You rely on chains for lifting and rigging tasks every day. Chain Working Load Limit (WLL) defines the maximum safe weight you can lift or secure without risking failure. Accurate WLL calculation protects you from costly accidents and regulatory penalties.

Improper use causes 68% of cargo securement failures and 83% of equipment-related damage claims. When you exceed load limits, you face increased wear, sudden breaks, and fines. Powerful Machinery delivers certified lifting and rigging products that help you meet safety standards and safeguard your operations.

74% of securement system failures result from inadequate WLL application.

Average liability claims for load-shift incidents reach ₹65 lakhs.

Compliance with DOT and CVSA standards is essential for legal and safety reasons.

Key Takeaways

Understand the Chain Working Load Limit (WLL) to ensure safe lifting and prevent accidents.

Always calculate WLL using the formula: Working Load Limit = Minimum Breaking Load / Safety Factor.

Regularly inspect lifting chains to catch wear and damage before they lead to failures.

Follow industry standards and regulations to maintain compliance and enhance safety.

Use certified chains from trusted manufacturers like Powerful Machinery for reliable performance.

Chain Working Load Limit (WLL)

Definition of WLL

You need to understand the chain working load limit (WLL) before you select any lifting equipment. The chain working load limit (wll) is the maximum force a chain or lifting device can safely handle during regular use.

Manufacturers calculate this limit by dividing the minimum breaking strength of the chain by a safety factor, which usually ranges from 3:1 to 6:1. This calculation ensures that the chain can withstand unexpected stresses and still perform safely.

You may also see the working load limit called the safe working load or recommended working load. When you follow the chain working load limit (WLL), you protect your team, your equipment, and your business from unnecessary risks.

The wll represents the highest load a chain can safely handle under specific conditions.

Exceeding the well can cause equipment failure, accidents, and severe injuries.

Working Load Limit vs Breaking Strength

You might wonder how the chain working load limit (wll) differs from breaking strength. The working load limit is the maximum safe force you can apply to a chain during normal operations. Breaking strength is the absolute maximum force the chain can withstand before it fails.

Manufacturers set the wall much lower than the breaking strength to include a safety margin. This margin accounts for unexpected loads, wear, and other factors that could affect performance.

Here is a quick comparison:

Aspect | Working Load Limit (WLL) | Breaking Strength |

|---|---|---|

Purpose | Safety limit for regular use | Absolute maximum force capacity |

Set by | Manufacturer | Material properties/testing |

Reflects | Safety, usability, and equipment life | Material capabilities |

Used for | Daily operations | Testing and certification |

Value | Less than Breaking Strength | Greater than WLL |

You should always use the well for daily lifting and rigging tasks. Never use the breaking strength as your guide for regular operations. The chain working load limit (wll) keeps your work safe and reliable.

Importance of Safety

You cannot ignore safety when working with chains and lifting equipment. The chain working load limit (WLL) is designed to provide a safety margin against unexpected stresses. If you exceed the well, you risk equipment failure and serious injuries.

Regular inspections help you spot signs of wear or damage before they become hazards. Following the working load limit and inspection guidelines reduces the chance of accidents and keeps your team safe.

The wll is calculated to ensure a safety margin for every lift.

Regular inspections prevent equipment failure.

Exceeding the wll can lead to severe injuries and costly downtime.

Powerful Machinery takes safety seriously. Every chain and lifting product meets or exceeds international safety standards. You can trust Powerful Machinery’s certified chains to deliver reliable performance and full traceability for every lift.

How to Calculate Working Load Limit?

Understanding how to calculate the working load limit is essential for safe lifting and rigging. You need to know the correct formula, apply the right safety factor, and see how these numbers work in real-world examples. This section will guide you step by step.

WLL Calculation Formula

You can determine the working load limit of a chain by using a simple formula. This formula helps you set a safe maximum load for your lifting equipment.

Working Load Limit = Minimum Breaking Load / Safety Factor

The working load limit (WLL) is the result of dividing the minimum breaking strength of the chain by the safety factor.

Both the grade and diameter of the chain influence the final working load limit.

You should always use the manufacturer’s minimum breaking load for your calculation. Never estimate or guess this value. Powerful Machinery provides certified minimum breaking loads for all Grade 80 and Grade 100 Chains, making your calculations accurate and reliable.

Safety Factors

The safety factor is a crucial part of every working load limit calculation. It adds a margin of safety to account for unexpected stresses, wear, or misuse. Different regions and applications require different safety factors.

Region | Safety Factor |

|---|---|

North America | 5:1 |

Europe | 10:1 or higher |

Asia | Lower for simple pulling or lashing |

In North America, you should use a safety factor of 5:1 for general lifting and rigging.

In Europe, the safety factor may be 10:1 or higher, especially for lifting people.

In Asia, the safety factor can be lower for simple pulling or lashing tasks.

The minimum design factor for chain slings, as required by ISO standards, is 4:1. Always check local regulations and standards before you perform any calculation.

Example Calculation

Let’s walk through a step-by-step example to show you how to calculate working load limit for a chain.

Find the Minimum Breaking Strength:

Suppose you have a Grade 80 chain from Powerful Machinery with a minimum breaking strength of 25,000 pounds.Select the Safety Factor:

For general lifting in North America, use a safety factor of 5.Apply the Formula:

Working Load Limit = Minimum Breaking Strength ÷ Safety Factor

Working Load Limit = 25,000 lbs ÷ 5

Working Load Limit = 5,000 lbs

Interpret the Result:

You should never lift more than 5,000 pounds with this chain, even though the chain can withstand up to 25,000 pounds before breaking.

The chain grade makes a big difference. Grade 100 chains from Powerful Machinery have even higher minimum breaking strengths, so their working load limits are greater for the same diameter and safety factor.

Always check the chain’s identification tag or documentation for the correct values before you start your calculation.

Tip: Use certified chains like Powerful Machinery’s Grade 80 and Grade 100 products. These chains come with clear markings and documentation, making your working load limit calculations straightforward and compliant with safety standards.

By following these steps, you ensure every lift stays within the safe working load limit. This practice protects your team, your equipment, and your reputation.

Factors Affecting WLL

You must understand the factors that influence the working load limit of your lifting chains. These factors determine the maximum load you can safely handle and help you select the right equipment for every job.

Chain Diameter

The diameter of your chain directly affects its capacity. Larger diameters allow the chain to support a higher maximum load.

For example, a Grade 100 chain from Powerful Machinery with a 16mm diameter will have a greater capacity than a 10mm chain of the same grade. Always check the manufacturer’s specifications to confirm the correct working load limit for your chain size.

Larger chain diameters increase the working load limit.

Both grade and diameter must be considered when determining capacity.

Angle of Use

The angle at which you use your chain sling changes the forces applied to each link. When you lift at an angle, the stress on the chain increases, reducing its effective capacity.

A straight vertical lift allows you to use the full working load limit. If you use the chain at an angle, such as in a basket or choker hitch, you must reduce the maximum load accordingly.

Lifting at an angle increases stress on the chain.

Always calculate the working load limit based on the angle of use.

Environmental Conditions

Environmental factors like temperature, humidity, and exposure to chemicals can weaken your chain. High temperatures may reduce the chain’s strength, while corrosion from moisture or chemicals can compromise its integrity.

Powerful Machinery’s chains feature protective finishes, but you should always consider the environment before lifting.

Extreme temperatures and corrosive environments lower the chain’s capacity.

Inspect chains regularly if used in harsh conditions.

Dynamic Forces

Chains experience additional stress from dynamic forces, such as shock loading or sudden movements. These forces can momentarily exceed the chain’s rated capacity, increasing the risk of failure. You should avoid jerking or dropping loads to maintain safety.

Sudden movements or impacts can exceed the chain’s maximum load.

Lift smoothly to protect your equipment and team.

Wear and Age

Over time, chains wear down at friction points and may stretch or lose material. This wear reduces the chain’s working load limit and overall capacity. Regular inspection and timely replacement are essential for safe lifting. Powerful Machinery’s chains come with traceability features, making it easier to monitor their condition.

Wear and age decrease the chain’s strength.

Replace chains that show signs of excessive wear or elongation.

Tip: Always follow inspection guidelines and use certified chains from Powerful Machinery to ensure you never exceed the safe working load limit.

Safety Standards and Compliance

Industry Regulations

You must follow strict industry regulations to ensure safe lifting operations. Major international standards set clear requirements for chain working load limits. These standards help you select the right chain, use it correctly, and avoid accidents.

Powerful Machinery designs every product to meet or exceed these global benchmarks. The table below highlights key standards and their focus:

Standard | Description |

|---|---|

OSHA | Ensures compliance with safety regulations for lifting equipment. |

ASME B30.9 | Requires proofloading of alloy lifting chain assemblies before use. |

NACM | Specifies chain specifications and requirements for safe use. |

ASTM | Sets standards for materials and performance of chains used in lifting. |

You should always check that your chains comply with these standards. Powerful Machinery’s chains carry certifications and markings for full traceability, giving you confidence in every lift.

Documentation

Proper documentation proves your compliance with safety regulations. You need to keep records that show your team follows all required procedures and uses certified equipment. The table below outlines common documentation you may need:

Regulatory Body | Common Documentation Required |

|---|---|

OSHA | Proof of completed OSHA training, written safety programs, hazard communication, PPE logs, and incident reports |

NFPA | Electrical safety training certificates, inspection and maintenance records, certifications for fire systems |

EPA | Hazardous waste handling certifications, safety data sheets, and spill prevention plans |

State/Local | Contractor licenses, insurance, surety bonds, business registration, tax compliance certificates |

You should store these documents in an organized system. Quick access to documentation helps you during audits or inspections and demonstrates your commitment to safety.

Common Misconceptions

Many workers misunderstand the chain working load limits. These misconceptions can lead to unsafe practices and accidents. You need to recognize and correct these beliefs:

WLL is the same as breaking strength. In reality, WLL is a safe working limit, not the maximum load before failure.

WLL is a fixed value. The wll can change based on load type, angle, and environmental conditions.

New equipment does not need inspection. Always inspect new chains for defects before use.

WLL applies only to individual components. The wll covers the entire lifting system, not just one part.

Relying on design factors to lift more than the wll is dangerous and undermines safety.

Note: Never justify lifting beyond the wll. Always follow the stated limits and regulations to protect your team and equipment.

You improve workplace safety when you understand and apply these standards. Powerful Machinery supports your compliance with certified products and clear documentation.

Inspection and Maintenance

Inspection Checklist

You need to perform regular inspections to keep your lifting chains safe and reliable. Inspections help you catch problems before they lead to accidents. Industry standards require documented periodic inspections at least once every 12 months.

If you use your chains in severe service conditions, you should inspect them monthly or quarterly. The table below shows recommended intervals:

Service Condition | Inspection Interval |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a qualified person |

During each inspection, check for visible damage, wear, and proper identification. Powerful Machinery chains feature clear markings and traceability codes, making close inspection easier and more effective. Always document your inspections for compliance and safety.

Removal Criteria

You must remove a chain from service if you find any signs of damage or doubt its integrity. Use the following criteria to decide when to retire a chain:

Missing or illegible identification tags

Cracks, breaks, or excessive wear

Nicks, gouges, or stretched links

Bent, twisted, or deformed components

Evidence of heat damage or weld splatter

Excessive pitting or corrosion

Chain or fittings that do not hinge freely

Any other condition that raises concern about safe use

If you spot any of these issues during regular inspections, take the chain out of service immediately. Powerful Machinery’s traceability features help you track the history and condition of each chain, supporting safe equipment management.

Storage Practices

Proper storage extends the life of your lifting chains and helps maintain their working load limit. Always store chains in a dry, mild climate to prevent corrosion. Make sure each chain is clean and dry before storage.

Keep chains off the ground and away from chemicals or corrosive environments. Use A-frames or racks to organize and transport multiple chains safely.

Tip: Good storage practices reduce the risk of hidden damage and make regular inspections more effective.

By following these inspection and maintenance guidelines, you protect your team and get the most value from Powerful Machinery’s durable, traceable products.

Accident Prevention

You play a key role in preventing accidents and extending the life of your lifting chains. By following best practices, you reduce the risk of equipment failure and workplace injuries. Powerful Machinery supports you with certified products and expert guidance, helping you create a safer work environment.

Training

Proper training forms the foundation of safe lifting operations. You need to understand how to use chains within their working load limits and recognize potential hazards. Many organizations offer training programs to help you build these skills:

Load Securement and Distribution: This course covers the North American Cargo Securement Standard. You learn how to apply working load limits and secure cargo safely.

Load Securement for Heavy Equipment: This training focuses on securing different types of heavy equipment, ensuring you know the specific requirements for each load.

You should complete these programs regularly to stay current with safety standards and best practices. Proper training helps you avoid common mistakes and keeps your team safe.

Monitoring Conditions

You must monitor environmental and operational conditions to prevent accidents. Real-time monitoring helps you detect hazards and respond quickly. The table below shows how monitoring supports safety:

Aspect | Description |

|---|---|

Hazard Detection | Identify safety hazards before they cause harm. |

Compliance Monitoring | Ensure operations meet safety regulations and standards. |

Incident Response | Respond quickly to incidents to reduce harm and downtime. |

Worker Health Monitoring | Track worker health, especially in hazardous conditions. |

Data Integration and Analysis | Analyze data from different sources for a complete safety overview. |

By tracking temperature, air quality, and equipment operation, you can take preventative measures before problems arise. Monitoring also helps you maintain compliance and protect your team from workplace injuries.

Proper Use

You must follow best practices every time you use lifting chains. These practices keep your equipment in top condition and prevent accidents:

Always use slings within the posted working load limit.

Distribute loads evenly among sling legs.

Avoid sudden stops, impacts, or rapid lifts.

Never use chains that are damaged, defective, or worn.

Protect chains from sharp edges with padding or protectors.

Inspect hooks and chains for wear or deformities before each use.

Remove any chain from service if you find damage.

These practices help you avoid equipment failure and ensure safe lifting operations.

Expert Consultation

Expert consultation gives you access to specialized knowledge and tailored safety programs. Professionals can assess your lifting operations, identify hazards, and develop custom safety strategies. They help you implement best practices and ensure compliance with industry standards.

Powerful Machinery offers expert support, on-site assessments, and guidance to help you prevent accidents and extend the life of your equipment.

Tip: Consult with safety experts to review your lifting practices and update your safety programs regularly.

By combining proper training, continuous monitoring, correct usage, and expert advice, you create a strong safety culture. These preventative measures protect your team, your equipment, and your business.

Powerful Machinery Chain Grades and Products

You need the right chain grades for safe and efficient lifting. Powerful Machinery offers a full range of industrial chains designed for demanding industrial applications. Each grade meets strict international standards and delivers reliable performance in the field.

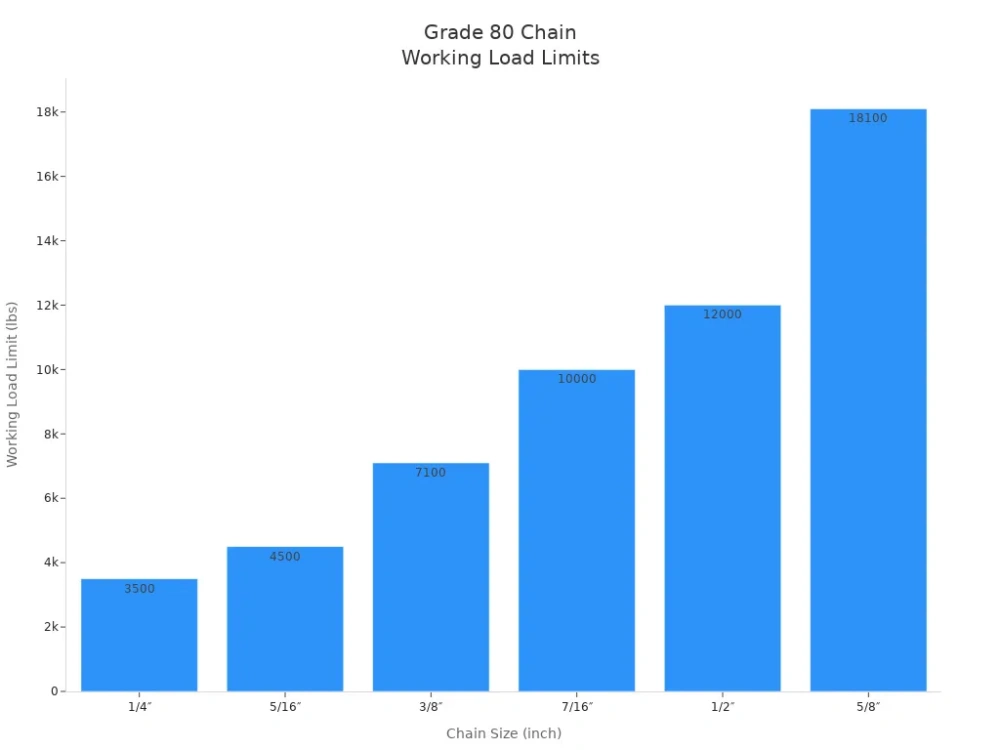

Grade 80 Chain

Grade 80 chains set the standard for heavy-duty lifting. You get high strength and excellent wear resistance because these industrial chains use premium alloy steel. Grade 80 chains are ideal for overhead lifting, rigging, and material handling. They meet ISO and EN safety standards, so you can trust them in critical operations.

Chain Size (inch) | Grade 70 WLL (lbs) | Grade 80 WLL (lbs) |

|---|---|---|

1/4″ | 3,150 | 3,500 |

5/16″ | 4,700 | 4,500 |

3/8″ | 6,600 | 7,100 |

7/16″ | 8,760 | 10,000 |

1/2″ | 11,300 | 12,000 |

5/8″ | 15,800 | 18,100 |

Larger Sizes | N/A | Up to 47,700 |

Grade 80 chains from Powerful Machinery feature clear markings for traceability. You can easily verify their working load limit before every lift.

Grade 100 Chain

You need Grade 100 chains for the toughest lifting jobs. This grade offers even higher strength than Grade 80, making it perfect for heavy construction, mining, and other demanding environments.

Grade 100 industrial chains handle heavier loads with a higher working load limit. Each chain comes with certification marks and date codes, so you always know your equipment meets the latest safety standards.

Feature | Grade 80 Chain | Grade 100 Chain |

|---|---|---|

Strength | High strength and durability | Even stronger, designed for heavier loads |

Working Load Limit (WLL) | Specific WLL marked on fittings | Higher WLL, can lift heavier loads |

Applications | Used in construction, manufacturing, etc. | Common in heavy construction, mining, etc. |

Grade 100 chains give you the confidence to tackle the most challenging lifting tasks.

Approved Applications

You can use Grade 80 and Grade 100 chains for overhead lifting, rigging, and load securement. G80 lifting chains also meet international safety standards for use in construction, marine, and logistics. These industrial chains are suitable for lifting, hoisting, and securing heavy loads in critical environments.

Note: Always check the chain grade and markings before each lift. Use only certified industrial chains from Powerful Machinery to ensure safety and compliance.

Powerful Machinery’s industrial chains deliver strength, durability, and full traceability. You get the right chain grade for every lifting challenge.

Conclusion

Understanding wll is essential for safe lifting operations and regulatory compliance. You protect your team and equipment when you follow best practices.

Always calculate wll accurately before every lift.

Select the right chain grade for your application.

Train operators to recognize wll limits and safe procedures.

Inspect and maintain chains regularly to prevent accidents.

Follow OSHA and industry standards for wll and lifting equipment.

Certified chains like Powerful Machinery’s Grade 80 and Grade 100 provide reliable wll, superior strength, and proven safety. You reduce risk and ensure every lift meets strict wll requirements.

FAQ

What does “Working Load Limit (WLL)” mean?

You see WLL as the maximum weight a chain can safely lift during normal use. Manufacturers calculate this value using the chain’s minimum breaking strength and a safety factor.

How do you identify the grade of a lifting chain?

You check the chain for stamped markings or tags. Powerful Machinery chains display grade, size, and certification codes for easy identification and traceability.

Can you use Grade 80 and Grade 100 chains for overhead lifting?

You use both Grade 80 and Grade 100 chains for overhead lifting. These chains meet international safety standards and provide reliable strength for demanding applications.

How often should you inspect lifting chains?

You inspect chains at least once every 12 months. If you use chains in severe conditions, increase inspection frequency to monthly or quarterly.

Tip: Always document inspections and remove chains showing wear or damage.

What is the difference between WLL and breaking strength?

Term | Meaning |

|---|---|

Working Load Limit | Maximum safe load for daily use |

Breaking Strength | The load at which the chain will fail |

You use WLL for operations. Breaking strength is for testing only.