If you work with lifting or rigging equipment, you may wonder what a master link is. A master link forms the central connection point in chain slings or wire rope assemblies, ensuring secure attachment and even weight distribution.

Selecting the right master link keeps your operations safe and efficient. Powerful Machinery delivers certified master links trusted by professionals in demanding industries worldwide.

Key Takeaways

A master link is essential for safe lifting. It connects different parts of a lifting assembly and ensures even weight distribution.

Always check the load rating of your master link before use. This step helps prevent accidents and ensures safe operations.

Inspect your master link regularly for wear or damage. Regular checks keep your lifting equipment safe and reliable.

Choose the right type of master link based on your lifting needs. Consider the chain type, load requirements, and safety standards.

Powerful Machinery offers certified master links that meet strict safety standards. Trust their products for strength and durability in demanding environments.

What is a Master Link?

Definition and Function

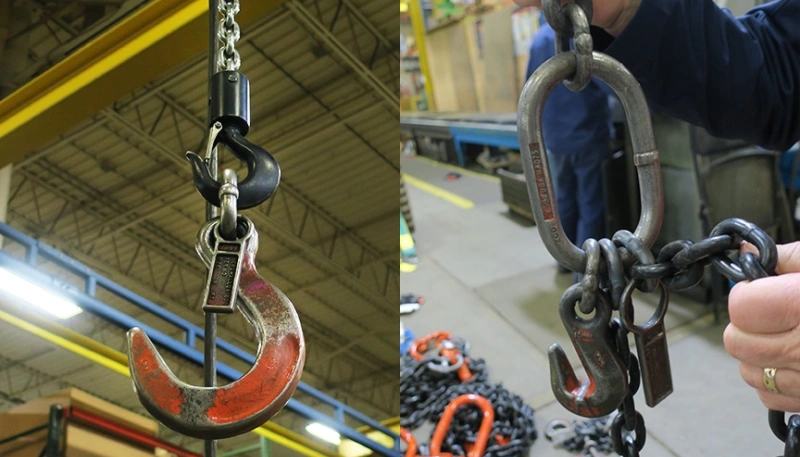

When you ask what a master link is, you look for the foundation of safe lifting and rigging. A master link is a heavy-duty metal loop that connects different parts of a lifting assembly. You often see it at the top of a chain sling or wire rope sling.

The master link acts as the main control point, holding everything together and ensuring the load stays balanced during lifting.

You might wonder what a master link’s mechanical role is in a chain assembly. The answer is simple. Master links serve as the primary components in the construction of lifting slings, whether single-leg or multiple-leg.

They function as control links, designed in an oblong shape to ensure even load distribution. This design helps prevent twisting or overloading, which keeps your lifting operation safe.

Powerful Machinery stands out as a trusted manufacturer of certified master links. The company uses high-grade alloy steel and advanced heat treatment to create links that meet the strictest industry standards. You can rely on their products for strength, durability, and consistent performance in demanding environments.

Tip: Always check what a master link’s load rating is before use. This step helps you avoid accidents and ensures your lifting system works as intended.

Common Uses in Lifting and Rigging

You will find the master link in many lifting and rigging applications. Its versatility makes it a key part of safe material handling. Here are the most common uses:

Used in chain slings

Employed with wire rope slings

Utilized in synthetic sling connections

Important for load-balancing applications

Integral in crane and hoist rigging

When you select a master link, you want to know it meets global safety standards. Powerful Machinery ensures every master link passes rigorous testing and certification. The table below shows how the company’s products comply with international requirements:

Evidence Description | Certification Standards |

|---|---|

Products meet or exceed global safety standards | EN and ISO standards |

Products tested to meet or exceed ASME B30.26 | ASME B30.26 and international standards |

Rigorous testing guarantees maximum safety and reliability | International standards |

If you ever ask yourself what a master link is, remember its role as the backbone of your lifting assembly. It connects, balances, and secures your load, making every lift safer and more efficient. Powerful Machinery’s expertise in manufacturing certified master links gives you confidence in every operation.

Why the Right Master Link Matters?

Safety and Reliability

You need to select the correct master link to keep your lifting operations safe. The right choice prevents accidents and protects your team. Each chain in your assembly relies on the master link to distribute weight evenly. If you use the wrong size or type, you risk overloading the chain or causing a dangerous imbalance.

Safety standards guide you in making the right selection. These standards ensure that every master link and chain combination meets strict requirements for strength and durability.

Standard | Description | Key Requirements |

|---|---|---|

ASME B30.26 | Rigging Hardware | 5:1 design factor, proof loading, temperature limits |

EN 1677 | Components for Slings | 4:1 design factor, material, and mechanical properties |

ISO 8539 | Forged Steel Lifting Components | Covers chain sling components, harmonized with EN standards |

Powerful Machinery’s master links meet or exceed these global standards. You can trust their products to deliver consistent safety and reliability in every lift. Their certifications show a commitment to quality that protects both people and equipment.

Tip: Always inspect your master link before each use. Look for signs of wear or damage to maintain the highest level of safety.

Performance in Industrial Applications

The master link serves as the critical connection point in your lifting system. It influences how the chain handles the load and how safely you can operate. When you connect master link components correctly, you ensure smooth load distribution and prevent dangerous stress points.

A well-chosen master link fits the hoist’s hook and matches the chain’s capacity. If you use a clip-type master link or any other type, make sure it matches your application’s needs.

In industrial settings, the master link must handle the combined load from all sling legs. The angle of each chain affects the tension, making the master link the most stressed part of the assembly. If it fails, the entire load could drop. That is why you must understand the properties and limits of each master link you use.

Powerful Machinery’s reputation for certified, high-quality products gives you peace of mind in demanding environments.

Types of Master Links

G80 Links by Powerful Machinery

When you need a reliable connection in your lifting system, G80 links from Powerful Machinery deliver unmatched strength and safety. These links use high-strength Grade 80 alloy steel and meet strict EN and ISO standards. You benefit from a durable powder-coated finish that resists corrosion and wear.

G80 links fit multi-leg chain sling assemblies and work seamlessly with G80 Omega Hooks and other lifting hooks. The superior alloy steel construction ensures toughness and a long service life. You can trust these links for demanding lifting operations, knowing they comply with international safety standards.

Attribute | Description |

|---|---|

Grade | High-strength Grade 80 alloy steel, EN and ISO compliant |

Finish | Powder-coated for corrosion and wear resistance |

Compatibility | Fits multi-leg chain sling assemblies and various hooks |

Safety Compliance | Meets EN and ISO safety standards |

Oblong, Pear-Shaped, and Master Link Assemblies

You will find several shapes and assemblies when you select a master link for your rigging setup. Each type serves a specific purpose:

Oblong master links work best at the top of multiple-leg chain sling assemblies. They collect sling legs into a single link, ensuring even load distribution.

Pear-shaped links fit smaller assemblies with two legs or fewer. Their shape provides a snug fit for hooks and controlled load alignment.

Master link assemblies, also called collector rings, gather multiple sling legs into one connection point. These assemblies prevent crowding and help balance heavy loads.

Link Type | Description | Applications |

|---|---|---|

Master Links | Elongated, oval shape for even load distribution | Single-leg setups, three- or four-leg sling configurations |

Pear-shaped Links | Wider at one end, ideal for a snug hook fit | Single-leg or two-leg sling assemblies |

Oblong Links | Allows multiple sling legs to fit neatly | Chain, wire rope, and synthetic slings |

One-Time Use vs Reusable Master Links

You must choose between one-time use and reusable master links based on your application. One-time use links work best in critical situations, such as racing or high-speed cycling, where safety is the top priority. You should replace these after each use to avoid failure. Reusable links suit casual riding or maintenance tasks.

You can use them multiple times, but you must inspect them regularly for wear.

“Our 10- and 11-speed PowerLocks are one-time use only, because as they are removed, there’s enough deformation at the interface where the pin clicks into the plate that a second install will not be as secure.”

If you need to connect master link components in a chain, always match the link type to your load and safety requirements. For some applications, a clip-type master link offers quick assembly and removal, but always follow manufacturer guidelines for safe use.

Master Link Applications

Industrial and Construction Chains

In industrial and construction settings, you rely on the master link to connect heavy-duty chains, wire ropes, and hooks. After cutting the chain to the right length, wrap it around the sprockets with care. Insert the connecting link through the chain ends if you use a master link.

Make sure the clip faces the correct way to avoid dislodgment. Check that all links move freely and the chain is not twisted during installation.

Matching the grade of the master link with the chain grade is crucial. Using a master link rated lower than the chain can cause failure. The chain should always fail first, giving you a warning before any major issue occurs. Powerful Machinery provides specialized solutions for these demanding environments.

Their master links come in various sizes and capacities, built to handle the stresses of lifting and rigging heavy loads. You can trust their products for both industrial and specialized applications, ensuring safety and efficiency on every project.

Note: Always inspect your master link and chain before each use. Regular checks help prevent accidents and extend the life of your equipment.

Choosing a Master Link

You must select the right master link for your lifting or rigging system. Begin by assessing the type of chain and the load requirements. Each chain has unique properties, and the master link must match these specifications for safe operation.

You need to consider the configuration of your sling assembly. Master links for multiple leg slings require correct configuration to ensure stability.

Review the standards and ratings for your components. Differences in standards can affect the performance and safety of your lifting system. Always check that the master link fits the connections to slings and hooks. Strength is critical.

The master link must be strong enough to handle the load, with a breaking load factor of at least 4:1 under Australian standards. Proof testing is essential. Look for a matching tag and proof test certificate when you receive master links as part of a sling assembly.

The table below summarizes the key factors you should assess before selecting a master link:

Factor | Description |

|---|---|

Configuration | Master links for multiple leg slings must be correctly configured. |

Standards/Ratings | Differences in standards and ratings must be considered when selecting components. |

Fit | They must fit their correct connections to slings and hooks. |

Strength | They must be sufficiently strong, with a breaking load factor of 4:1 under Australian standards. |

Proof Testing | Look for a matching tag and proof test certificate for master links delivered as part of a sling assembly. |

Tip: Always verify the chain grade and master link rating before installation. This step helps prevent accidents and ensures proper master link installation.

Master Link Inspection

Inspection Steps and Safety Tips

You must inspect your master link regularly to maintain safety and durability in every lifting operation. Start by checking the identification markings. If you find missing or illegible identification, do not use the link. Examine the surface for heat damage, such as weld spatter or arc strikes.

Look for excessive pitting or corrosion, which can weaken the metal. Make sure all components remain straight and free from bends or twists. Surface nicks or gouges can also reduce durability, so inspect carefully.

Use the table below as a quick reference during your inspection:

Inspection Step | Description |

|---|---|

Missing or illegible identification | Check for proper identification on the shackle. |

Indications of heat damage | Look for weld spatter or arc strikes. |

Excessive pitting or corrosion | Inspect for signs of corrosion. |

Bent, twisted, distorted components | Ensure load-bearing components are not deformed. |

Excessive nicks or gouges | Check for surface damage. |

10% reduction in dimensions | Measure for any significant wear. |

Incomplete pin engagement | Verify that the pin is fully engaged. |

Excessive thread damage | Inspect threads for wear. |

Unauthorized modifications | Look for signs of welding or alterations. |

Visible damage | Any other damage that raises safety concerns. |

Safety note: Always follow manufacturer guidelines and refer to installation diagrams when inspecting or assembling your master link. This practice helps you avoid mistakes and keeps your equipment in top condition.

Powerful Machinery recommends routine inspections before each use. Their certified products undergo strict quality checks, but your regular maintenance ensures ongoing safety and durability.

When to Replace a Master Link?

You should replace your master link if you notice any of the following issues:

Elongation of the chain

Insecure fit of the master link

Chain sagging beyond acceptable limits

If you see any of these signs, do not attempt a temporary fix. Remove the damaged link and install a new one. For a bicycle, always thread the new chain through the drivetrain and use a fresh master link for every replacement. This step guarantees safety and extends the life of your equipment.

Powerful Machinery’s master links are engineered for long-term durability, but even the best hardware needs replacement after heavy use or visible damage. Regular inspections and timely replacement keep your lifting systems safe and reliable.

Conclusion

You improve safety and efficiency when you choose and maintain certified master links. Keep these key points in mind:

Select certified lifting chains and master links based on grade, configuration, and load requirements.

Inspect your equipment before each use and maintain proper documentation.

Store, clean, and lubricate your links to extend service life.

Powerful Machinery’s G80 Links offer robust welded construction and precision strength for demanding jobs.

For expert guidance, Powerful Machinery provides dedicated customer care, on-site support, and a seamless online experience to help you select the right master link for every application.

FAQ

What is the main purpose of a master link?

A master link connects multiple sling legs or lifting components. You use it to distribute weight evenly and ensure safe lifting in rigging systems.

How do you choose the correct master link size?

Measure your chain diameter and hook opening. Use Powerful Machinery’s sizing charts to match these measurements. Always select a master link with a working load limit that meets or exceeds your application’s requirements.

Can you reuse a master link after heavy lifting?

You can reuse a master link if it passes inspection. Check for cracks, deformation, or excessive wear. Replace the link if you find any damage or if it fails to meet safety standards.

Does Powerful Machinery offer technical support for product selection?

Yes! You can contact Powerful Machinery’s technical team for guidance. They help you choose the right master link and provide custom solutions for unique lifting needs.