When you choose lifting chains for rigging, pay close attention to weight and strength. For example, common sizes and grades have these typical limits:

Chain Grade | Weight Limit (lbs) |

|---|---|

9/32″ Grade 100 | 4,300 |

3/8″ Grade 100 | 8,800 |

1/2″ Grade 100 | 15,000 |

Grade 100 chains support about 25% more weight than Grade 80. Modern lifting chains use lightweight, high-strength materials and smart technology to boost safety, making it vital to match the right chain grade to your job’s demands.

Key Takeaways

Understand the weight limits of different chain grades. Grade 100 chains can lift 25% more than Grade 80 chains, making them a better choice for heavy loads.

Always check the weight per meter and working load limit before selecting a lifting chain. This ensures you choose a chain that balances strength and manageability.

Select the appropriate chain grade for overhead lifting. Only Grade 80, Grade 100, and Grade 120 chains are suitable for this purpose.

Inspect your lifting chains regularly for wear and damage. Daily checks help maintain safety and extend the life of your equipment.

Choose chains made from corrosion-resistant materials for marine applications. Stainless steel or galvanized chains perform best in harsh environments.

Lifting Chains for Rigging

Typical Weights

When you select lifting chains for rigging, you need to understand how much each type weighs and how that affects your operation. The weight of a chain depends on its material, diameter, and grade. Here is a quick comparison of the most common types used in the industry:

Type of Chain | Diameter Range | Weight per Meter | Working Load Limit |

|---|---|---|---|

G80 | 8 mm to 16 mm | 2.2 kg (10 mm) | High |

G100 | 10 mm to 13 mm | 2.0 kg (10 mm) | Higher than G80 |

Stainless Steel | 10 mm | 2.3 kg | Lower than alloy |

You will notice that G100 chains weigh slightly less than G80 chains of the same diameter, yet they offer a higher working load limit. Stainless steel chains are a bit heavier and have lower strength, but they provide excellent corrosion resistance.

Powerful Machinery offers a full range of these lifting chains for rigging, with precise specifications to match your project needs.

Tip: Always check the chain’s weight per meter and working load limit before making your selection. This ensures you get the right balance of strength and manageability for your lifting chains for rigging.

Weight-to-Strength Ratios

The weight-to-strength ratio is a critical factor when you choose lifting chains for rigging. This ratio tells you how much weight a chain can safely lift compared to its own mass. A higher ratio means you can handle heavier loads without adding unnecessary weight to your rigging system.

Chain Type | Weight-to-Strength Ratio | Notes |

|---|---|---|

G80 | High tensile strength exceeding ordinary steel | Designed for various industrial lifting applications |

G100 | Higher quality than G80, specific ratios not detailed | Preferred for higher quality requests |

Stainless Steel | Not specified | Commonly used for corrosion resistance and durability |

When you use G100 lifting chains for rigging, you benefit from a 25% higher working load limit compared to G80, while keeping the chain weight manageable. This advantage allows you to maximize lifting efficiency and safety, especially in overhead applications.

Safety Factors in Rigging

You must always consider safety factors when working with lifting chains for rigging. The grade of the chain determines if it is suitable for overhead lifting. Here is a quick guide:

Chain Grade | Description | Suitable for Overhead Lifting |

|---|---|---|

Grade 30 | Economical, multipurpose chain for light construction and marine | No |

Grade 43 | Stronger than Grade 30, used in towing and logging | No |

Grade 70 | Used for securing loads during transport | No |

Grade 80 | Heat-treated alloy steel, suitable for overhead lifting | Yes |

Grade 100 | 25% higher WLL than Grade 80, safe for overhead lifting | Yes |

Grade 120 | 50% stronger than Grade 80, suitable for demanding lifting | Yes |

Other factors that affect the safety and performance of lifting chains for rigging include:

Chain diameter: Larger diameters provide higher strength and greater working load limits.

Angle of lift: The angle between the legs in multi-leg sling configurations changes the working load limit.

Temperature: High temperatures can reduce a chain’s strength.

Wear and deformation: Regular use can cause wear, which lowers the chain’s working load limit.

Powerful Machinery stands out as a trusted supplier of certified lifting chains for rigging. The company maintains a 100% on-time delivery rate, responds to inquiries in two hours or less, and holds a customer rating of 4.4 out of 5.

You can rely on Powerful Machinery’s products to meet or exceed international safety standards, ensuring your lifting chains for rigging deliver both performance and peace of mind.

Chain Grades and Selection

Choosing the right chain grades is essential for safe and efficient lifting. You will find that each grade offers unique properties, making it important to match the chain to your specific needs. Understanding the differences between chain grades helps you make informed decisions for your rigging operations.

Material and Design

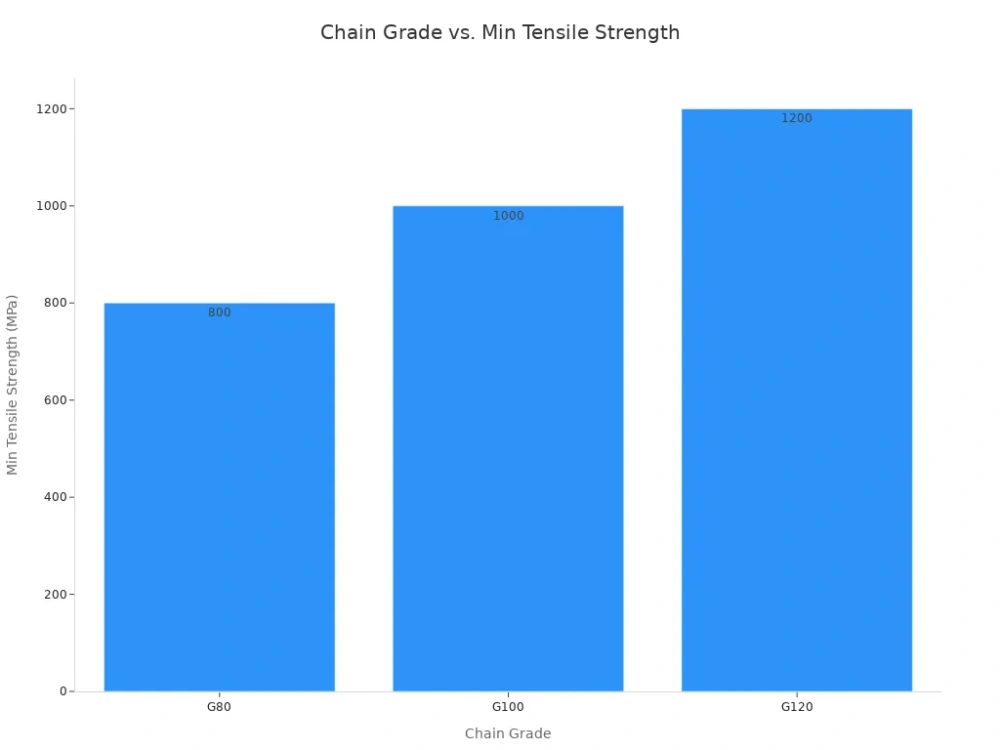

Chain grades are classified by their material composition, heat treatment, and mechanical properties. The most common chain grades for lifting include Grade 80, Grade 100, and stainless steel. Each grade has a specific minimum tensile strength and is designed for particular applications.

Grade | Minimum Tensile Strength (MPa) | Base Material | Heat Treatment | Key Alloying Elements |

|---|---|---|---|---|

G80 | 800 | Medium-carbon steel | Quenching & Tempering | C (0.25-0.35%), Mn |

G100 | 1,000 | High-strength low-alloy steel | Controlled quenching | Cr, Mo, V |

G120 | 1,200 | Advanced HSLA steel | Precision tempering | Cr, Ni, Mo, Nb/V |

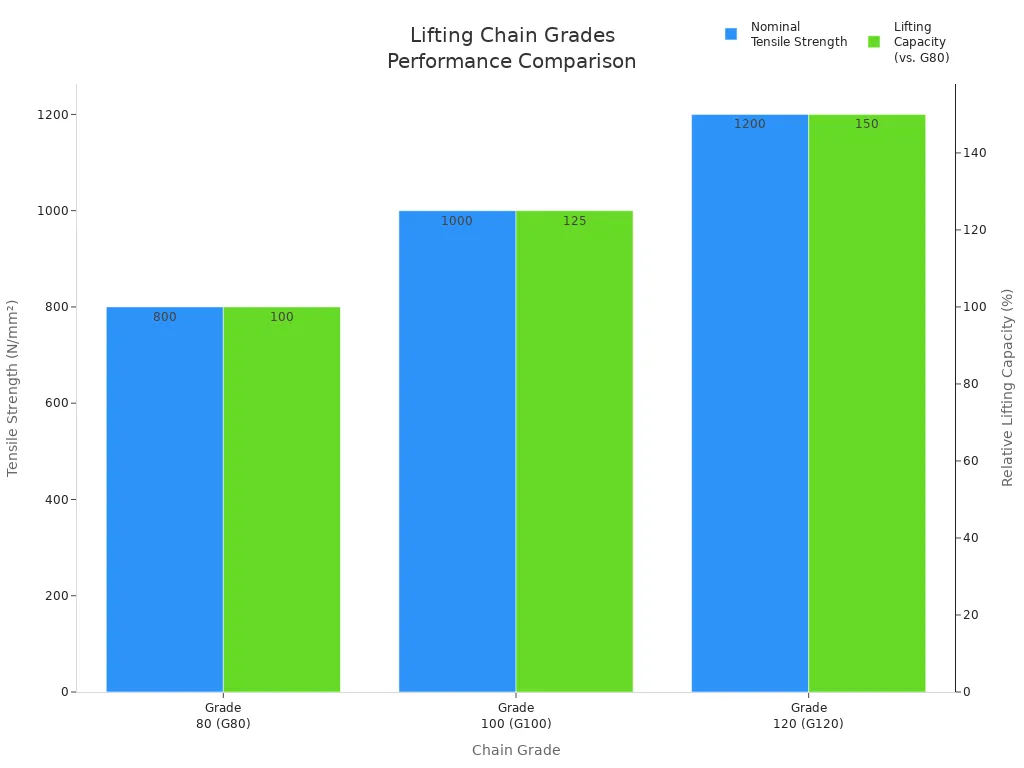

You can see that as the grade increases, the minimum tensile strength also rises. Grade 80 chains use heat-treated alloy steel, providing a solid balance of strength and durability. Grade 100 chains use higher-strength alloy steel, offering about 25% more lifting capacity than Grade 80.

Grade 120 chains push performance even further, using advanced alloys for the highest strength and toughness.

Stainless steel chains are also available. These chains resist corrosion but have lower strength compared to alloy grades. You should select stainless steel when you need durability in wet or corrosive environments.

Key Properties of Chain Grades

Grade 80: Stable performance up to 200°C. Prone to rust. Suitable for static loads.

Grade 100: Retains 80% strength at 300°C. Options for corrosion resistance. High strength for dynamic lifting.

Grade 120: Exceptional toughness. Ideal for critical dynamic lifts. Withstands extreme conditions.

The design of the chain also affects performance. Chains with larger diameters provide higher working load limits. The link shape and finish can improve resistance to wear and corrosion.

Powerful Machinery manufactures chains using advanced heat treatment and alloying techniques, ensuring each grade meets or exceeds industry standards.

Application Factors

Selecting the right chain grades depends on several factors. You must consider the load, environment, and application. Lower grades like 30, 40, and 70 are not suitable for overhead lifting. You should always use higher grades, such as 80, 100, or 120, for lifting heavy loads above ground.

Feature | Grade 80 (G80) | Grade 100 (G100) | Grade 120 (G120) |

|---|---|---|---|

Material Composition | Heat-Treated Alloy Steel | Higher Strength Alloy | Advanced Alloy Steel |

Nominal Tensile Strength | ~800 N/mm² | ~1000 N/mm² | ~1200 N/mm² |

Lifting Capacity (vs. G80) | Baseline | ~25% Higher | ~50% Higher |

When you choose chain grades, always check the working load limit (WLL) and never exceed it. The WLL depends on the chain size, grade, lift angle, and temperature.

High temperatures can weaken alloy chains, especially above 400°F. For outdoor or marine use, corrosion resistance becomes critical. Stainless steel or galvanized chains perform better in these environments.

Tip: Inspect your chains daily. Look for signs of wear, deformation, or corrosion. Regular maintenance ensures safety and extends the life of your lifting equipment.

You should also consider the frequency and type of lifts. For dynamic or repetitive lifting, higher chain grades like 100 or 120 provide better fatigue resistance. Powerful Machinery offers a wide range of chain grades, including custom solutions for unique environments and load requirements.

Certifications

Certifications guarantee that your lifting chains meet strict safety and quality standards. You must use chains that comply with international regulations for industrial applications. Powerful Machinery ensures every chain meets or exceeds the following standards:

Compliance Standard | Testing Process | Certification Provided |

|---|---|---|

ISO | Rigorous load and non-destructive testing | Certificate of conformity |

ASTM | Strict loler testing and examination | Certificate of conformity |

OSHA | Adherence to safety standards | Certificate of conformity |

ASME | Advanced heat treatment for strength | Certificate of conformity |

NACM | High-quality steel selection | Certificate of conformity |

You should only allow trained and qualified personnel to operate lifting equipment. Regular inspections and maintenance are vital for operational safety. The International Standards Organization (ISO) sets global guidelines for lifting chains.

ISO 4309 covers care, maintenance, and inspection of wire ropes, while the ISO 16881 series provides safety recommendations for steel wire ropes.

Powerful Machinery provides full documentation and certificates for every product. Each chain undergoes rigorous testing, including proof loading and non-destructive examination. This commitment to quality ensures your lifting chains deliver reliable performance in every application.

Note: Environmental factors such as high temperatures and corrosive agents can affect chain performance. Always select chain grades and finishes designed for your operating conditions.

By understanding chain grades, material properties, and certification requirements, you can select the best lifting chain for your needs. Powerful Machinery stands ready to support you with certified, high-performance solutions for every lifting challenge.

Types of Lifting Chains

Grade 80 Lifting Chain Slings

You rely on grade 80 lifting chain slings for heavy-duty lifting in construction, manufacturing, and shipping. These slings use durable G80 alloy steel, which delivers high strength and resists wear.

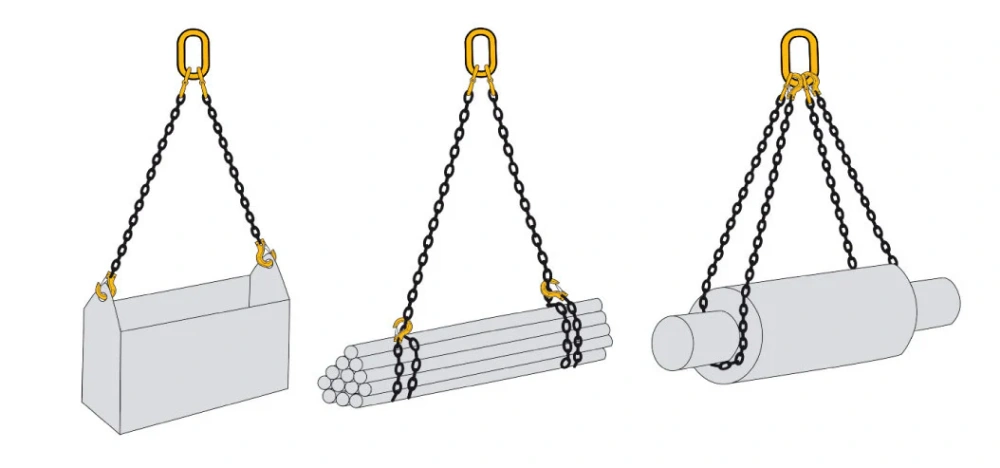

Each sling offers a balanced load distribution, thanks to its 4-leg grab hooks. This design reduces the risk of accidents and ensures secure lifting. Grade 80 lifting chain slings handle loads up to 11,000 lbs (5 tons) and provide excellent performance in demanding environments.

Feature/Use Case | Description |

|---|---|

Material | Durable G80 Alloy Steel ensures long-term use and resists wear and tear. |

Load Capacity | Designed for heavy-duty applications with a capacity of 11,000 lbs (5 tons). |

Safety Features | 4-leg grab hooks provide secure and balanced load distribution. |

Versatile Applications | Suitable for factories, construction sites, and ports. |

Construction | Heavy-duty with powder coating for extra protection against corrosion. |

Ease of Use | High security and safety factors make it reliable and easy to operate. |

Value | Combines high quality with a fair price. |

You must always use alloy sling chains for lifting and never exceed the working load limit. Grade 80 lifting chain slings from Powerful Machinery meet ISO9001, OSHA, and ASTM standards, ensuring you get certified safety and reliability.

G80 Alloy and Lifting Chains

G80 alloy chains give you a strong and lightweight option for overhead lifting. These chains offer twice the strength of regular steel chains and maintain their ultimate breaking strength even in tough conditions. You benefit from improved strength-to-weight ratios, making them easier to handle without sacrificing safety.

Powerful Machinery’s G80 alloy chains undergo rigorous testing and feature patented self-locking hooks for added security. You can trust these chains for dynamic lifting tasks in factories, warehouses, and construction sites.

Tip: Schedule routine inspections for your G80 alloy chains. Identify any signs of wear or damage and remove damaged slings from service immediately.

Log Boom and Passing Link Chains

Log boom chains serve you best in marine and logging operations. You use them to link logs together for floating barriers or containment. These chains resist corrosion and wear, making them ideal for harsh water environments.

Passing link chains, on the other hand, work well for general utility, farm, and industrial uses. Their wide links pass through each other easily, reducing the risk of kinks or binding. While not suitable for overhead lifting, passing link chains offer reliable performance for non-lifting tasks.

Powerful Machinery’s log boom and passing link chains come with certifications from TUV Rheinland, EURO CERT, and the China Classification Society. You receive products that meet strict international standards for safety and durability.

Always store your chains in a dry, mild climate to prevent corrosion and maintain their ultimate breaking strength.

Application Matching

Selecting the right lifting chain for your industry ensures you meet safety standards and maximize load capacity. Each environment demands a specific approach to chain selection, considering working load limit, durability, and the type of load you handle.

Use the table below to compare chain grades, their working load limits, and the best applications for each:

Chain Grade | Working Load Limit (lbs) | Suitable Applications | Overhead Lifting Approved |

|---|---|---|---|

Grade 30 | 1,300 – 6,900 | Light construction, marine | No |

Grade 43 | 2,600 – 13,000 | Towing, logging | No |

Grade 70 | 3,150 – 15,800 | Cargo securement | No |

Grade 80 | 3,500 – 18,100 | Overhead lifting | Yes |

Construction and Industry

In construction and industrial settings, you often face heavy lifting tasks that require chains with high capacity and a strict safety factor. Grade 80 and Grade 100 chains are ideal for these environments. You can use single-leg chain slings for straightforward lifts or double-leg chain slings for balanced load distribution.

Always check the working load limit and follow load capacity guidelines to prevent overloading. Powerful Machinery offers custom assemblies and expert consultation, ensuring your lifting applications meet all safety standards.

Tip: Schedule pre-use inspections before every lift. This practice helps you identify wear or damage and maintain compliance with safety standards.

Marine and Offshore

Marine and offshore applications demand chains with excellent corrosion resistance and reliable load capacity. Grade 30 and Grade 43 chains work well for general marine use, while galvanized or stainless options provide extra durability.

For heavy lifting or mooring, choose chains with a higher safety factor and a certified load limit. Powerful Machinery supplies log boom chains and custom solutions tailored for harsh marine environments, supporting your lifting applications with proven reliability.

Warehouse and Logistics

In warehouse and logistics operations, you need chains that balance capacity, flexibility, and ease of use. Grade 70 and Grade 80 chains handle cargo securement and heavy lifting efficiently. Use single-leg chain slings for quick lifts or double-leg chain slings for larger loads.

Always match the chain’s working load limit to the load you plan to move. Powerful Machinery provides chain slings and accessories designed for fast-paced logistics applications, ensuring your operations stay safe and productive.

Powerful Machinery supports construction, marine, and logistics industries with tailored lifting solutions, including inspection and maintenance services for ongoing safety and performance.

Industry Standards

Quality and Testing

You need lifting chains that meet the highest standards for safety and reliability. Powerful Machinery uses strict testing procedures to guarantee every chain’s performance. Non-destructive testing methods, such as ultrasonic testing and magnetic particle inspection, help identify flaws without damaging the chain.

Load testing checks how chains perform under heavy weights, while fatigue testing ensures durability over time. These procedures confirm that each chain meets the required specification for working load limit, breaking load, and manufacturing test force.

Regular inspections and proper training help prevent most lifting chain failures. You should always follow the recommended safety coefficients, including working load limit and breaking load limit.

Powerful Machinery’s commitment to quality means you receive products that have passed rigorous specification checks and testing. This approach reduces risk and increases trust in your lifting operations.

Certifications and Compliance

You want assurance that your lifting chains comply with global standards. Powerful Machinery’s products meet or exceed ISO, ASTM, and OSHA requirements. The company follows the ISO 9001:2015 quality management system, ensuring stable performance from production to delivery.

Chains also comply with ASME B30.9 and ASTM-A906 specifications for chain slings and rigging hardware.

Manufacturers like Powerful Machinery provide certificates of conformity for every product. These certificates prove that chains have passed all required specification tests and meet international standards. You can rely on Powerful Machinery for lifting chains that deliver safety, reliability, and compliance in every application.

Note: Human error causes most lifting operation failures. You should always train your team, inspect equipment regularly, and follow all safety standards to maintain a safe work environment.

Certification | Specification Met | Testing Process |

|---|---|---|

ISO 9001:2015 | Quality Management | Non-destructive, Load, Fatigue |

ASTM-A906 | Chain Slings | Proof Load, Inspection |

OSHA | Safety Standards | Regular Audits, Training |

ASME B30.9 | Rigging Hardware | Specification Review |

Powerful Machinery’s dedication to quality and compliance places you at the forefront of safe lifting practices. You gain confidence knowing your equipment meets the strictest standards in the industry.

Conclusion

You now understand the typical weights and types of lifting chains used in rigging. Selecting the correct chain grade and type is vital for safety, efficiency, and cost-effectiveness.

Not all chains work for overhead lifting; always match the grade to your task.

Chain grades reflect their break strength and safe working limits.

Use alloy chain slings for overhead lifts.

Strength | Description |

|---|---|

Safety | Certified lifting components ensure every project is built on a foundation of safety and reliability. |

Reliability | Engineered solutions are fully traceable and trusted for major projects. |

Performance | Designed to handle immense dynamic stress with precision. |

Versatility | Grade 80 and Grade 100 chains suit a wide range of lifting tasks. |

Consult Powerful Machinery for expert advice, custom chain sling configurations, and inspection services. You gain peace of mind knowing your lifting solution meets the highest standards.

FAQ

What factors affect the safety of a lifting chain?

You must inspect each chain before use. Look for wear, deformation, or corrosion. Always follow the manufacturer’s guidelines. Use chains that meet the required safety standard. Proper training and regular maintenance help you prevent accidents and ensure safety.

How do you choose the right chain for overhead lifting?

You should select a chain with the correct grade and working load limit. Grade 80 and Grade 100 chains are approved for overhead lifting. Always check the chain’s specifications and certifications. Using the right chain improves safety and efficiency.

Can you use any chain for marine applications?

You need chains with corrosion resistance for marine environments. Stainless steel or galvanized chains work best. Always verify the chain’s safety features and ensure it meets the required standard. Regular inspection helps you maintain safety in harsh conditions.

How often should you inspect your lifting chain?

You must inspect each chain before every use. Look for signs of wear, stretching, or damage. Schedule regular professional inspections. Frequent checks help you maintain safety and extend the chain’s lifespan.

What certifications should your chain have for industrial use?

You should use chains that meet ISO, ASTM, or OSHA certifications. These certifications guarantee the chain’s safety and reliability. Always request documentation from your supplier. Certified chains help you comply with every safety standard.

Tip: Always store your chain in a dry area. Proper storage helps you maintain safety and prolongs the chain’s service life.

Chain Grade | Overhead Lifting | Marine Use | Certification Required |

|---|---|---|---|

Grade 80 | Yes | Yes | Yes |

Grade 100 | Yes | Yes | Yes |

Stainless Steel | No | Yes | Yes |