You should never attempt chain hoist horizontal use. Powerful Machinery designs chain hoists for vertical lifting only. Pulling loads sideways can create serious safety issues for you and your team.

You risk damaging equipment and putting yourself in harm’s way. Powerful Machinery puts safety first and always recommends proper lifting solutions for every project.

Key Takeaways

Chain hoists are designed for vertical lifting only. Using them horizontally can lead to equipment damage and safety hazards.

Attempting horizontal pulling with a chain hoist can cause chain skipping, motor overload, and unstable loads, increasing the risk of accidents.

Always follow manufacturer guidelines to maintain safety and protect your warranty. Ignoring these can void your warranty and lead to costly repairs.

Consider using winches, lever blocks, or capstan systems for horizontal pulling tasks. These tools are designed to handle side loads safely.

In emergencies, if you must use a chain hoist horizontally, keep the load light and follow strict safety precautions to minimize risks.

Chain Hoist Horizontal Use Risks

Design Limitations

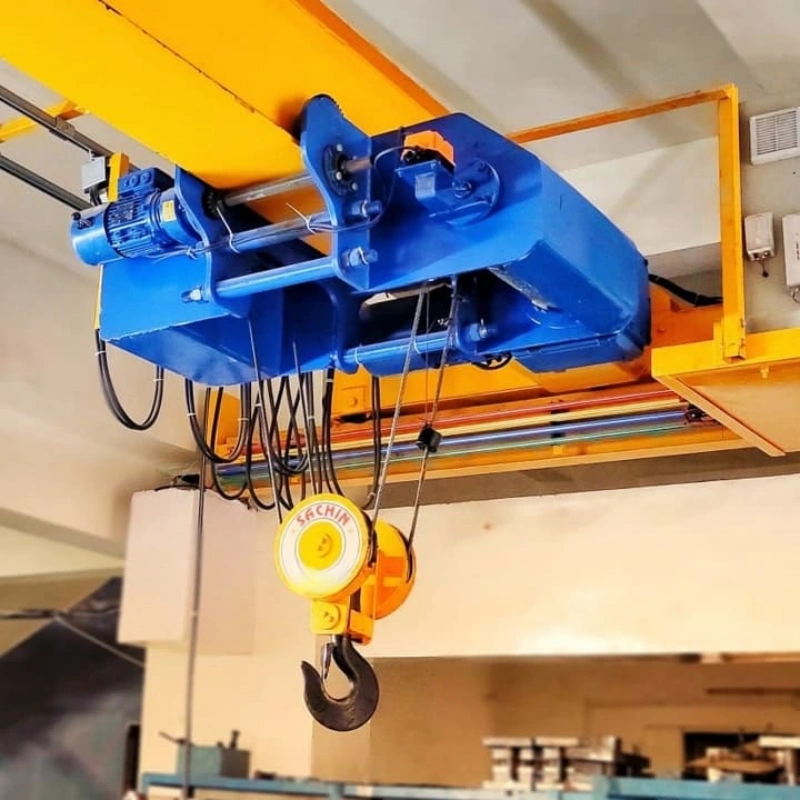

You need to understand why chain hoists, including those from Powerful Machinery, are engineered for vertical lifting only. The mechanical system inside a chain hoist operates by pulling a chain looped around a pulley. This system engages gears to lift loads straight up and down.

The design does not support side forces or off-angle movement. When you attempt a chain hoist horizontally, you force the equipment to work against its intended direction. This creates structural design limitations that can lead to abnormal engagement of the chain and gears.

The lack of horizontal guiding mechanisms means the hoist cannot keep loads stable or aligned during pulling. You risk equipment damage and reduce the efficiency of your lifting operation.

Safety Hazards

Chain hoist horizontal use introduces several safety hazards that you cannot ignore. The following table outlines the most common dangers:

Hazard Type | Description |

|---|---|

Structural Design Limitations | Chain hoists are designed for vertical lifting, leading to abnormal engagement and potential equipment damage. |

Safety Risks | Risks include chain skipping, motor overload, and detachment of mounting brackets due to unintended forces. |

Performance Issues | Lack of horizontal guiding mechanisms results in unstable movement and poor braking performance. |

When you use a chain hoist for horizontal pulling, you expose yourself and your team to safety risks. The chain can skip or slip off the lift wheel. The motor may overload, and the mounting brackets can detach under sideways force.

These hazards increase the chance of accidents and injuries. You also face the risk of equipment damage, which can lead to costly repairs or replacements.

Manufacturer Guidelines and Warranty

Major manufacturers, including Powerful Machinery, provide clear guidelines against the horizontal use. You must follow these instructions to maintain safety and protect your investment. The table below summarizes key considerations from manufacturer recommendations:

Key Considerations | Description |

|---|---|

Load Stability and Direction Control | Horizontal use can cause the load to swing or twist, necessitating proper guiding tools to maintain stability. |

Friction, Track Support, and Proper Guiding | A surface support is essential to prevent the chain from rubbing or skewing during horizontal pulls. |

Safety Risk Reduction Through Correct Hoist Selection | Not all hoists can handle side forces; selecting the right design minimizes risks of chain binding or gear strain. |

Reduced Lifting Efficiency and Higher Mechanical Stress | Horizontal pulling increases drag on internal gears, potentially shortening the hoist’s service life. |

Chain Skewing Risks During Non-Vertical Pulling | Side pulling can lead to chain bunching or slipping off the lift wheel, especially at large angles. |

Motor and Gearbox Protection Through Correct Alignment | Sideways tension can strain internal bearings, making alignment crucial for performance. |

Following Manufacturer Guidelines and Load Limits | Adhering to manuals and load charts is vital for maintaining equipment integrity during horizontal use. |

Using Trolleys, Slings, and Anchors for Correct Load Pathing | Additional tools help stabilize horizontal pulls and ensure proper load pathing. |

Preventing Side Loading Through Proper Equipment Choice | Choosing a hoist capable of handling angled pulls helps avoid damage and repair costs. |

If you ignore these guidelines and attempt improper horizontal pulling, you risk voiding your warranty. Manufacturers will not cover equipment damage caused by misuse. Always use the right equipment for the job and consult the manual before attempting any pulling operation.

Powerful Machinery recommends following all safety instructions and using certified lifting solutions for every application.

Electric Chain Hoist Safety Concerns

Component Stress and Failure

When you use an electric chain hoist for horizontal pulling, you expose the equipment to forces it was not designed to handle. This practice increases stress on the motor, gears, and load chain. You may notice several common failures:

Worn load chain

Twisted or kinked load chain

Corroded chain, especially in humid conditions

Improperly lubricated chain

Abnormal noise and vibration during operation

Horizontal pulling introduces uneven stress, which can lead to excessive wear and a shorter service life. You risk damaging the internal gears and the hoist body. Dusty or wet environments can make these problems worse, causing the chain to wear out faster and reducing overall performance.

Braking and Load Stability

Electric chain hoists rely on precise vertical alignment for safe operation. When you pull horizontally, you compromise the stability of the load. The braking system may not function as intended, increasing the risk of uncontrolled movement or swinging. You can see the main risks in the table below:

Risk Type | Description |

|---|---|

Excessive Wear | Components may wear out prematurely due to unintended forces. |

Reduced Stability | Side loads can cause binding or derailment, increasing tip-over risk. |

Equipment Damage | Prolonged use can damage internal mechanisms, leading to failures. |

Voided Warranty | Warranties may be voided if used outside the intended design. |

You must always consider these safety concerns before using electric chain hoists in any non-vertical application. Unstable loads can lead to accidents and injuries, putting your team at risk.

Powerful Machinery Product Standards

Powerful Machinery designs every electric chain hoist to meet or exceed international safety standards. You benefit from features such as overload protection, emergency stop functions, and explosion-proof motors. These hoists offer high efficiency and reliable performance in demanding environments.

You can trust the durability of each component, including spark-resistant parts and stainless steel load chains. Powerful Machinery ensures that every electric chain hoist delivers consistent performance and safety, even in challenging conditions.

Tip: Always use your electric chain hoist according to the manufacturer’s guidelines. This practice protects your equipment, your warranty, and your team’s safety.

Alternatives to Chain Hoist Horizontal Use

When you need to move heavy loads horizontally, you should always choose dedicated equipment designed for that purpose. Using the right tool not only improves efficiency but also keeps your team safe. Below, you will find better alternatives to chain hoists for horizontal pulling tasks.

Winches and Pullers

Winches and pullers offer a professional horizontal pulling alternative. These devices are built to handle side loads and provide controlled movement across flat or slightly inclined surfaces. You can select from several types, each with unique features:

Type of Winch | Description | Capacity |

|---|---|---|

Manual Winch | Provides extra strength for heavy objects, using gears for controlled pulling. | Varies by model |

Electric Winch | Designed for ease of use, suitable for horizontal pulling applications. | Varies by model |

Dutton-Lainson Winch | Specifically built for horizontal pulling with a 1,400 lb capacity. | 1,400 lb |

Thern Winches | Manual and powered options for pulling heavy loads horizontally. | Varies by model |

Winches differ from hoists in both design and safety. Winches focus on horizontal movement and include basic safety features like brakes. Hoists, on the other hand, are made for vertical lifting and come with advanced safety systems such as overload protection and emergency stops.

Capstans and Hydraulic Systems

Capstan winches and hydraulic systems provide strong and reliable options for horizontal pulling. You benefit from constant pulling power, which means the force does not drop as the line extends.

Many capstan winches are lightweight and portable, so you can use them in remote or tight spaces. The design allows you to operate the equipment from a safe distance, reducing the risk of injury. Compact construction makes these systems ideal for confined areas where space is limited.

Note: Capstan winches and hydraulic systems give you flexibility and safety for demanding horizontal pulling jobs.

Powerful Machinery Solutions

Powerful Machinery offers a range of dedicated equipment for horizontal pulling. You can choose between chain blocks (hand chain hoists) and lever blocks (come-alongs), each designed for specific tasks.

Chain blocks use a gear reduction system for steady movement, while lever blocks use a ratchet-and-pawl system for precise, incremental control. Lever blocks stand out for their flexibility, allowing you to pull loads vertically, horizontally, or at an angle.

This makes them suitable for tight spaces and high-altitude work. Powerful Machinery builds all products with durability and simplicity in mind, ensuring you get reliable performance and easy maintenance.

If you want to maximize safety and efficiency, always select equipment that matches your application. Powerful Machinery’s solutions meet strict industry standards, giving you confidence in every pull.

Emergency Guidelines for Chain Hoist Horizontal Use

You may face situations where you must use a chain hoist for horizontal pulling in an emergency. You should only do this as a last resort and follow strict safety recommendations.

Powerful Machinery always urges you to use the right equipment for each application. If you must proceed, you need to understand the limits and take every possible precaution.

Load and Distance Limits

You must keep the load as light as possible. Never exceed 50% of the chain hoist’s rated vertical capacity. Shorten the pulling distance to the minimum required. The longer the distance, the higher the risk of misalignment and damage. You should avoid sharp angles and keep the pulling path straight.

If you notice any resistance or abnormal noise, stop immediately to prevent further damage.

Operational Precautions

You need to follow proper usage recommendations and take extra precautions during emergency horizontal use. Manufacturer guidelines play a key role in shaping your actions:

Manufacturer guidelines dictate maintenance schedules and safety protocols.

These guidelines ensure the reliability of chain hoists based on testing and experience.

Adhering to these guidelines influences training, inspections, and operational procedures, especially in emergencies.

You must inspect the hoist before and after use. Check for signs of wear, bent hooks, or twisted chains. Use additional protective measures such as slings or trolleys to stabilize the load. Make sure you and your team have received proper training on emergency procedures.

Never allow untrained personnel to operate the hoist.

The table below highlights the main risks you face during emergency horizontal pulling:

Risk Type | Description |

|---|---|

Misalignment of Load | Hoists are not designed for side loads, leading to potential misalignment. |

Excessive Wear | Horizontal pulling can cause uneven wear on the hoist’s components. |

Inefficient Operation | The hoist may jam or require more maintenance when misused. |

Safety Hazards | Unstable loads or hoist failure can lead to accidents and injuries. |

Monitoring and Safety Protocols

You must monitor the operation closely at all times. Assign a spotter to watch for shifting loads or unusual sounds. Stop work immediately if you see any sign of damage or instability. Review all safety recommendations before starting and after finishing the task.

Keep a record of any incidents or maintenance needs. These measures help you maintain control and reduce the risk of accidents. Always remember, Powerful Machinery recommends using equipment designed for horizontal pulling whenever possible.

Note: Emergency use does not replace proper usage recommendations. Always return to standard procedures as soon as possible.

Conclusion

You face serious risks when you use chain hoists for horizontal pulling. Manufacturer guidelines help you prevent accidents and improve safety.

Compliance Benefits | Design Considerations |

|---|---|

Documented safety measures | Minimum slip index requirements |

Reduced liability exposure | Material compatibility with footwear |

Insurance requirement fulfillment | Environmental condition effects |

Audit preparation support | Maintenance impact on performance |

Powerful Machinery recommends come-alongs for horizontal applications. These tools offer efficient movement and suit utility or automotive work. Consulting with Powerful Machinery gives you access to certified experts, proactive compliance, and practical training.

Benefit | Description |

|---|---|

Experience and Qualifications | Consultants with hands-on experience and certifications ensure knowledgeable guidance. |

Proactive Compliance | Mock audits help identify deficiencies before official inspections, enhancing compliance readiness. |

Comprehensive Training | Targeted training programs build competent workers, essential for implementing safety policies. |

Practical Evaluation | Hands-on assessments confirm that team members can apply safety procedures effectively. |

You protect your team and equipment when you choose the right solutions.

FAQ

Can you use a chain hoist for horizontal pulling in any situation?

You should avoid using a chain hoist for horizontal pulling. The design supports vertical lifting only. Emergency use may require it, but you must follow strict safety guidelines and manufacturer instructions to reduce risks.

What happens if you use a chain hoist incorrectly?

Incorrect use of a chain hoist can cause equipment damage, personal injury, and void your warranty. You risk chain skipping, gear strain, and unstable loads. Always follow the recommended procedures for safe operation.

How do you maintain a chain hoist for optimal performance?

You should inspect your chain hoist regularly. Check for wear, bent hooks, and twisted chains. Lubricate moving parts as needed. Follow the manufacturer’s maintenance schedule to ensure safe and reliable lifting every time.

What alternatives exist for horizontal pulling instead of a chain hoist?

You can use winches, lever blocks, or capstan systems for horizontal pulling. These tools handle side loads better than a chain hoist. Powerful Machinery offers solutions designed for safe and efficient horizontal movement.

Why does Powerful Machinery recommend vertical use for a chain hoist?

Powerful Machinery engineers each chain hoist for vertical lifting. The internal gears and chain mechanism work best in this direction. Using a chain hoist vertically ensures safety, stability, and long-lasting equipment performance.

Tip: Always choose the right tool for your lifting or pulling task. Consult Powerful Machinery for expert advice on chain hoist applications.

Chain Hoist Safety Tips | Description |

|---|---|

Inspect before use | Look for damage or wear |

Follow guidelines | Use the chain hoist only as intended |

Train operators | Ensure proper handling |