You want peace of mind every time you lift a heavy load. Powerful Machinery gives you certified solutions trusted by professionals worldwide. You choose from nylon, polyester, wire rope, or chain slings, each designed for your job. Picking the best lifting slings improves safety and keeps your project running smoothly.

Key Takeaways

Choose the right sling type for your project. Chain slings are best for heavy loads, while synthetic slings are ideal for delicate items.

Always check the working load limit before lifting. This ensures safety and prevents accidents during operations.

Inspect your slings regularly to catch any damage early. Regular checks help maintain safety and reliability.

Select slings made from materials that suit your environment. For marine use, opt for corrosion-resistant options like stainless steel.

Proper storage and cleaning extend the life of your slings. Keep them in a dry, cool place and clean them after each use.

Best Lifting Slings Comparison

Sling Types Overview

You want the best lifting slings for your project. Powerful Machinery offers a full range of options to match your needs. You can choose from chain, wire rope, synthetic, and round slings. Each sling type brings unique advantages for construction and marine work.

Chain slings deliver unmatched strength and durability. Wire rope slings offer flexibility and high load capacity. Synthetic slings, including nylon and polyester, provide lightweight handling and gentle lifting for sensitive loads. Round slings give you flexibility and easy inspection.

Here’s a quick comparison to help you decide:

Sling Type | Material | Lifting Capacity | Ideal Applications |

|---|---|---|---|

Chain Slings | Alloy Steel | Very High | Heavy industrial lifting, foundries, steel handling |

Wire Rope Slings | Steel (Galv./SS) | High | Construction, rigging, marine, flexible heavy lifts |

Nylon Slings | Nylon Webbing | Moderate | Indoor, light/medium loads, general material handling |

Polyester Webbing | Moderate | Marine, boat handling, chemical plants | |

Polyester/Nylon | Moderate | Versatile lifting, sensitive or irregular loads |

Material and Capacity

You need slings that match your load and environment. Chain slings handle the heaviest loads and resist abrasion, UV, and chemicals. Wire rope slings give you high strength and flexibility, perfect for rugged sites.

Synthetic slings, like nylon and polyester, are lightweight and strong, making them easy to use and ideal for delicate surfaces. Round slings offer flexibility and less than 1% stretch, so you get precise control. For marine use, stainless or galvanized wire rope resists corrosion and stands up to harsh conditions.

Ideal Applications

You can trust Powerful Machinery slings for every industry. Use chain slings for heavy equipment and steel in construction. Choose wire rope slings for rigging and marine lifts.

Nylon slings work best for indoor jobs and general handling. Polyester slings excel in marine and chemical environments. Round slings adapt to irregular shapes and sensitive loads.

Every Powerful Machinery sling meets Grade 80 or Grade 100 standards. You get certified ratings, batch tracking, and full compliance with international safety standards. This means you lift with confidence, every time.

Types of Lifting Slings

Choosing the right lifting sling makes your job safer and more efficient. Powerful Machinery gives you a complete selection of slings for every construction or marine challenge. You get certified quality, proven materials, and options that fit your exact needs.

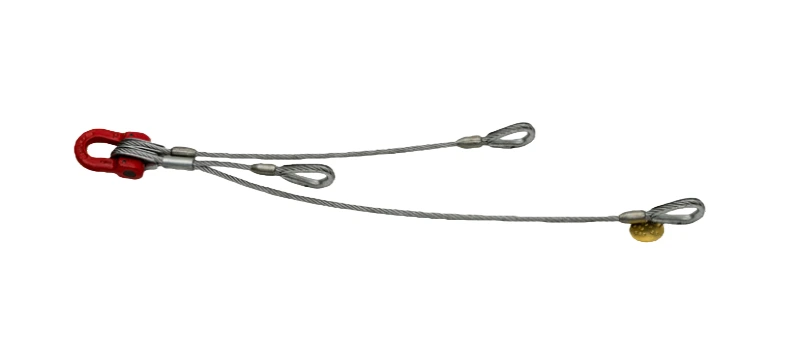

Wire Rope Slings

Wire rope slings give you the perfect balance of strength and flexibility. You can use them for heavy lifting in construction, shipyards, and marine operations. These slings handle tough environments and resist crushing or bending. You get reliable performance, even with sharp edges or abrasive surfaces.

Powerful Machinery offers wire rope slings in galvanized or stainless steel, so you can pick the best option for harsh marine conditions. Every sling meets strict international standards and comes with batch tracking for safety.

Chain Slings

Chain slings deliver unmatched durability for your heaviest lifting jobs. You can trust them in steel plants, construction sites, and marine yards. These slings handle high temperatures and rough loads without breaking down.

Powerful Machinery uses high-tensile alloy steel for every chain sling, giving you maximum strength and long service life. You get adjustable leg options to match different load shapes. Each sling passes proof testing and includes a metal tag with certification details.

Synthetic Slings (Nylon & Polyester)

Synthetic slings give you lightweight handling and gentle lifting for sensitive or finished loads. You can use nylon slings indoors for general material handling. Polyester slings work well in marine and chemical environments because they resist moisture and chemicals.

These slings bend easily around odd-shaped loads and reduce the risk of surface damage. Powerful Machinery’s synthetic slings include batch tracking and clear load ratings, so you always know your lifting limits.

Round Slings

Round slings offer flexibility and easy inspection. You can use them for lifting irregular or delicate loads in construction and marine settings. These slings have a strong core of polyester or nylon fibers, covered by a durable sleeve.

You get precise control with less than 1% stretch. Powerful Machinery’s round slings meet Grade 80 and Grade 100 standards, giving you confidence in every lift.

Powerful Machinery tests every sling to twice its working load limit. You get full certification, traceability, and peace of mind for every lifting operation.

Feature | Chain Slings | Wire Rope Slings | Synthetic Slings |

|---|---|---|---|

Material | Alloy Steel Chain | Strands of Steel Wire | Nylon or Polyester |

Best For | Very heavy, hot, or sharp loads | General heavy lifting, flexible use | Delicate or odd-shaped loads |

Temperature | Handles high heat | Wide range | Sensitive to heat |

Sharp Edges | Excellent resistance | Good resistance | Needs edge protection |

Weight | Heavy | Medium | Very light |

Rust | Can rust if untreated | Can rust if untreated | No rust |

Best Slings for Construction

Top Wire Rope Slings

You want the best lifting sling for tough construction jobs. Wire rope slings from Powerful Machinery give you high strength and flexibility. You can trust these slings for lifting heavy loads like steel beams, concrete panels, and machinery. The wire rope slings handle sharp edges and rough surfaces without losing durability.

You get options in galvanized or stainless steel, so you can match the sling to your site conditions. Each sling meets a strict working load limit and passes proof testing for safety.

Powerful Machinery wire rope slings hold certifications from ISO9001, TUV Rheinland, OSHA, and more. You see the certification tag on every sling, so you know you are using a product that meets international standards.

Customers like Ben Carter from Canada say, “These wire rope slings made our tower crane lifts faster and safer.” You get batch tracking for every sling, which supports inspections and traceability.

Top Chain Slings

You need chain slings when you face the heaviest lifting applications. Powerful Machinery chain slings use high-tensile alloy steel for maximum strength and long service life. You can use them for moving large steel structures, heavy equipment, and crane lifting straps on busy construction sites.

The adjustable leg options let you handle different load shapes with ease. Each chain sling comes with a metal tag showing the working load limit and certification details.

Chain slings from Powerful Machinery meet Grade 80 and Grade 100 standards. You get full compliance with industry certifications like ISO9001, ASTM, and Tested Safety.

Customers trust these slings for their durability and reliability. David Müller from Germany says, “We rely on these chain slings for every critical lift. They never let us down.”

Best Synthetic Slings

You want synthetic slings when you need lightweight handling and protection for delicate loads. These slings are easy to carry and set up, which saves you time and effort.

Synthetic slings from Powerful Machinery include both nylon and polyester options. You can use slip-resistant nylon lifting slings for general material handling indoors. Polyester slings work well in outdoor or chemical environments.

Here’s why you should choose synthetic slings for your construction site:

Advantage | Description |

|---|---|

Lightweight | Synthetic slings are significantly lighter than wire rope or chain, enhancing handling and transport. |

Flexibility | They conform to the shape of the load, providing a secure grip and reducing damage risk. |

Load Protection | Less likely to damage delicate surfaces, suitable for high-value or fragile items. |

High Strength-to-Weight Ratio | Despite being lightweight, they offer excellent lifting capacity for heavy tasks. |

Resistance to Environmental Factors | More resistant to abrasion, corrosion, and extreme weather, making them reliable in various conditions. |

You get clear load ratings and batch tracking for every synthetic sling. These slings meet the highest safety standards and support regular inspections. You can replace them easily and choose from a wide range of sizes. Synthetic slings give you the best lifting strap for sensitive or irregular loads.

Use Cases in Construction

You can use Powerful Machinery slings for almost every construction task. Here are some real-world examples:

Move steel beams, concrete panels, and heavy machinery with wire rope slings. You improve precision and reduce manual labor.

Use chain slings for lifting large structures and equipment. You get unmatched durability and high strength for the toughest jobs.

Choose synthetic slings for handling glass panels, finished materials, or fragile items. You protect surfaces and speed up your workflow.

Large infrastructure projects in cities use high-capacity wire rope slings for tower crane operations. You boost safety and speed on your site. You can trust Powerful Machinery slings because they hold certifications like ISO9001, TUV Rheinland, OSHA, and more.

Tip: Always check the working load limit before every lift. You keep your team safe and your project on track.

You want the best lifting slings for your construction site. Powerful Machinery gives you certified, reliable, and flexible options for every lifting challenge.

Best Slings for Marine Use

Corrosion-Resistant Wire Rope

You need wire rope slings that stand up to the toughest marine environments. Saltwater, humidity, and UV rays can break down ordinary slings, but Powerful Machinery gives you wire rope slings built for the sea. Choose from galvanized or stainless steel options.

These slings resist corrosion and deliver high strength for every lift. You can use them for shipyard work, dockside loading, or offshore construction. Each sling comes with a clear working load limit, so you always know your safe lifting range.

Powerful Machinery wire rope slings meet strict international standards. You see certifications from DNV-GL, IMCA, and ISO9001 on every tag. You get batch tracking for every sling, making inspections and traceability simple.

Customers like Liam O’Connell from Australia say, “These wire rope slings handle our heaviest marine lifts and never let us down.” You can trust these slings for critical lifting applications where safety matters most.

Synthetic Slings for Marine

You want synthetic slings when you need flexibility and protection for sensitive loads. Powerful Machinery offers synthetic slings made from high-strength polyester or nylon fibers. These slings are lightweight, easy to handle, and perfect for boat handling or lifting delicate equipment.

You get a non-abrasive surface that protects valuable cargo from scratches or dents. Specialty coated slings with polyurethane coatings give you extra durability and abrasion resistance.

Synthetic slings resist corrosion and chemicals, so you can use them in saltwater or harsh weather.

You get precise control for every lift, making them ideal for sensitive or irregular loads.

These slings maintain high load capacities, even in tough conditions.

You see the working load limit clearly marked on every sling. Batch tracking supports your safety checks and inspections. You can rely on synthetic slings for marine lifting because they combine strength, flexibility, and certified safety.

Chain Slings for Marine

You need chain slings for the most demanding marine jobs. Powerful Machinery chain slings deliver unmatched durability and performance. Use them for recovering sunken gear, securing heavy anchors, or lifting massive ship components.

Chain slings show superior heat tolerance and abrasion resistance compared to synthetic slings or wire rope slings. You get reliable lifting, even in harsh saltwater environments.

Each chain sling meets Grade 80 or Grade 100 standards. You see certification tags and batch records for every sling. These slings pass proof testing and comply with international safety standards. You can trust chain slings for heavy-duty marine lifting applications where failure is not an option.

Note: Chain slings are heavier than other types. For smaller vessels, you may prefer synthetic slings or wire rope slings for easier handling.

Use Cases in Marine Operations

You face unique challenges in marine lifting. Powerful Machinery gives you the best lifting slings for every situation. Here are some common use cases:

Use corrosion-resistant wire rope slings for ship-to-shore transfers, mooring, and offshore platform lifts.

Choose synthetic slings for handling boat hulls, sensitive equipment, or irregularly shaped cargo.

Rely on chain slings for anchor recovery, heavy mooring, or lifting large marine structures with crane lifting straps.

Every sling from Powerful Machinery meets international safety standards. You see compliance with IMCA guidelines, DNV-GL certification, and resistance to corrosion and UV radiation.

Standard/Guideline | Description |

|---|---|

IMCA Guidelines | Safe use of lifting equipment, with focus on inspections and handling in saltwater environments |

DNV-GL Standards | Certification and standards for safety and performance in marine lifting |

Corrosion and UV Resistance | Slings must resist corrosion and UV exposure for long service life in marine operations |

You want peace of mind for every lift. Powerful Machinery slings give you certified safety, high strength, and reliable performance in every marine operation.

How to Choose a Lifting Sling?

Selecting the right lifting sling gives you control, safety, and efficiency for every job. You want to match your sling to your load, environment, and lifting applications. Follow these steps to make the best choice with Powerful Machinery.

Assessing Load and Environment

Start by looking at your load. You need to know the weight, size, and shape. Check the working load limit on each sling to make sure it can handle your task. Think about the environment. High heat, chemicals, or moisture can affect sling performance.

For example, synthetic slings work well in wet or chemical-rich areas, but you should avoid them in high temperatures. Use this table to guide your decision:

Factor | Description |

|---|---|

Load Weight and Size | Make sure the sling’s working load limit exceeds your load. Consider shape. |

Environmental Conditions | Heat, chemicals, and humidity impact sling performance. |

Load Type | Delicate loads need synthetic slings. Heavy or abrasive loads need chain or wire rope. |

Frequency of Use | For frequent lifting, choose wire rope or chain for durability. |

Safety Standards | Always check for compliance with safety standards. |

Material Selection

Choose the material that matches your needs. You want high strength for heavy loads, so pick chain or wire rope slings. For delicate or finished items, select nylon or polyester slings.

Synthetic slings are lightweight and easy to handle. Wire rope slings give you flexibility and high strength for tough jobs. Chain slings work best for extreme lifting applications and crane lifting straps.

Configuration Options

Pick the right configuration for your load. Powerful Machinery helps you with custom solutions. You can choose single-leg, two-leg, three-leg, or four-leg slings. Adjustable options let you handle different shapes and lifting points. Make sure your sling fits your equipment and lifting method.

Assess your load and application.

Evaluate the environment.

Check compatibility with your lifting equipment.

Compliance and Certification

You want peace of mind with every lift. Powerful Machinery slings meet ISO-9001, OSHA, and other international standards. Each sling comes with batch tracking, so you can access inspection histories and compliance records using RFID tags or QR codes.

This ensures safety and traceability for every lifting operation. Always review certification tags and documentation before use.

Tip: Choose Powerful Machinery for certified ratings, batch tracking, and custom-engineered slings that fit your unique lifting needs.

Safety and Maintenance

You want every lift to be safe and efficient. Proper care and regular checks for your sling and slings keep your team protected and your equipment reliable. Follow these essential practices to get the most from your Powerful Machinery lifting solutions.

Inspection Guidelines

You should inspect each sling before use and at set intervals. Regular checks help you spot damage early and prevent accidents. Use this table to guide your inspection schedule:

Inspection Type | Frequency |

|---|---|

Initial Inspections | When the sling is first acquired |

Frequent or Pre-Shift Inspections | Daily, weekly, or before every use |

Periodic Inspections | Every 6 to 12 months |

Special Inspections | After incidents or repairs |

International standards like OSHA 1910.184 and ASME B30.9 require yearly inspections at a minimum. For harsh conditions, inspect your slings more often.

Proper Storage

You can extend the life of your sling with smart storage. Follow these best practices:

Store slings in a clean, dry, and well-ventilated area.

Keep them away from direct sunlight and extreme temperatures.

Use lockers or rigging boxes to protect slings from dirt and UV rays.

Choose a cool, dark space to maintain strength and flexibility.

Keep slings away from chemicals that could cause damage.

Cleaning and Care

You keep your sling in top shape by cleaning it regularly. Use mild soap and water to remove dirt and contaminants. Avoid harsh chemicals that can weaken the material. Always dry your slings completely before storing them. Regular cleaning and inspections help you spot wear and prevent early failure.

Extending Sling Life

You want your slings to last. Inspect them often, store them properly, and clean them after each use. Replace any sling that shows signs of wear, cuts, or broken stitching. Follow international safety standards for inspections and maintenance. When you care for your slings, you protect your team and your investment.

Tip: A well-maintained sling delivers reliable performance and keeps every lift safe.

Conclusion

You want the best lifting slings for every project. Powerful Machinery gives you certified solutions that improve safety, speed up rigging cycles, and protect valuable assets. You avoid hand injuries and work efficiently in tight spaces. See the main benefits below:

Benefit | Description |

|---|---|

Improved Safety | Lighter design reduces injuries and muscle strain. |

No Hand Lacerations | Prevents cuts from jagged wire ropes. |

Asset Protection | Soft body design keeps equipment safe. |

Faster Rigging Cycles | Quick setup means more lifts each day. |

Improved Flexibility | Easy use in tight spaces boosts efficiency. |

Choose the best lifting sling for your needs. Visit Powerful Machinery’s website to get expert advice and find the right solution.

FAQ

What materials do Powerful Machinery lifting slings use?

You get slings made from nylon, polyester, wire rope, and high-tensile alloy chain. Each material offers unique benefits for different lifting jobs. Choose the best fit for your load and environment.

How do I know which sling is right for my job?

Check your load weight, shape, and environment. Use chain or wire rope for heavy, rugged tasks. Pick synthetic slings for delicate or irregular loads. You can always contact Powerful Machinery for expert advice.

Are the Powerful Machinery slings certified for safety?

Absolutely! Every sling meets or exceeds international standards like ISO9001, OSHA, and TUV Rheinland. You see certification tags and batch tracking on every product. You lift with confidence and full traceability.

How often should I inspect my lifting slings?

Inspect your slings before each use. Schedule periodic checks every 6 to 12 months. If you spot damage or after any incident, inspect immediately. Regular inspections keep your team safe and your equipment reliable.