Rigging equipment gives you the power to lift, move, and secure heavy loads safely. Rigging handles the setup and connection of hardware, while lifting focuses on raising or lowering objects. In construction, industrial, and marine sectors, you rely on this gear to prevent injuries and avoid costly accidents.

Reports show that poor rigging practices cause nearly one-third of load drops and contribute to thousands of workplace injuries every year. As infrastructure projects expand worldwide, demand for reliable solutions and strict safety protocols continues to grow.

Powerful Machinery delivers certified rigging options trusted by professionals across the globe.

Key Takeaways

Rigging equipment is essential for safely lifting and moving heavy loads in various industries, including construction and marine.

Proper selection and use of rigging gear prevent accidents and protect workers, reducing the risk of injuries and load drops.

Routine inspections of rigging equipment are crucial. Check for wear and damage before each use to ensure safety and compliance.

Always match rigging equipment to the specific load and environmental conditions to maintain safety and efficiency during operations.

Choose certified rigging products from reputable suppliers to ensure reliability and adherence to safety standards.

Rigging Equipment Overview

What Is Rigging Equipment?

You use rigging equipment to connect, secure, and move heavy loads in a safe and controlled way. This gear includes a wide range of hardware and accessories that help you lift, pull, or position objects during construction, manufacturing, or marine operations.

When you set up a rigging system, you combine different components to create a strong and reliable link between the load and the lifting device.

Some of the most common types of rigging equipment you will find in major industries include:

Slings

Pulleys

Each piece plays a specific role in making sure your lifting tasks run smoothly and safely.

Key Functions in Industry

Rigging supports many critical functions across different sectors. You rely on these tools to handle everything from simple lifts to complex, multi-point hoisting operations. The table below shows how different types of rigging equipment serve key functions in heavy load operations:

Rigging Equipment Type | Key Function |

|---|---|

Hoists and Winches | Increase efficiency by reducing manual labor and improving load handling precision. |

Slings | Secure loads during lifting operations, providing stability. |

Shackles and Hooks | Facilitate connections between slings, ropes, chains, and the load. |

Rigging Frames and Spreaders | Distribute loads evenly during lifting, especially in complex scenarios. |

Pulleys and Block Systems | Increase lifting capacity and change the direction of force. |

Specialized Rigging Equipment | Offer tailored solutions for specific heavy lifting challenges. |

Note: Proper selection and use of rigging equipment help you prevent accidents and protect your team.

Powerful Machinery’s Role

When you choose Powerful Machinery, you gain access to a global leader in certified rigging solutions. The company designs and manufactures high-performance products like lifting chains, wire ropes, hooks, and shackles.

Every item meets strict international safety standards, so you can trust your rigging operations to run efficiently and safely. Powerful Machinery also offers custom-engineered solutions, ensuring you always have the right equipment for your unique project needs.

Rigging vs Lifting

Functional Differences

You encounter rigging and lifting equipment on nearly every job site, but each serves a distinct purpose. Rigging equipment secures and stabilizes heavy loads, while lifting equipment moves those loads using mechanical force.

You select rigging gear to connect your load to cranes, hoists, or other lifting devices, ensuring everything stays balanced and safe throughout the operation. Lifting equipment, such as cranes and hoists, uses motors or hydraulics to raise or lower objects.

The table below highlights the main differences between rigging and lifting equipment in terms of design and application:

Aspect | Lifting Equipment | Rigging Equipment |

|---|---|---|

Functionality | Moves heavy loads using mechanical force | Secures and stabilizes loads for safe handling |

Design and Purpose | Built with mechanisms like hydraulics and motors | Connects loads to lifting equipment and ensures balance |

Application in Operations | Used directly for moving loads (e.g., cranes, hoists) | Works alongside lifting equipment for load stability (e.g., slings, shackles) |

Tip: You should always match the right rigging gear to your lifting equipment to maximize safety and efficiency.

How Rigging Complements Lifting?

Rigging and lifting equipment work together to ensure safe and successful load handling. You follow a step-by-step process to achieve this:

Assess load specifications, including weight and dimensions, to choose the best rigging gear.

Match capacity ratings between your rigging gear and lifting equipment.

Consider environmental factors, such as temperature and moisture, when selecting materials.

Calculate the total load weight, including all accessories.

Account for load distribution and attach rigging gear to maintain stability.

Factor in equipment capacity and never exceed working load limits.

Secure load attachment to prevent shifting or slippage.

Use appropriate sling angles for stability.

Inspect all rigging connections before lifting.

Conduct pre-lift inspections and replace any damaged components.

You create a safer work environment by following these steps and understanding how rigging supports lifting operations. This approach helps you prevent accidents and protect your team during every lift.

Types of Rigging Equipment

When you select rigging equipment for your project, you need to understand the main types of rigging equipment and how each functions. These rigging components play a vital role in lifting, securing, and moving heavy loads.

Powerful Machinery offers a complete range of certified products that meet strict international safety standards, ensuring you get reliable performance in every application.

Chains and Wire Ropes

Chains and wire ropes form the backbone of many rigging systems. You use these rigging components to support and move heavy loads in construction, marine, and industrial settings. Chains and wire ropes have specified tensile strengths that indicate their load handling capabilities.

Chain slings and wire rope slings are designed to support heavy loads due to their robust material composition. The tensile strength of lifting equipment is crucial for ensuring safety and preventing overloading.

Chains and wire ropes come in various grades, such as Grade 80 and Grade 100, which offer high strength for demanding tasks.

Powerful Machinery manufactures lifting chains and wire ropes that meet ISO9001, TUV Rheinland, and other global certifications.

You can rely on these products for consistent performance in harsh environments.

Tip: Always check the rated capacity and inspect chains and wire ropes before each use to prevent accidents.

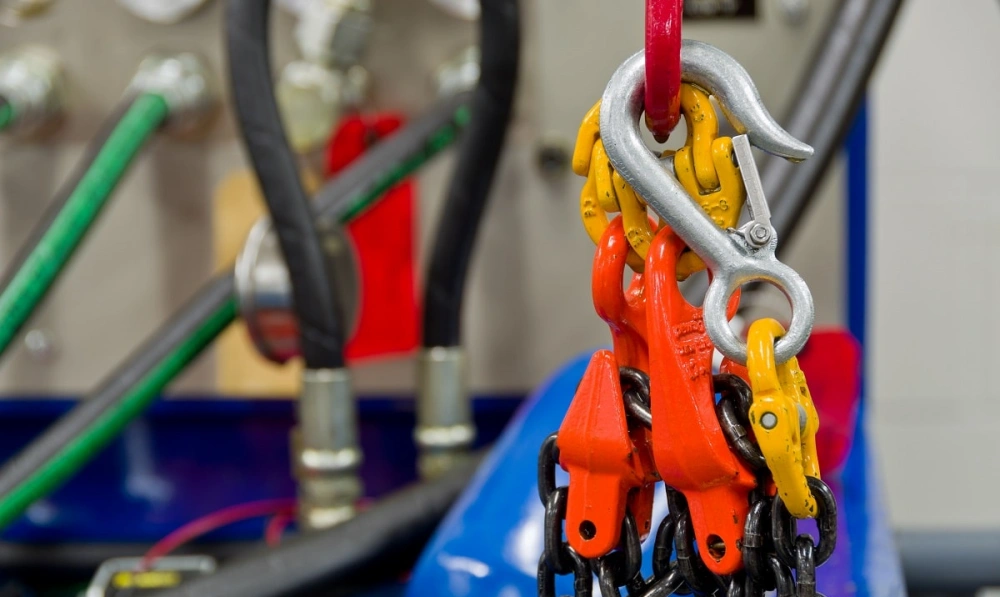

Hooks and Shackles

Hooks and shackles connect different rigging components and secure loads during lifting operations. You find these parts in almost every rigging setup. Powerful Machinery produces hooks and shackles that comply with international safety standards, giving you peace of mind on the job site.

Standard | Description |

|---|---|

ASME B30.10 | Covers the fabrication, attachment, use, inspection, and maintenance of hooks used for load handling. |

ASME B30.26 | Addresses the construction, installation, operation, inspection, and maintenance of rigging hardware, including shackles. |

Hooks come in various shapes, such as eye hooks, clevis hooks, and swivel hooks.

Shackles include anchor shackles and chain shackles, each designed for specific load requirements.

You should always match the hook and shackle type to your load and lifting method.

Eyebolts and Nuts

Eyebolts and nuts serve as anchor points for lifting and securing loads. You use these rigging components to attach slings, ropes, or chains to machinery and structures. Material specifications play a key role in their performance and durability.

Material Type | Properties |

|---|---|

Stainless Steel | Excellent corrosion resistance; ideal for demanding applications; common grades include 304 and 316. |

Galvanized Steel | Zinc coating for corrosion protection; suitable for industrial applications with moderate moisture exposure. |

Material options include low-carbon steel, stainless steel, and steel.

Finishes range from plain, galvanized, black oxide, to zinc.

Powerful Machinery offers eyebolts and nuts engineered for maximum strength and corrosion resistance.

Note: Always verify the material and finish to match your working environment.

Slings and Tie Downs

Slings and tie downs secure loads during lifting and transport. You choose from wire rope slings, chain slings, synthetic slings, and webbing slings based on your application. Tie downs keep cargo stable during movement.

Frequent inspections should be conducted daily or before each shift in normal conditions.

For severe conditions, inspect before each use.

Periodic inspections must occur at least once every 12 months.

Service Type | Inspection Interval |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified Person |

Powerful Machinery supplies slings and tie downs that meet OSHA and ISO standards.

You benefit from products designed for durability and safety in every lift.

Pulleys and Blocks

Pulleys and blocks provide mechanical advantages in rigging equipment systems. You use these rigging components to change the direction of force and reduce the effort needed to lift heavy loads.

Basic mechanical advantage systems are easy to set up and ideal for quick deployment.

They provide a manageable boost in lifting power, suitable for light to moderate loads.

In rescue scenarios, a simple 3:1 Z-rig can be quickly assembled for immediate results.

Pulleys and blocks allow you to lift heavier loads with less effort. For example, if you use a pulley system with a 2:1 mechanical advantage, you only need to exert half the force required to hold the load, though you must pull twice the distance.

Tip: Always inspect pulleys and blocks for wear and ensure they are rated for your intended load.

Spreader Beams

Spreader beams distribute loads evenly during lifting operations. You use these rigging components in construction and marine applications to stabilize large or awkward loads.

Typical work configurations include 20º, 30º, and 45º angles.

Load capacities range from 10 tons to more than 1,000 tons.

Powerful Machinery manufactures spreader beams that meet EURO CERT and EAC standards, ensuring safe and efficient load handling.

Note: Select the correct spreader beam configuration and capacity for your specific lifting scenario.

When you understand the types of rigging equipment and their functions, you make informed decisions that improve safety and efficiency. Powerful Machinery’s certified product range covers all major rigging components, giving you confidence in every lift.

Rigging Equipment Applications

Construction

You rely on lifting and rigging equipment every day in construction. These tools help you complete lifting operations safely and efficiently. You use rigging equipment to move steel beams, concrete panels, and prefabricated structures. Common applications include:

Lifting heavy loads to elevated work zones

Securing loads during transport across the job site

Constructing apparatus for the effective operation of cranes and hoists

You must follow OSHA guidelines for all rigging operations. This ensures your team stays safe and your project meets regulatory standards. You also need to inspect your lifting and rigging gear before each use. Construction projects demand reliable equipment that can withstand harsh conditions and heavy use.

Industrial & Manufacturing

In industrial environments, you use lifting and rigging equipment to move machinery, raw materials, and finished products. You must select the right gear for each lifting operation to prevent accidents and meet OSHA requirements. The table below shows how you apply rigging equipment in different industrial settings:

Application in Industry | Description |

|---|---|

Machinery Movement | You lift, slide, and transport heavy machinery across your facility. |

Manufacturing Industries | You depend on rigging in auto, aerospace, electronics, food processing, and shipbuilding. |

Safety Measures | You inspect equipment, train personnel, secure work areas, and use communication signals. |

You often use hooks, spreader bars, shackles, slings, steel nuts, and wire ropes. These components support safe rigging operations and help you maintain compliance with OSHA standards.

Marine & Transportation

You face unique challenges in marine and transportation lifting operations. You must secure cargo for long journeys and adapt to changing sea conditions. The table below highlights the main challenges you address with advanced lifting and rigging solutions:

Challenge Type | Description |

|---|---|

Cargo Stability | You use advanced lashing equipment to keep cargo stable and safe at sea. |

Adaptability to Conditions | You rely on smart sensors and real-time monitoring to adjust to dynamic marine environments. |

Heavy and Oversized Cargo Handling | You secure massive loads during offshore installations with modern lashing systems. |

Vessel Stability | You improve vessel stability and reduce accident risks with enhanced lashing solutions. |

You must follow OSHA regulations and inspect all rigging operations before each voyage. Reliable lifting and rigging equipment ensures your cargo arrives safely.

Event Staging

You use lifting and rigging equipment to create safe and dynamic event environments. Theatrical rigging involves fixed systems for precise control of scenery and stage elements. Event rigging requires temporary systems tailored to each venue.

You follow custom rigging plans based on structural assessments. Key components include:

Structural objects such as trusses and pipes

Support objects like hoists and bridles

Rigging hardware, including shackles and slings

Modern technology gives you automated systems, computer-aided design, and real-time load monitoring. These advances make your rigging operations safer and more efficient. You must always comply with OSHA standards and inspect your equipment before every event.

Tip: You improve safety and efficiency by choosing certified lifting and rigging equipment for all applications.

Rigging Safety & Standards

Risk Assessment & Planning

You must prioritize safety before starting any rigging operation. Begin with a risk assessment to identify hazards such as load characteristics, weather, and equipment specifications. Follow these essential steps to create a safe work environment:

Conduct a thorough risk assessment and planning session.

Ensure all team members receive proper training and certification.

Inspect rigging equipment for wear, corrosion, and correct function before use.

Organize emergency drills and simulations for your crew.

Set up reliable communication systems, including hand signals and radios.

These protocols help you reduce accidents and comply with health and safety regulations.

Regulatory Compliance (OSHA, ASME, ISO)

You must follow strict regulations and standards to protect your team and meet legal requirements. The table below highlights key organizations and their focus areas:

Organization | Key Focus | Key Standards |

|---|---|---|

OSHA | Workplace safety regulations | General Duty Clause, inspections, citations |

ASME | Rigging and lifting safety standards | ASME B30 series (cranes, rigging equipment) |

ANSI | Standards development accreditation | ANSI/ASSP Z359, ASME lifting equipment rules |

You need to inspect rigging before each shift, avoid using untagged gear, and never exceed rated loads. Remove damaged slings immediately and proof-test custom lifting accessories. Make sure cranes and rigging personnel are qualified. These safety standards reflect industry standards and health and safety legislation.

Sourcing Certified Equipment

You should only source rigging equipment from suppliers who meet recognized standards. Look for proof of certification and compliance with ASME B30 guidelines. Suppliers must provide certificates and update their protocols to match the latest industry standards.

The table below shows important criteria for sourcing certified equipment:

Criteria | Description |

|---|---|

Compliance with ASME B30 guidelines | Suppliers must follow established safety and operational standards. |

Proof of certification | Certificates show evidence of testing and compliance. |

Regular updates to guidelines | Suppliers should reflect the latest technologies and practices. |

Detailed definitions of equipment | Clear descriptions and recertification requirements are essential. |

Certified inspectors should perform unbiased inspection services. Avoid conflicts of interest by choosing inspectors who are not sales representatives.

Powerful Machinery’s Safety Commitment

Powerful Machinery sets the benchmark for rigging safety. You benefit from products certified to ISO9001, TUV Rheinland, EURO CERT, EAC, OSHA, and ASME standards. The company’s rigorous testing protocols and commitment to health and safety regulations ensure every component meets or exceeds global requirements.

Powerful Machinery partners with you to deliver reliable solutions that protect your team and support compliance with all safety standards.

Tip: Choose certified equipment and follow strict safety protocols to maintain rigging safety on every project.

Rigging Equipment Inspection & Maintenance

Routine Inspections

You must treat inspections as a non-negotiable part of every rigging setup. Routine inspections help you catch issues before they become hazards. Always check your equipment before each use. Look for signs of wear, cracks, corrosion, or deformation.

Follow manufacturer guidelines for each component. Keep detailed records of all inspections and maintenance activities. This practice helps you track the history of your gear and schedule future tasks efficiently.

Here is a quick reference table for recommended inspection procedures:

Procedure | Description |

|---|---|

Regular Inspections | Conduct visual inspections before each use, checking for wear, cracks, or corrosion. |

Follow Manufacturer Guidelines | Adhere to specific inspection and maintenance requirements outlined by the manufacturer. |

Keep Detailed Records | Maintain records of inspections and maintenance to track history and schedule tasks effectively. |

Lubrication | Regularly lubricate moving parts to prevent friction and wear. |

Training and Education | Ensure staff are trained in inspection procedures to improve safety and equipment lifespan. |

You should also inspect specific components closely:

Slings: Check for tags, cuts, kinks, and confirm you have the correct type for the lift.

Shackles: Inspect for bends, cracks, and verify the correct size.

Hooks: Look for twists, cracks, and test latch functionality.

Hardware/Devices: Check for cracks and ensure IDs or tags are present.

Set up: Protect edges and assign a signal person for communication.

By making inspections a habit, you reduce the risk of accidents and extend the life of your rigging equipment.

Maintenance Best Practices

You can extend the service life of your rigging equipment by following best practices for maintenance. Store slings and other gear off the ground in a cool, dry, and dark place. Avoid exposing equipment to extreme temperatures or direct sunlight.

Keep all items clean to prevent degradation from dust, dirt, and moisture. Never store slings in chemically active environments. Use edge protection to prevent wear and damage during use.

Follow these steps for effective maintenance:

Conduct regular inspections to identify potential issues early.

Lubricate moving parts on schedule to reduce wear and ensure smooth operation.

Inspect wire ropes for wear and corrosion frequently.

Proper rigging procedures include caring for your equipment during and between uses. This approach helps you maintain lifting capacities and ensures safe operation.

Powerful Machinery’s products undergo rigorous testing and inspection processes, so you receive equipment that meets the highest standards for durability and reliability.

Inspection Tools & Templates

You need the right tools and templates to perform thorough rigging inspections. Use checklists designed for each type of equipment, such as:

Rigging hardware inspection

Hooks inspection

Wire rope slings inspection

Web slings inspection

Round slings inspection

Below-the-hook lifting devices inspection

When you inspect, check both the exterior and interior of each item. Review maintenance items like fluids, lights, brakes, and batteries. Verify documentation and keep a log of defects or damage, including photos when possible.

Enter data immediately and generate real-time reports. Include sections for observations, recommendations, and corrective actions in your inspection templates.

Standardized checklists help you stay organized and ensure nothing gets overlooked during rigging inspections. Powerful Machinery provides guidance and resources to help you implement these tools effectively.

Compliance with Standards

You must ensure your inspection procedures align with international standards. Start with an initial inspection for any new, altered, modified, or repaired rigging equipment before returning it to service. Perform frequent inspections daily or before each use.

Assign a competent person to check for damage or defects. Schedule periodic inspections for a thorough, documented review of all lifting equipment, including below-the-hook devices and slings. This process ensures compliance with OSHA and ASME standards.

Powerful Machinery’s inspection and maintenance protocols meet or exceed global requirements. The company’s commitment to quality means you can trust every product to perform safely in demanding environments.

By following these standards, you protect your team and maintain the integrity of your rigging operations.

Tip: Consistent inspections and maintenance routines are your best defense against equipment failure and workplace accidents.

Selecting Rigging Equipment

Matching Equipment to Load

You must match rigging equipment to the specific load you plan to lift. Start by identifying the exact weight and type of load. Consider the environment, such as exposure to heat, moisture, or chemicals, since these factors affect material selection.

Evaluate the lifting angle, because it changes the stress on your equipment. Always ensure the equipment capacity meets the job requirements. Follow these steps for safe selection:

Determine load type and weight.

Assess environmental conditions.

Analyze lifting angles.

Match equipment capacity to the job.

Tip: Accurate load assessment helps you prevent overload and maintain safety.

Criteria for Selection

You need to choose equipment based on site conditions and application. Review the table below to compare sling types and their key considerations:

Sling Type | Key Considerations |

|---|---|

Synthetic Web Slings | Lightweight, flexible; ideal for fragile surfaces; sensitive to cutting, heat, chemicals. |

Synthetic Round Slings | Flexible; may hide internal damage. |

Wire Rope Slings | Rigid, temperature-resistant; can wear at sharp edges. |

Alloy Steel Chain Slings | Durable in harsh environments; heavy, may damage sensitive surfaces. |

Remember, sling angles affect force distribution. Lower angles increase force on each sling leg. Multi-leg slings can shift load distribution, raising the risk of overload.

Supplier Reputation

You should select equipment from suppliers with a proven reputation for safety and reliability. Trusted suppliers perform strict quality control checks and provide certifications for every product. This commitment reduces the risk of accidents and builds long-term trust.

Powerful Machinery stands out by offering certified equipment and custom-engineered solutions. You benefit from expert support and products that meet international standards.

Cost Considerations

You must factor in the cost when purchasing equipment for large projects. Delivery timelines can increase expenses, especially if you need rush orders. Custom-engineered equipment often costs more than standard items.

The source of purchase, whether local or online, affects pricing and support services. Maintaining a diverse inventory for quick fulfillment may raise costs. Using lifting specialists adds expense but improves efficiency. Buying in bulk can lower the cost per item.

Note: Weigh upfront costs against long-term reliability and safety. Powerful Machinery provides competitive pricing and expert guidance to help you maximize value.

Conclusion

You improve workplace safety and efficiency when you understand rigging equipment types, uses, and safety protocols. Regular inspections deliver proven benefits:

Reduce accidents and load failures.

Extend equipment lifespan.

Minimize downtime.

Ensure regulatory compliance.

Sourcing certified products from Powerful Machinery strengthens your operations.

Key Factor | Description |

|---|---|

Quality Assurance | Every component meets strict performance and safety standards. |

Safety Standards | Products exceed international requirements for reliability. |

Reliable Delivery | You receive efficient, dependable service worldwide. |

Apply best practices for selection, use, and maintenance to protect your team and assets.

FAQ

What is the difference between rigging and lifting equipment?

Rigging equipment secures and connects loads. Lifting equipment moves loads using mechanical force. You use rigging gear to attach objects to cranes or hoists for safe handling.

How often should you inspect rigging equipment?

You should inspect rigging equipment before each use. Schedule periodic inspections every 12 months. Increase inspection frequency for severe service conditions or critical lifts.

What certifications should you look for in rigging equipment?

Look for certifications such as ISO9001, OSHA, ASME, and TUV Rheinland. These standards ensure your equipment meets global safety and quality requirements.

Why choose Powerful Machinery for rigging solutions?

You benefit from certified products, custom-engineered solutions, and global support. Powerful Machinery delivers reliability, safety, and compliance for demanding projects.

Can you use the same rigging equipment for every application?

Application Type | Equipment Needed |

|---|---|

Construction | Heavy-duty chains, slings |

Marine | Corrosion-resistant gear |

Event Staging | Lightweight, flexible gear |

You must match equipment to your specific application for safety and efficiency.