You must understand the difference between eye bolts and hoist rings when choosing rigging hardware for lifting operations. Eye bolts provide a fixed anchor point, while hoist rings allow full rotation and pivoting, making them ideal for complex lifting operations that require movement in multiple directions.

Safety and load capacity remain critical. Improper selection can lead to serious workplace injuries—crane-related deaths average 42 per year, often due to poor training or rushed jobs. Powerful Machinery delivers certified solutions, ensuring you select the right hardware for every application.

Key Takeaways

Eye bolts provide fixed anchor points for straight-line lifting. Use them for vertical lifts where load alignment is perfect.

Hoist rings allow for 360-degree movement and 180-degree pivoting. Choose them for complex lifts that require flexibility and safety.

Always check the rated load capacity of your hardware. Selecting the right type ensures safety and prevents accidents.

Regularly inspect your rigging hardware for wear and damage. This practice helps maintain safety and reliability during lifting operations.

Consider the environment when choosing hardware. Stainless steel eye bolts resist corrosion, making them ideal for marine and outdoor use.

Definitions

What Are Eye Bolts?

You often see eye bolts in lifting and rigging tasks. These fasteners have a looped head, called the “eye,” which lets you attach cables, ropes, or hooks. Eye bolts come in two main types: shouldered and non-shouldered.

Shouldered eye bolts handle angular loads, while non-shouldered versions work best for straight-line pulls. According to international rigging standards, eye bolts are designed for straight-line pulling or lifting. You can use them in many settings, from construction sites to marine environments.

Tip: Always check if your eye bolts are rated for the load and direction you need. Using the wrong type can lead to unsafe lifting.

Here is a quick comparison of official definitions:

Term | Definition |

|---|---|

Eye Bolt | A fastener with a looped head for attaching cables, ropes, or hooks, designed for straight-line pulling or lifting. Available in shouldered and non-shouldered versions. |

Hoist Ring | A complex lifting device with a body, bail, shoulder pin, and bushing, allowing for multi-axis movement. Suitable for handling complex loads that may move or rotate during lifting. Constructed from high-grade alloy steel. |

What Are Hoist Rings?

Hoist rings give you more flexibility than eye bolts. You use hoist rings when you need to lift loads that might move or rotate. These devices have a body, bail, shoulder pin, and bushing.

This design lets the ring rotate and pivot, so you can lift from different angles without stressing the hardware. Hoist rings are made from high-grade alloy steel, which means they handle heavy, complex loads safely. You often find hoist rings in commercial lifting applications where safety and movement matter most.

Note: Hoist rings are ideal for situations where the load may shift or where you need to lift from multiple directions.

By understanding the differences between eye bolts and hoist rings, you can choose the right hardware for your lifting needs.

Types

Eye Bolt Types

You encounter several different types of eye bolts in industrial lifting. Each type serves a specific purpose and fits unique applications. The table below gives you a clear overview:

Type of Eye Bolt | Description | Common Applications |

|---|---|---|

Plain Eyebolts | No shoulder, best for vertical lifting in-line with the shank. | Marine, construction, securing cables. |

Shoulder Eyebolts | Has a shoulder for angular loads, spreads the weight evenly. | Heavy-duty lifting, rigging, and construction. |

Welded Eye Bolt | Eye welded to shank for a permanent, strong connection. | Construction, rigging, industrial lifting. |

Heavy Duty Special Eye Bolt | Fully threaded shank welded to an eye nut for maximum strength. | Heavy machinery, maritime use. |

Machine Eye Bolt | The threaded shank for machinery offers a solid hold. | Construction, manufacturing industries. |

You often choose between these types of eye bolts based on load direction, environment, and safety needs. Powerful Machinery’s Stainless Steel Eye Bolts stand out in the market.

Made from AISI 316 stainless steel, they deliver excellent corrosion resistance and durability, even in harsh marine or outdoor conditions. You benefit from their strength and compliance with international standards, making them a reliable choice for demanding projects.

Tip: Always match the type of eye bolt to your lifting scenario. Using the correct type increases safety and extends hardware life.

Hoist Ring Types

You also find several types of hoist rings designed for different rigging needs. The table below summarizes the most common types of hoist rings:

Hoist Ring Type | Description |

|---|---|

Swivel Hoist Rings | Pivot 180° and swivel 360°, ideal for lifting from any direction. |

Side-Pull Hoist Rings | Designed for side mounting, rated for straight lifts, WLL reduced on angled lifts. |

Side-Load Hoist Rings | Pivot up to 90° from the bolt axis, maintain 75% of rated load. |

Flip Flop/Pivoting Lift Rings | Pivot 180°, cannot swivel, designed for side mounting only. |

You select from these types of hoist rings when you need flexibility in movement or must lift loads from multiple angles. Swivel hoist rings are the most common because they allow you to maintain optimal working load limits in any direction.

Powerful Machinery offers a full range of certified rigging hardware, including both eye bolts and hoist rings. You can trust their products for strength, safety, and compliance with global standards.

Eye Bolts vs Hoist Rings: Comparison

Design & Movement

When you compare eye bolts vs hoist rings, you notice clear differences in design and movement.

Eye bolts feature a fixed loop that creates secure anchor points for straight-line pulls. You cannot rotate or pivot them once installed.

Hoist rings use a more advanced design. They pivot 180 degrees and swivel 360 degrees, allowing you to align the lifting points with the direction of the load. This flexibility reduces stress on the hardware and increases safety during complex lifting applications.

Note: Hoist rings provide movement in multiple directions, making them ideal for loads that shift or require repositioning during lifts.

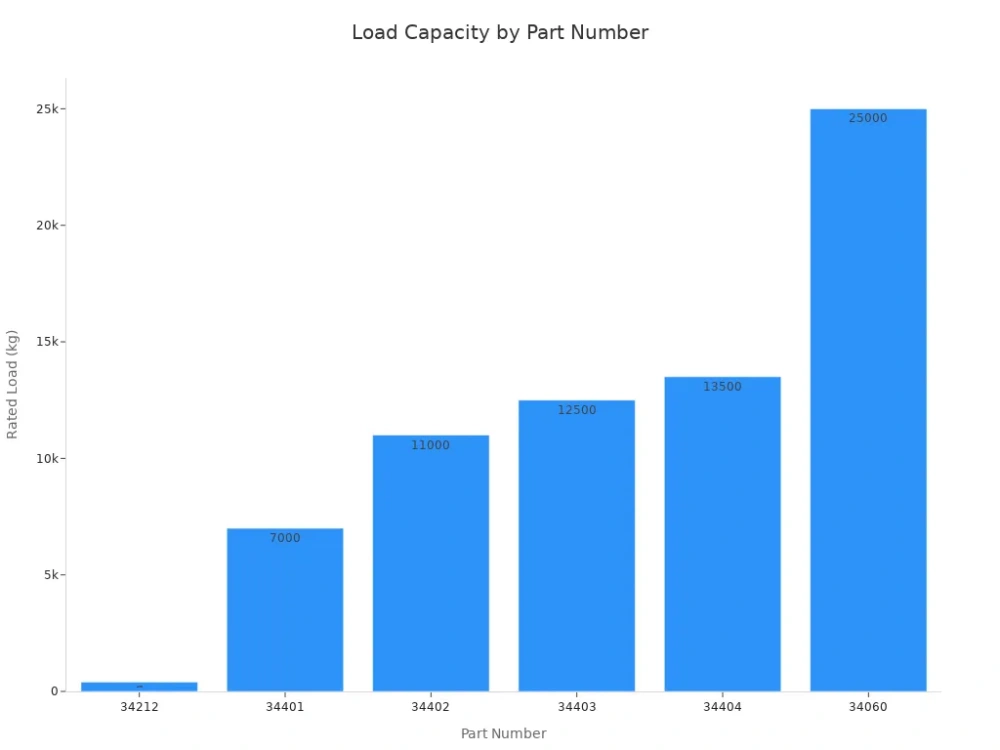

Load Capacity

Rated load capacities play a critical role in your hardware selection. Eye bolts vs hoist rings both offer a wide range of working load limits, but their performance varies based on application and direction of force.

Part No. | Rated Load (kg) |

|---|---|

34212 | 400 |

34401 | 7000 |

34402 | 11000 |

34403 | 12500 |

34404 | 13500 |

34060 | 25000 |

Eye bolts can sometimes offer higher-rated load capacities, especially for straight, in-line pulls.

Hoist rings maintain their full working load limit from any angle, which is essential for angular lifts.

Always check the rated load capacities for your specific lifting applications to ensure you meet the required safety factor.

Safety

Safety remains the top priority in any lifting operation.

Eye bolts provide secure anchor points for straight pulls, but they cannot pivot. If you apply a side load, you risk hardware failure.

Hoist rings include advanced safety features. They pivot and swivel, aligning with the load direction and maintaining the working load limit from any angle. This design prevents lateral stress and reduces the chance of accidents.

Powerful Machinery ensures safety by integrating quality at every stage. The company uses automated welding systems, precision forging presses, and rigorous testing to guarantee that each component meets international standards.

Cost

Cost often influences your decision between eye bolts vs hoist rings.

Eye bolts are generally more affordable, making them a cost-effective solution for many lifting applications.

Hoist rings cost more due to their complex design and added safety features. However, their versatility and ability to handle angular loads can justify the investment for demanding jobs.

Tip: Consider both the initial cost and the long-term value when choosing between these two types of hardware.

Application

You must match your hardware to the specific needs of your project. The table below summarizes the best use cases for eye bolts vs hoist rings:

Feature | Eye Bolts | Hoist Rings |

|---|---|---|

Best Use | Straight, in-line pulls | Angular lifting |

Mobility | Stationary anchor points | 360° swivel design for movement |

Rated Load Capacities | 800-24,000 lbs | 800-10,000 lbs |

Operation | Simple design, easy to inspect | Requires knowledge for maintenance |

Price | Generally cheaper | More expensive |

Use eye bolts when you need secure anchor points for vertical lifts or simple rigging.

Choose hoist rings for complex lifting applications that involve shifting loads or require movement in multiple directions.

Powerful Machinery’s commitment to quality and safety ensures that every product, from eye bolts to hoist rings, delivers reliable performance in the most demanding environments.

Advantages

Eye Bolts

You gain several key advantages when you choose eye bolts for your lifting and rigging needs. These components deliver high tensile strength, allowing you to handle substantial loads with confidence.

Powerful Machinery’s Stainless Steel Eye Bolts stand out in marine, construction, and industrial environments. Their corrosion resistance ensures reliable performance, even in harsh or wet conditions. You can install them quickly using standard tools, which saves you time on the job site.

High tensile strength supports heavy-duty lifting and rigging.

Corrosion resistance makes them ideal for marine and outdoor applications.

Easy installation streamlines your workflow.

Versatility allows use in anchoring, hoisting, and securing cables or ropes.

Compliance with international standards guarantees safety and reliability.

You often rely on eye bolts to anchor machinery, secure loads on construction sites, or provide fastening points on boats and docks. Their forged design offers enhanced durability, which is essential for demanding projects.

As safety standards evolve, you can trust these fastening solutions to deliver consistent performance across a wide range of applications. The advantages of eye bolts make them a dependable choice for professionals who value strength and versatility.

Hoist Rings

Hoist rings offer you unmatched flexibility for complex lifting operations. Their unique design allows for both rotation and pivoting, which means you can lift loads from multiple directions without worrying about hardware failure. You do not need to set up fixed-direction lifting points, which simplifies your rigging process.

180-degree pivoting and 360-degree swiveling enable automatic alignment with the direction of pull.

The full rated working load limit applies from any angle, reducing lateral stress and increasing safety.

You can lift and rotate loads through tight spaces, improving operational efficiency.

The design eliminates the need for extra hardware, making your setup cleaner and faster.

When you work with hoist rings, you reduce the risk of unexpected movement during lifting. The rotating mechanism aligns with the load, preventing damage from angular pulls. You benefit from a safer, more adaptable lifting solution that meets the demands of modern industrial environments.

Disadvantages

Eye Bolts

When you select eye bolts for lifting, you need to understand the disadvantages of eye bolts. These fasteners work well for straight-line pulls, but they do not perform as well when you apply side loads. If you use them at an angle, you risk bending or breaking the bolt. This can lead to dangerous situations on the job site.

Eye bolts do not swivel or pivot. You cannot adjust the direction once you install them.

You must align the load perfectly with the bolt axis. Any misalignment increases the risk of failure.

The disadvantages of eye bolts include a higher chance of hardware fatigue if you use them for repeated lifts at improper angles.

Note: Always inspect your eye bolts before each use. Look for signs of wear, bending, or corrosion. Replace any damaged hardware immediately.

Hoist Rings

Hoist rings offer more flexibility, but you should also consider their disadvantages. These devices have moving parts, which means you need to perform regular maintenance. If you neglect this, the hardware may not function as intended.

Hoist rings cost more than standard eye bolts. You may need to invest more up front for complex lifting jobs.

You must follow the manufacturer’s instructions for installation. Improper setup can reduce the working load limit.

The disadvantages include the need for periodic lubrication and inspection of the swivel mechanism.

Tip: Keep a maintenance log for your hoist rings. This helps you track inspections and ensures safe operation.

By understanding these disadvantages, you can make better decisions when choosing rigging hardware for your lifting operations.

Lifting and Rigging: Selection Guide

Key Criteria

When you select lifting and rigging equipment, you must focus on several key criteria. Start by evaluating the weight and shape of your load. The type of lift—vertical, angular, or rotational—will influence your choice between eye bolts and hoist rings. You should also consider the environment.

For example, marine or outdoor settings require corrosion-resistant hardware. Always check compatibility between all rigging hardware to ensure a safe and efficient lift. Powerful Machinery offers custom-engineered solutions for unique challenges.

Their team uses advanced tools like 3D scanning and laser measurement to map load centers, even on irregular machinery. You benefit from their expertise in structural analysis and OSHA-compliant safety protocols.

Decision Checklist

You can use the following checklist to guide your selection process for lifting and rigging hardware:

Key Considerations | Description |

|---|---|

Assess Load Characteristics | Evaluate the weight and type of load to determine appropriate lifting hardware. |

Choose the Right Hoist Type | Select between manual, lever, or electric hoists based on operational needs. |

Ensure Compatibility Between Components | Verify that all lifting components work together safely and effectively. |

Adhere to Safety Standards | Follow industry regulations and safety protocols to protect operators and equipment. |

Tip: Always document your lifting and rigging plan before starting any operation. This step helps prevent mistakes and improve safety.

Safety Standards

You must follow strict safety standards when selecting eye bolts and hoist rings for lifting and rigging. International regulations require clear identification, rated load markings, and maintenance of legible labels throughout the hardware’s life.

For hoist rings, you also need to check the specified torque value. Powerful Machinery’s products meet or exceed global certifications, including ISO9001, TUV Rheinland, and OSHA.

Requirement | Description |

|---|---|

Manufacturer Identification | The name or trademark of the manufacturer must be marked. |

Rated Load | Rated load must be marked, indicating the maximum allowable working load. |

Alloy Grade | Grade for alloy eyebolts must be specified. |

Torque Value | Torque value must be specified for swivel hoist rings. |

Maintenance of Identification | Identification must remain legible throughout the hardware’s life. |

Note: Choosing certified lifting and rigging hardware from Powerful Machinery ensures you meet all international safety standards and achieve reliable performance in every project.

Best Use Cases

When to Use Eye Bolts

You should use eye bolts when you need a secure and reliable anchor point for lifting heavy machinery, metal beams, or concrete panels.

These fasteners work best for vertical lifts, especially when you screw them directly into the load and attach a chain or cable. In many industries, you use standard eye bolts for straight-line lifting, while shoulder eye bolts handle angled movements safely.

You use eye bolts to attach hooks, cables, or other lifting equipment.

You rely on them for lifting and rigging tasks that require a fixed anchor.

You use them across construction, marine, and industrial settings for heavy load handling.

You benefit from their versatility, as you can use them in both temporary and permanent installations.

Powerful Machinery’s stainless steel eye bolts provide excellent corrosion resistance, making them ideal for marine and outdoor use. You can trust their compliance with international standards, which ensures safety and reliability in every lift.

Tip: Always inspect your eye bolts before each use to confirm they are rated for the load and installed correctly.

When to Use Hoist Rings?

You use hoist rings when your lifting operation demands flexibility and safety in complex rigging scenarios. Hoist rings allow you to lift loads at various angles without losing capacity or risking hardware failure.

Their design features a 180-degree bail pivot and a 360-degree body swivel, so you can align the hardware with the direction of pull.

Feature | Benefit |

|---|---|

180-degree bail pivot | You align with the direction of pull, which enhances safety. |

360-degree body swivel | You lift at multiple angles without reducing load capacity. |

Fully rated WLL | You maintain load integrity and avoid lateral stress or deformation. |

You use hoist rings for lifting irregularly shaped machinery, rotating loads, or when you need to reposition equipment during the lift. In demanding environments, you benefit from advanced safety features like load moment indicators and remote control operation.

Powerful Machinery’s commitment to innovation and product reliability ensures you complete critical lifts efficiently and safely.

Note: You should always follow the manufacturer’s installation guidelines to maximize the performance and safety of your hoist rings.

Conclusion

You now understand that eye bolts work best for straight, in-line lifts, while hoist rings excel in complex, multi-directional rigging. Choosing certified, high-quality hardware protects you and your team. Regular inspections and adherence to safety standards help prevent accidents.

Factor | Why It Matters |

|---|---|

Certified Hardware | Meets industry regulations for safe lifting |

Safety Factor | Provides a margin for unexpected load changes |

Regular Inspection | Prevents equipment failure and legal issues |

For expert advice on safety, efficiency, and durability, consult Powerful Machinery. Their team helps you select the right solution for every lifting challenge.

FAQ

What is the main difference between an eye bolt and a hoist ring?

You use an eye bolt for straight, in-line lifts. A hoist ring allows for rotation and pivoting, making it safer for lifting at angles or with shifting loads.

Can you use eye bolts for angular lifts?

No, you should not use standard eye bolts for angular lifts. Only shoulder eye bolts handle slight angles, but hoist rings remain the safest choice for multi-directional lifting.

How do you choose the right size eye bolt or hoist ring?

You must check the load weight, lifting angle, and thread size. Always select hardware rated above your maximum load. Consult the manufacturer charts or Powerful Machinery’s technical team for guidance.

Are Powerful Machinery’s stainless steel eye bolts suitable for marine use?

Yes. Powerful Machinery’s stainless steel eye bolts resist corrosion and perform well in marine and outdoor environments. You can rely on their compliance with international safety standards.