A lifting sling is a vital tool that helps you move heavy loads safely and efficiently in industries like construction, manufacturing, and logistics. You will find several types of slings in the workplace, each designed for unique tasks and environments. The table below shows the most common types and their key features:

Sling Type | Material | Key Characteristics | Common Applications |

|---|---|---|---|

Polyester | Polyester | Lightweight, flexible, moisture and UV-resistant | Manufacturing, logistics, construction |

Nylon | Nylon | Superior elasticity, strength, cushioning effect | Shipping, automotive, heavy machinery |

Steel | Steel | High strength, durable, heat and abrasion-resistant | Mining, oil & gas, construction |

Chain | Alloy Steel | Exceptional load capacity, adjustable, heat-resistant | Foundries, steel mills |

Choosing the best lifting slings for your job protects workers and equipment. Powerful Machinery stands out as a trusted source for certified solutions, offering enhanced safety and improved productivity, as echoed by customers worldwide.

Key Takeaways

Lifting slings are essential tools for safely moving heavy loads in various industries, including construction and manufacturing.

Choosing the right type of lifting sling, such as polyester, nylon, or steel, enhances safety and efficiency during lifting operations.

Regular inspection and maintenance of lifting slings are crucial to prevent accidents and ensure reliable performance.

Understanding the working load limit (WLL) of slings helps avoid overload and protects both the load and the lifting team.

Proper training and adherence to safety practices are vital for effective use of lifting slings in any industrial setting.

What is a Lifting Sling?

Definition and Function

A lifting sling is a specialized tool that helps you move, lift, or position heavy objects safely. You will find lifting slings in many industries, including construction, manufacturing, and logistics. These tools connect a load to a lifting device, such as a crane or hoist.

The main purpose of a lifting sling is to support and stabilize the load during lifting operations.

You can choose from several types of lifting slings, each designed for specific tasks and environments. Some slings use synthetic materials, while others use steel or chain. The right lifting sling protects both the load and the workers. When you select the correct sling, you reduce the risk of accidents and damage.

The primary functions of lifting slings in industrial settings include:

Function/Characteristic | Description |

|---|---|

Load Support | Synthetic lifting slings can support heavy loads effectively. |

Material Benefits | Their soft material provides better load protection compared to traditional wire ropes. |

Customization | The strength and dimensions can be tailored to meet specific industrial needs. |

Scratch and Cut Resistance | Made from tough synthetic fibers, they resist scratches and cuts when dragged over sharp edges. |

Safety Features | They are non-conductive and non-flammable, making them safe for use in explosive environments. |

You can see that lifting slings offer more than just strength. They also provide safety and flexibility. The use of lifting slings allows you to handle a wide range of loads, from fragile items to bulky machinery.

Key Benefits for Industry

Lifting slings bring many advantages to your workplace. You can use them to improve efficiency, safety, and cost savings. The best lifting slings match your specific needs and help you complete tasks faster and with less risk.

Here are some documented benefits of using lifting slings in heavy industry:

Benefit | Description |

|---|---|

Versatility | Lifting slings come in various materials and models, suitable for different applications. |

Durability | Designed to withstand harsh conditions, they have a high breaking strength for heavy loads. |

Cost-effectiveness | Require less maintenance and can be reused, leading to long-term savings for businesses. |

Applications | Used in various industries for lifting steel beams, moving furniture, and transporting watercraft. |

You will notice that lifting slings adapt to many tasks. You can use them for lifting steel beams on a construction site or moving delicate equipment in a factory. Their durability means you do not need to replace them often, which saves money over time.

The use of lifting slings also improves safety and efficiency in your operations. In construction and infrastructure projects, you can achieve a 15% increase in operational efficiency and a 20% reduction in load handling time. In manufacturing, lifting slings help decrease equipment downtime by 10%.

They also enhance precision and safety when you handle components.

Tip: Always match the type of lifting sling to your specific task. This ensures the highest level of safety and performance.

When you understand the key benefits and functions of lifting slings, you can make better choices for your projects. You will protect your team, your equipment, and your bottom line by using the right lifting sling for every job.

Types of Lifting Slings

You will find several types of lifting slings in the market. Each type has unique features that make it suitable for specific tasks and environments. Choosing the right sling type helps you achieve safe and efficient lifting operations. Here is a quick overview:

Category | Description |

|---|---|

Wire Rope Slings | Made from wire ropes, suitable for heavy loads. |

Composed of chains, ideal for rugged applications. | |

Synthetic Slings | Made from synthetic materials, lightweight and flexible. |

You can also group the main types of lifting slings as follows:

Wire rope slings

Chain Slings by Powerful Machinery

Chain slings stand out for their strength and durability. You can use them for lifting heavy and abrasive loads in tough environments. Powerful Machinery offers chain slings made from high-strength alloy steel. These slings come in single, double, triple, and quadruple leg designs.

You can adjust their length and choose from different hooks and attachments. Chain slings work best in steel manufacturing, shipbuilding, and construction.

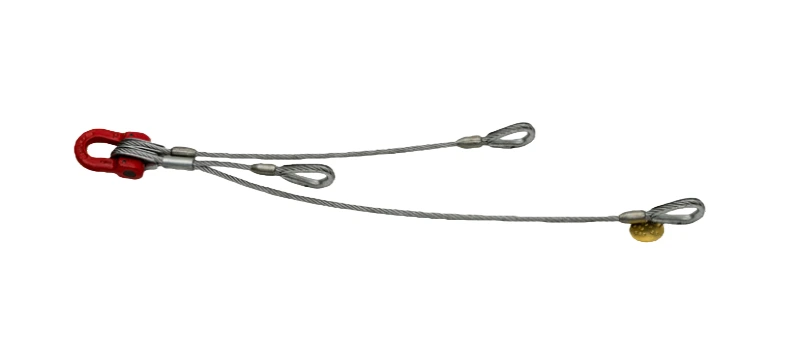

Wire Rope Slings

Wire rope slings use steel wires twisted together for extra strength. You will find them in construction and manufacturing, where you need to lift very heavy loads. These slings resist abrasion and handle rough surfaces well.

They are a good choice when you need a balance of flexibility and durability. However, you should avoid using them with delicate or easily damaged loads.

Flat Web Slings

Flat web slings are made from strong polyester webbing. You will notice their wide, flat design helps spread the load evenly. This reduces pressure on the lifted object. Flat web slings are lightweight, flexible, and easy to handle. You can use them for lifting fragile or finished items.

Powerful Machinery provides flat web slings that meet strict safety standards. You can select custom lengths and reinforced eyes for extra durability. Flat web slings are color-coded for easy identification.

Round Webbing Slings

Round webbing slings use a continuous loop of polyester yarn. You will find them soft and flexible, making them ideal for lifting irregular or delicate loads. The outer sleeve protects the internal fibers from wear. These slings are color-coded by capacity and offer high strength with low weight.

Powerful Machinery’s round webbing slings meet international standards and come with clear labeling for safety.

Specialty and Textile Slings

Some lifting slings use advanced synthetic fibers or special designs for unique tasks. Specialty slings include one-way lifting slings and high-performance textile slings. You can use these types for specific lifting needs, such as handling sensitive equipment or working in environments with strict safety requirements.

Powerful Machinery offers a range of specialty slings to match your project.

Tip: Always match the sling type to your load and environment. The right choice improves safety and extends the life of your lifting slings.

You will see that the best lifting slings depend on your application. Each type of lifting sling offers different advantages. By understanding sling types, you can select the safest and most effective option for your job.

Lifting Sling Materials

Choosing the right sling materials helps you achieve safe and efficient lifting operations. You will find that each type of material offers unique advantages for different environments and tasks. Powerful Machinery uses certified materials that meet strict international standards, giving you confidence in every lift.

Alloy Steel Chains

Alloy steel chains give you high strength and durability. You can use these slings in harsh environments, such as steel mills or construction sites. Alloy steel resists corrosion, chemicals, and UV exposure.

You can repair these chains if they get damaged, which adds value over time. However, alloy steel chains feel heavy and may not suit delicate loads.

Galvanized Wire Rope

Galvanized wire rope slings work well for heavy-duty lifting. You will notice that wire rope resists abrasion and handles rough surfaces. Galvanization protects the steel from moisture, reducing the risk of corrosion. These slings perform best in outdoor or marine settings.

You should inspect the wire rope regularly because moisture and extreme temperatures can weaken the structure.

Polyester and Nylon Webbing

Polyester and nylon webbing slings offer flexibility and strength. You can use these slings for lifting fragile or irregularly shaped loads. Polyester resists abrasion and UV rays, while nylon provides extra elasticity. Both materials feel lightweight and easy to handle.

You should avoid exposing these slings to harsh chemicals or sharp edges.

Advanced Synthetics

Advanced synthetics, such as high-performance fibers, give you lightweight and versatile lifting slings. These materials protect delicate loads and work well in specialized applications. You will find advanced synthetics useful in industries where weight and flexibility matter most.

You should keep these slings away from high heat and chemicals to maintain their performance.

Material Suitability and Selection

You need to match sling materials to your environment and load type. The table below compares the main options:

Material Type | Advantages | Disadvantages |

|---|---|---|

Alloy Steel Chains | High-strength, durable, flexible, repairable, resistant to corrosion, chemicals, and UV exposure | Heavy, can damage sensitive parts, more expensive than other options |

Synthetic Slings | Lightweight, flexible, protects delicate loads, inexpensive, versatile | Low heat-resistance, susceptible to cuts and tears, not as durable as steel |

Polyester/Nylon Slings | Strong, flexible, inexpensive, and can mold to irregular shapes | Different resistance characteristics to chemicals, not repairable |

Environmental factors also affect sling performance:

Environmental Factor | Impact on Sling Performance |

|---|---|

Moisture | Causes corrosion, weakening the structural integrity of wire rope slings. |

Temperature Extremes | High heat can evaporate lubricants and weaken materials; low temperatures can make steel brittle. |

Chemical Exposure | Degrades synthetic materials, leading to fiber weakening and potential failure. |

UV Radiation | Causes fading and brittleness in synthetic fibers, reducing service life. |

Abrasive Environments | Leads to wear and damage, affecting the lifespan of slings. |

You should always choose lifting slings that meet international standards. Powerful Machinery’s products comply with ISO guidelines, including ISO 4309 for wire rope and ISO 16881 for steel wire ropes. These certifications help you select the best lifting slings for your project.

Tip: Always inspect your slings before use and store them properly to extend their service life.

How to Choose a Lifting Sling?

Selecting the best lifting slings for your project requires careful planning. You must consider the load, environment, equipment, and safety standards. Powerful Machinery offers customizable solutions to help you choose your sling with confidence.

Follow this step-by-step guide to make the right decision for your lifting operations.

Assessing Load and Application

Start by understanding the load you need to lift. You must know the weight, shape, and delicacy of the object. This information helps you choose your sling with the correct working load limit and design. Consider these steps:

Determine the weight and strength of the load. Always check the working load limit (WLL) of the sling.

Identify the center of gravity. The shape and design of the load affect how you position the sling for safe lifting.

Inspect for sharp edges. If the object has sharp corners, select chain or wire rope slings to prevent damage.

Evaluate the flexibility needed. Some loads require slings that conform to irregular shapes, such as round webbing slings.

Tip: Always match the sling type to the load and lifting operations. This reduces the risk of accidents and protects both the load and your team.

Environmental Considerations

The environment plays a major role in choosing the right sling. You must assess where you will use the sling and what conditions it will face. Consider these factors:

Temperature: High heat can weaken synthetic slings. Alloy steel chains perform better in extreme temperatures.

Moisture: Wet environments may cause corrosion in wire rope slings. Polyester slings resist moisture and UV rays.

Chemicals: Exposure to chemicals can degrade synthetic fibers. Use steel or chain slings in chemical plants.

Abrasive surfaces: Rough surfaces can wear down slings quickly. Choose durable materials for these settings.

Powerful Machinery provides slings designed for harsh environments. You can select materials that match your specific needs and ensure safe lifting operations.

Working Load Limit (WLL)

The working load limit is the maximum weight a sling can safely lift. You must always check the WLL before starting any lifting operations. Each type of sling has a different design factor and capacity. The table below shows typical WLL ranges:

Type of Sling | Design Factor | Capacity Example |

|---|---|---|

Alloy Chain Slings | 4:1 | 1/2” single-leg Grade 100 = ~15,000 lbs WLL |

Wire Rope Slings | 5:1 | 1/2″ 6×19 IWRC single-leg = ~2.5 tons WLL |

Synthetic Web Slings | 5:1 | 2” wide, 2-ply polyester sling (vertical) = ~6,400 lbs |

Round Slings | N/A | Typically, provide flexibility and conformity |

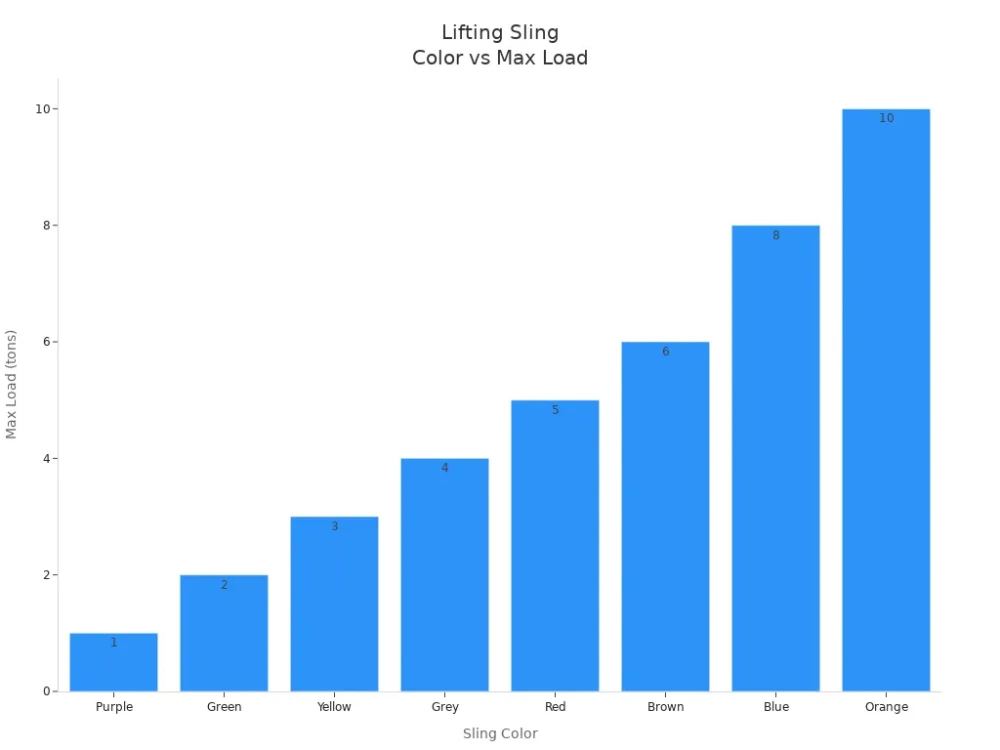

Color-coding makes it easy to identify the WLL of synthetic slings. The table below shows common color codes and their maximum loads:

Color | Maximum Load |

|---|---|

Purple | 1 ton |

Green | 2 tons |

Yellow | 3 tons |

Grey | 4 tons |

Red | 5 tons |

Brown | 6 tons |

Blue | 8 tons |

Orange | 10 tons or more |

You must always check the sewn-in label on the sling. The label shows the working load limit and confirms compliance with safety standards. Never rely only on color. Verify the label and documentation before use.

Note: Powerful Machinery’s slings come with clear labels and certifications. This ensures you meet international safety standards in every lift.

Compatibility with Equipment

You must ensure the sling fits your lifting equipment. Check the hooks, shackles, and master links for compatibility. The sling should attach securely to cranes, hoists, or other lifting devices. Consider these points:

Sling length: Choose a length that allows safe positioning and load balance.

Attachments: Select hooks or connectors that match your equipment.

Equipment capacity: Make sure your lifting device can handle the weight of the load and sling.

Powerful Machinery offers customizable slings and hardware. You can request specific lengths, attachments, and configurations to fit your project.

Safety Reminder: Always inspect your equipment and slings before each use. Replace any damaged parts immediately.

Step-by-Step Guide to Choosing Your Sling

Follow these steps to select the best lifting slings for your job:

Assess the load’s weight, shape, and delicacy.

Evaluate the environment for temperature, moisture, chemicals, and abrasion.

Check the working load limit using color codes and sewn-in labels.

Confirm compatibility with your lifting equipment.

Review certifications and safety factors. Powerful Machinery’s products meet ISO and EN standards.

Consult with experts if you have unique requirements. Powerful Machinery provides custom-engineered solutions for complex lifting operations.

The combination of color codes and sewn-in labels gives you instant visual references for load capacities. This system reduces the risk of accidents and ensures you use the right sling every time.

Tip: When you know how to choose the right sling, you protect your team and equipment. You also improve efficiency and safety in your lifting operations.

Lifting Sling Safety and Best Practices

You must follow strict lifting sling safety procedures to protect your team and equipment. Using best practices for using lifting slings helps you avoid accidents and ensures reliable operations. Here are the main areas you should focus on:

Proper Rigging Techniques

You should always use the correct rigging methods when attaching slings to loads. Make sure you balance the load and secure all connections. Check that hooks, shackles, and master links fit properly. Never twist or knot slings. Use edge protection if you lift items with sharp corners.

This prevents cuts and extends the life of your lifting slings.

Sling safety tips: Always inspect the rigging setup before lifting. Replace any damaged parts right away.

Personnel Training

Only trained personnel should handle lifting slings. Training must cover how to select the right sling, check for damage, and understand load limits. You should also learn about sling angles and safe rigging practices. Regular training keeps everyone aware of hazards and helps you follow the best safety standards.

Learn how to store and care for slings.

Practice regular checks before each use.

Stay updated on new safety guidelines.

Load Monitoring and Angles

You need to monitor the load during every lift. Watch for shifting or swinging. Always keep the load within the working load limit. Pay attention to sling angles, as they affect the force on each leg of the sling. Smaller angles increase tension and risk. Use the best rigging angle for your setup to keep operations safe.

Sling safety tips: Never exceed the rated capacity. Adjust the rigging if the load is unstable.

Edge Protection and Prohibited Actions

Sharp edges can damage synthetic slings quickly. Always use edge protection or barriers to prevent cuts. Never drag slings on the ground or use them to pull stuck loads. Do not repair damaged synthetic slings. Replace them if you see any signs of wear or if the identification label is missing.

Common Cause of Failure | How to Prevent It |

|---|---|

Improper Installations | Follow proper rigging procedures |

Overload | Stay within working load limits |

Damaged Synthetic Slings | Inspect and replace as needed |

Stretched or Bent Links | Remove from service immediately |

You should always choose certified lifting slings from trusted suppliers like Powerful Machinery. Their products meet international safety standards and come with clear documentation. Regular inspections, proper training, and following best practices keep your workplace safe and efficient.

Maintenance and Inspection of Lifting Slings

Keeping your lifting slings in top condition protects your team and equipment. You need to follow a clear routine for maintenance, inspection, and storage. This ensures every lift is safe and reliable.

How Often Do Slings Need to Be Inspected?

You should inspect lifting slings before each use. Daily checks help you spot damage or defects early. OSHA and other safety standards require:

Inspect slings, fastenings, and attachments before daily use.

Perform additional inspections if conditions change or if you notice anything unusual.

Schedule periodic inspections at least once every 12 months for normal service.

Increase inspection frequency to monthly or quarterly for slings used in severe conditions.

Remove any damaged or defective sling from service immediately.

Sling Inspection Criteria

You must know what to look for during regular inspections. Use this checklist to guide you:

Check for missing or unreadable identification tags.

Look for visible damage, such as cuts, fraying, or knots.

Inspect for heat or chemical damage.

Examine hooks and fittings for cracks, deformation, or excessive wear.

Remove slings from service if you see any of these issues.

Inspection Criteria | Description |

|---|---|

Visual Inspection | Make sure all parts are visible and clean. |

Removal Criteria | Take slings out of service if you find any damage. |

Damage Types | Watch for broken wires, severe abrasion, or corrosion. |

Cleaning and Storage

Proper sling cleaning and storage extend the life of your equipment. For upkeep, follow these steps:

Clean synthetic slings with warm water and mild soap. Use a wire brush for wire rope slings.

Store slings in a clean, dry, and temperature-controlled area.

Hang or lay slings flat to prevent tangling or crushing.

Keep slings away from chemicals, sunlight, and extreme temperatures.

Tip: Regular inspections and proper storage help you avoid early wear and keep your lifting slings ready for use.

Repair and Disposal

Never repair damaged slings yourself. If you find a worn or defective sling:

Tag it with “DO NOT USE.”

Cut the eye and fittings to prevent accidental reuse.

Cut wire rope slings into smaller pieces before disposal.

Remove all tags and labels before recycling.

Always follow manufacturer guidelines and use certified products for safe lifting operations.

Industrial Applications of Lifting Slings

Lifting slings play a vital role in many industries. You will see them used in construction, manufacturing, warehousing, marine, transportation, and logistics. Each sector relies on industrial lifting slings to move heavy loads safely and efficiently.

Powerful Machinery supplies certified lifting solutions that meet the demands of these environments. Their products support a wide range of lifting applications, making them a trusted choice for professionals worldwide.

Construction and Building

You often use lifting slings in construction to lift, lower, and move suspended loads. These tools attach to cranes and hoists, helping you handle heavy materials and equipment on job sites. Common sling applications in construction include:

Moving steel beams and concrete panels

Lifting prefabricated structures

Positioning large machinery

Lifting slings make your work safer and more efficient. Powerful Machinery’s industrial lifting slings withstand harsh site conditions and provide reliable performance for every lift.

Manufacturing and Warehousing

In manufacturing and warehousing, lifting slings help you move heavy loads with ease. You can reduce labor costs because slings minimize manual handling. Their lightweight design makes them easy to use and increases efficiency.

You can adjust webbing slings for different load shapes and sizes, which streamlines your operations. Typical lifting sling applications in these settings include:

Transferring delicate components without damage

Supporting robotic systems for precise handling

Moving car parts quickly in assembly plants

Powerful Machinery’s industrial lifting slings offer compatibility with various lifting equipment, helping you maintain a smooth workflow.

Marine, Transportation, and Logistics

Marine and logistics industries face unique challenges. You need slings that resist corrosion and perform well outdoors. The table below shows the best sling types for different environments:

Environment Type | Recommended Sling Type |

|---|---|

Outdoor or Marine | Corrosion-resistant wire ropes or synthetic slings |

High-Temperature Areas | Chain slings with heat-resistant coatings |

High-Cycle Use | Heavy-duty wire rope slings, grade 100 chain slings |

You should always check the sling label and working load limit before each lift. Inspect slings for damage and use edge protection for sharp corners. Proper storage and handling extend the life of your lifting slings.

Powerful Machinery’s products deliver the reliability you need for demanding marine and logistics operations.

Note: The versatility and strength of industrial lifting slings from Powerful Machinery ensure you can tackle any lifting challenge across industries.

Conclusion

You play a key role in keeping your workplace safe when you understand lifting slings and their proper use. Always inspect slings before use, check load capacity, and use correct lifting techniques. Protect slings from sharp edges and store them properly. Training helps you stay safe and confident.

Powerful Machinery gives you certified solutions and expert support for every lifting challenge.

Inspect slings for damage before each use.

Check load capacity to prevent overload.

Use proper lifting techniques for stability.

Protect slings from sharp edges.

Store and handle slings correctly.

Invest in operator training.

FAQ

What is the difference between a chain sling and a web sling?

You use chain slings for heavy, rugged loads. They resist heat and abrasion. Web slings work best for delicate or finished items. They offer flexibility and protect surfaces.

How do you know which lifting sling to choose?

You check the load weight, shape, and environment. You read the working load limit on the label. You match the sling type to your lifting equipment and task.

How often should you inspect lifting slings?

You inspect slings before every use. You schedule a detailed inspection at least once a year. You increase inspection frequency for slings used in harsh conditions.

Can you repair a damaged lifting sling?

You should never repair a damaged sling yourself. You must remove it from service and replace it with a certified product. This keeps your lifting operations safe.