You rely on rigging hardware to move, lift, and secure heavy loads safely across industries. Rigging hardware forms the backbone of lifting operations, protecting people and assets while supporting demanding projects.

Improper rigging causes 27% of load drops in the lifting industry, making safety and proper equipment essential. The global market for lifting and rigging hardware continues to expand, reflecting its importance in construction, marine, and cargo sectors.

Region | Market Size in 2021 (USD million) | Market Size in 2025 (USD million) | Growth Rate (%) |

|---|---|---|---|

North America | 1122.25 | 1410.82 | 79.55 |

Europe | 1128.49 | 1411.36 | 79.96 |

Asia Pacific | 876.03 | 1057.97 | 82.80 |

Powerful Machinery delivers certified rigging solutions engineered for safety and reliability. You benefit from our expertise and commitment to quality in every lifting operation.

Key Takeaways

Rigging hardware is essential for safely moving and securing heavy loads across various industries.

Always select rigging equipment that matches the load’s weight and type to prevent accidents.

Regular inspections and maintenance of rigging hardware are crucial for safety and compliance with industry standards.

Use certified rigging products to ensure reliability and reduce the risk of equipment failure during lifting operations.

Consult experts for guidance on rigging hardware selection and best practices to enhance safety and efficiency.

Rigging Hardware Overview

What Is Rigging Hardware?

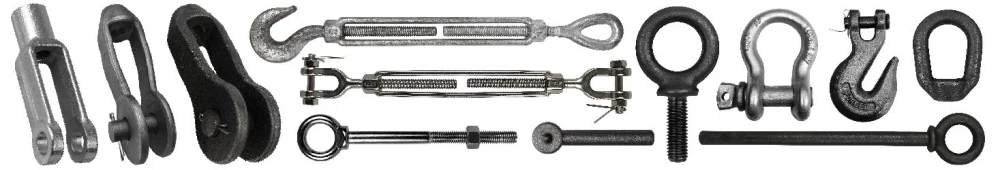

You depend on rigging hardware every time you move, lift, or secure heavy objects in your workplace. Rigging hardware includes specialized components such as shackles, hooks, slings, and wire ropes. These parts connect loads to cranes, hoists, or other lifting devices.

You use rigging hardware to create safe and reliable connections that support the weight and movement of materials.

Rigging hardware stands at the core of safe material handling. You find it in construction sites, shipyards, warehouses, and entertainment venues. Each piece must meet strict standards to prevent accidents and ensure smooth operations.

Powerful Machinery supplies certified rigging hardware that meets or exceeds international safety requirements. You can trust their products because they undergo thorough inspections before entering service.

Competent personnel check for damage or defects, and frequent inspections take place daily or before each use. Periodic reviews guarantee that every component remains in top condition.

Core Functions and Uses

You rely on rigging hardware for three main functions:

Lifting: You attach loads to cranes or hoists for vertical or horizontal movement.

Securing: You stabilize and anchor materials during transport or storage.

Moving: You guide and control the direction of heavy objects with precision.

Note: Proper rigging hardware selection and use protect your team and equipment from costly accidents.

You see rigging hardware in action when lifting steel beams on a construction site, securing cargo on a ship, or moving stage equipment in an arena. Powerful Machinery supports your operations with a wide range of certified products and expert guidance.

Their commitment to quality and safety helps you complete projects efficiently and safely.

Types of Rigging Hardware

Rigging equipment forms the backbone of safe lifting operations. You use different types of rigging hardware to connect, secure, and move loads in various environments. Each component serves a specific purpose and meets strict safety standards.

Powerful Machinery offers a full range of certified rigging equipment that complies with international regulations, ensuring reliability in every application.

Shackles and Hooks

Shackles are essential connectors in rigging equipment. You use shackles to join slings, hooks, and other hardware. They come in several types, each designed for specific tasks. The table below shows common types of shackles and their features:

Type of Shackle | Description | Typical Load Capacity (WLL) |

|---|---|---|

Round Pin Shackles | Designed for in-line applications, not recommended for overhead lifting. | N/A |

Specialty Types | Includes synthetic sling shackles, wide body shackles, and long reach shackles. | N/A |

Carbon Steel Shackles | Design Factor of 6:1, ductile, available in various designs. | N/A |

Alloy Steel Shackles | Design Factor of 5:1, stronger than carbon steel, smaller design possible. | N/A |

Galvanized Shackles | Coated for corrosion resistance, suitable for industrial applications. | N/A |

Stainless Steel Shackles | Best corrosion resistance, ideal for marine use. | N/A |

You rely on shackles for secure connections in lifting, towing, and anchoring. Powerful Machinery manufactures shackles from high-tensile steel and stainless steel, meeting ISO and ASTM standards for strength and durability.

Hooks play a vital role in rigging equipment. You use hooks to attach loads to slings or lifting devices. Rigging hooks come in several types, such as eye hooks, clevis hooks, and swivel hooks. Each type offers unique advantages for different lifting scenarios.

Common reasons for hook failure include overloading beyond the working load limit, tip loading, and continued use of worn hooks. You must inspect hooks regularly and retire any that show signs of wear, stretching, or cracks.

Tip: Always match the right type of shackle and hook to your rigging application. Inspect shackles and hooks before each use to prevent accidents.

Slings and Wire Ropes

Slings are flexible straps that connect loads to lifting devices. You choose from several types of slings, including wire rope slings and synthetic slings. Each type offers distinct benefits for different environments.

Feature | Wire Rope Slings | Synthetic Slings |

|---|---|---|

Durability | Resistant to abrasion, heat, and crushing | Vulnerable to sharp edges & UV damage |

Safety | Better for extreme environments | Excels in lightweight, delicate lifts |

Wire rope slings provide strength and durability for heavy-duty rigging equipment. You use them in construction, marine, and industrial settings. Synthetic slings offer lightweight handling and flexibility, making them ideal for delicate or irregular loads.

International standards govern the manufacturing of slings and wire ropes. Powerful Machinery produces slings and wire ropes that comply with ISO 7531:1987, ensuring consistent quality and safety.

Standard Code | Description | Notes |

|---|---|---|

ISO 7531:1987 | Wire rope slings for general purposes — Characteristics and specifications | Specifies type, working load limit, and manufacturer of slings and sling assemblies. |

You must select slings based on load type, environment, and required safety factors. Powerful Machinery offers custom-engineered slings and wire ropes for specialized projects.

Blocks, Pulleys, and Turnbuckles

Blocks and pulleys increase lifting capacity and change the direction of force. You use these rigging equipment components to lift heavy loads with less effort. Block and tackle systems provide a significant mechanical advantage, allowing you to move large objects safely.

Type of Pulley System | Mechanical Advantage | Description |

|---|---|---|

Simple Pulley System | 3:1 | A 100-pound pull raises a 300-pound load. |

Compound Pulley System | 6:1 (2:1 + 3:1) | Combines simple systems for more advantage. |

Complex Pulley System | 5:1 | More efficient, less friction. |

You use blocks and pulleys to amplify force and reduce input effort. Fixed pulleys change the direction of force, while movable pulleys increase mechanical advantage. Powerful Machinery supplies blocks and pulleys designed for high-load applications, meeting international safety standards.

Turnbuckles allow you to adjust tension in rigging systems. You use turnbuckles to tighten or loosen connections without twisting the attached lines. Turnbuckles consist of two threaded eye bolts or hooks connected by a central body. You rotate the body to adjust the tension or length of ropes, cables, or chains.

Note: Blocks, pulleys, and turnbuckles help you control heavy loads with precision. Always use certified rigging equipment for critical lifts.

Eye Bolts, Nuts, and Accessories

Eye bolts and nuts serve as anchor points in rigging equipment. You install eye bolts to secure loads or attach lifting devices. In critical lifting applications, you must apply the correct tightening torque using a calibrated torque wrench.

Always follow the manufacturer’s specified values to prevent loosening and failure due to excessive tensile stress. If no torque value is provided, do not proceed until you receive official confirmation.

The choice of material, such as forged carbon steel or stainless steel, affects the safety and durability of your rigging hardware. Powerful Machinery manufactures eye bolts and nuts from premium materials, ensuring long-lasting performance.

Accessories complete your rigging equipment setup. You use slings, shackles, hooks, and specialized hardware to attach, distribute, and control loads. Safety harnesses provide secure attachment points for riggers working aloft.

Slings attach loads to lifting devices.

Shackles join rigging components.

Hooks facilitate load attachment.

Safety harnesses protect riggers during elevated work.

Alert: Always use certified accessories and follow manufacturer guidelines for installation and inspection.

Powerful Machinery delivers a comprehensive range of rigging hardware and accessories, all tested to exceed international standards. You benefit from reliable products and expert support for every lifting operation.

Rigging Hardware Selection

Load and Application

You must select rigging hardware that matches the exact weight and type of your load. Start by knowing the weight and center of gravity. This helps you prevent accidents during lifting operations. Always use load-rated hardware that meets or exceeds the working load limit for your lifting equipment.

The working load limit is based on the minimum breaking load and a safety factor. You should also check for the proper size and ensure the hardware fits your lifting setup. The angle of load application affects the rated capacity, so adjust your selection for any changes in angle.

If your setup is temporary or permanent, this will influence your hardware choice. Powerful Machinery offers custom-engineered solutions to help you select the right rigging hardware for every lifting scenario.

Know the load weight and center of gravity.

Use load-rated hardware that matches or exceeds the working load limit.

Adjust for load angle and application type.

Check for proper size and fit.

Environment and Frequency

The environment plays a major role in your hardware selection. High temperatures can weaken synthetic fibers and change steel properties. Chemicals and salt can cause corrosion or damage protective finishes. Abrasion from rough surfaces or dust can shorten the life of your hardware.

Wind and dynamic loads can create shock loads, which may lead to fatigue. You must also consider how often you use the hardware. Frequent lifting of heavy loads requires more durable materials and regular inspection.

Powerful Machinery provides expert support to help you choose materials that withstand harsh conditions and frequent use.

Consider temperature, chemicals, and salt exposure.

Watch for abrasion and dust.

Prepare for wind and dynamic loads.

Inspect hardware regularly if used often.

Compatibility and Standards

You need to ensure all rigging components work together safely. Avoid using items that have been repaired or modified. Never use shackles with the wrong size or pins that are not properly rated. Do not use homemade or unmarked devices. Always check for missing or illegible identification tags.

Damaged or corroded hardware, broken wires, or deformed parts can cause failure during lifting. Make sure your rigging hardware complies with industry standards such as ASME and OSHA. Powerful Machinery supplies load-rated hardware that meets or exceeds these standards, giving you confidence in every lift.

Use only certified, load-rated hardware.

Avoid modified or homemade equipment.

Check for proper identification and condition.

Ensure compliance with industry standards.

Tip: Consult Powerful Machinery’s experts for guidance on selecting the safest and most reliable rigging hardware for your lifting operations.

Rigging Safety Standards

Working Load Limits and Ratings

You must always know the safe working load for every piece of rigging hardware you use. The working load limit is the maximum load a component can safely handle during lifting. Manufacturers determine this limit by testing the material strength, design, and performance under stress.

They use both static and dynamic tests to ensure each part meets strict requirements. You will find the working load limit clearly marked on certified equipment. Exceeding this limit can cause equipment failure and put your team at risk.

Working load limit: Maximum load a component can safely handle.

Material strength: Includes tensile and yield strength.

Design factors: Shape, size, and intended use affect the limit.

Testing: Static and dynamic tests confirm safety.

Safety factors: Built in to reduce risk and increase reliability.

WLL is calculated using both theoretical calculations and real-world testing. This process ensures you can trust your rigging hardware during every lift.

Industry Regulations

You must follow industry standards and regulations to keep every lifting operation safe. In the United States, OSHA and ASME set the main rules for rigging hardware. These organizations require regular inspections, proper labeling, and strict adherence to load limits.

Regulation | Description |

|---|---|

OSHA 29 CFR 1926.251 | Sets requirements for rigging equipment in material handling operations. |

ASME B30.20 | Covers below-the-hook lifting devices and is often referenced by OSHA. |

Internationally, you see similar standards from ISO and ANSI. These groups focus on workplace safety, equipment care, and fall protection.

Organization | Focus | Key Standards |

|---|---|---|

OSHA | Workplace safety regulations | General Duty Clause, inspections, citations |

ASME | Rigging safety standards | ASME B30 series for cranes and rigging |

ANSI | Standards development accreditation | ANSI/ASSP Z359 fall protection series |

ISO | International safety guidelines | ISO 4309 for wire rope care, ISO 16881 safety |

Powerful Machinery’s products meet or exceed these industry standards. You benefit from certified rigging hardware that supports safe and reliable lifting worldwide.

Qualified Riggers

You need qualified riggers to ensure every lift is safe and efficient. A qualified rigger has the right training, experience, and knowledge to identify hazards and prevent accidents. Certification is not required by OSHA, but it shows that a rigger understands best practices and industry standards.

Recognized degree, certification, or extensive training in rigging.

Ability to spot hazards and take action to avoid them.

Demonstrated competence in safe lifting operations.

Tip: Always use qualified riggers for critical lifts. Their expertise protects your team and equipment.

Powerful Machinery supports your commitment to safety by providing certified products and expert guidance for every project.

Rigging Hardware Inspection

Inspection Frequency

You must inspect rigging hardware on a regular schedule to keep your lifting operations safe. The frequency depends on how often you use the equipment and the environment. In normal service, you should perform inspections at least every 12 months.

If you work in severe conditions, such as high temperatures or heavy use, you need to inspect monthly or quarterly. Special service conditions require a qualified person to set the schedule.

Service Condition | |

|---|---|

Normal Service | At least every 12 months |

Severe Service | Monthly to quarterly |

Special Service | As recommended |

You should also consider how often you use the hardware, the harshness of the environment, and the type of loads you handle. Powerful Machinery recommends regular inspections and offers guidance to help you set the right schedule for your operation.

What to Check?

When you inspect rigging hardware, you need to check for wear, cracks, and other signs of damage. Always look for missing or illegible identification tags. If you find any, remove the item from service right away.

For synthetic slings, check for wear such as cuts, tears, or chemical exposure. For alloy chains, check for cracks, stretched or bent links, and heat damage. Wire ropes require you to check for wear, broken wires, corrosion, and deformation.

Type of Damage | Description | Consequences |

|---|---|---|

Missing/Illegible Identification Tags | Tags are required for all rigging equipment | Immediate removal from service |

Damage to Synthetic Slings | Cuts, tears, UV, or chemical exposure | Remove sling from service |

Stretched/Bent Links on Alloy Chains | Cracks, excessive wear, heat damage | Removethe chain from service |

Broken Wires/Corrosion on Wire Rope | Kinking, distortion, or corrosion | Remove the wire rope from service |

Tip: Always check for wear and check for cracks during every inspection. Remove defective items immediately.

When to Replace?

You must replace rigging hardware if you find any critical damage. For wire rope slings, replace them if you see corrosion, bending, abrasions, or damaged hooks. Alloy chains need replacement if you find welding defects, deformed links, or rust.

Synthetic slings must be replaced if you see acid burns, melting, or tears. Never use hardware that fails inspection.

Rigging Hardware Type | Signs of Damage |

|---|---|

Wire Rope Slings | Corrosion, bending, abrasions, damaged hooks, and excessive wear |

Alloy Chains | Welding defects, deformed links, rust, heat damage |

Synthetic Web/Round Slings | Acid burns, melting, charring, tears, and distortion |

Powerful Machinery supports you with the best practices for inspection and replacement. Their team helps you identify when to retire equipment and select safe replacements.

Rigging Maintenance

Maintenance Benefits

You protect your team and equipment when you follow a regular maintenance schedule. Proper care extends the life of your rigging hardware and keeps your operations running smoothly.

Industry studies show that routine checks and maintenance reduce unexpected failures and help you meet legal requirements for safety. You also see better performance from your equipment when you keep it in top condition.

Evidence Point | Description |

|---|---|

Regular inspections | Routine checks significantly extend the lifespan of rigging slings and reduce unexpected failures. |

Compliance | Regular maintenance ensures compliance with legal requirements, which is crucial for safety. |

Performance | Proper care and maintenance lead to reliable performance of rigging hardware. |

Powerful Machinery recommends that you set up a maintenance plan for all your lifting equipment. Their products are built for durability, but regular care ensures you get the best results and maximum safety.

Best Practices

You can prevent corrosion and damage by following proven maintenance and safety tips. Start with regular visual inspections to spot wear and tear early. Always follow the manufacturer’s guidelines for each piece of hardware. Keep detailed records of all inspections and maintenance activities.

Lubricate moving parts to prevent rust and reduce friction. Train your staff in proper inspection and maintenance procedures.

Clean and polish stainless steel components to maintain their protective layer.

Use anodes for cathodic protection against corrosion.

Wash cables and terminals with fresh water after exposure to salt or chemicals.

Avoid covering stainless steel with materials that trap moisture.

Inspect rigging often to catch cracks or other issues before they become serious.

Tip: Consistent maintenance and safety tips help you avoid costly repairs and downtime. You keep your rigging hardware strong and reliable for every lift.

Powerful Machinery provides detailed maintenance recommendations for all their products. You can rely on their support to keep your equipment performing at its best.

Rigging Applications

Construction and Marine

You see rigging hardware at the heart of construction and marine projects. On construction sites, you use lifting equipment to move steel beams, concrete panels, and heavy machinery. In marine environments, you rely on specialized rigging to secure cargo, lift anchors, and handle mooring lines.

You must protect metal rigging from seawater damage by using hot-dip galvanizing with a thick protective layer. For long-term exposure, you add fluorocarbon anti-corrosion paint. You rinse hardware with fresh water after each operation to remove salt and prevent corrosion.

Fiber rigging needs protection from UV rays and oil stains, so you store and clean it properly. In deep-sea work, you use sacrificial anodes like zinc blocks to shield your equipment from corrosion. Powerful Machinery supports you with certified products designed for harsh construction and marine conditions.

Transportation and Cargo

You depend on rigging hardware to secure and move goods in transportation and cargo handling. You use blocks and pulleys to lift containers and heavy freight. Eye bolts and rigging hooks help you attach loads to cranes and hoists. Wire ropes and stainless steel nuts keep cargo stable during transit.

You choose the right lifting equipment to match the weight and shape of each load. Powerful Machinery supplies reliable solutions for ports, rail yards, and logistics centers around the world. Their products help you keep shipments safe and operations efficient.

Blocks and pulleys for lifting and guiding loads

Eye bolts for secure attachment points

Rigging hooks for connecting slings and chains

Wire ropes and accessories for stability

Stainless steel nuts for corrosion resistance

Entertainment and Other Industries

You use rigging to create safe and dynamic stage setups in the entertainment industry. You trust ETCP Certified Electricians and Technicians to manage and supervise lifting operations. You promote electrical safety and follow best practices in every venue. You support ongoing training to keep your team up to date.

You follow regulations from ANSI, ESTA, and OSHA to protect performers, crew, and audiences. Compliance with these standards reduces legal risks and keeps everyone safe. You always choose qualified personnel for overhead work because safety is critical.

Powerful Machinery’s expertise and certified hardware support your projects in theaters, arenas, and event spaces worldwide.

Note: You find rigging hardware in many other industries, including energy, mining, and manufacturing. Powerful Machinery’s global customer base trusts their products for strength, reliability, and compliance with international standards.

Conclusion

You secure long-term success when you choose the right rigging hardware and follow strict inspection and maintenance routines. Reliable products from certified suppliers like Powerful Machinery help you improve efficiency and protect your team.

Investing in high-performance gear reduces downtime and ensures safety in every lift. Consult industry experts and always follow best practices to keep your operations running smoothly.

FAQ

What is the difference between a shackle and a hook?

You use a shackle to connect two rigging components. You use a hook to attach a load to lifting equipment. Both play unique roles in safe lifting operations.

How often should you inspect rigging hardware?

You should inspect rigging hardware before each use. Schedule formal inspections at least once a year. Increase inspection frequency for harsh environments or heavy use.

Why do you need certified rigging hardware?

Certified rigging hardware meets strict safety and quality standards. You reduce the risk of accidents and ensure compliance with industry regulations when you choose certified products.

Does Powerful Machinery offer custom rigging solutions?

Yes. You can request custom-engineered rigging hardware from Powerful Machinery. Their team works with you to design products that fit your project’s exact requirements.