You may wonder what a grade 70 chain is. This high-strength chain, made for transport and cargo securement, helps you keep heavy loads safe during transit. Using the right chain prevents accidents, as improperly secured loads cause about 25% of truck-related incidents.

Common mistakes include choosing the wrong size, failing to tighten, or skipping equipment checks. Always follow manufacturer instructions and FMCSA guidelines. Powerful Machinery, a trusted name in high-performance chains, ensures you get reliable products for every job.

Key Takeaways

Grade 70 chain is designed for securing heavy loads during transport, making it essential for safety in trucking and towing.

Always check for the ‘G70’ stamp on the chain to ensure it meets the required strength and safety standards.

Inspect your chain regularly for wear or damage to prevent accidents and ensure reliable performance.

Never exceed the working load limit of your chain to avoid failure and potential hazards during transport.

Use appropriate accessories like clevis grab hooks and load binders to enhance the safety and effectiveness of your chain system.

What is Grade 70 Chain?

Definition and Main Uses

When you ask what grade 70 chain is, you look for a chain that stands out for its strength and reliability. Grade 70 chain, also called transport chain, is a high-strength chain designed for securing heavy loads during transport.

You find this chain specified by NACM and ASTM standards, which set the rules for its size, strength, and safety. These standards make sure you use a chain that meets strict requirements for cargo securement.

Manufacturers use heat-treated carbon steel to make grade 70 chain. This material gives the chain extra strength and durability. You often see this chain used in trucking, towing, and agriculture. Truck drivers use it to tie down large equipment or secure cargo on flatbeds.

Farmers use it to haul machinery or move heavy loads around the farm. Towing professionals rely on it to pull vehicles safely. When you choose a grade 70 chain, you pick a tool built for tough jobs.

Tip: Always check the markings on your chain. Grade 70 chain usually has a “G70” stamp, so you know you have the right chain for the job.

Powerful Machinery’s G70 Transport Chain

You want a chain that delivers both performance and safety. Powerful Machinery’s G70 Transport Chain gives you both. This chain uses heat-treated high-carbon steel, which means you get a product that lasts longer and resists wear.

The yellow zinc coating adds abrasion resistance and helps prevent rust, so your chain stays strong even in harsh weather.

Here is a quick look at what makes Powerful Machinery’s G70 Transport Chain a top choice:

Feature | G70 Transport Chain by Powerful Machinery |

|---|---|

Grade | G70 (Grade 70) |

Material | Heat-treated high-carbon steel |

Abrasion Resistance | Yellow (gold) chrome coating |

Working Load Limit (WLL) | Rated for heavy load securing |

Recommended Applications | Load securement, towing, agriculture, transport |

Prohibition | Not for overhead lifting |

You also want to know that your chain meets important safety standards. Powerful Machinery’s G70 Transport Chain complies with these certifications:

Certification/Standard | Description |

|---|---|

U.S. DOT | Meets regulations for cargo securement |

WSTDA | Complies with Web Sling & Tie Down Association |

OSHA | Adheres to Occupational Safety and Health rules |

When you choose Powerful Machinery, you get more than just a chain. You get a product trusted by professionals in construction, transportation, and agriculture. You also get peace of mind, knowing your chain meets the highest standards for safety and performance.

If you want to learn more about what a grade 70 chain is or see the full range of options, you can visit the Powerful Machinery G70 Transport Chain page.

Key Features of Grade 70 Chain

Material and Construction

When you choose a grade 70 chain, you get a product built for strength and reliability. Manufacturers use high-strength carbon steel to make this chain. The steel goes through a heat treatment process that boosts its toughness and durability.

This process makes the chain about 20% stronger than a grade 43 chain, which means you can trust it to secure heavy loads safely.

The chemical makeup of the steel gives the chain its unique properties. Here is a table showing the typical elements found in the steel:

Element (Symbol and Name) | Percentage Range (%) |

|---|---|

C (Carbon) | 0.65 – 0.75 |

Mn (Manganese) | 0.60 – 0.90 |

Si (Silicon) | 0.15 – 0.40 |

P (Phosphorus) | ≤ 0.04 |

S (Sulfur) | ≤ 0.05 |

The carbon content, around 0.70%, increases the hardness and toughness of the chain. The heat treatment process locks in these qualities, so you get a chain that stands up to tough jobs. You also notice a yellow zinc finish on the grade 70 chain.

This coating adds a layer of protection against rust and corrosion, making the chain last longer even in harsh weather.

Note: The yellow zinc finish not only protects the chain but also helps you identify it quickly during inspections.

Working Load Limit and Strength

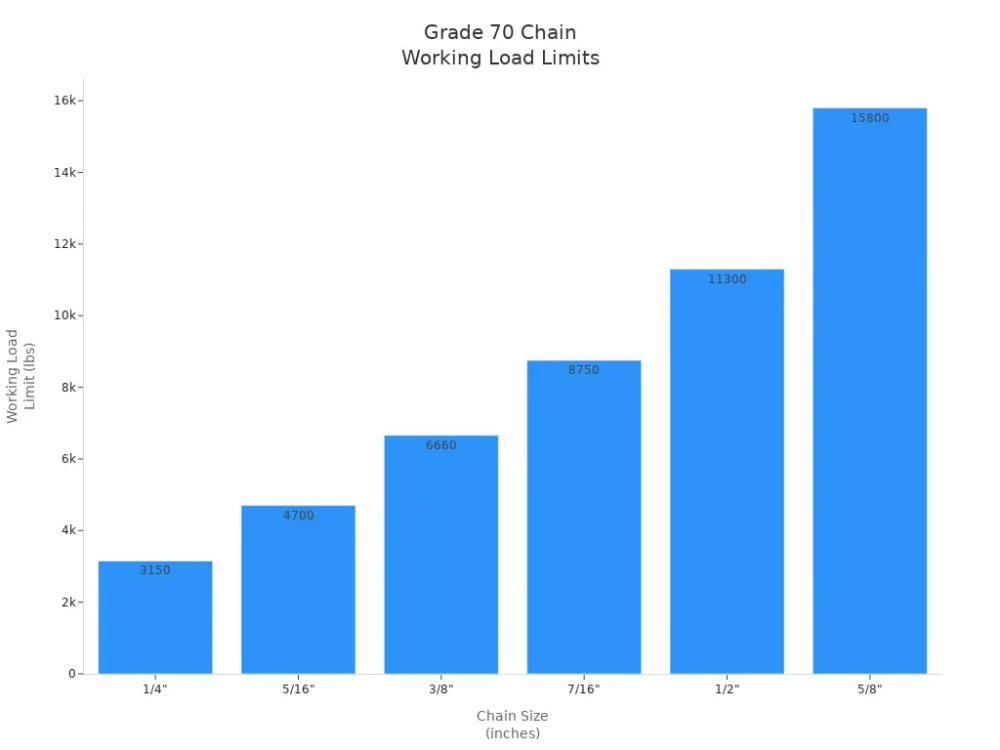

You need to know how much weight your chain can handle. The working load limit tells you the maximum weight you can safely secure with the chain. This number depends on the size of the chain. For grade 70 chain, the working load limit is much higher than that of lower-grade chains.

Here is a table showing the working load limit for different chain sizes:

Chain Size | Grade 70 Working Load Limit (lbs) |

|---|---|

1/4″ | 3,150 |

5/16″ | 4,700 |

3/8″ | 6,660 |

7/16″ | 8,750 |

1/2″ | 11,300 |

5/8″ | 15,800 |

The minimum breaking force is another important number. For example, a 1/2 inch grade 70 chain must have a minimum breaking strength of 45,200 lbs. A 7/16 inch chain must break at no less than 35,000 lbs.

These numbers show you how much force the chain can take before it fails. Always use the working load limit, not the breaking force, when you secure cargo. This keeps you and your load safe.

Tip: Never exceed the working load limit of your chain. Overloading can cause the chain to fail and lead to accidents.

Powerful Machinery’s G70 Transport Chain meets or exceeds all industry standards for strength and safety. The chain is tested to ensure it matches the required working load limit and breaking force for each size. You can rely on these chains for demanding jobs in transport, construction, and agriculture.

Corrosion Resistance and Markings

You want your chain to last, even when exposed to rain, mud, or chemicals. Grade 70 chain comes with a yellow zinc coating that resists corrosion. This finish keeps the chain strong and reliable, even after months of outdoor use.

The coating also makes the chain easy to spot during inspections, which helps you stay compliant with safety rules.

Proper markings help you identify the right chain for the job. Grade 70 chain must have clear markings on each link. Look for these marks:

Marking Type | Description |

|---|---|

7 | Embossed on the link |

70 | Embossed on the link |

D7 or D70 | May include a letter before the number, indicating the manufacturer’s ID code |

These markings show you that the chain meets grade 70 standards. They also help inspectors verify that you use the correct chain for cargo securement. Powerful Machinery ensures every chain is properly marked and finished, so you can work with confidence.

Alert: Always check for proper markings before using any chain for load securement. Missing or unclear markings can lead to compliance issues and safety risks.

With these features, grade 70 chain stands out as a top choice for anyone who needs strength, durability, and safety in cargo control.

Compatible Accessories and Applications

Hooks and Load Binders

When you use a grade 70 chain, you need the right accessories to ensure safe and secure operations. The clevis grab hook is the most common hook for this type of chain. You attach it easily to the chain links, which lets you adjust the length or create a tight connection.

Clevis grab hooks work well for heavy-duty jobs, such as securing steel coils or large equipment.

Load binders are another essential accessory. You use them to tighten the chain and keep your cargo from shifting during transport. There are two main types: lever binders and ratchet binders. Lever binders use a simple lever action, while ratchet binders let you tighten the chain gradually for more control.

Always choose a load binder with a working load limit that matches or exceeds your chain’s rating. For example, if your chain has a safe working load of 6,600 pounds, your binder should meet or exceed this number.

Powerful Machinery offers a full range of hooks and load binders designed for grade 70 chain. Each accessory meets strict safety standards, including a 4:1 safety factor recommended by the National Association of Chain Manufacturers.

These products also comply with DOT and CVSA regulations, so you stay compliant during inspections.

Tip: Always inspect your hooks and binders before each use. Look for signs of wear or damage to keep your chain system safe.

Common Applications for Grade 70 Chain

You find grade 70 chain in many industries because of its strength and reliability. Here are some of the most common uses:

Load securement: You use the chain to tie down heavy cargo on trucks and trailers.

Towing: The chain helps you pull vehicles or equipment safely.

Construction: You rely on the chain to move building materials or secure machinery.

Agriculture: The chain is useful for hauling farm equipment or fencing supplies.

Logging: You use the chain to drag logs or anchor equipment in the field.

Each application requires a chain that can handle tough conditions. Powerful Machinery’s grade 70 chain stands up to these demands, giving you confidence in every job. When you pair the chain with the right hooks and binders, you create a secure system that protects your cargo and meets industry standards.

Note: Never use grade 70 chain for overhead lifting. Always follow the manufacturer’s guidelines for safe use.

Safety and Usage Guidelines

Inspection and Maintenance

You must inspect your chain before every use. Regular checks help you spot problems early and keep your cargo secure. Look for signs of wear or damage that could make the chain unsafe. Use this table to guide your inspection:

Damage Type | Description | Required Action |

|---|---|---|

Stretched or Bent Links | Links that look longer or bent from too much force | Replace the chain immediately |

Cracks and Gouges | Cracks or deep marks, especially near stress points | Replace the chain immediately |

Hook and Connector Damage | Hooks or connectors that are bent, open, or have latch problems | Replace the damaged part immediately |

You should also check for rust, missing markings, or any deformities. If you find any of these issues, remove the chain from service. Always keep your chain clean and store it in a dry place. This helps prevent corrosion and extends the life of your chain.

International safety standards require that all tie-down equipment, including your chain, stay in good working condition. The working load limit must match the weight of your cargo. You must secure all attachments to prevent loosening during transport.

Powerful Machinery tests every chain to meet or exceed global safety standards, so you can trust your equipment in the field.

Proper Use and Overhead Lifting Warning

You need to use your chain only for its intended purpose. Grade 70 chain is made for load securement and towing, not for overhead lifting. Using it for lifting can lead to serious accidents. Always follow this warning:

Grade 70 chain is not rated or approved for overhead lifting. Use only Grade 80 or higher for lifting tasks.

If you use the chain for overhead lifting, you risk injury, equipment failure, or even death. Grade 70 chain does not have the safety standards required for lifting people or heavy objects above ground. Stick to using this chain for tying down, towing, or hauling.

Powerful Machinery takes safety seriously. Every chain comes with certifications and third-party testing. You receive documentation that proves your chain meets strict safety standards. This gives you peace of mind and helps you pass inspections with confidence.

Tip: Always read the manufacturer’s instructions and follow all safety standards when using your chain.

Conclusion

Grade 70 chain gives you a higher strength-to-weight ratio and a 20% higher load rating than Grade 43. You benefit from heat-treated carbon steel, a gold chromate finish for easy inspection, and dependable grab hooks.

Choosing certified chains like Powerful Machinery’s G70 Transport Chain means you get products that meet DOT and NACM standards, resist wear, and offer secure hooking options.

Always inspect your chain, never exceed the working load limit, and use only approved chains for cargo securement. Reliable brands help you protect your load and lower long-term costs.

FAQ

What does the “G70” marking mean on a chain?

You see “G70” stamped on the links. This marking shows the chain is Grade 70. It means the chain meets strict strength and safety standards for transport and cargo securement.

Can you use Grade 70 chain for lifting?

Warning:

You should never use Grade 70 chain for overhead lifting. Use only Grade 80 or higher for lifting people or heavy objects above ground.

How do you choose the right size Grade 70 chain?

Check your cargo weight. Match the working load limit (WLL) of the chain to your load. Use this table for quick reference:

Chain Size | WLL (lbs) |

|---|---|

5/16″ | 4,700 |

3/8″ | 6,600 |

How do you maintain a Grade 70 chain?

Inspect your chain before each use. Look for bent links, cracks, or rust. Clean the chain and store it in a dry place. Replace damaged chains right away.