When you compare the g4 vs g43 chain, strength becomes the clear differentiator. The G43 chain delivers a minimum breaking strength of 16,200 lbs, making it a top choice for heavy-duty towing and transport. The table below shows how G43 outpaces lower grades:

Chain Grade | Minimum Breaking Strength (lbs) |

|---|---|

G30 | 7,600 |

G40/G43 | 11,600 |

G43 | 16,200 |

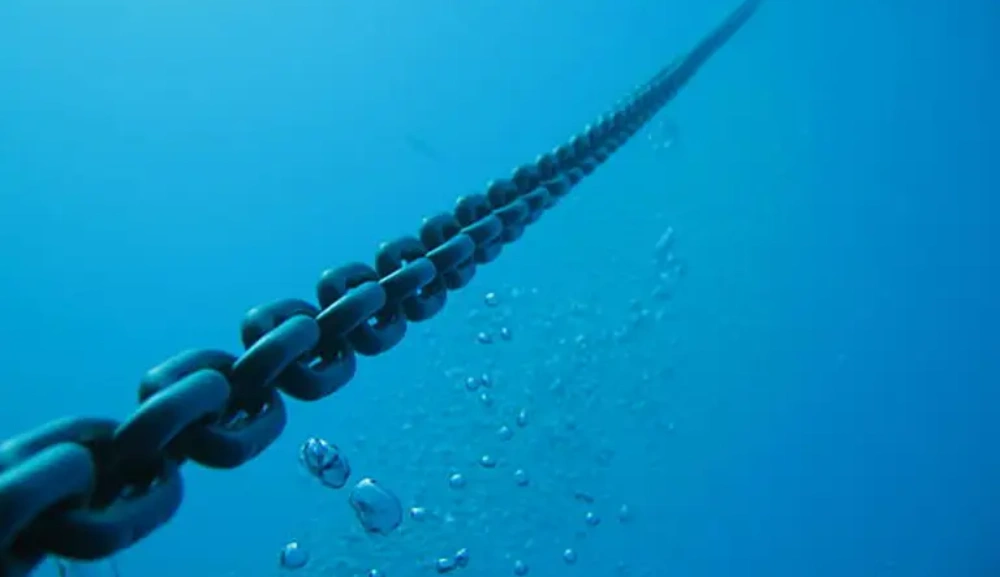

If you need reliable performance in marine environments, you should select a G43 chain with a hot-dip galvanized finish for superior corrosion resistance. Powerful Machinery stands as your trusted partner for high-quality anchor and lifting chains, helping you make the right choice for every application.

Key Takeaways

G43 chains offer a higher minimum breaking strength, making them ideal for heavy-duty towing and transport tasks.

G4 chains excel in marine environments due to their excellent corrosion resistance, especially when hot-dip galvanized.

Always check the working load limit before selecting a chain to ensure safety and performance for your specific application.

Choose G4 chains for anchoring and mooring, while G43 chains are better suited for load binding and towing.

Regularly inspect chains for wear and damage, especially in marine settings, to maintain safety and reliability.

G4 vs G43 Chain Strength

Breaking Strength

When you compare the G4 vs G43 chain, you notice a clear difference in minimum breaking strength. The G43 chain stands out with a higher minimum tensile strength, making it suitable for demanding applications.

For example, Powerful Machinery’s G43 High Test Chain in a 3/8” size offers a minimum breaking strength of 16,200 lbs. This level of strength ensures you can rely on the chain for towing, transport, and heavy-duty binding.

The G4 chain, often used in marine settings, also provides impressive strength for its size. For a 5/16” G4 chain, you get a minimum breaking strength of 9,600 lbs. This value meets the needs of most anchoring and mooring tasks.

The table below highlights the difference in breaking strength between G4 and G43 chains of similar sizes:

Chain Size | G4 Chain Breaking Strength (lbs) | G43 Chain Breaking Strength (lbs) |

|---|---|---|

5/16″ | 9,600 | 11,700 |

3/8″ | 13,500 | 16,200 |

1/2″ | 22,500 | 27,600 |

You can see that the G43 chain consistently delivers a higher minimum tensile strength, making it the preferred choice when you need extra security and durability.

Working Load Limits

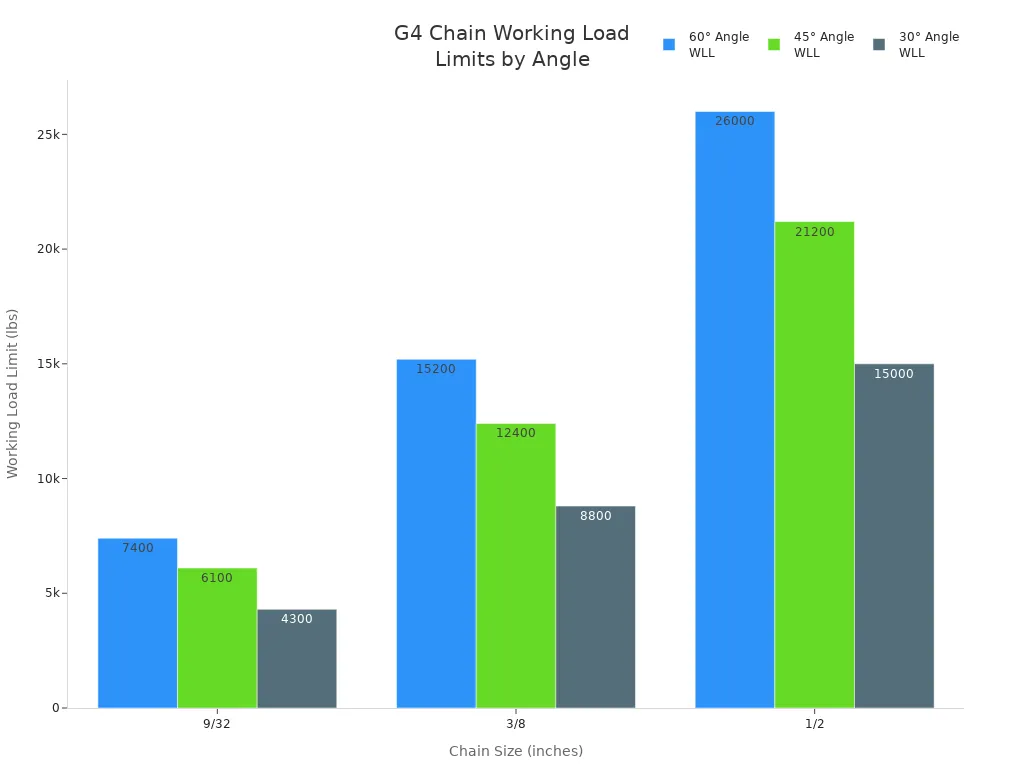

The working load limit tells you the maximum load a chain can safely handle during regular use. This value is critical for safety and performance. G4 and G43 chains have different working load limits, reflecting their intended applications.

For G4 chains, the working load limit varies by size and angle of use. For example, a 3/8” G4 chain has a working load limit of 4,000 lbs at a straight pull. When you use the chain at different angles, the limit changes. The table below shows how the working load limit shifts with the angle:

Chain Size (inches) | 60° Angle WLL (lbs) | 45° Angle WLL (lbs) | 30° Angle WLL (lbs) |

|---|---|---|---|

9/32 | 7,400 | 6,100 | 4,300 |

3/8 | 15,200 | 12,400 | 8,800 |

1/2 | 26,000 | 21,200 | 15,000 |

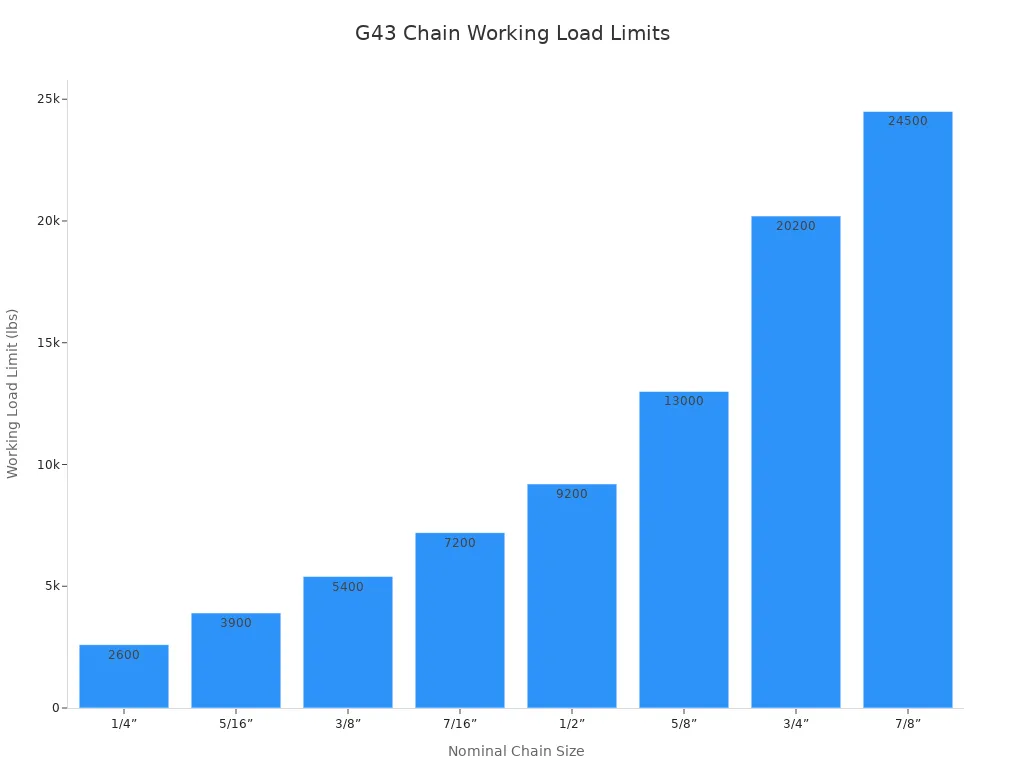

G43 chains, such as those from Powerful Machinery, offer even higher working load limits. For a 3/8” G43 chain, you get a working load limit of 5,400 lbs. The table below summarizes the working load limits for G43 chains across different sizes:

Nominal Chain Size | Working Load Limit (MAX.) | Proof Test (Min.) | Breaking Force (Min.) |

|---|---|---|---|

1/4” | 2,600 lbs | 3,900 lbs | 7,800 lbs |

5/16” | 3,900 lbs | 5,850 lbs | 11,700 lbs |

3/8” | 5,400 lbs | 8,100 lbs | 16,200 lbs |

7/16” | 7,200 lbs | 10,800 lbs | 21,600 lbs |

1/2” | 9,200 lbs | 13,800 lbs | 27,600 lbs |

5/8” | 13,000 lbs | 19,500 lbs | 39,000 lbs |

3/4” | 20,200 lbs | 30,300 lbs | 60,600 lbs |

7/8” | 24,500 lbs | 36,750 lbs | 73,500 lbs |

You should always check the working load limit before selecting a chain for your project. The G43 chain gives you a higher limit, which means you can handle heavier loads with confidence.

Material and Construction

The material and construction of a chain play a major role in its strength and durability. G4 chains use Grade 40 high-test steel, which provides about 20% more strength than standard BBB (Grade 30) chains.

This material allows you to use a smaller, lighter chain without sacrificing holding power. Many G4 chains feature hot-dip galvanization, which boosts corrosion resistance and extends the chain’s lifespan in harsh marine environments.

Material Type | Impact on Strength and Durability |

|---|---|

Grade 40 High-Test Steel | Provides approximately 20% higher strength than standard BBB (Grade 30) chain, allowing for a smaller, lighter chain without compromising holding power. |

Hot-Dip Galvanization | Enhances corrosion resistance, making the chain suitable for harsh marine environments and extending its lifespan. |

G43 chains, like Powerful Machinery’s G43 High Test Chain, use high-carbon steel. This material gives the chain excellent strength and durability. The construction meets ASTM and NACM standards, ensuring each chain delivers consistent performance and safety.

You can identify G43 chains by the “G43” marking on each link, which guarantees you are using a certified product.

When you evaluate the g4 vs g43 chain, you see that material and construction directly affect the minimum tensile strength of the chain. G43 chains excel in applications that demand higher strength and a greater working load limit. G4 chains, with their corrosion-resistant finish, remain the top choice for marine use.

Tip: Always match the chain’s material and construction to your specific application. This approach ensures you get the right balance of strength, durability, and safety.

Chain Uses and Applications

Marine Applications

You often see G4 chains used as anchor chains in marine environments. These chains deliver reliable performance for windlass systems, mooring, and anchoring. The G4 chain provides the right balance of strength and corrosion resistance, especially when you select a hot-dip galvanized finish.

Powerful Machinery offers marine-grade anchor chain solutions that meet the demands of saltwater exposure and heavy loads. The table below highlights common marine applications and the performance requirements you should consider:

Application | Performance Requirements |

|---|---|

Windlass Chains | Strength, corrosion resistance, compatibility with windlasses |

When you choose a G4 chain for your boat or vessel, you ensure your anchor system remains secure and durable in harsh conditions.

Towing and Transport

You rely on G43 chains for towing, load binding, and cargo securement in the trucking and transport industries. These chains offer higher strength than lower grades, making them ideal for heavy-duty tasks.

Powerful Machinery’s G43 High Test Chain stands out for its durability and compliance with ASTM and NACM standards. You can use these chains for logging, construction, and agricultural applications. The table below shows the primary uses and important standards for G43 chains:

Primary Uses of G43 Chains | Standards and Considerations |

|---|---|

Load Binding/Tie-Downs | Must not be used for overhead lifting |

Towing | Refer to the manufacturer’s specifications for safe use |

Logging | Consider specific application requirements |

Construction | Ensure the necessary strength (WLL) is met |

Agriculture | Evaluate environmental factors |

You should always check the working load limit and follow manufacturer guidelines to maximize safety and performance.

Industrial and Lifting

You encounter chains in industrial settings where lifting and securing heavy loads is routine. G43 chains provide superior strength compared to Grade 30, making them suitable for container securement, farming, and marine uses.

For overhead lifting, you should select specialized chains like Powerful Machinery’s Grade 80 Chain or G80 Alloy Chain. These products meet strict safety standards and deliver reliable performance under high loads. The table below compares chain grades and their typical applications:

Chain Grade | Strength Comparison | Applications |

|---|---|---|

G43 | Stronger than G30 | Container securement, logging, farming, towing, and marine applications |

Note: Always consult classification rules or local regulations before selecting a chain for commercial operations. When in doubt, rely on the numbers and certified products from Powerful Machinery to ensure compliance and safety.

G4 vs G43 Chain Differences

Comparison Table

When you compare the G4 vs G43 chains, you see clear differences in their specifications and performance. The table below gives you a side-by-side look at the most important features:

Feature | G4 Chain | G43 Chain |

|---|---|---|

Material Type | High Carbon Steel | High Carbon Steel |

Typical Use | Marine (anchor, windlass, mooring) | Towing, transport, load binding, logging |

Strength | High (suitable for marine anchoring) | Higher (ideal for heavy-duty towing) |

Working Load Limit | Moderate to High (varies by size/angle) | Higher (up to 5,400 lbs for 3/8″ size) |

Corrosion Resistance | Excellent (hot-dip galvanized options) | Good (galvanized or zinc-plated available) |

Standards | Meets marine and windlass requirements | ASTM, NACM certified |

Markings | Marked every foot for windlass compatibility | Marked “G43” for easy identification |

Cost | Slightly higher due to marine-grade finish | Generally less expensive |

Note: The integrity of the galvanizing layer is crucial for both chains. If you use a chain in saltwater, you should check the coating regularly. Once the galvanizing is damaged, corrosion can spread quickly and reduce the chain’s performance.

Pros and Cons

You need to weigh the pros and cons before choosing between the g4 vs g43 chain. Each type offers unique advantages for specific applications.

G4 Chain

Pros:

Delivers reliable strength for marine anchoring and mooring.

Hot-dip galvanized finish provides excellent corrosion resistance in saltwater.

Marked every foot, making it compatible with most windlasses.

Maintains holding power with a lighter chain size.

Cons:

Slightly higher cost due to marine-grade materials and finish.

The working load limit is lower than G43 for the same size.

Galvanizing can degrade over time, especially if the chain is re-galvanized.

G43 Chain

Pros:

Offers higher strength and working load limits, making it ideal for towing, transport, and heavy-duty binding.

Generally less expensive than marine-grade chains.

Certified to ASTM and NACM standards for safety and reliability.

Available in various finishes, including galvanized and zinc-plated.

Cons:

Corrosion resistance is good, but not as high as marine-specific chains.

Not recommended for overhead lifting or long-term saltwater use.

If the galvanizing is damaged, corrosion can spread quickly.

Tip: If you need a chain for offshore or long-term marine use, choose a chain with the best corrosion resistance, such as stainless steel or a high-quality galvanized G4. For towing and heavy-duty transport, the G43 chain from Powerful Machinery gives you the strength and load capacity you need at a competitive price.

You can see that the main differences between these chains come down to strength, load capacity, corrosion resistance, and cost. Powerful Machinery provides certified options in both categories, so you can select the right chain for your specific needs.

Choosing the Right Chain

Application Scenarios

Selecting the right chain for your project starts with understanding the demands of your application. You need to consider the type of load, the required strength, and the environment where you will use the chain.

For marine anchoring, you should choose a chain that offers excellent corrosion resistance and reliable holding power. In towing or transport, prioritize chains with higher working load limits and certified strength ratings.

The table below helps you match chain grades to common applications:

Chain Grade | Recommended Applications |

|---|---|

Grade 30 | Light construction, agricultural, and marine industries |

Grade 43 | Container securement, logging, farming, towing, and marine |

Grade 70 | Load securement, towing, trucking, and logging |

Grade 80 | Overhead lifting, heavy-duty towing |

Grade 100 | Overhead lifting, construction, manufacturing, rigging |

Grade 120 | Overhead lifting, ultra-premium strength |

You should always check the chain’s markings, such as “G43” or “G4,” to confirm its grade and suitability for your task. Powerful Machinery offers certified products that meet industry standards, giving you confidence in every application.

Tip: Never exceed the working load limit. Doing so can deform the chain or shackle, reducing safety and performance.

Safety and Standards

Safety must guide your chain selection process. You need to verify both the break load and the working load limit before using any chain. The G43 chain features a safety factor of 3:1, while other grades may offer a 4:1 ratio. Always match the chain grade to your application to ensure optimal strength and reliability.

Chains used in towing and logging are not approved for overhead lifting. You should look for embossed markings on each link to identify the grade. Powerful Machinery’s chains comply with ASTM and NACM standards, ensuring consistent quality and safety.

Check the chain’s certification and markings.

Confirm the working load limit for your specific chain size.

Use only certified chains for critical applications like anchor systems or overhead lifting.

By following these guidelines, you protect your equipment and maintain safe operations in every scenario.

Conclusion

You can see the main differences between G4 and G43 chains in their strength, safety factor, and best uses. The table below highlights these points:

Chain Type | Minimum Breaking Strength | Working Load Limit | Safety Factor |

|---|---|---|---|

G4 | Lower than G43 | Varies | Higher (4) |

G43 | Higher than G30 | Prioritized | Lower (3) |

Choose a G4 chain for your anchor system in marine settings. Select G43 for towing or heavy-duty transport. Powerful Machinery provides certified solutions for every application. Reach out for expert advice and the right product for your needs.

FAQ

What is the main difference between G4 and G43 chains?

You will notice that G43 chains offer higher strength and working load limits. G4 chains provide excellent corrosion resistance, making them ideal for marine use. Always match the chain grade to your application for the best results.

Can you use a G43 chain as an anchor chain?

You should not use a G43 chain as an anchor chain for marine environments. G4 chains are specifically designed for anchor systems and windlasses. They provide the right balance of strength and corrosion resistance for saltwater conditions.

Are G43 chains suitable for overhead lifting?

You cannot use G43 chains for overhead lifting. For lifting applications, you need to select Grade 80 or higher chains. These chains meet strict safety standards and provide the necessary strength for lifting heavy loads.

How do you identify the grade of a chain?

You can identify the grade by looking for markings on each link. G43 chains have “G43” stamped on them. G4 chains often have markings every foot for windlass compatibility. Always check these markings before use.

What maintenance does a marine chain require?

You should rinse your marine chain with fresh water after each use. Inspect the chain regularly for signs of corrosion or wear. Replace the chain if you see any damage to ensure your anchor system remains secure.