You can calculate chain sling capacity by using the Chain Sling Working Load Limit Calculation formula: divide the Minimum Breaking Strength by the industry design factor, usually 5 to 1.

Always consider the chain size, sling configuration, and lifting angle before lifting. Follow safety guidelines and check manufacturer instructions. Powerful Machinery provides certified, high-performance chain sling options for different lifting needs.

Key Takeaways

Calculate chain sling capacity by dividing the Minimum Breaking Strength by the safety factor, usually 5 to 1.

Always inspect your chain slings for wear and damage before each use to ensure safety and reliability.

Consider the lifting angle and configuration, as they significantly affect the working load limit of your sling.

Use certified chain slings from trusted manufacturers like Powerful Machinery to guarantee safety and performance.

Follow manufacturer guidelines and safety standards to prevent accidents and ensure effective lifting operations.

Chain Sling Basics

Powerful Machinery stands out as a trusted manufacturer of lifting solutions. You can rely on their chain slings for safe and efficient lifting in construction, marine, and transportation industries.

Every product meets strict international standards, including ASME, NACM, ASTM, and OSHA. Powerful Machinery proof tests each sling to twice its working load limit and provides certificates for every item. You receive a metal tag with proof test and certification details for easy verification.

Types and Configurations

You will find several types of chain slings designed for different lifting tasks. Each configuration offers unique advantages for load handling and stability.

Type | Description | Common Use |

|---|---|---|

Grade 80 1-Leg Lifting Sling | Used for lifting in a single-leg configuration with load distribution. | Construction, general lifting, and rigging tasks. |

Grade 80 4-Leg Rigging Chain | Designed for lifting with four attachment points for balanced load handling. | Lifting large, unbalanced, or heavy loads. |

Grade 100 Round Binding Sling | Used for securing loads, offering flexibility for various shapes. | Binding irregularly shaped objects during lifting. |

Grade 100 3-Leg Lifting Sling | Used for lifting large, unbalanced, or complex loads. | Lifting large and irregularly shaped loads. |

Grade 100 2-Leg Lifting Chains | Suitable for lifting with two attachment points to distribute the load evenly. | Medium-duty lifting tasks in construction. |

Grade 100 4-Leg Sling Chain | Designed for heavy-duty lifting with four points of attachment. | Lifting very heavy and large loads. |

Tip: You can choose single-leg slings for lifting from one central point, double-leg slings for stable loads, and multi-leg slings for complex or heavy objects.

Chain Grades and Specifications

Chain grade affects strength and performance. Powerful Machinery offers Grade 80 and Grade 100 chain slings, each with specific benefits.

Chain Grade | Working Load Limit | Strength-to-Weight Ratio | Applications |

|---|---|---|---|

Grade 80 | Lower than Grade 100 | Moderate | General lifting tasks |

Grade 100 | 25% higher than Grade 80 | Higher | Overhead lifting applications |

Grade 80 chains give you flexibility and cost-effectiveness for everyday lifting.

Grade 100 chains provide higher strength and durability for heavier loads.

Both grades meet international safety standards and undergo rigorous proof testing.

You can select the right chain sling based on your lifting needs, load weight, and required safety standards.

Working Load Limit Essentials

What is Working Load Limit?

You need to understand the working load limit before you start any lifting operation. Working load limit means the maximum load a chain sling or rigging component can safely handle during regular use. Manufacturers determine this value by dividing the minimum breaking strength of the chain by a safety factor, usually 5 to 1.

You will see the working load limit listed in pounds or kilograms on product tags and certificates. This rating helps you avoid dangerous situations and ensures you do not overload your equipment. If you exceed the working load limit, you risk sling failure, injury, and costly damage.

For example, overloaded slings have caused serious accidents, including worker injuries and equipment collapse. You protect yourself and your team by always staying within the rated limits.

Factors Affecting WLL

Several factors influence the working load limit of chain slings. You must consider each one before lifting any load.

Factor | Description |

|---|---|

Larger chain size and higher grade allow you to lift heavier loads safely. | |

Number of Legs | Multi-leg slings distribute weight, increasing the overall working load limit. |

Angle of Lift | Narrower angles between sling legs and vertical lines increase tension and reduce capacity. |

Wear and Tear | Damaged or worn chains lower the working load limit and threaten safety. |

Environmental Conditions | Extreme temperatures and corrosion weaken chains, reducing their load-bearing ability. |

Chain size plays a major role in determining how much weight you can lift. Always check the grade and size before selecting a sling.

You should inspect your chain slings for wear and tear. Corrosion and damage can lower the working load limit and lead to failures.

Workload limits remain valid between -40°F and 400°F. If you operate outside this range, you must consult the manufacturer.

OSHA regulations require you to never exceed the rated capacity of your sling.

Tip: Always use certified chain slings from Powerful Machinery and follow manufacturer guidelines for safe lifting.

Chain Sling Working Load Limit Calculation

Calculation of Working Load Limit

You need to understand the chain sling working load limit calculation before you lift any load. This process helps you determine how much weight your sling can safely handle. Manufacturers like Powerful Machinery use strict standards to certify each sling. They consider the chain size, grade, and the angle at which you use the sling.

You can use a simple formula for the calculation of the working load limit:

Working Load Limit (WLL) = Minimum Breaking Strength ÷ Safety Factor

Most manufacturers use a safety factor of 5. For example, if your chain sling has a minimum breaking strength of 25,000 pounds, the working load limit will be 5,000 pounds. You must check the chain size and grade because these details affect the final result.

Different sling configurations also change the chain sling working load limit calculation. You will see single-leg, double-leg, triple-leg, and quadruple-leg slings. Multi-leg slings distribute the load across more chains, but the angle between the legs and the vertical line reduces the capacity.

You should always measure the angle and use the correct formula for your configuration.

Tip: Always use certified chain slings from Powerful Machinery. Each sling comes with a metal tag that shows the working load limit and proof test details.

Manufacturers follow standards like AS 3775 to calculate and certify the working load limit. Powerful Machinery uses diagrams and tables to show the WLL for different chain grades, such as Grade 80 and Grade 100. You can trust these ratings because they meet international safety requirements.

Chain sling working load limit calculation depends on:

Chain size

Sling configuration

Angle of use

You should never guess the capacity. Always use the data provided by the manufacturer.

Using Load Tables and Manufacturer Data

You can use load tables to quickly find the chain sling working load limit calculation. These tables list the safe working load for each chain size and grade. Powerful Machinery provides certified load tables for all its products.

Here is a sample table that shows the most commonly referenced chain grades and their uses:

Chain Grade | Description | Suitable for Overhead Lifting |

|---|---|---|

Grade 30 | Economical, multipurpose chain for light construction and marine applications. | No |

Grade 43 | Stronger than Grade 30, used in towing and logging. | No |

Grade 70 | Used for securing loads during transport. | No |

Grade 80 | Suitable for overhead lifting and heavy-duty towing. | Yes |

Grade 100 | 25% higher WLL than Grade 80, safe for overhead lifting. | Yes |

Grade 120 | 50% stronger than Grade 80, suitable for demanding lifting applications. | Yes |

You should always select a chain grade that matches your lifting needs. Grade 80 and Grade 100 chains are safe for overhead lifting. Grade 100 offers a higher working load limit, so you can lift heavier loads with the same chain size.

When you use load tables, follow these steps:

Find the chain size and grade on the table.

Check the configuration of your sling (single-leg, double-leg, etc.).

Look for the angle of use. Most tables show the WLL for different angles.

Use the lowest value as your maximum safe load.

Note: Powerful Machinery tests every chain sling to twice its working load limit and provides certificates for each product. You can rely on their data for safe lifting.

You should always use the manufacturer’s certified data for chain sling working load limit calculation. Never exceed the listed working load limit. If you have special lifting requirements, contact Powerful Machinery for custom solutions.

Lifting Angles and Load Distribution

Angle Impact on Capacity

You must pay close attention to the lifting angle when you use chain slings. The angle between the sling legs and the vertical line, known as β, directly affects the working load limit (WLL). As the angle increases, the tension on each leg rises, which reduces the safe lifting capacity.

You can use the formula for a two-leg sling:WLL = 2 x WLL of a single leg x cos(β)

This formula shows that the cosine of the angle plays a key role. When the angle is small, the cosine value is high, so the sling can carry more weight. As the angle gets larger, the cosine value drops, and the WLL decreases.

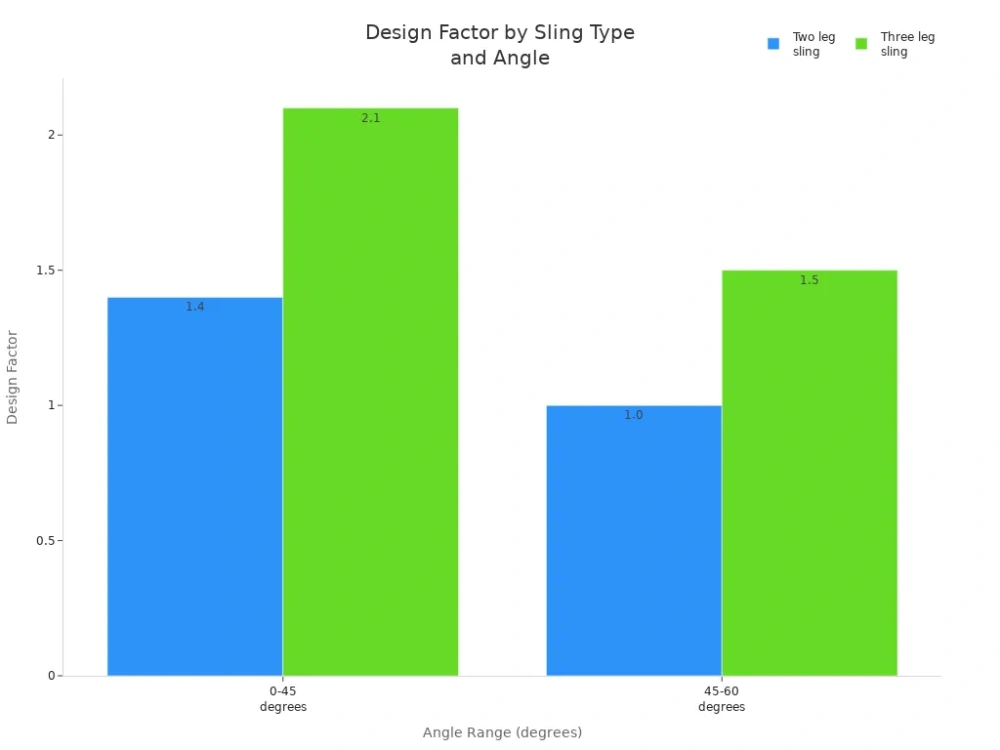

Here is a table that shows how the design factor changes with different sling types and angle ranges:

Sling Type | Angle Range (degrees) | Design Factor |

|---|---|---|

Two-leg sling | 0-45 | 1.4 |

Two-leg sling | 45-60 | 1.0 |

Three-leg sling | 0-45 | 2.1 |

Three-leg sling | 45-60 | 1.5 |

Tip: Always measure the angle before lifting. If you have special angle requirements, tell Powerful Machinery when you place your order. Their team can help you select the right sling for your application.

Multi-Leg and Asymmetrical Loads

You should use multi-leg chain slings for lifting heavy or irregularly shaped loads. These slings distribute the weight evenly across all legs, which improves stability and safety. Uneven load distribution can cause one leg to carry more weight, increasing the risk of sling failure.

Multi-leg sling assemblies spread the load’s weight across several legs.

The angle of each leg affects how much weight it carries.

Vertical angles (90 degrees) give equal tension, while lower angles increase tension on each leg.

Multi-leg slings work best for tall lifts, long distances, or when you need extra stability.

You may need more sling legs in windy conditions or on uneven ground.

Note: When you order chain slings from Powerful Machinery, describe your lifting scenario. Share details about load shape, weight, and required angles. Their experts will recommend the safest and most effective sling configuration for your needs.

Edge Conditions and Protection

Sharp Edges and Edge Radius

You must always check for sharp edges before lifting a load with a chain sling. Sharp corners can cut or damage the chain, which lowers the working load limit (WLL) and puts your safety at risk.

The edge radius, or how rounded the edge is, plays a big role in how much weight your sling can safely handle. If the edge is too sharp, the chain cannot sit properly and may get damaged.

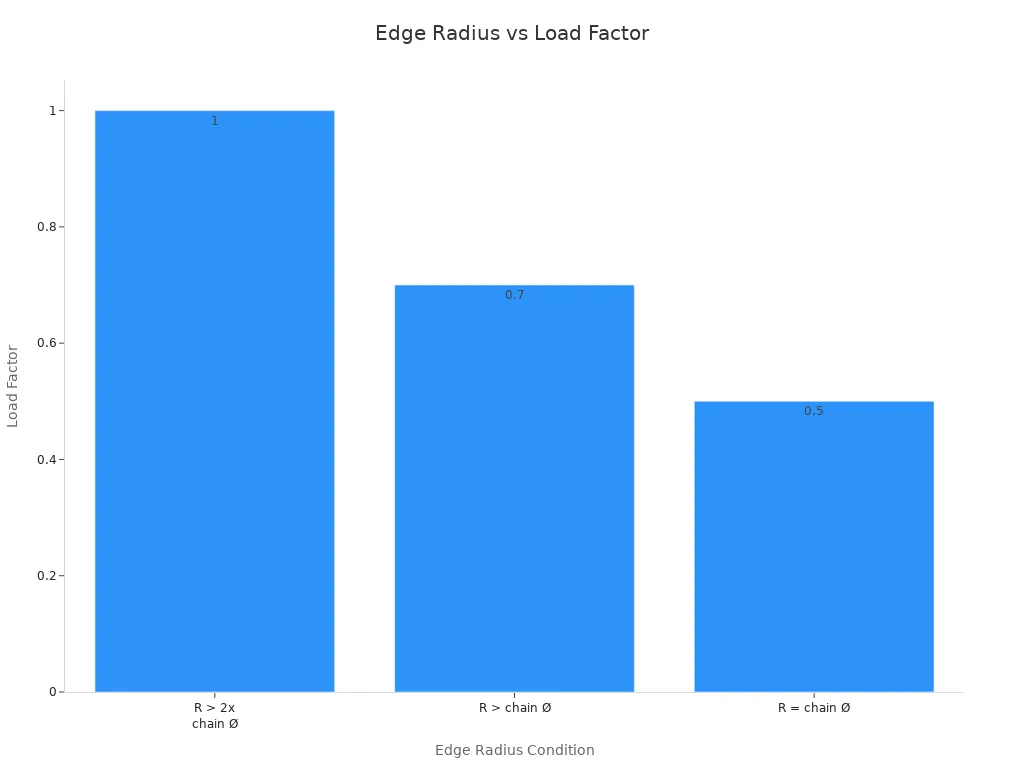

Here is a table that shows how the edge radius affects the load factor for your chain sling:

Edge Radius Condition | Load Factor |

|---|---|

R > 2x chain Ø | 1 |

R > chain Ø | 0.7 |

R = chain Ø | 0.5 |

If the edge radius is more than twice the chain diameter, you can use the full WLL. If the radius is equal to the chain diameter, you must reduce the WLL by half. Always check the edge before lifting.

Tip: Never let the chain rest directly on sharp or narrow edges. Use edge protection to keep your sling safe and strong.

Lug Diameter and Protection Methods

You can protect your chain sling by using the right edge protection methods. These tools help prevent direct contact between the chain and sharp edges. They also help the chain move smoothly and last longer.

Use padding or edge protectors to keep chains away from sharp corners.

Corner pads, wear pads, and corner protectors add a barrier between the chain and the load.

Covers, sleeves, and reinforced eyes give extra protection in tough spots.

Place corner protectors directly on the load’s edges to stop the sling from being cut.

Powerful Machinery recommends these steps for safe use and product durability:

Shields protect your sling from sharp edges and rough surfaces.

Friction reduction pads help your chain last longer by minimizing heat and wear.

Barriers keep dirt and debris away from your sling.

Smoother surfaces allow for better rope movement and less damage.

Using these methods extends the life of your chain sling and keeps your lifting jobs safe.

Enhanced durability protects your cargo during handling.

Improved load stability helps prevent accidents.

Cost-effective solutions reduce damage and save money.

All products meet industry safety standards.

Versatile protection works for many types of loads and can be reused.

Note: Always follow Powerful Machinery’s recommendations for edge protection. This ensures your chain sling stays reliable and safe for every lift.

Inspection and Safety Practices

Length Tolerances

You need to measure the length of your chain sling from the bearing point of the master link to the bearing point of the hook. Accurate measurement helps you spot signs of overloading or excessive wear. If the measured length is longer than the tag indicates, you may have a problem.

When the chain elongates by 20% or more, you must remove the sling from service. Always check the manufacturer’s guidelines for acceptable elongation limits. This routine protects you and your team from unexpected failures.

Regular Inspection and Maintenance

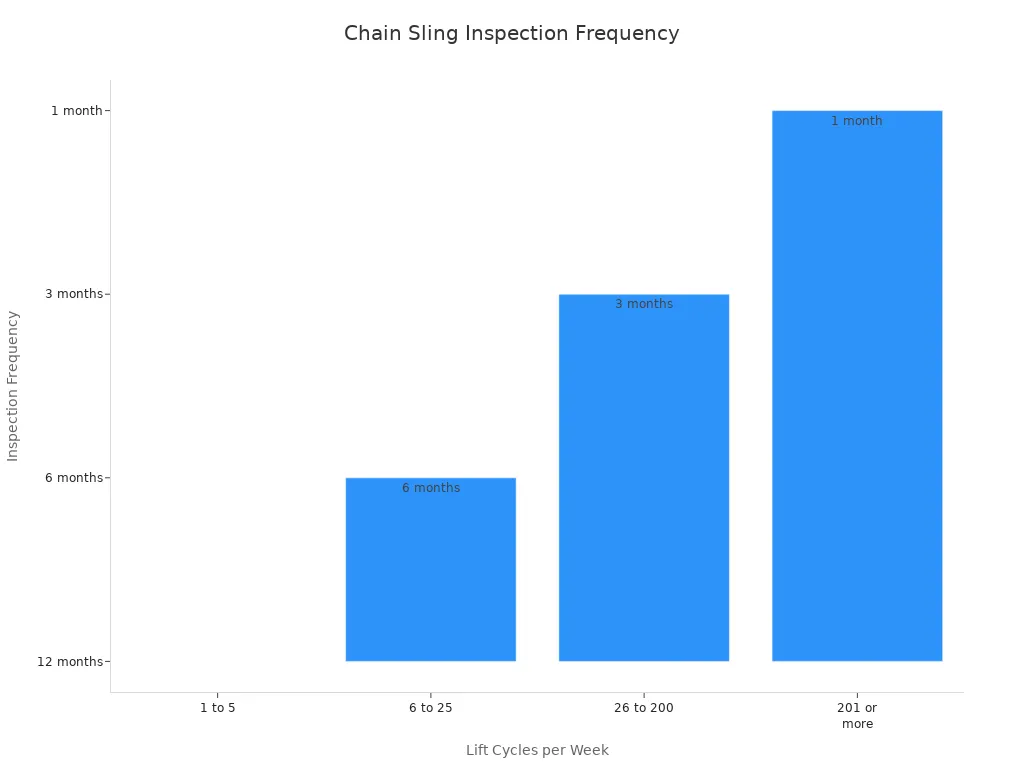

You should inspect your chain slings regularly to maintain safety and reliability. Inspection frequency depends on service conditions and how often you use the sling. The following tables show how often you need to inspect your equipment:

Service Condition | Inspection Frequency |

|---|---|

Normal Service | Annually |

Severe Service | Monthly to Quarterly |

Initial Inspection | Before the slings go into service |

Lift Cycles per Week | Inspection Frequency |

|---|---|

1 to 5 | Every 12 months |

6 to 25 | Every 6 months |

26 to 200 | Every 3 months |

201 or more | Every month |

Routine inspections help you find wear, damage, or elongation early. Remove any sling with defects right away. Scheduling inspections at least once a year keeps your equipment reliable and extends its lifespan.

Trained inspectors can spot problems before they become serious. Documented inspections also show your commitment to safety and help you follow legal requirements.

Documentation Requirement | Source |

|---|---|

Periodic inspections must be documented and records retained as per ASME B30.9 | Mazzella Companies |

Employers must maintain a record of the most recent thorough inspection | Mazzella Companies |

A record of each inspected sling is required per OSHA 1910.184 | Mazzella Companies |

Employers must retain a certificate of the proof test | eCFR |

The certificate must be available for examination | eCFR |

Safe Use Guidelines

You must follow best practices to keep your lifting operations safe. Choose stable lifting points and balance the load. Use padding to protect chains from sharp edges. Understand hitch types such as vertical, choker, and basket, and know their load capacities. Control the load with tag lines and lift slowly to reduce risks. Use hooks with latches that match the chain size and load.

Select shackles with the right working load limit and secure them properly. Follow manufacturer instructions for chain binders to avoid over-tightening. Compliance with standards like ASME B30.10 is essential.

Proper training in rigging procedures helps everyone understand securement and safety. Always use the correct safety factor when calculating working load limits.

Powerful Machinery supports your safety by providing certified products, clear documentation, and expert guidance. Reliable equipment and regular inspections protect your team and keep your projects running smoothly.

Conclusion

You can calculate chain sling capacity accurately by following these essential steps:

Use the correct formula for your sling configuration and account for lifting angles.

Measure sling length and angles precisely with proper tools.

Refer to manufacturer charts for load factors and reduction values.

Inspect your equipment before every use and avoid common mistakes such as miscalculating total load or neglecting manufacturer specifications.

Certified chain slings, like those from Powerful Machinery, offer proven reliability and safety for lifting operations in demanding environments.

Common Mistake | How to Avoid |

|---|---|

Miscalculating total load | Include all components and check the manufacturer data |

Improper rigging | Understand sling angles and dynamic loading |

Lack of inspection | Perform regular checks before each use |

FAQ

What factors affect the capacity of a chain sling?

You must consider chain size, grade, number of legs, sling configuration, and lifting angle. Wear, damage, and environmental conditions also impact capacity. Always check the manufacturer’s data before lifting.

How often should you inspect your chain sling?

You should inspect your chain sling before each use. Schedule regular, detailed inspections based on usage. For heavy use, inspect monthly. For light use, inspect at least once a year.

Can you use a chain sling with sharp-edged loads?

You can use a chain sling with sharp-edged loads only if you protect the chain. Use edge protectors or padding to prevent damage. Unprotected chains may fail or lose capacity.

Where can you find the working load limit for your chain sling?

You can find the working load limit on the metal tag attached to the sling. The manufacturer’s certificate and load tables also provide this information. Always use the lowest value listed.

Does Powerful Machinery offer custom chain sling solutions?

Yes! Powerful Machinery offers custom chain sling solutions. You can request specific lengths, configurations, and attachments. Their team helps you choose the best option for your lifting needs.