You rely on electric chain hoists to lift and move heavy loads with speed and accuracy. These hoists use electric motors and advanced components to handle the weight of the load efficiently, making them essential in factories and construction sites.

With global market growth projected at 4.3% CAGR and a value nearing $3 billion by 2028, electric chain hoists continue to drive automation and safety in lifting applications. Powerful Machinery stands out as a trusted provider, offering certified electric hoist solutions that deliver versatility in various industries.

The application of electric chain hoists extends across multiple sectors, supported by robust safety devices and innovative types of electric chain hoists. You benefit from precise control, the reliable working principle of electric chain hoists, and durable components designed for demanding applications.

Key Takeaways

Electric chain hoists are essential for lifting heavy loads quickly and safely in various industries.

Regular inspections and maintenance of key components, like the lifting chain and safety clutch, ensure optimal performance and safety.

Advanced safety features, such as real-time monitoring and automated limit switches, enhance operational safety and reduce risks.

Choosing the right electric chain hoist involves understanding your load capacity, safety ratings, and specific application needs.

Staying updated on technological advancements, like IoT integration, can improve efficiency and safety in lifting operations.

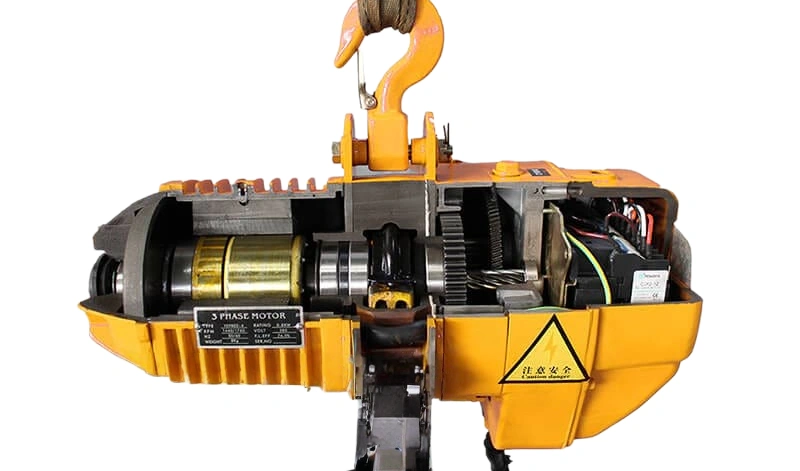

Electric Chain Hoist Parts

Key Components and Their Functions

You depend on electric chain hoists to deliver consistent performance in demanding environments. Understanding the main components of electric chain hoists helps you maximize their efficiency and ensure safe operation.

Powerful Machinery designs each hoist with precision, focusing on durability and compliance with international standards.

Lifting Chain

This is the core load-bearing element. The lifting chain carries the weight and enables vertical movement. Powerful Machinery uses high-strength alloy chains to support heavy lifting capacity and resist wear.Sprocket

The sprocket engages with the lifting chain. It allows smooth movement and reduces friction, which is essential for reliable operation and long service life.Rope Guide

The rope guide keeps the lifting chain aligned during operation. It prevents tangling and ensures smooth lifting, which is vital for safety and maintaining lifting capacity.Safety Clutch

The safety clutch protects the hoist and the load. It prevents lifting loads that exceed the maximum lifting capacity, reducing the risk of equipment damage.Lifting Motor

The lifting motor provides the power needed to raise heavy loads. Powerful Machinery equips its hoists with robust motors to deliver stable performance and support wide applications across industries.Limit Technology

Limit switches stop the hoist at designated points. This prevents overtravel and ensures safe operation, especially when handling loads near the maximum lifting capacity.

Tip:

You should regularly inspect these key components to maintain optimal performance and safety. Powerful Machinery offers technical support and spare parts to help you keep your equipment in top condition.

Safety Features and Controls

Safety features play a crucial role in preventing accidents and protecting both operators and equipment. Powerful Machinery integrates advanced safety systems into every electric chain hoist, ensuring compliance with international standards and reliable operation.

Safety Feature | Description |

|---|---|

Real-time Monitoring Systems | Provides immediate feedback on equipment status, alerts to potential issues like overheating or excessive load. |

Automated Limit Switches and Sensors | Prevents over-travel and detects hazardous conditions, enhancing reliability and safety. |

Remote Operation Capabilities | Reduces risk by allowing operation from a safe distance, improving control and oversight. |

You benefit from these safety features, which help you maintain control and reduce risks in every lifting task. Powerful Machinery’s electric chain hoists meet rigorous certifications, ensuring reliability and performance in wide application scenarios.

Certification/Standard | Description |

|---|---|

CE | Meets EU safety standards. |

ISO9001:2000 | Ensures quality management. |

ASME 30.5 | Mobile crane safety. |

ASME 30.4 | Pedestal and portal crane safety. |

ANSI/ASME 30.2 | Overhead and gantry crane safety. |

OSHA 1926.1400 | Construction crane safety. |

You can trust Powerful Machinery to deliver electric chain hoists that combine robust components, advanced safety features, and certified quality. These hoists support high lifting capacity and wide application, making them a reliable choice for your material handling needs.

Types and Working Principles

Types of Electric Chain Hoists

You encounter several types of electric hoists in industrial settings. Powerful Machinery offers single-phase and three-phase models, electric trolley hoists for horizontal movement, and low headroom hoist for tight spaces.

Each electric hoist suits specific tasks and environments. The table below compares common hoist types and their applications:

Type of Hoist | Application Description |

|---|---|

Chain Hoists | Handle heavier loads in rigorous environments. |

Wire Rope Hoists | Excel in high-speed and long-lift applications. |

Rope Hoists | Adapt to various lifting tasks based on project needs. |

You select the electric hoist that matches your lifting requirements, ensuring efficiency and safety.

How Does an Electric Chain Hoist Work?

You operate an electric hoist using a control pendant. The electric motor starts the lifting process, converting electrical energy into mechanical force. The gearbox modifies this force, delivering high torque at low speed for heavy loads. You control the speed and direction with the pendant, achieving precise movement.

Safety systems protect you and your equipment. The brake engages automatically when the motor stops, preventing accidental descent. Limit switches halt the electric hoist at maximum or minimum heights, avoiding damage and ensuring safe operation.

Service Classifications and Specifications

You rely on electric hoist specifications to match your workload. Powerful Machinery provides an electric hoist with customizable lifting capacity, height, and speed. The table below outlines key specifications and service classifications:

Specification/Classification | Details |

|---|---|

Lifting Capacity | 1t to 32t (customizable up to 50t) |

Lifting Height | 6m to 48m |

Lifting Speed | 0.4/1.2 to 2.4/11.8m/min |

Working Class | M3, M4, M5 |

Ambient Temperature | -20°C to 40°C |

Service Class H4 | High-volume handling, 300 starts/hour |

Service Class H3 | General shop, 150 starts/hour |

Service Class H2 | Light loads, 75 starts/hour |

You choose the electric hoist that fits your application, considering capacity, speed, and duty cycle. Powerful Machinery ensures every electric hoist meets international standards for performance and reliability.

Applications and Advantages

Industrial Uses of Electric Chain Hoists

You see electric chain hoists in many industries. These electric lifting equipment excel in manufacturing, warehousing, and construction. You use them for shifting engines, lifting transformers, moving dies, handling injection mold tools, hoisting turbines, and transporting steel coils.

Powerful Machinery’s electric chain hoists deliver reliable performance in each application. The table below shows where you benefit most from electric chain hoists:

Industry | Application Requirements |

|---|---|

Manufacturing | Load stability, safety features, and optimized suspension methods |

Warehousing | Efficient load handling, safety mechanisms |

Construction | High load capacities, robust safety features |

Key Benefits and Productivity

You improve productivity with electric chain hoists. This electric lifting equipment reduces fatigue and cycle times during repeated lifting tasks. You achieve consistent output, which leads to predictable cycle times and standardized workflows. Operators guide loads instead of lifting them, increasing efficiency.

Electric chain hoists also enhance safety. Smooth operation reduces physical shock and mental fatigue, creating a calmer work environment. You stay alert and precise, lowering the risk of mistakes. The table below highlights the benefits you gain from electric chain hoists:

Benefit Type | Description |

|---|---|

Productivity | Electric chain hoists improve productivity by reducing fatigue and cycle times in repeated lifts. |

Consistency | Electric hoists provide consistent output, leading to predictable cycle times and standardized workflows. |

Operator Efficiency | Operators shift from lifting to guiding loads, enhancing efficiency during frequent or heavy lifts. |

Technological Advancements

You experience advanced technology in modern electric chain hoists. IoT integration enables real-time monitoring and diagnostics, helping you plan maintenance and improve safety. Smart controls automate tasks and improve precision.

Variable frequency control regulates motor speed, ensuring smooth acceleration and deceleration. You avoid sudden movements that could cause load swing. Automation and robotics integration boost operational efficiency.

Facility managers make data-driven decisions, and operators view real-time information without risking safety. Active safety management and optimized motion control enhance operational safety. Real-time data collection and analysis improve efficiency and maintenance planning.

Electric chain hoists from Powerful Machinery meet international standards, ensuring compliance and quality in every application.

Ensuring Safety and Maintenance

Safety Considerations and Best Practices

You must prioritize safety every time you operate electric chain hoists. Following safety precautions protects you, your team, and your equipment. Here are essential guidelines for ensuring safety:

Conduct routine inspections before each use. Check for visible damage and cleanliness.

Lubricate moving parts regularly to reduce friction and wear.

Clean the hoist after every operation to maintain performance.

Inspect the load chain for damage and keep it lubricated.

Check electrical components for signs of wear or damage.

Ensure all operators receive proper training.

Schedule annual professional servicing.

Perform regular load tests to confirm safe operation.

Keep detailed records of all inspections and maintenance.

Tip: Proper training and consistent record keeping help you maintain a reliable electric chain hoist and reduce risks.

Electric Chain Hoist Inspection and Maintenance Tips

You can extend the lifespan of your equipment by following these maintenance tips. Preventive maintenance keeps your hoist in optimal condition and reduces downtime.

Key Aspect | Description |

|---|---|

Preventive Maintenance | Keeps the hoist efficient and productive for longer periods. |

Early Issue Detection | Identifies problems early, avoiding costly repairs. |

Downtime Reduction | Prevents unexpected breakdowns and keeps your operations running smoothly. |

Regular cleaning prevents dust and grease buildup. Early detection of wear or damage improves performance and longevity. Always use high-quality chains and lubricants for the best results.

Electric Chain Hoist Troubleshooting

When you face operational issues, follow these troubleshooting steps:

Check power supply connections to ensure the hoist receives electricity.

Inspect switch circuits for overheating or mechanical damage.

Measure the voltage supply with a voltmeter to confirm it is within range.

Address brake issues by checking for worn parts or loose hardware.

Inspect for gearbox oil leakage, looking for worn seals or loose bolts.

Check for motor malfunctions such as overheating, blown fuses, or wiring errors.

If you cannot resolve the issue, contact a qualified technician or Powerful Machinery’s support team.

Selecting the Right Electric Chain Hoist

Choosing a reliable electric chain hoist requires careful consideration. You should:

Understand your load capacity needs and select a hoist that exceeds them for safety.

Check safety ratings and certifications, such as ANSI or ASME.

Assess your operating environment, including temperature and humidity.

Look for innovative features like overload protection and ergonomic controls.

Consider customization options from Powerful Machinery to match your unique requirements.

Feature | Description |

|---|---|

Compatibility with Materials | Handles a range of materials, from textiles to heavy steel. |

Flexibility for Future Needs | Upgrades and adjustments available for changing production demands. |

Custom Handling Systems | Tailored solutions improve automation and reduce labor costs. |

You ensure long-term value and safety by choosing a reliable electric chain hoist that fits your application.

Conclusion

Electric chain hoists play a vital role in modern industry. You rely on them for safe, efficient lifting in sectors like automotive, logistics, and metals processing.

They use a motor-driven chain system with key parts such as the motor, gearbox, and safety hook.

Compliance with OSHA and ASME standards ensures reliability.

You improve safety and productivity by choosing certified equipment and following regular maintenance. Powerful Machinery offers tailored solutions and ongoing support. Stay updated on smart controls and variable speed features to maximize performance and protect your investment.

FAQ

What is an electric chain hoist?

You use an electric chain hoist to lift and lower heavy loads with an electric motor and a strong chain. Powerful Machinery designs these hoists for factories, warehouses, and construction sites. You benefit from precise control and reliable performance.

How do you operate an electric chain hoist safely?

You inspect the hoist before each use. You follow load limits and use the control pendant for smooth operation. You keep the area clear and ensure proper training for all operators. Powerful Machinery includes safety features like limit switches and overload protection.

What maintenance does an electric chain hoist require?

You clean the hoist regularly. You lubricate the chain and moving parts. You check for wear or damage. You schedule annual professional servicing. Powerful Machinery offers technical support and spare parts to help you maintain your equipment.

How do you choose the right electric chain hoist?

You assess your load capacity, lift height, and duty cycle. You check certifications and safety features. You consider your workspace and power supply. Powerful Machinery provides customizable options to match your specific needs.