When comparing chain block vs chain hoist, the main difference lies in how each lifting device operates and best suits your needs. Many industrial professionals work with heavy loads every day, so understanding these differences becomes essential.

Over 65% of manufacturing facilities use chain blocks to improve efficiency, and more than 60% of market demand is for electric models. Choosing the right equipment ensures safety and boosts productivity in your operational environment.

Powerful Machinery stands as a trusted name, delivering certified solutions that help you select the best tool for every lifting challenge.

Key Takeaways

Chain blocks are manual devices ideal for lifting lighter loads with precision. They are perfect for tasks requiring careful control.

Chain hoists can be manual or powered, making them versatile for heavy lifting in busy environments. They save time and effort for frequent tasks.

Always check the load capacity and safety features of your lifting device before use. This ensures safe and efficient lifting operations.

Consider your operational environment and lifting frequency when choosing between a chain block and a chain hoist. Match the device to your specific needs.

Powerful Machinery offers certified lifting solutions that meet safety standards. Their products enhance efficiency and reliability in various industrial applications.

Chain Block vs Chain Hoist: Definitions

What Is a Chain Block?

You use a chain block when you need to lift heavy loads by hand. This device works through a simple mechanical system that gives you a big advantage with little effort. The chain block uses a hand chain that you pull to start the lifting process.

Inside, a gear system multiplies your force, making it possible to raise weights that would be impossible to lift alone. The load chain, made from high-strength steel, loops around a sprocket and supports the weight.

Two hooks, each with a safety latch, secure the device to both the lifting point and the load. A braking system with a ratchet and clutch keeps the load from slipping back, so you can lower it safely.

Here is a table showing the main components and their functions:

Component | Description |

|---|---|

Hand Chain | Pulled by you to start lifting. |

Load Chain | Made of strong steel, it holds the weight and loops around the sprocket. |

Hook | Two hooks attach to the lifting point and the load, each with a safety latch. |

Gear System | Uses several gears to increase your lifting power. |

Sprocket | Works with the load chain to lift the load smoothly. |

Braking System | The ratchet and clutch stop the load from slipping and allow safe lowering. |

You often see chain blocks in construction, manufacturing, and warehouses. They are reliable, easy to use, and do not need electricity or batteries. When you compare a chain block vs a chain hoist, you notice that the chain block is usually a manual device, perfect for jobs where you need control and safety.

What Is a Chain Hoist?

A chain hoist is a lifting device that helps you move heavy objects with ease. You can find both manual and powered versions. The manual chain hoist works much like a chain block, using a hand chain and gear system to lift loads.

Powered chain hoists use an electric motor or air power to do the lifting for you, making them ideal for frequent or heavy-duty tasks.

The main parts of a chain hoist include:

Main shaft: Connects the gears and drives the lifting action.

Lifting chain wheel: Moves the lifting chain up or down.

Hand chain wheel: Lets you engage the lifting mechanism by pulling the hand chain.

Brake system: Holds the load in place or lets you lower it gently.

Hooks: Attach the hoist to a support and connect to the load.

Chain guides and strippers: Keep the chain from tangling and remove debris.

When you pull the hand chain, you turn a small gear that drives a larger gear connected to the load chain. This setup increases your lifting power. The brake system locks the load in place when you stop pulling, so you can work safely.

Powered chain hoists add features like a motor, control panel, chain container, and limit switches to prevent overtravel.

You use chain hoists in factories, shipyards, and logistics centers. They handle a wide range of weights and can be operated by hand or with power, depending on your needs.

Terminology in Industry

You may notice that the terms chain block and chain hoist sometimes get used interchangeably, but there are important differences. In the lifting equipment industry:

A chain block usually means a manual, hand-operated device that uses a chain to lift loads. It focuses on simplicity and mechanical advantage.

A chain hoist is a broader term. It includes both manual and powered devices. You use it for heavier or more frequent lifting tasks.

The term manual chain hoist refers to devices that use a hand chain for lifting, much like a chain block.

In some regions, people use chain block to describe a simple, manually operated lifting device, while chain hoist can mean both manual and powered options.

When you look at the technical differences between chain hoists and chain blocks, you see that chain blocks are always manual, while chain hoists can be manual or powered. This distinction helps you choose the right tool for your lifting job.

Tip: Always check the type of chain device you need before starting a project. The right choice improves safety and efficiency.

Mechanisms of Chain Block and Chain Hoist

Manual Operation

You operate both chain blocks and manual chain hoists by hand, but each uses a different mechanism. When you use a chain block, you wind the chain around two wheels.

This action lifts the load with steady manual effort. Manual chain hoists work by pulling a hand chain, which turns a wheel and engages gears and friction plates. This system multiplies your force, making it easier to lift heavy objects.

Here is a table that compares the manual operation features:

Feature | Manual Chain Hoists | Chain Blocks |

|---|---|---|

Operation Mechanism | The hand chain is pulled, turning a wheel that engages gears and friction plates. | The chain is wound around two wheels; manual pulling lifts the load. |

Load Capacity | Designed to lift heavy weights with a single person’s effort due to the mechanical advantage. | Can be attached to lifting slings for even load distribution. |

Safety Features | Built-in brake system to secure the load when not in motion. | Typically includes safety hooks but may not have a dedicated brake system. |

Tip: You can use chain blocks with lifting slings to distribute weight evenly and improve safety.

Powered Options

You find powered hoists in many industrial settings. These devices use electric motors or wire rope systems to lift loads. Electric chain hoists give you precise speed control and operate at constant speeds. This feature increases productivity compared to manual chain blocks.

Although electric hoists cost more upfront, you save money over time because you need fewer workers and complete tasks faster.

Electric chain hoists

Wire rope hoists

Note: Powered hoists suit environments where you lift heavy loads often or need to move items quickly.

Mechanical Advantage

Both chain blocks and chain hoists use gears and sprockets to create mechanical advantage. When you pull the hand chain, the gear mechanism amplifies your input force.

This reduction ratio lets you lift heavier loads with less effort. You benefit from easier lifting and safer operation, especially when working with large or awkward items.

The gear mechanism multiplies your force.

You lift heavy objects with less physical strain.

Mechanical advantage improves safety and efficiency.

Mechanical advantage is the reason you can lift loads much heavier than you could manage alone.

Types and Models

Chain Block Types

You will find several types of chain blocks on the market. Each type offers unique features for different lifting tasks. The most common types include public, private, hybrid, and consortium chain blocks. These types vary in their design and application. You can use the table below to compare their key traits and use cases:

Type | Key Traits | Use Cases |

|---|---|---|

Public | Decentralized, transparent, supports many applications | Trading assets, crowdfunding, open-source work |

Private | Restricted participation, enhanced privacy, centralized | Internal logistics, payroll |

Hybrid | Selective transparency, customizable access | Data-sharing in regulated industries |

Consortium | Shared cost and risk, collaborative processes | Secure data sharing, supply chain management |

You should select the type that matches your lifting needs and workplace requirements. Each type provides specific features that help you achieve safe and efficient lifting.

Chain Hoist Types

When you look at types of chain hoists, you see a range of models designed for different environments. You can choose from manual chain hoists, lever chain hoists, and electric chain hoists. Each type offers distinct features:

Manual chain hoists use manual force. They are lightweight and portable. You can use them where power is limited. They offer versatile load capacity.

Lever chain hoists use a lever mechanism. You get precise control and a compact design. These hoists work well for delicate handling and confined spaces.

Electric chain hoists use electricity for automated lifting. You get smooth control and can handle heavy loads. Electric chain hoists come in many capacities and suit frequent lifting tasks.

You should consider the features of each type before making a choice. Electric chain hoists provide speed and efficiency for busy industrial settings.

Capacity and Design

You need to understand the capacity and design of chain blocks and chain hoists before you select a model. The table below shows the typical load capacity range for each device:

Type of Hoist | Load Capacity Range |

|---|---|

Chain Blocks | 750 kg to 10,000 kg |

Chain Hoists | 250 kg to 50,000 kg |

The capacity of each device depends on several design features:

Load chain strength

Gear train design

Overall construction quality

Safety margins

Material properties

Manufacturers design chain blocks and electric chain hoists with a safety ratio, often 4:1. This means a device rated for a certain load capacity will withstand loads much greater than its stated limit.

For example, a hoist rated for 1 ton will not fail until it reaches at least 4 tons. This design feature ensures you get reliable performance and safety during lifting operations.

Tip: Always check the load capacity and design features before you use any chain or electric chain hoist. This step helps you avoid accidents and ensures efficient lifting.

Applications in Industry

Chain Block Uses

You will find the chain block in many industrial settings where lifting heavy loads is a daily task. This device gives you a simple and reliable way to move materials safely. The table below shows where you can use a chain block and the main tasks it performs:

Industry | Primary Tasks |

|---|---|

Construction | Lifting heavy materials like steel beams and concrete blocks on construction sites. |

Manufacturing | Lifting and positioning heavy machinery and components in manufacturing plants. |

Mining | Lifting and transporting heavy materials within mines. |

Warehousing and Logistics | Moving heavy goods and equipment efficiently in warehouses. |

Marine and Offshore | Lifting heavy equipment and cargo in marine environments. |

You can depend on a chain block for precise lifting operations in tight spaces. Its compact design and strong chain make it ideal for both indoor and outdoor applications.

Chain Hoist Uses

You use a chain hoist when you need to handle high-capacity lifting in demanding environments. The main applications of chain hoists include large-scale production, construction, aerospace, automotive, and food processing. These devices help you lift and move heavy loads quickly, which boosts productivity in your workflow.

Some advantages of using a chain hoist in industrial applications are:

Cost-effective: You save money compared to other lifting devices.

Maneuverability: You can use it in many production settings, even in extreme conditions.

Improved efficiency: You complete lifting operations faster and with less effort.

Enhanced safety: Built-in safety features protect you and your team.

Versatility and adaptability: You can choose from different types to fit your needs.

Cost-effectiveness: You reduce damage to goods and increase output.

You will see chain hoists in many applications where speed, safety, and reliability matter most.

Powerful Machinery Product Integration

When you choose Powerful Machinery for your lifting needs, you get more than just equipment. You benefit from advanced features that fit seamlessly into your industrial applications. Powerful Machinery’s chain block and chain hoist products offer:

Automation and smart control for easier lifting operations.

IoT connectivity for remote monitoring and maintenance alerts.

Lightweight designs for easy transport and flexible installation.

Increased safety with overload protection and ergonomic controls.

Eco-friendly operation that supports sustainable practices.

You can trust Powerful Machinery’s products because they meet strict international standards, such as ISO 9001:2015 for quality, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety.

Every product goes through careful inspection and testing, so you know your lifting equipment will perform reliably in any industrial environment.

Tip: Powerful Machinery’s certified quality and innovative features help you achieve safe, efficient, and versatile lifting in construction, manufacturing, logistics, and more.

Safety Features and Best Practices

Chain Block Safety

When you use a chain block, you need to pay close attention to safety features. Modern chain blocks include several important safety features to protect you and your team:

Limit switches stop the chain block from over-travel, which helps prevent accidents.

Load brakes hold the load securely in place, even if you stop pulling the chain.

Emergency shut-off switches let you stop the device quickly if something goes wrong.

Lifting hooks come with safety catches to keep the load from slipping off.

Hooks are shaped to reduce the risk of accidental release.

These safety features help you avoid common hazards and keep your work environment secure. Always check that these features are present and in good working order before you start lifting.

Chain Hoist Safety Features

Chain hoists offer advanced safety features that help prevent workplace accidents. You can see how these features work in the table below:

Safety Feature | Description |

|---|---|

Pre-Operation Checks | Inspect chains, hooks, and parts to make sure everything works properly. |

Proper Setup | Mount the hoist securely and balance the load to avoid tipping or falling. |

Safe Lifting Techniques | Lift loads slowly and never stand under a suspended load. |

Lubricate moving parts and replace damaged components right away. | |

Emergency Preparedness | Know how to lower loads safely if the hoist fails and report any problems. |

Powerful Machinery designs its chain hoists with these safety features in mind. You get secure hooks, safety latches, and overload protection as standard. These features help you meet strict safety considerations in every lifting task.

Safe Operation Guidelines

You can follow these best practices to ensure the safe operation of chain blocks and chain hoists:

Check the load capacity before lifting to make sure it matches the device’s rating.

Attach the load securely using the correct rigging techniques.

Always lift vertically and avoid pulling at an angle.

Keep the path clear of obstacles and people.

Operate the lever or controls smoothly to keep the load stable.

Inspect hooks, chains, and other parts regularly during use.

Train all operators in emergency response procedures.

Powerful Machinery supports your safety by meeting or exceeding international standards such as ASME, ISO, and OSHA. The company uses certified lifting chains, thorough inspections, and proof testing to ensure every product meets the highest safety standards.

You can trust Powerful Machinery to deliver equipment that keeps your team safe and productive.

Tip: Make safety features and best practices a part of your daily routine. This approach helps you avoid accidents and ensures reliable lifting every time.

Choosing the Right Device

Assessing Needs

When you start selecting the right equipment for your lifting tasks, you need to look at several important factors to consider when choosing a device. You should think about the weight of the load, how high you need to lift, and how often you will use the device. The table below helps you compare these key points:

Factor | Description |

|---|---|

Load Capacity | Check the weight you need to lift. Electric hoists can handle heavier loads than manual blocks. |

Lifting Height | Decide how high you must lift. Electric hoists reach greater heights. |

Operational Environment | Look at temperature, humidity, and other conditions. Electric hoists can be built for harsh environments. |

Frequency of Use | Think about how often you will use the equipment. Electric hoists work better for frequent tasks. |

Budget Constraints | Compare upfront costs with long-term savings. Electric hoists cost more at first but save money over time. |

You also need to consider how you will handle the load. If you need both hands on the load for safety or precision, choose a device that allows this. If you can manage with one hand, a manual option may work well.

Tip: Write down your lifting needs before you choose a device. This step helps you match the right tool to your job.

Environment and Frequency

The place where you use your lifting device matters a lot. If you work in a harsh environment, like a construction site or shipyard, you need equipment that can handle tough conditions. Chain hoists are strong and resist wear, making them a good choice for these places.

How often you use the device also affects your choice. If you only lift things once in a while, a manual chain block is usually enough. If you lift heavy items many times each day, an electric chain hoist is better.

Electric hoists are built for continuous use and can handle the demands of a busy production line. Manual hoists work best for occasional lifts or maintenance tasks.

Note: Always match the type of hoist to how often you plan to use it. This helps you avoid breakdowns and keeps your work running smoothly.

Budget and Value

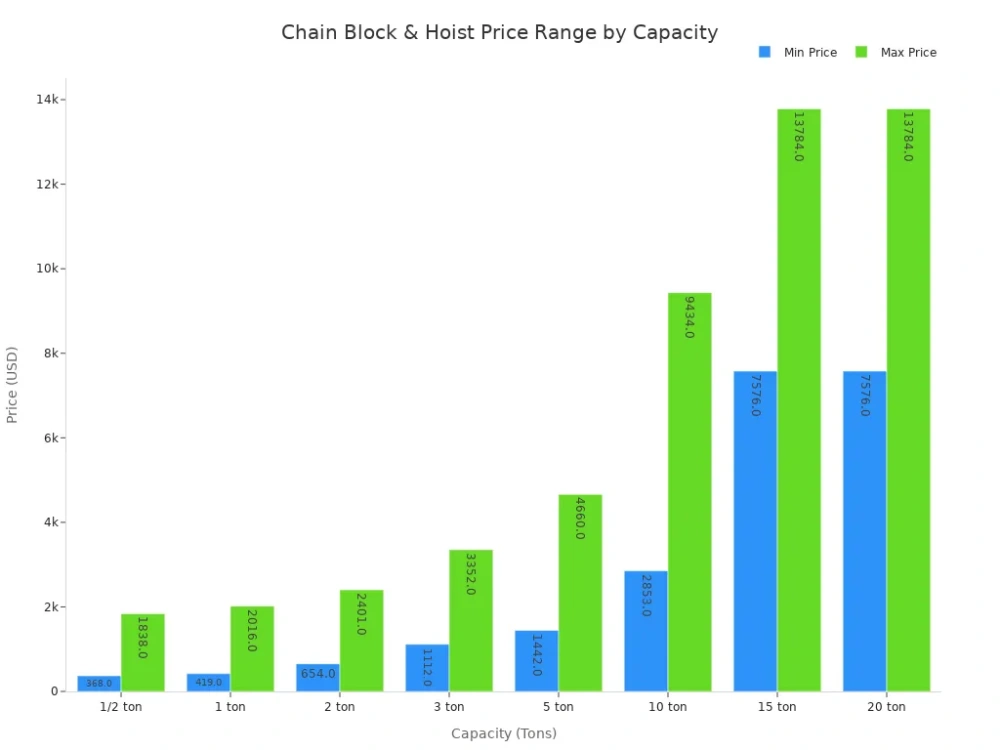

Cost is always important when you buy lifting equipment. The price depends on the capacity you need. The table below shows typical price ranges for different capacities:

Capacity (Tons) | Price Range |

|---|---|

1/2 | $368.00 – $1,838.00 |

1 | $419.00 – $2,016.00 |

2 | $654.00 – $2,401.00 |

3 | $1,112.00 – $3,352.00 |

5 | $1,442.00 – $4,660.00 |

10 | $2,853.00 – $9,434.00 |

15 | $7,576.00 – $13,784.00 |

20 | $7,576.00 – $13,784.00 |

You may notice that electric hoists cost more at first. Over time, you save money because they last longer, need less maintenance, and have safety features that protect your team and equipment. Manual chain blocks have a lower starting price and work well for smaller jobs or places with limited power.

Remember: The best value comes from equipment that fits your needs and lasts for years.

Powerful Machinery Solutions

You can rely on Powerful Machinery for custom solutions that fit your unique lifting needs. The company offers a wide range of certified products and can tailor equipment for special jobs. Here are some customization options you can request:

Customization Option | Description |

|---|---|

Special jaw opening | Fits non-standard material sizes |

Extended jaws | Reaches materials in tight or awkward spaces |

Remote lock closed capabilities | Let’s you operate clamps safely from a distance |

Special application clamps | Designed for unique assembly or production needs |

Powerful Machinery works with you from the first consultation to the final product. You get equipment that meets strict international standards and matches your project exactly. The company’s team helps you choose the right chain block or chain hoist, so you always have the best tool for the job.

Powerful Machinery’s certified products and custom services give you confidence in every lift.

Summary of Key Differences

Manual vs Powered

When you compare a chain block vs a chain hoist, you see clear differences in how each device operates. Manual options require you to pull a hand chain or wind a mechanism. This gives you precise control over the lifting process, especially when you need to position a load carefully.

Powered models, such as electric or pneumatic hoists, use motors to lift heavy loads at a fixed speed. You only need to press a button to start lifting. The table below highlights the main differences:

Feature | Manual Operation | Powered Operation |

|---|---|---|

Speed Control | Depends on your effort | Fixed speed once activated |

Load Positioning | Very precise with hand chain pulls | Less precise, operates at set speed |

Operation Method | Requires physical effort | Button or switch activation |

Typical Use Case | Careful positioning, small lifts | General lifting, frequent heavy loads |

Tip: Manual devices work best when you need careful control. Powered devices save time for repetitive lifting.

Application Suitability

You should always match your equipment to your work environment. Chain block vs chain hoist choices depend on your needs. Manual chain blocks are great for lighter loads and places without power. Powered hoists handle heavier lifting and continuous use in busy settings. The right choice improves safety and productivity.

Chain hoists are versatile and cost-effective for lighter loads and areas without electricity.

Powered hoists excel with heavy loads and frequent lifting in demanding environments.

Your selection impacts efficiency, safety, and how quickly you finish tasks.

Selection Checklist

Choosing the right lifting device means checking every detail. Use this checklist to guide your decision:

Assess your operational environment and load characteristics.

Analyze your space: headroom, floor space, and structure.

Break down the load: weight, shape, and material.

Consider how often you will lift: regular tasks or occasional heavy lifts.

Also, make sure you have the right accessories for lifting:

Slings for secure lifting setups.

Shackles and hooks for safe connections.

Hoists and winches for raising and lowering.

Wire rope and accessories for strength.

Spreader bars and lifting beams for balance.

A structured checklist helps you select the right gear, inspect equipment, and follow best practices. This ensures you never overlook a critical tool during planning.

Remember: The right choice between a chain block vs a chain hoist keeps your lifting safe, efficient, and reliable.

Conclusion

You now understand the key differences between a chain block and a chain hoist. The table below highlights how each device fits different needs:

Feature | Chain Pulley Block | Wire Rope Hoist |

|---|---|---|

Load Capacity | Up to 10 tons | Up to 40 tons |

Power Source | Manual operation | Electric powered |

Lifting Speed | Slower, manual chain pull | Faster, precision options |

Frequency of Use | Occasional tasks | Continuous operations |

Precision and Control | Reliable, limited | High, advanced systems |

Maintenance Needs | Low | More regular servicing |

Cost of Ownership | Economical | Higher, but efficient |

Choosing the right lifting equipment means you must match the device to your task and environment. When you consult certified providers like Powerful Machinery, you benefit from:

Equipment that meets recognized safety standards

Expert guidance for your specific lifting needs

Support for operator training and regular maintenance

Visit the Powerful Machinery website to explore certified, reliable lifting solutions for your next project.

FAQ

What is the main difference between a chain block and a chain hoist?

You use a chain block for manual lifting. A chain hoist can be manual or powered. Chain hoists often handle heavier loads and offer more options for frequent lifting tasks.

Can you use a chain block outdoors?

Yes, you can use a chain block outdoors. Make sure you choose a model with corrosion-resistant materials. Always inspect the device before use to ensure safe operation in outdoor environments.

How often should you inspect your lifting equipment?

You should inspect your chain block or chain hoist before every use. Schedule a thorough inspection at least once a month. Regular checks help you spot wear, damage, or safety issues early.

What safety features should you look for in a chain hoist?

Look for secure hooks, safety latches, and overload protection. These features help you prevent accidents and keep your team safe during lifting operations.

Does Powerful Machinery offer custom lifting solutions?

Yes, Powerful Machinery provides custom-engineered lifting solutions. You can request special features or sizes to fit your unique project needs. Visit their website for more details.