinery workshops. You should always check the manufacturer’s specifications before lifting in high-temperature areas. If you exceed the recommended temperature range, you risk catastrophic failures and reduced sling performance.

Chain slings operate safely up to 1000°F.

You use them in steel mills and heavy industry.

Exceeding temperature limits can cause sling failure.

Tip: Always inspect your chain slings after exposure to high heat. Look for signs of discoloration, deformation, or loss of strength.

Chemical Exposure

You face chemical hazards in many industrial settings. Powerful Machinery’s chain slings resist corrosion and chemical attack due to advanced coatings and alloy steel construction. You can use these slings outdoors or in environments with moisture, acids, or alkalis.

However, some chemicals may still affect the integrity of the sling over time. You should avoid prolonged exposure to aggressive chemicals and clean your slings regularly.

Chemical Type | Recommended Action |

|---|---|

Acids | Rinse and inspect often |

Alkalis | Store in dry conditions |

Saltwater | Use corrosion-resistant slings |

Note: If you notice rust, pitting, or surface damage, remove the sling from service and consult a qualified inspector.

Manufacturer Consultation

You encounter unique challenges in extreme environments. Powerful Machinery offers expert guidance for custom lifting solutions. You should contact the manufacturer when planning lifts in high-temperature or chemically active areas.

The team can recommend the best chain sling grade, coating, and configuration for your application. You gain peace of mind by using certified products designed for harsh conditions.

Consult Powerful Machinery for custom solutions.

Request advice for lifts in extreme temperatures or chemical exposure.

Rely on certified chain slings for safety and reliability.

Alert: Never use chain slings outside their specified limits without manufacturer approval. Your safety depends on proper selection and expert advice.

Conclusion

You ensure safe lifting when you choose certified, high-quality chain slings. Regular inspection and proper maintenance protect your team and equipment. Adhering to safety standards reduces risk and increases reliability.

Select chain slings with trusted certifications.

Inspect and maintain your equipment consistently.

Consult Powerful Machinery for custom solutions and expert guidance.

For expert advice or tailored lifting solutions, reach out to Powerful Machinery. You gain confidence and safety with every lift.

FAQ

What industries use chain slings most often?

You see chain slings in construction, manufacturing, shipping, and transportation. These industries rely on chain slings for lifting heavy loads, securing cargo, and handling materials in demanding environments.

How do you inspect a chain sling before use?

You check for visible damage, wear, or deformation. You confirm the identification tag is readable. You inspect hooks and connectors for cracks or bends. You remove any sling with defects from service immediately.

Can you use chain slings outdoors or in harsh environments?

You use chain slings outdoors and in harsh conditions. Powerful Machinery designs chain slings with corrosion-resistant coatings and high-strength alloy steel. You trust them for reliable performance in extreme temperatures and chemical exposure.

How do you choose the right chain sling configuration?

You match the sling configuration to your load type and lifting needs. Single-leg slings work for simple lifts. Multi-leg slings provide stability for heavy or irregular loads. You consult product specifications for safe selection.

What certifications should you look for in chain slings?

You look for certifications such as OSHA, ISO, ASTM, and NACM. These certifications ensure your chain sling meets strict safety and quality standards. You check the identification tag for compliance information.