You rely on a strong lifting chain and a dependable chain block for every heavy job. Safe chain block repair ensures that your lifting chain works as intended and keeps your team protected. Regular maintenance stands at the heart of safety and reliability in every lifting job.

Industry studies indicate that following a regular maintenance schedule can help prevent malfunctions and extend the life of your chain block. Key steps include checking every chain for wear, testing brake systems, and ensuring proper lubrication.

Powerful Machinery delivers certified lifting chain solutions and stands by you with high-quality products. When you notice unusual noises, visible damage, or a stiff chain, use the right tools and consider professional help for chain block repair to maintain peak performance and ensure safety.

Key Takeaways

Prioritize safety by wearing personal protective equipment like hard hats, gloves, and safety glasses during chain block repairs.

Conduct regular inspections of chains, hooks, and brakes to identify wear and prevent accidents before they happen.

Use certified replacement parts from Powerful Machinery to ensure compatibility and maintain safety standards during repairs.

Follow proper cleaning and lubrication practices to extend the lifespan of your chain block and keep it running smoothly.

Schedule annual professional inspections to ensure your chain block meets safety regulations and remains reliable for lifting jobs.

Safety First with Powerful Machinery Chain Blocks

Before you begin any chain block repair, you must prioritize safety. Powerful Machinery chain blocks meet strict international standards, ensuring you work with equipment that delivers reliability and peace of mind. You protect yourself and your team by following these essential steps.

Personal Protective Equipment

You need to wear the right gear every time you handle a chain block. Choose a hard hat, safety glasses, and gloves to shield yourself from falling objects and sharp chain links.

Steel-toed boots help prevent injuries if a chain or component drops. High-visibility clothing keeps you noticeable in busy work zones. You should never skip PPE, even for quick chain inspections.

Workspace Preparation

You create a safe environment by preparing your workspace before starting chain block repair. Clear away debris and ensure the floor is dry and stable. Set up barriers or warning signs to keep unauthorized personnel away from the chain block area.

You must check that the lighting is adequate so you can see every chain link and hook clearly. Secure the chain block to prevent accidental movement. You inspect chains, hooks, and brakes for visible damage or wear.

You verify the load weight and balance before lifting. Proper setup prevents side-loading and reduces the risk of accidents.

Tip: Powerful Machinery chain blocks undergo rigorous testing to 150% of their rated capacity and maintain a safety coefficient of at least 4:1. These products meet or exceed EN13157, ASME B30, CE, and ISO standards. Optional overload protection systems are available for enhanced safety.

Lockout and Tagout Steps

You must follow lockout and tagout procedures to prevent accidental activation during chain block repair. Disconnect the chain block from any power source. Attach a lock and tag to the control mechanism, signaling that maintenance is in progress. You record the lockout in your maintenance log.

Only authorized personnel should remove locks and tags after confirming the chain block is safe to use. This step protects everyone from unexpected chain movement.

Safety Feature | Description |

|---|---|

Pre-Operation Checks | Inspect chains, hooks, and brakes; verify load weight and balance. |

Proper Setup | Securely mount the hoist and balance the load to prevent side-loading. |

Safe Lifting Techniques | Lift slowly, stay out of the danger zone, and monitor the load continuously. |

You reduce risks and ensure safer lifting jobs by following these steps. Powerful Machinery’s certified chain blocks give you confidence that your equipment meets the highest safety standards.

Common Chain Block Repair Issues

Worn Chains and Hooks

You often see wear and tear on the hoist chain and hooks after repeated lifting jobs. Worn chains can lead to dangerous situations if you ignore them. You must inspect the hoist chain for signs of stretching, corrosion, or cracks. Damaged hoist chain links weaken the entire system.

Replace any hoist chain that shows visible damage. Hooks also require close attention. Look for cracks, deformation, or signs of stretching. If you spot a damaged hoist chain or hook, swap it out immediately. You protect your team and equipment by staying alert to these issues.

Tip: Clean the hoist chain thoroughly with a dry cloth and brush away dirt. Grease important parts like chain links and gear teeth to keep the hoist running smoothly.

Stuck Lever Block Troubleshooting

You may encounter a stuck lever block during hoist operation. This issue can halt your lifting job and create safety risks. Common causes include chain jamming, brake issues, and environmental factors.

Chain jamming happens when the hoist chain gets twisted or debris blocks its path. Brake problems can cause slippage or wear, making the lever block hard to operate. Environmental factors, such as dust or moisture, also contribute to a stuck lever block.

To fix a stuck lever block, follow these steps:

Inspect the hoist chain for kinks, twists, or foreign objects.

Lubricate the hoist chain to reduce friction.

Check the brake system for wear or slippage.

You can identify and fix a stuck lever block quickly by following these troubleshooting steps. Regular maintenance prevents most stuck lever block issues.

Gear and Brake Problems

You must pay attention to gear and brake problems in your hoist. Worn gears can cause the hoist chain to slip or jam. Brake issues may lead to uncontrolled lowering or failure to hold the load. Always check the hoist chain and gears for signs of wear. Replace damaged hoist chain components as needed.

Test the brake system before every lifting job. You ensure safe operation by addressing these problems early.

Common Hoist Chain Issues | Prevention and Repair Steps |

|---|---|

Overloading | Follow Safe Working Load guidelines |

Ignoring Inspections | Conduct checks before each use |

Improper Rigging | Balance and secure the load |

Inadequate Maintenance | Lubricate and replace worn parts |

Ignoring Guidelines | Use manufacturer procedures |

You keep your hoist chain and lever block in top condition by following these repair tips. Powerful Machinery’s certified products help you maintain safety and reliability in every lifting job.

Tools and Parts for Chain Block Repair

Essential Hand Tools

You need the right tools to repair a hoist and keep your chain block in top condition. Choose a set of wrenches, screwdrivers, and pliers for most chain block repairs. You use a socket set to remove bolts and nuts from the hoist. A hammer helps you tap out stuck pins or links.

You rely on a chain gauge to measure wear and check if you need to replace hoist chain components. You keep a torque wrench handy to tighten bolts to the correct specification. You use a wire brush to clean chain links and hoist gears. You must inspect your tools before every job to ensure safety and efficiency.

Tip: Organize your tools in a toolbox for quick access during chain block repair. This reduces downtime and keeps your workspace tidy.

Lubricants and Cleaning Supplies

You maintain your hoist and chain block by using proper lubricants and cleaning supplies. Choose a high-quality chain lubricant to reduce friction and prevent rust. You apply lubricant to chain links, gears, and moving parts of the hoist. You use a degreaser to clean old oil and grime from the chain.

A dry cloth helps you wipe down chain surfaces after cleaning. You select a non-abrasive cleaner for delicate hoist components. You avoid using water on steel chain links to prevent corrosion. You keep all cleaning supplies within reach to streamline your chain block repair process.

Cleaning Supply | Purpose |

|---|---|

Chain Lubricant | Reduces friction, prevents rust |

Degreaser | Removes old oil and grime |

Wire Brush | Cleans chain links and gears |

Dry Cloth | Wipes chain surfaces |

Powerful Machinery Replacement Parts

You trust Powerful Machinery for certified replacement parts when you repair your hoist and chain block. These replacement parts ensure compatibility with your existing chain block. You improve reliability and reduce the risk of failure during operation.

You meet strict safety standards with every replacement, which enhances overall safety. You select replacement chains, hooks, gears, and brake components that match your hoist specifications. You use only certified replacement parts to maintain the integrity of your chain block.

You extend the lifespan of your hoist by choosing quality replacement products from Powerful Machinery.

Certified replacement parts ensure compatibility with your chain block.

They enhance reliability and reduce the likelihood of failure.

Adherence to safety standards improves safety during use.

Note: Powerful Machinery replacement parts undergo rigorous testing and meet international certifications. You can find the full range of replacement chains, hooks, and hoist components at Powerful Machinery’s official website.

Chain Block Repair Steps

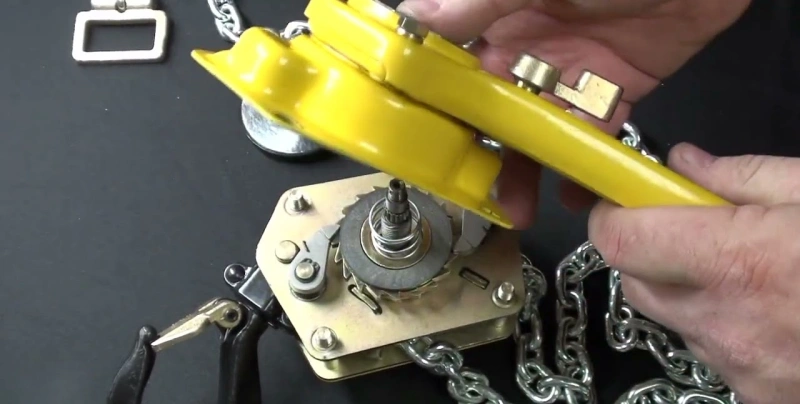

Disassembly and Inspection

You start chain block repair by disassembling the hoist and inspecting every component. Begin with a clean chain block to avoid introducing dirt or debris. Follow these steps for a thorough inspection:

Remove the hoist cover and examine the top hook for distortion, and check the safety catch.

Inspect the hoist body for cracks or other damage.

Check the hand chain wheel and guide for smooth operation.

Verify the slack end anchor for the load chain is secure.

Assess the load chain for wear, bent links, and corrosion.

Inspect the bottom hook and safety catch for distortion and proper function.

Conduct an operational test with a light load to ensure the hoist moves smoothly.

During inspection, you often find issues such as wear between chain links, stretching from overload, nicks, gouges, cracks, twisting, kinking, and corrosion. Hooks may show deformation, cracks, or material loss.

Replace any damaged parts immediately. You minimize risk by checking each hoist component before proceeding.

Safety Reminder: Always disconnect the hoist from any power source and secure the chain block before starting chain block repair. Wear PPE and keep your workspace clear.

Cleaning and Lubrication

You maintain the hoist by cleaning and lubricating all chain block components. Use approved cleaning agents and lubricants that protect against rust and reduce wear. The following table shows the benefits of recommended products:

Feature | Description |

|---|---|

FDA-Approved Ingredients | Safe for incidental food contact |

Unsurpassed Lubricity | Provides excellent lubrication for hoist operation |

Superior Rust Protection | Shields chain and hoist from corrosion |

Non-drip Characteristics | Prevents mess and waste during chain block repair |

Anti-wear Additives | Extends the life of hoist and chain components |

Cleaning Aid | Removes old oil, dirt, and enhances maintenance |

Apply lubricant to the load chain, hand chain wheel, and gears. Clean the chain with a wire brush and wipe down surfaces with a dry cloth. Avoid water on steel chain links to prevent corrosion. Proper cleaning and lubrication keep the hoist running smoothly and extend the life of your chain block.

Tip: Lubricate the chain after every chain block repair and before each hoist operation. This reduces friction and prevents rust.

Replacing Damaged Components

You replace damaged hoist parts during chain block repair to restore safe operation. Remove worn chains, hooks, gears, and brake components. Use only certified replacement parts from Powerful Machinery to ensure compatibility and reliability.

Inspect the new chain for straightness and proper pitch. Check hooks for latch function and integrity. Install the new components according to the manufacturer’s instructions.

Common issues that require replacement include:

Interlink wear between chain links

Permanent chain stretching

Surface nicks, gouges, and cracks

Twisting or kinking of the chain

Rust and pitting

Hook deformation or material loss

You protect your team and equipment by replacing damaged hoist parts promptly. Record each chain block repair in your maintenance log.

Note: Never reuse damaged chains or hooks. Always use certified parts for chain block repair.

Reassembly and Testing

You reassemble the hoist after chain block repair by following manufacturer’s instructions. Ensure all parts fit securely and the chain moves freely. Lubricate the load chain and hand chain wheel as recommended. Attach the nameplate and tags, making sure they are legible.

Test the hoist with a light load to verify smooth chain travel. Measure the pitch and crown of the chain; scrap the chain if elongation exceeds limits. Inspect hooks for latch function and integrity. Test the brake by lifting a small load and checking for creep.

Maintain records of each chain block repair and schedule regular inspections.

Best Practice | Description |

|---|---|

Read Manufacturer Instructions | Follow Powerful Machinery’s guidelines for hoist operation |

Regular Inspection | Inspect the hoist regularly and replace worn parts |

Lubrication | Lubricate the chain as recommended |

Brake Testing | Test brake holding ability with a controlled load |

Safety Reminder: Position yourself away from the load during testing. Raise and lower loads steadily. Maintain communication with your team. Familiarize yourself with emergency procedures.

You complete the chain block repair by confirming the hoist operates safely and efficiently. Powerful Machinery’s certified products and guidelines help you achieve reliable performance in every lifting job.

Post-Repair Safety Checks

You must confirm that your hoist and chain block are safe for lifting jobs after every repair. Powerful Machinery recommends a series of checks that align with international safety standards. These steps help you avoid equipment failures and protect your team.

Load Testing

You start by performing load tests on the hoist. These tests verify the structural integrity and performance of the chain block. You follow industry standards such as ASME B30.20 and OSHA Section 1926.251, which require testing to 125% of the working load limit. You use different types of load tests to ensure reliability.

Type of Load Test | Description |

|---|---|

Proof Load Test | Simulates operational load with a static load above WLL. |

Functional Load Test | Applies dynamic loads for real operating conditions. |

Ultimate Load Test | Determines maximum load-bearing capacity. |

Cyclical Fatigue Test | Evaluates equipment under repeated stress. |

You conduct a proof load test before using a repaired hoist. You schedule periodic tests as required by the manufacturer. You always test after any incident involving the chain block.

Visual Inspection

You inspect the chain and hoist components for signs of damage. You check chains for gouges, nicks, corrosion, and distorted links. You measure a section of chain for elongation and look for twist or side bow. You verify that pins are in their original position and rollers run freely.

You ensure the chain feeds smoothly into and away from the sprockets under load. You check for discoloration or pitting. You inspect ropes and web straps for safety. These steps help you spot issues before they become hazards.

Tip: Powerful Machinery recommends visual inspections after every repair and before each lifting job. This practice prevents catastrophic failures and severe injuries.

Functionality Verification

You confirm that the hoist operates as intended. You inspect the block body for cracks and defects. You check the lifting chain and hand chain for wear. You ensure all bolts, pins, and fasteners are tight.

You examine hooks and latches for proper function. You conduct operational tests with a light load to verify smooth chain movement. You record results in your maintenance log.

Inspect the block body for cracks and corrosion.

Check the chain and hand chain for damage.

Tighten bolts, pins, and fasteners.

Examine hooks and latches.

Test hoist with a light load.

Consequence | Description |

|---|---|

Catastrophic Failures | Neglecting inspections can cause accidents. |

Severe Injuries | Lack of safety checks can injure personnel. |

Fatalities | In extreme cases, neglecting safety checks can lead to loss of life. |

Economic Losses | Skipping inspections may result in financial losses and legal issues. |

Reduced Operational Integrity | Regular maintenance ensures the reliability of lifting equipment. |

You maintain safety and reliability by following these post-repair checks. Powerful Machinery’s certified chain blocks meet strict standards, giving you confidence in every lifting job.

When to Call a Professional?

Severe Damage Signs

You must recognize when your chain block needs more than routine maintenance. Severe damage can compromise safety and performance. If you notice rust or discoloration on the chain, this signals corrosion that weakens the metal. Pitting and stress cracking reduce the chain’s tensile strength.

Non-uniform links affect the chain’s ability to function properly. You should also look for nicks, gouges, holes, cuts, or tears. Melting or charring from heat damage means immediate removal from service. Excessive abrasions or frayed fibers indicate wear that must be addressed.

Ignoring these signs can lead to accidents on the job site. You must remove the chain from service or seek professional repair if you see any of these issues.

Visible corrosion or rust

Nicks, gouges, or abrasions

Melting or charring

Holes, cuts, or tears

Non-uniform chain links

Note: You must remove a chain sling from service if wear exceeds manufacturer limits or if defects such as stretch, deformation, cracks, or burned links are present.

Complex Mechanical Issues

You may encounter mechanical problems that require specialized knowledge. If the chain block shows signs of internal gear failure, brake malfunction, or persistent jamming, you should not attempt repairs yourself. Complex issues often involve intricate parts that need precise adjustment.

You risk further damage or injury if you try to fix these problems without proper training. Powerful Machinery offers expert support and service options. You can contact their team for guidance or schedule a professional repair to restore your chain block’s reliability.

Annual Professional Inspections

You must schedule annual inspections for your chain block. Qualified personnel perform these checks under OSHA regulations and ASME standards. Inspections ensure your chain meets certification requirements and remains safe for lifting jobs.

If your chain block operates under severe service conditions, you may need monthly or quarterly inspections. Keeping records of each inspection helps you track maintenance and identify issues early.

Inspection Type | Frequency | Conditions |

|---|---|---|

Annual Inspection | Required | By qualified personnel under OSHA regulations |

Chain Sling Certification | Annual | Under Canadian law and ASME B30.9 standards |

Severe Service Conditions | Monthly/Quarterly | For equipment subjected to harsh conditions |

Tip: Powerful Machinery provides comprehensive inspection and maintenance services. You can rely on their certified technicians to keep your chain block in top condition.

Conclusion

You improve safety and efficiency by following essential chain block repair tips. Regular maintenance and safety checks help you prevent accidents and extend the life of your chain. You inspect the chain before every use, verify the tonnage, and avoid overloading.

You check hooks and ensure the chain hangs vertically without twisted links. You lift slowly, monitor for kinks, and use gentle force to protect the chain. You never stand under suspended loads and always follow manufacturer guidelines. Routine lubrication and inspections keep your chain reliable.

Practice | Benefit |

|---|---|

Proper chain handling | Reduces injury risk and boosts productivity |

Ongoing chain care | Extends equipment lifespan |

Certified chain repair | Ensures workplace safety |

Powerful Machinery delivers certified chain products and expert support. You trust their quality checks, comprehensive testing, and full traceability. You prioritize safety and ongoing care for every chain lifting job.

FAQ

How often should you inspect your chain block?

You should inspect your chain block before every use. Schedule a thorough inspection at least once a year. Increase inspection frequency if you use the equipment in harsh environments or for heavy-duty lifting jobs.

What signs show your chain block needs repair?

Look for these signs:

Stiff or jammed chain movement

Visible rust or corrosion

Deformed hooks or links

Unusual noises during operation

Tip: Replace any damaged parts immediately to maintain safety.

Can you use non-certified parts for chain block repair?

You should always use certified replacement parts from Powerful Machinery. Non-certified parts may not fit correctly or meet safety standards. Certified parts ensure reliable performance and protect your team.

Where can you find maintenance guidelines for Powerful Machinery chain blocks?

You can find detailed maintenance guidelines in the user manual provided with your chain block. Visit Powerful Machinery’s official website for additional resources and support.