When you handle heavy loads in your facility, you rely on the right lifting equipment to keep your operation safe and efficient. Selecting the correct Chain sling parts for overhead lifting gives you the foundation for secure lifting.

Powerful Machinery’s certified chain slings stand out because they meet stringent international safety standards. You gain peace of mind knowing these products help prevent accidents and ensure reliable performance during every lifting operation. Each time you choose a chain sling from Powerful Machinery, you commit to lifting safety.

You protect your team and your investment with equipment that consistently delivers under pressure. In the world of lifting, quality matters. Powerful Machinery’s chain slings support your lifting goals with unmatched reliability.

You can trust their products for lifting applications in construction, marine, transportation, and cargo handling. As you plan your next lifting job, remember that certified equipment from Powerful Machinery means lifting with confidence.

Key Takeaways

Choose certified chain sling parts to ensure safety and efficiency in lifting operations.

Understand chain grades and select the right one for your lifting needs to prevent equipment failure.

Inspect hooks, attachments, and connectors regularly to maintain safety and compliance with regulations.

Follow proper installation guidelines and load distribution practices to enhance stability during lifts.

Train your team on lifting procedures and store slings correctly to extend their lifespan and ensure readiness.

Chain Sling Parts for Overhead Lifting

When you select chain sling parts for overhead lifting, you build the foundation for safe and efficient lifting operations. Each chain sling consists of several essential lifting chains and components. These include the chain itself, hooks, attachments, master links, and connectors.

Powerful Machinery offers a complete range of certified chain sling parts for overhead lifting, ensuring every component meets or exceeds international safety standards. You can trust these lifting chains in demanding environments, from construction sites to marine terminals.

Matching the right grade and type of chain sling parts for overhead lifting is critical. You must ensure compatibility between all lifting chains, hooks, and connectors. This practice prevents weak points and guarantees that the entire chain sling assembly performs as intended.

When you use certified lifting chains from Powerful Machinery, you reduce the risk of failure and extend the service life of your lifting chain components.

Chain Grades & Selection

You need to understand chain grades before choosing the right chain sling for your lifting application. The grade of the chain determines its strength, durability, and working load limit. The most common grades for lifting chains are Grade 80, Grade 100, and Grade 120.

All three grades are suitable for overhead lifting if manufactured and proof-tested according to industry standards.

Grade 80 alloy chain is the standard for overhead lifting. It is known for its heat-treated design, which provides strength and durability. Grade 100 lifting chains offer a 25% higher working load limit than Grade 80, making them ideal for heavier lifting tasks.

Grade 120 lifting chains are the strongest, with a 50% increase in strength over Grade 80 and 20% more than Grade 100. This grade is perfect for specialized, high-performance lifts.

Tip: Always check the chain grade stamped on your lifting chains. Never mix different grades in one chain sling assembly.

Here is a quick comparison of chain grades:

Chain Grade | Nominal Stress (N/mm²) | Approx. WLL (kg) | Primary Application |

|---|---|---|---|

Grade 80 | 800 | ~2,100 | Standard for overhead lifting, rigging |

Grade 100 | 1000 | ~2,650 | Heavy lifting, where weight saving is a benefit |

Grade 120 | 1200 | ~3,200 | Demanding, specialized high-performance lifts |

The selection of chain grade impacts both safety and longevity. Grade 100 lifting chains use high-performance alloy steel and a specialized heat-treatment process. This enhances strength and toughness. Grade 120 lifting chains feature advanced alloy steel and a unique profile-link geometry.

This design reduces internal wear and extends service life. You should always match the grade of all chain sling parts for overhead lifting to maintain system integrity.

Hooks & Attachments

Hooks and attachments connect the lifting chains to the load. You must choose the right hook type for your lifting chain assembly. Powerful Machinery supplies a variety of hooks, each designed for specific lifting tasks.

Common hook types include:

Hook Type | Description | Use Case |

|---|---|---|

Grab Hooks | Narrow throat holds a chain for tie-down and lifting. | Used in load-rated lifting slings. |

Standard Grab Hook | Non-cradle type may require a WLL reduction of 20%. | Tie-down applications. |

Cradle Grab Hook | Supports the chain link; there is no WLL reduction when used correctly. | Preferred for most lifting applications. |

Barrel Hooks | Wide end point for lifting barrels or drums, used with multi-leg slings. | Lifting barrels at 30-45° angles. |

You must ensure all hooks and attachments meet safety standards such as ASME B30.20, ASME BTH-1, and OSHA regulations. These standards require proper labeling, proof load testing, and regular inspections. Each lifting chain hook must display the manufacturer’s name and rated load capacity.

Before every lift, inspect your hooks and attachments for signs of wear or damage. Schedule periodic inspections by qualified personnel and keep records for compliance.

Note: Never use a damaged or unmarked hook in your chain sling assembly. Replace worn hooks immediately to maintain lifting safety.

Master Links & Connectors

Master links and connectors play a vital role in chain sling assemblies. You use master links to connect multiple sling legs to a single lifting point. This ensures stability and even weight distribution during lifting.

In multi-leg chain sling assemblies, oblong master links collect all the sling legs and balance the load. This design enhances safety and prevents tipping or shifting during lifting.

Connectors join the lifting chains, hooks, and master links together. You must select connectors that match the grade and size of your lifting chains. Using mismatched or uncertified connectors can create weak points in the chain sling assembly.

Powerful Machinery provides master links and connectors that meet strict international standards, giving you confidence in every lift.

When you assemble your chain sling parts for overhead lifting, always verify the compatibility of all lifting chains, hooks, master links, and connectors. This practice ensures the entire lifting chain system works together safely and efficiently.

Safety Reminder: Only use certified master links and connectors with your chain sling. Regularly inspect these lifting chain components for cracks, deformation, or excessive wear.

By understanding and selecting the right chain sling parts for overhead lifting, you protect your team and your equipment. Powerful Machinery’s certified lifting chains, hooks, and connectors give you the reliability you need for every lifting operation.

Material Specifications & Safety Standards

Alloy Grades & Compliance

You must pay close attention to the materials used in your chain sling assemblies. The right alloy grades give your lifting equipment the strength and durability needed for demanding tasks.

Powerful Machinery manufactures chain slings using high-quality alloy steel, which meets or exceeds the most recognized international standards. These include OSHA, Federal NACM, ASTM, and ISO standards. Each of these standards sets strict requirements for the composition, heat treatment, and mechanical properties of the materials.

You will find that the working load limits for chain slings are based on a 4:1 design factor, as required by ISO standards.

ASME B30.9.1 requires proofloading for all new and repaired alloy lifting chain assemblies.

Compliance with these standards ensures that your chain slings have the necessary strength and ductility for safe lifting operations.

Higher alloy grades, such as G100 and G120, provide increased working load limits. These grades are essential for heavy-duty lifting and help you maintain safety in your workplace. Using the correct materials and matching all components to the same grade prevents weak points in your assembly.

If you use mismatched or lower-grade chains, you risk equipment failure and potential safety incidents. Powerful Machinery’s certified chain slings give you confidence that every component meets the highest standards for lifting.

Tip: Always verify the grade and certification of your chain sling materials before each use. This practice protects your team and your equipment.

Identification Tags & Documentation

Identification tags and proper documentation play a critical role in lifting safety and regulatory compliance. Every chain sling from Powerful Machinery comes with a durable identification tag. This tag displays essential information, such as the manufacturer, grade, working load limit, length, and serial number.

You can quickly check these details before each lift to ensure you use the correct equipment.

Proper documentation supports traceability and quality control. You must keep records of all inspections, repairs, and proof tests. A competent person should inspect your chain slings at least once a year and document the results in writing.

These records must be available for examination at any time. Documentation should include detailed specifications, test results, and certification records for each chain sling.

This traceability system allows you to identify production batches quickly, which enhances safety measures.

Maintaining accurate records helps you meet international safety standards and regulatory requirements.

Thorough documentation supports regular inspections and ensures your lifting equipment remains reliable.

Note: Never remove or alter identification tags. Missing or unreadable tags can lead to compliance issues and compromise safety.

Proof Testing & Regulations

Proof testing verifies the strength and integrity of your chain sling assemblies. According to OSHA regulations, each new, repaired, or reconditioned alloy steel chain sling must undergo proof testing by the manufacturer or a qualified person before use.

This process includes all welded components in the sling assembly. You must retain a certificate of the proof test for examination.

Here is a summary of proof testing requirements for different sling types:

Sling Type | Proof Testing Requirement |

|---|---|

Alloy Steel Chain Slings | Must be proof tested by the manufacturer or a qualified person before initial use. |

Wire Rope Slings | Must be proof tested if they are new, repaired, or incorporate previously used fittings. |

Metal Mesh Slings | Must be proof tested by the manufacturer or a qualified person before initial use. |

Synthetic Rope Slings | Must be proof tested if they incorporate previously used fittings or are repaired. |

Synthetic Webbing Slings | Must be proof tested if they incorporate previously used fittings or are repaired. |

Polyester Roundslings | Must be proof tested if they incorporate previously used fittings or are repaired. |

High-Performance Roundslings | Must be proof tested if they incorporate previously used fittings or are repaired. |

You should follow a regular inspection schedule to maintain compliance with industry standards:

Initial inspections must occur before first use.

Frequent or pre-shift inspections should take place daily, weekly, or before every use or shift.

Periodic inspections are required every 6 to 12 months.

Special inspections must follow any incidents or repairs.

Proof testing and regular inspections confirm that your chain slings meet all safety standards. These practices help you identify potential issues before they become hazards. Powerful Machinery provides full documentation and certification for every chain sling, supporting your compliance with all relevant regulations.

Safety Reminder: Never use a chain sling that has not passed proof testing or lacks proper documentation. Your commitment to safety protects your team and your operation.

Assembly Configurations & Lifting Chains

Sling Leg Designs

You must select the right sling leg design for each lifting operation. Powerful Machinery offers single, double, triple, and quadruple leg configurations. Each configuration supports different lifting needs and affects load distribution. Single-leg slings provide a direct vertical lift.

Double-leg slings offer more stability and balance for uneven loads. Triple-leg slings help stabilize loads and prevent rotation. Quadruple-leg slings give you the highest stability for complex lifting tasks.

Sling Configuration | Typical Use Case | Stability | Load Distribution |

|---|---|---|---|

Single-leg | Straight vertical lifting | Basic | Direct |

Double-leg | Balanced loads | Improved | Shared between two legs |

Triple-leg | Irregular or rotating loads | High | Two legs bear most weight |

Quadruple-leg | Large, complex loads | Maximum | Two-leg rule applies |

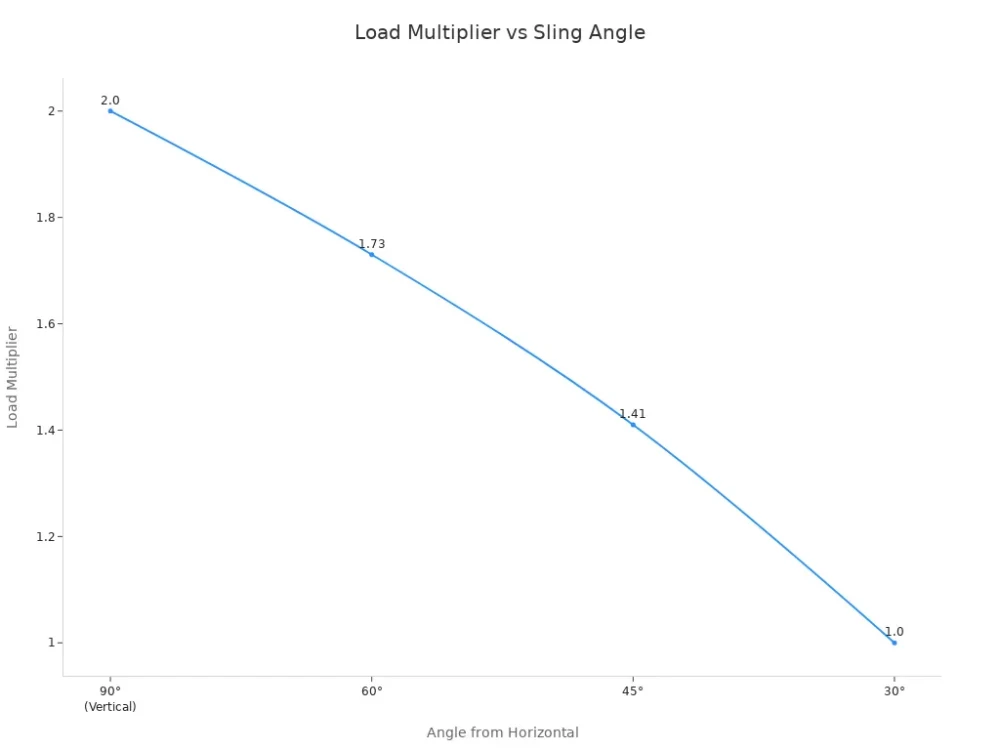

You must consider the angle from horizontal when using multi-leg configurations. The load multiplier changes as the angle decreases. This affects the tension on each leg and the overall load capacity.

Angle from Horizontal | Load Multiplier (Tension) |

|---|---|

90° (Vertical) | 2.00 × single-leg vertical capacity |

60° | 1.73 × single-leg vertical capacity |

45° | 1.41 × single-leg vertical capacity |

30° | 1.00 × single-leg vertical capacity |

For example, a quadruple-leg sling lifting a 20,000-pound load must be rated as if only two legs carry the full load. This approach ensures safety and maintains the required performance.

Designation Codes

You must understand designation codes to select the correct chain sling for lifting. Codes like G80, G100, and G120 indicate the grade of alloy steel. Grade 80 chains provide strength and ductility for general lifting. Grade 100 chains offer a 25% higher load capacity and lighter weight, which improves handling and performance.

Grade 120 chains deliver the highest load capacity and durability, making them ideal for demanding lifting configurations. Each code helps you match the sling to your lifting requirements and ensures safe operation.

Compatibility & Replacement

When you replace components in a chain sling assembly, you must verify compatibility. Follow these steps:

Assess the weight, size, and shape of the load to determine the correct configuration and load capacity.

Match the chain grade to the load. Use only Grade 80, Grade 100, or Grade 120 chains as specified.

Select the proper sling configuration for stability and performance.

Consider environmental factors such as temperature, chemicals, and moisture, which can affect durability.

After replacing any component, recalculate the working load limit. Use the lowest load capacity of any part in the assembly as the maximum safe limit. This practice maintains safety and ensures consistent performance.

Powerful Machinery Chain Slings

Powerful Machinery provides customizable chain sling configurations for every lifting scenario. You can select chain size, length, material grade, and adjustability to match your lifting needs. Grade 100 chains offer superior durability and performance for heavy-duty lifting.

Each sling undergoes strict certification and quality assurance, including ISO, TUV Rheinland, EURO CERT, and OSHA standards. Regular inspections by certified technicians confirm the durability and reliability of every configuration.

Clients worldwide trust Powerful Machinery for lifting solutions that deliver consistent performance and long service life.

Customization Aspect | Description |

|---|---|

Chain Size | Select specific sizes for load capacity. |

Length | Choose custom lengths for different lifting tasks. |

Configuration | Options for single, double, triple, and quadruple-leg configurations. |

Material Grade | Grade 100 chains for strength and durability. |

Adjustability | Adjustable slings for versatile lifting performance. |

Tip: Always use certified chain slings and follow inspection schedules to maintain durability and safety in every lifting configuration.

Safety, Maintenance & Best Practices

Installation Guidelines

You must follow strict installation guidelines to ensure safety and stability during every lifting operation. Choose the correct sling type for your load. Use a vertical hitch for maximum working load limit.

Select a choker hitch when you need to secure irregular loads, but remember this reduces the working load limit by about 25%. A basket hitch provides excellent stability for broad-based objects. Always check the lifting equipment for wear, damage, or heat exposure before use.

Consider the load weight, type, and environment when selecting your sling. Store and clean your slings regularly to maintain performance.

Common Installation Errors | Description |

|---|---|

Improper connection methods | Using incorrect techniques can cause failures during lifting. |

Neglecting inspections | Skipping checks allows minor issues to become major safety hazards. |

Using incorrect materials/grades | Materials that do not meet specifications can compromise lifting stability. |

Tip: Always follow the manufacturer’s recommendations for installation and never exceed the sling’s rated capacity.

Inspection & Maintenance

You must perform routine maintenance and sling inspection to keep your lifting equipment reliable. Conduct an initial inspection when you receive a new chain sling. Inspect slings daily, weekly, or before each use. Schedule periodic inspections every 6 to 12 months, including detailed functional testing.

After any incident or repair, perform a special inspection to confirm safety.

Inspection Type | Frequency Description |

|---|---|

Initial Inspections | Upon acquisition of the chain sling |

Frequent or Pre-Shift | Daily, weekly, or before each use or shift |

Periodic | Every 6 to 12 months, with functional tests |

Special | After incidents or repairs |

Clean chains after use to remove contaminants. Lubricate chains to reduce friction and wear. Store slings properly to prevent moisture damage. Handle slings carefully to avoid kinking and strain. Never exceed the sling’s capacity to maintain load stability.

Environmental Factors

Environmental conditions can affect the performance and safety of your lifting equipment. Moisture from rain, humidity, or saltwater can cause corrosion and weaken the sling. High temperatures may evaporate lubricants and reduce material strength.

Low temperatures can make steel brittle. Chemical exposure from acids or solvents can degrade materials and reduce load stability. UV radiation and abrasive environments also damage slings over time.

Training & Storage

You must train your team on proper lifting, installation, and maintenance procedures. Store chain slings in a designated, dry place, off the ground, and away from chemicals. Hang slings on the wall in a cool, dark area to protect them from moisture, dirt, UV light, and dust.

Proper storage extends the life of your lifting equipment and ensures readiness for every lift.

Note: Regular training and proper storage help prevent accidents and maintain the highest safety standards in your facility.

Conclusion

You improve safety and efficiency when you choose certified chain sling parts for every lifting operation. You reduce workplace accidents by balancing the load, using padding at sharp corners, and storing chain slings in a dry, clean environment.

You must inspect and certify chain slings routinely, as required by industry standards. You protect your team by replacing damaged safety latches, never exceeding rated capacity, and ensuring slings fit freely.

Powerful Machinery supports your lifting needs with reliable products and expert guidance. You can trust their solutions for every lifting challenge.

Balance the load to avoid overloading a single leg or causing a sling to slip.

Use padding at sharp corners to prevent link deformation and protect the load.

Store chain slings properly in a dry, clean environment.

Chain slings must be routinely inspected and certified to ensure safety in lifting operations.

Replace any damaged safety latches.

Determine the weight of the load before lifting and never exceed the rated capacity.

Ensure slings and fittings fit freely and do not force them into place.

Keep hands and fingers away from tensioned slings during lifts.

Perform a trial lift and trial lower to ensure stability.

You set the standard for safe lifting when you follow best practices and trust Powerful Machinery for your lifting equipment.

FAQ

What industries use chain slings for lifting?

You see chain slings in construction, marine, transportation, and manufacturing. These industries rely on chain slings for safe lifting of heavy materials. You can trust certified chain slings for demanding lifting tasks in harsh environments.

How do you select the right chain sling for lifting?

You must consider the load weight, shape, and lifting angle. Choose the correct configuration and grade for your lifting needs. Always check the working load limit before each lifting operation.

How often should you inspect chain slings for lifting?

You should inspect chain slings before every lifting operation. Schedule periodic inspections every 6 to 12 months. After any incident or repair, perform a special inspection to confirm lifting safety.

Can you use chain slings for lifting in outdoor environments?

You can use chain slings for lifting outdoors. High-quality chain slings resist corrosion and wear. Always check for environmental factors that may affect lifting safety, such as moisture or extreme temperatures.

What should you do if a chain sling shows damage during lifting?

You must stop the lifting operation immediately. Remove the damaged chain sling from service. Replace it with a certified chain sling before resuming any lifting task.