Rigging hardware refers to the essential components you use for lifting, securing, and moving heavy loads in industries like construction and manufacturing. You often depend on reliable gear such as shackles, turnbuckles, hooks, master links, and swivel hoist rings.

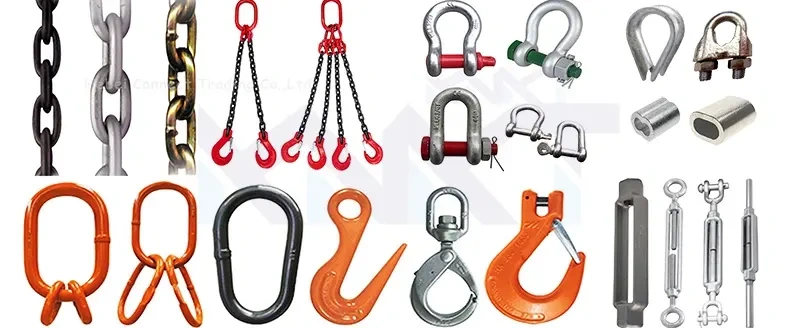

These types of rigging hardware play a critical role in safe lifting operations. Choosing the right hardware and following strict maintenance reduces the risk of workplace injuries. In fact, poor rigging leads to 27% of load drop incidents and most crane-related fatalities. Below, you can see the most common hardware types:

Rigging Hardware | Description |

|---|---|

Shackles | Used in many applications, available in screw pin and bolt pin types |

Turnbuckles | Adjust sling length and minimize weight |

Swivel Hoist Rings | Rotate freely for dynamic loads |

Master Links | Connect multiple slings |

Hooks | Essential for crane operations |

Key Takeaways

Understand the main types of rigging hardware, such as shackles, hooks, and slings, to ensure safe lifting operations.

Always inspect rigging equipment before use to prevent accidents and ensure compliance with safety standards.

Choose the right rigging hardware based on load characteristics and environmental conditions for optimal performance.

Follow strict maintenance practices, including regular inspections and proper storage, to extend the life of your rigging equipment.

Invest in training for your team to improve safety awareness and reduce the risk of lifting-related incidents.

Types of Rigging Hardware

You need to understand the main types of rigging hardware before you start any lifting or rigging project. Each piece of rigging equipment plays a unique role in keeping loads secure and operations safe.

Powerful Machinery offers a full range of rigging supplies designed for strength and reliability. Let’s explore the essential rigging hardware types you will encounter.

Shackles and Their Uses

Shackles are the backbone of many rigging systems. You use shackles to connect chains, wire ropes, and slings. Powerful Machinery manufactures different types of rigging shackles, including screw pin and bolt pin styles. These rigging supplies reinforce the integrity of your rigging equipment and prevent loads from slipping.

Tip: Always check the load capacity before using shackles. Some shackles can handle up to 1,500 metric tons, making them suitable for construction, marine, transportation, and mining.

Load Capacity | Common Applications |

|---|---|

Up to 1,500 metric tons | Construction, Transportation, Marine, Oil and Gas, Mining, Agriculture, Entertainment |

Rigging Hooks

Rigging hooks serve as the main point of contact between your crane and the load. You rely on hooks for precision and strength during lifting operations. Powerful Machinery offers a variety of rigging hooks, including clevis, eye, and swivel types. These rigging supplies connect chains, ropes, and slings, helping you prevent load slippage.

ASME B30.20 sets the standards for design, use, and inspection of rigging hooks.

You must inspect hooks before every lift and at least once a year, depending on usage.

Slings for Lifting

Slings form the backbone of lifting operations. You use slings to cradle and balance heavy loads. Powerful Machinery provides several types of rigging equipment, such as chain slings, wire rope slings, flat webbed slings, and round slings.

Alloy chain slings offer high strength and durability for harsh environments.

Synthetic slings, made from nylon or polyester, are lightweight and flexible. These slings mold to the shape of the load, protecting delicate items.

Web slings and round slings are ideal for sensitive loads but have lower lifting capacities.

Note: Always match the sling material to your load and environment. Chain slings work best for rugged jobs, while synthetic slings suit fragile items.

Turnbuckles in Rigging

Turnbuckles help you adjust the tension and length of cables, chains, or ropes. You use turnbuckles to fine-tune your rigging equipment for maximum safety and efficiency. Powerful Machinery’s turnbuckles feature threaded end fittings and a central frame, allowing precise tension control.

Clockwise rotation shortens the assembly and increases tension.

Counterclockwise rotation lengthens the assembly and reduces tension.

Turnbuckles work in marine, industrial, and construction settings.

Eyebolts and Hoist Rings

Eyebolts and hoist rings act as anchor points in rigging systems. You use eyebolts for straight pulls, but they cannot pivot. Hoist rings swivel and pivot, aligning with the load direction and reducing the risk of accidents.

Feature | Eyebolts | Hoist Rings |

|---|---|---|

Load Direction | Secure for straight pulls, cannot pivot | Allows movement in multiple directions |

Safety | Less safe for side loads, risk of failure | Enhanced safety, maintains load limit at any angle |

Design | Stationary anchor points | 360° swivel design to prevent lateral stress |

Tip: Choose hoist rings when you need to lift loads at different angles. Eyebolts work best for vertical lifts.

Pulleys and Blocks

Pulleys and blocks increase your mechanical advantage, making it easier to lift heavy objects. You use these rigging supplies to reduce the force needed for lifting. Powerful Machinery offers pulleys and blocks with roller or plain bearings for efficient operation.

Description | Value |

|---|---|

Mechanical Advantage (ideal) | Equal to the number of parts in the line that support the load |

Example of Mechanical Advantage | A 3:1 system allows a 100-pound pull to lift a 300-pound load |

Typical Efficiency Rates | 1.04 (roller bearing), 1.09 (plain bearing) |

The more rope segments you use, the greater the mechanical advantage.

Roller bearing sheaves offer higher efficiency than plain bearing sheaves.

Wire Ropes and Chains

Wire ropes and chains are essential types of rigging hardware for lifting and securing loads. You use wire ropes when you need flexibility and strength. Chains provide durability and resist harsh environments.

Feature | Wire Rope | Chain |

|---|---|---|

Breaking Strength | High | High |

Durability | Good, affected by temperature extremes | Excellent, resists harsh environments |

Maintenance | Complex, harder to inspect | Simple, easy to inspect |

Cost | More expensive | More affordable |

Flexibility | High, adapts to load shape | Lower, less adaptable |

Typical Uses | Flexible lifting applications | Heavy-duty lifting, tough environments |

Note: Use wire ropes for loads that need flexibility. Choose chains for heavy-duty jobs and environments that demand durability.

Steel Nuts and Accessories

Steel nuts and accessories work with eyebolts and other rigging equipment to anchor your rigging system. You use these rigging supplies to secure connections and maintain system integrity. Powerful Machinery produces high-quality steel nuts, washers, and fittings for reliable performance.

Steel nuts help anchor loads and prevent movement.

Accessories include thimbles, clips, and master links for added security.

Lifting Beams and Spreaders

Lifting beams and spreaders stabilize loads during lifting. You use these rigging hardware types to distribute weight evenly and prevent load damage. Powerful Machinery offers adjustable lifting beams and spreader bars for various applications.

Feature | Spreader Beam | Lifting Beam |

|---|---|---|

Force on Beam | Compression | Bending |

Crane Connection | Two angled top connections | Single central hook |

Bottom Lift Points | At each end | Multiple points along beam |

Headroom Required | High | Low |

Weight Efficiency | High | Lower |

Adjustability | Often fixed length | Adjustable bottom lugs |

Tip: Use spreader beams for wide loads that need even weight distribution. Lifting beams fit tight spaces and allow multiple lift points.

You now know the main types of rigging hardware and how each piece of rigging equipment supports safe and efficient lifting. Powerful Machinery’s certified rigging supplies help you tackle any lifting challenge with confidence.

Choosing Rigging Hardware

Assessing Load and Application

You must start every lifting and rigging project by evaluating the load. You need to know the weight, shape, and material of the object you plan to lift. The center of gravity affects stability during lifting operations. You can locate the center of gravity by lifting the load slightly and watching for shifts.

This step helps you choose the right rigging equipment and prevents accidents. Powerful Machinery offers industrial rigging equipment designed for different load types and lifting operations.

Tip: Always select rigging equipment rated for a load limit greater than your actual load. This ensures safety during lifting and moving tasks.

Load characteristics include weight, dimensions, and material.

The center of gravity determines how the load will behave during lifting and rigging operations.

Matching rigging equipment to the load reduces risk and improves efficiency.

Environment and Safety Standards

You must consider the environment before selecting rigging hardware. Moisture, temperature, and exposure to chemicals can affect rigging equipment. Stainless steel works best in wet conditions. Galvanized finishes resist corrosion. Powerful Machinery provides certified rigging hardware that meets international standards.

Standard | Description |

|---|---|

ASME B30.26 | Covers construction, installation, operation, inspection, and maintenance of rigging hardware for lifting operations. |

OSHA requires rigging inspections before each use.

Remove defective rigging equipment from service.

Identification and rated load must be visible on all rigging hardware.

Safety considerations for rigging operations include regular rigging inspections, proper training, and compliance with standards.

Matching Hardware to Tasks

You must match rigging hardware to the specific lifting and rigging task. Each job may require different rigging equipment, such as swivel hoist rings for dynamic loads or lifting beams for wide objects. Powerful Machinery offers custom solutions for specialized lifting operations.

Criteria | Custom Rigging Solution Benefits |

|---|---|

Non-standard load geometry | Tailored equipment meets specific load requirements |

Limited clearance | Custom solutions fit in tight spaces |

Insufficient stability/capacity | Ensures safety and efficiency during lifting operations |

“Just like you would select the best club for the distance and lie of the ball on the hole, you select the pieces of rigging equipment and slings that will best help to support and/or manipulate the load for a successful lift.”

Using certified rigging hardware from reputable manufacturers enhances safety and reliability.

Proper training ensures you use the right rigging equipment for each lifting and rigging operation.

Regular rigging inspections and maintenance extend the life of your rigging hardware.

You improve safety considerations for rigging operations by choosing the correct rigging equipment, following standards, and investing in training. Powerful Machinery supports you with certified products and custom solutions for all lifting and rigging needs.

Safety and Maintenance in Lifting and Rigging

Usage Guidelines

You must follow strict safety guidelines every time you perform heavy lifting. Start by confirming the weight of the load. Always use rigging hardware rated for the specific load you plan to lift. Select the correct hitch for stability.

Account for sling angles and tension, since improper angles can overload your rigging hardware during heavy lifting. Inspect all lifting hardware before each use. OSHA regulations require these inspections to prevent accidents. You should know the working load limit of every component.

When you perform heavy lifting, always adjust calculations for lifting angles. This keeps your equipment within safe operating limits.

Tip: Proper training helps you calculate load weights, determine stability, and inspect equipment. Ongoing training reduces human error and improves safety during heavy lifting.

Inspection Procedures

You need to inspect rigging hardware regularly to ensure safe heavy lifting. OSHA and ASME standards require documented inspections at least every 12 months for normal service. If you use equipment in severe service, inspect it monthly or quarterly.

During inspection, use a wire rope gauge to measure the diameter. Run a cloth along the wire ropes to detect broken wires. Pay close attention to areas near attachments and sheaves, since these spots often show wear. Inspect shackles, hooks, and other hardware for cracks or corrosion.

Document your findings with photographs. Maintain a consistent inspection schedule based on how often you perform heavy lifting.

Inspection Interval | Service Condition | Requirement |

|---|---|---|

12 months | Normal Service | Annual documented inspection |

Monthly/Quarterly | Severe Service | Frequent inspections |

Maintenance Best Practices

You extend the life of your rigging hardware by following maintenance best practices. Always conduct visual inspections before each heavy lifting operation. Replace damaged components immediately. Lubricate moving parts to prevent friction and corrosion.

Store synthetic slings in climate-controlled areas to avoid damage. Keep detailed records of inspections and maintenance. Follow manufacturer guidelines for every piece of rigging hardware. Train your staff in proper inspection and maintenance procedures.

When you maintain your equipment, you reduce accidents and downtime during heavy lifting. Facilities that follow these steps see longer equipment lifespan and fewer safety incidents.

Note: Companies that invest in ongoing training and maintenance experience fewer accidents and greater efficiency in heavy lifting operations.

Cause Type | Description |

|---|---|

Hardware Integrity | Corroded or cracked pins and bolts can fail during heavy lifting. |

Maintenance | Inadequate inspection leads to undetected damage. |

Inspection Practices | Skipping pre-use checks allows unsafe hardware in heavy lifting. |

Safety Culture | Weak tracking and replacement criteria increase risks. |

You improve safety and efficiency when you prioritize inspection, maintenance, and training for every heavy lifting project.

Conclusion

Choosing the right rigging hardware keeps your workplace safe and efficient. If you use the wrong gear or skip inspections, you risk serious accidents:

Misuse Type | Consequence |

|---|---|

Ignoring Weight Limits | It can cause dropped loads, injuries, or even death. |

Poor Inspection and Maintenance | Damaged equipment may fail and lead to accidents. |

You should inspect your equipment daily, follow proper maintenance steps, and consult experts for complex lifts. Trust Powerful Machinery for certified solutions.

Plan every lift carefully

Keep your team trained

Never use damaged hardware

Stay alert and make safety your top priority.

FAQ

What is the proper way to use a shackle?

You should inspect the shackle before each lift. Always align the load with the shackle’s body. Avoid side loading. Secure the pin tightly. Follow proper safety protocols to prevent accidents.

How do you ensure you are using eyebolts correctly?

You must choose the right eyebolt for your load. Always tighten it fully. Lift straight up. Never exceed the rated capacity. If you need to lift at an angle, use a swivel hoist ring.

What are the main types of hooks used for rigging?

You will find clevis hooks, eye hooks, and swivel hooks. Each type fits different lifting tasks. Always check the hook’s latch and inspect for wear. Use certified hooks for safe lifting.

What should you know about using turnbuckles?

You should select the correct size and material. Turn the body to adjust tension. Inspect threads for damage. Never overload a turnbuckle. Using turnbuckles properly helps maintain stability in your rigging system.

Do rigging courses help improve safety?

You gain essential skills from rigging courses. Training teaches you how to select hardware, inspect equipment, and follow proper safety protocols. Courses help you reduce risks and improve workplace safety.