You ensure lifting sling safety by selecting the right sling, inspecting it before each use, following load limits, applying proper rigging, and maintaining your equipment. These steps protect you from accidents and extend your gear’s lifespan.

Recent data shows 27% of load drops result from poor rigging, while 60% of crane-related fatalities involve rigging failures.

Source | Statistic |

|---|---|

Konecranes Training Inst. | 27% of load drops are tied to poor rigging practices |

CDC | 60% of crane-related fatalities stem from rigging failures |

Powerful Machinery provides certified lifting solutions you can trust. Always follow safety steps, whether you are new or experienced.

Key Takeaways

Always select the right lifting sling based on load type and environment to ensure safety and efficiency.

Inspect slings before each use to identify damage and prevent accidents; regular checks enhance safety and equipment lifespan.

Understand the working load limits of slings and never exceed them to avoid serious risks like equipment failure and injuries.

Follow proper rigging techniques and training to ensure safe lifting operations; clear communication among team members is essential.

Store slings properly in a clean, dry place away from sunlight and chemicals to extend their service life and maintain performance.

Lifting Sling Safety Guidance

What Are Lifting Slings?

You rely on lifting slings to move heavy loads safely and efficiently in industrial environments. These essential tools come in several forms, each designed for specific tasks.

Wire rope slings support construction, automotive, and oil industries during heavy-duty operations.

Chain slings deliver strength and durability in harsh settings such as foundries and steel mills.

Synthetic slings protect delicate items, reducing the risk of damage during lifting.

Lifting slings play a vital role in safe lifting operations. You select the right sling based on the load type and working conditions. This decision ensures that you maintain control and stability throughout the lifting process.

Powerful Machinery offers a comprehensive range of certified lifting slings, meeting international standards for quality and reliability.

Why Lifting Sling Safety Matters?

You must follow lifting sling safety guidance to protect yourself and your team. Regular inspections help you identify damage early, preventing accidents and equipment failure. Training teaches you to recognize hazards, such as sharp edges or improper rigging.

Post-use inspections after handling dangerous loads keep your workplace secure.

Consider these key points:

Routine inspections reduce the risk of sling failure, preventing injuries and fatalities.

Regular checks help you avoid workflow disruptions and maintain operational efficiency.

Commitment to safety boosts morale and productivity across your team.

Neglecting lifting sling safety guidance can result in property damage and legal liabilities. Early identification of wear signs prevents accidents and protects your company’s reputation. You demonstrate responsibility and professionalism by prioritizing safety every time you use lifting slings.

Powerful Machinery stands as a trusted partner, providing certified products and expert guidance for all your lifting needs.

Types of Lifting Slings

You encounter several types of slings in industrial lifting. Each type offers unique features and suits specific tasks. Understanding these differences helps you choose the right equipment for your operation.

Tip: Always match the sling type to your load and environment for maximum safety and efficiency.

Chain Slings

Chain slings deliver unmatched strength and durability. You can use them for heavy-duty lifting, especially in harsh or high-temperature environments. Their flexibility allows you to handle complex shapes and adjust configurations as needed.

Chain slings resist heat, chemicals, and abrasion, making them ideal for foundries, steel mills, and construction sites. Powerful Machinery manufactures chain slings from high-tensile steel, offering single, double, triple, and quadruple leg designs.

You benefit from products that meet or exceed ISO9001, TUV Rheinland, and OSHA standards, ensuring safety and reliability.

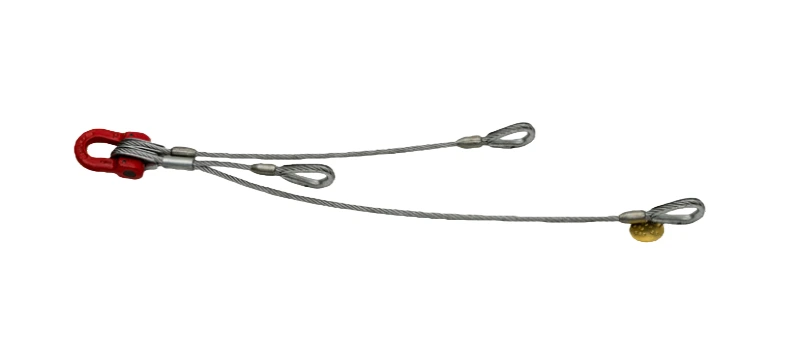

Wire Rope Slings

Wire rope slings combine strength with flexibility. You can use them for general lifting applications, including construction and transportation. These slings handle a wide range of loads and adapt to various lifting configurations.

Their lightweight design makes them easy to handle, while their robust construction ensures long service life. Powerful Machinery’s wire rope slings comply with international standards such as ASTM and China Classification Society, giving you confidence in every lift.

Synthetic Slings

Synthetic slings offer lightweight handling and excellent protection for delicate or irregular loads. You can use them in construction, warehousing, and logistics when you need to avoid damaging sensitive materials. These slings absorb shock and reduce the risk of scratching or crushing your cargo.

Powerful Machinery provides polyester round webbing slings and flat web slings, all color-coded for easy identification. Each sling carries certifications like EN 1492-1, EN 1492-2, and CE, so you know you are using safe and reliable lifting slings.

Sling Type | Distinguishing Features | Typical Use Cases |

|---|---|---|

Chain Slings | High-strength, durable, flexible, heat and chemical-resistant | Heavy-duty lifting, hot materials, complex shapes |

Wire Rope Slings | Strong, flexible, lightweight | General lifting, construction |

Synthetic Slings | Lightweight, protects delicate loads, not heat-resistant | Construction, delicate or irregular loads |

Certification/Standard | Description |

|---|---|

ISO9001 | Quality management systems |

TUV Rheinland | Product safety and quality assurance |

OSHA | Occupational Safety and Health Administration |

ASTM | American Society for Testing and Materials |

EN 1492-1/2 | European standards for synthetic slings |

CE | European product safety certification |

You ensure safe and efficient lifting by selecting the right sling for your application. Powerful Machinery supports you with certified products for every lifting challenge.

Selecting the Right Sling

Choosing the right type of lifting sling is the foundation of lifting sling safety. You must evaluate your load, the environment, and the task before you select a sling. Using the wrong sling for the load can lead to accidents, equipment damage, or even injury.

This guidance will help you understand how to choose the right sling for every application.

Assessing Load and Environment

You start by examining the load and the environment where you will use the sling. Consider these factors:

Weight of the load

Shape and dimensions

Surface finish and balance

Designated lifting points

Positioning and center of gravity

Environmental and weather conditions

Temperature and sensitivity of the material

You must know the exact weight and configuration of the load. This information helps you select the correct sling size and type. For example, heavy, unbalanced, or oddly shaped loads may require a chain sling with multiple legs.

If you work in a high-temperature or corrosive environment, you need a sling that can withstand those conditions. Powerful Machinery offers a full range of chain slings, wire rope slings, and synthetic slings, each designed for specific environments and lifting challenges.

Tip: Always check the reach required to achieve the correct lifting angle. The angle affects the share of the load on each pick point and the sling’s working load limit.

Matching Sling Type to Task

You must match the sling type to your lifting task. Each sling has unique characteristics that make it suitable for certain applications. The table below summarizes the main types:

Sling Type | Defining Characteristics | Typical Applications |

|---|---|---|

Chain Slings | Strong metal alloy chains, heat-resistant, adjustable, rugged | High heat, heavy loads, sharp edges, construction, and foundries |

Wire Rope Slings | Twisted steel wires, strong, flexible, and abrasion-resistant | General heavy lifting, factories, construction |

Synthetic Slings | Nylon or polyester fibers, lightweight, gentle on loads, color-coded | Delicate items, sensitive surfaces, warehousing, logistics |

You should use chain slings for heavy-duty tasks in harsh environments. Wire rope slings work well for general lifting where flexibility is important. Synthetic slings are best for delicate or irregularly shaped loads. Powerful Machinery provides certified options in each category, so you always have the right tool for the job.

Note: Never use a sling for a task it was not designed for. This practice ensures safety and extends the life of your equipment.

Understanding Working Load Limits

You must understand the working load limit for every sling you use. The working load limit is the maximum weight a sling can safely lift under specific conditions. Manufacturers determine this limit by dividing the minimum breaking strength by a safety factor.

For example, a wire rope sling with a breaking strength of 100,000 lbs and a design factor of 5:1 will have a working load limit of 20,000 lbs.

Sling angles also affect the rated capacity. The American Society of Mechanical Engineers (ASME) and the Web Sling & Tie Down Association (WSTDA) provide charts that show how sling angles reduce capacity. Always check these charts before lifting.

Every sling from Powerful Machinery comes with a traceability label. This label includes:

Information on Sling Tag |

|---|

Manufacturer or repair entity |

Material of the sling |

Rated load for at least one hitch type |

Individual sling identification (serial number) |

Manufacturer code or stock number |

Number of legs (for bridle assemblies) |

Traceability ensures you can verify the sling’s history, specifications, and compliance with international standards. This information is critical for audits, inspections, and safe operation.

Alert: Never use a sling without a clear and legible traceability tag. If the tag is missing or unreadable, remove the sling from service immediately.

By following this guidance, you ensure lifting sling safety and protect your team and equipment. Powerful Machinery’s certified slings and clear labeling make it easy to comply with industry standards and best practices.

If you ever have questions about how to choose the right sling, consult your supplier or a qualified lifting professional.

Lifting Sling Safety: Inspection and Traceability

Pre-Use Inspection Steps

You must inspect the sling before every lift to ensure safety and prevent accidents. Begin with a visual check for cuts, frays, abrasions, or broken stitching. Confirm that the sling’s label is present and legible, showing the working load limit, material type, and manufacturer details.

Verify the working load limit and mode of use.

Determine the load mass and center of gravity.

Ensure the sling is strong enough and the correct length.

Place slings to distribute the load evenly.

Avoid using slings that are knotted, twisted, or unprotected from sharp edges.

Prevent shock loading and secure the load to avoid slipping.

Best practice: Designate a Competent Person to perform daily pre-use sling inspections. Inspect synthetic web slings upon receipt and before each use to catch any damage or defects early.

Inspection Frequency and Records

You need to follow a regular inspection schedule to maintain lifting sling safety. Safety agencies recommend initial, monthly, quarterly, and annual inspections. Keep detailed records for each inspection, including dates, sling identification, defects, and recommended actions.

Inspection Type | Frequency | Documentation Required |

|---|---|---|

Initial Inspection | Before use | Record of inspection details |

Monthly Inspection | Monthly | Detailed records of each inspection |

Quarterly Inspection | Quarterly | Records showing compliance with safety standards |

Annual Inspection | Annually | Comprehensive documentation for audits |

Maintain these records to demonstrate compliance with standards and to track the history of each sling.

Identifying Damage and Wear

You must recognize the signs of a damaged lifting sling to prevent failures. Look for cuts, tears, or abrasions on the sling surface. Broken or damaged stitching signals that the sling is unsafe. Inspect hardware and fittings for deformation, cracks, or corrosion.

Unusual twisting or knotting can indicate internal damage or uneven weight distribution.

If you find any of these issues, remove the sling from service immediately. Powerful Machinery complies with ASME B30.9 and OSHA standards, providing durable tags with working load limits, manufacturer information, serial numbers, and inspection records.

These traceability features help you maintain safety and meet regulatory requirements.

Use of Lifting Slings: Proper Rigging Methods

Training and Competency

You must prioritize training and competency before you begin any use of lifting slings. Only personnel who are trained and experienced should handle lifting slings. OSHA defines a competent rigger as someone who possesses the necessary knowledge and skills to perform rigging tasks safely.

You need to understand the instructions for the use of lifting slings and follow them every time.

Receive formal training on sling types, load calculations, and safe lifting procedures.

Gain hands-on experience under supervision before operating independently.

Review the instructions for use regularly to stay updated on safety protocols.

Confirm your competency with periodic assessments and refresher courses.

Proper training ensures you recognize hazards, select the right equipment, and apply the appropriate method of rigging. You protect yourself and your team by following guidance and maintaining high standards of safety.

Rigging Techniques

You must apply best practices for rigging to achieve safe and efficient lifting operations. Begin by inspecting all rigging equipment for signs of wear or damage before each use. Choose the correct rigging based on the load type and weight.

Assess load specifications to identify the right sling and rigging gear.

Verify that all equipment has capacity ratings matching the load and lifting machinery.

Consider environmental factors, such as temperature and humidity, when selecting materials.

Perform precise load calculations, including weight and distribution.

Securely attach rigging gear to the load to prevent slippage.

Use proper sling angles to maintain load stability and avoid improper hitching and sling angles.

Establish clear communication among rigging personnel and crane operators.

You should conduct regular inspections of rigging equipment before and during use. Comprehensive training for riggers on safe rigging practices is essential. Clear communication protocols during hoisting operations help prevent misunderstandings and accidents.

Powerful Machinery provides detailed instructions for use and guidance for every sling, supporting your commitment to lifting sling safety.

Tip: Always follow the instructions for use of lifting slings provided by the manufacturer. This practice extends equipment life and reduces risk.

Securing Loads and Center of Gravity

You must secure loads properly and determine the center of gravity before lifting. Start by identifying the weight of the load and its center of gravity. This step ensures that your rigging equipment can handle the load without exceeding its capacity.

Distribute the weight evenly to maintain balance during the lift.

Understanding the center of gravity is crucial for calculating sling angles. A vertical sling at a 90-degree angle maximizes the working load limit, while a 45-degree angle reduces it by half.

You must avoid improper hitching and sling angles to prevent overload and instability.

Attach the sling to the appropriate lifting points and avoid sharp edges that could damage the sling. Ensure the load is balanced and securely rigged to prevent shifting during the lift. Powerful Machinery’s instructions for use include clear guidance on securing loads and calculating sling angles.

You maintain safety and protect your equipment by following these practices.

Note: Always check the load’s center of gravity and sling angle before lifting. This step is vital for the safe use of lifting slings and prevents accidents.

Overloading the Sling and Other Key Warnings

Risks of Overloading

You face a serious risk when overloading the sling during lifting operations. Ignoring load limits can result in instant equipment failure. Overloading chain slings often leads to irreversible damage, making them unsafe for future use.

Exceeding the rated safety factor increases the chance of dropped loads, structural damage, and severe injuries. You must consider environmental factors, such as temperature and corrosion, because these can amplify the consequences of overloading. Catastrophic failures may occur, putting both personnel and property at risk.

Overloading can cause dropped loads and equipment damage.

Permanent damage to chain links may result from a single overload.

Ignoring weight limits can lead to severe injuries or even death.

Common Mistakes to Avoid

You can prevent most lifting accidents by following proper guidance and avoiding frequent errors. Many incidents occur because operators ignore pre-use sling inspections or use the wrong sling for the load or environment.

Overloading remains a common mistake, especially when the working load limit is not checked. Improper hitching and sling angles also increase risk. You should always store slings in a cool, dry place to prevent degradation.

Not reading identification tags or checking the working load limit.

Failing to inspect slings for fraying, cuts, or damage before use.

Using rigging equipment without regular inspections.

Neglecting proper sling storage, which can lead to corrosion.

Lifting loads with unknown weight or using slings with unknown capacity.

Critical Safety Warnings

You must follow strict safety warnings to avoid lifting sling failures. Always inspect your sling before every lift and remove it from service if you spot any damage. Never alter or modify slings by tying knots or adding makeshift devices.

Stay within the rated working load limit and consider sling angle and hitch type in every calculation. Secure every connection to both the load and the lifting hook. Use edge protection or padding where slings contact sharp corners.

Tip: Powerful Machinery provides clear safety instructions and certified products. Following this guidance helps you minimize risk and maintain a safe working environment.

Environmental and Chemical Factors

Environmental conditions play a major role in how long your lifting slings last and how well they perform. You must understand how temperature, chemicals, and sunlight can affect your equipment. By choosing slings with the right resistance features, you protect your investment and maintain safety on every lift.

Powerful Machinery designs products to withstand harsh environments, giving you confidence in demanding settings.

Temperature Limits

Temperature extremes can change the properties of lifting slings. High heat can cause lubricants in wire rope to evaporate and may even melt or weaken synthetic slings. Low temperatures can make steel brittle and cause synthetic slings to stiffen or crack. You should always check the temperature range for your sling before use.

Temperature Condition | Effect on Wire Rope | Effect on Synthetic Slings |

|---|---|---|

High Heat | Lubricants evaporate, possibly melting | Loss of strength, potential melting |

Low Temperature | Steel becomes brittle | Stiffening, increased risk of cracking |

Powerful Machinery’s chain slings and wire rope slings are engineered for stability in both hot and cold environments. Synthetic slings from Powerful Machinery use high-quality polyester to reduce the risk of heat or cold damage.

Chemical Resistance

Chemical exposure can weaken lifting slings over time. Polyester slings offer moderate resistance to acids but can break down when exposed to strong alkalis. Nylon slings resist alkaline substances well and are not affected by grease or oil. Fiber rope slings deteriorate quickly if exposed to caustics or acids.

Material | Chemical Type | Resistance Level |

|---|---|---|

Polyester | Acids | Moderate resistance, avoid strong corrosives |

Polyester | Alkalis | Vulnerable, can weaken fibers |

Nylon | Alkaline substances | Good resistance |

Nylon | Grease and oil | Unaffected |

Fiber Rope | Caustics and acids | Rapid deterioration, avoid chemicals |

You should always store slings away from chemicals and clean them after exposure. Powerful Machinery’s polyester slings are tested for chemical resistance, making them reliable for industrial use.

Sunlight and UV Protection

Sunlight, especially ultraviolet (UV) rays, can damage synthetic lifting slings. Over time, UV exposure breaks down the fibers, much like rust affects metal. This process reduces the sling’s strength and makes it brittle. In just two to three years, UV light can cut the strength of synthetic slings by half.

You should store slings indoors or in shaded areas to prevent this kind of damage.

Powerful Machinery’s synthetic slings use UV-resistant polyester to slow down fiber degradation. Always inspect slings for signs of fading or brittleness if they have been exposed to sunlight.

Tip: Protect your slings from extreme temperatures, chemicals, and sunlight to extend their service life and maintain reliable lifting performance.

Maintenance and Storage for Lifting Slings

Cleaning Procedures

You maintain lifting sling integrity by following proper cleaning procedures. After each use, clean slings with mild soap and water to remove dirt and contaminants. Avoid harsh chemicals, which can damage webbing or synthetic fibers. For metal components, use a wire brush or cloth to eliminate debris.

Regular cleaning prevents buildup that can weaken the sling and compromise safety. Powerful Machinery recommends cleaning slings as needed to ensure optimal performance and longevity.

Clean slings with mild soap and water after use.

Avoid harsh chemicals that may damage the sling material.

Remove dirt or debris from metal parts using a wire brush or cloth.

Tip: Clean slings immediately after exposure to mud, chemicals, or corrosive substances to prevent long-term damage.

Storage Best Practices

Proper sling storage protects your equipment from environmental hazards and extends its lifespan. You should store slings in a location away from direct sunlight to prevent degradation. Keep slings clean and free from contaminants before placing them in storage.

Organize slings by hanging them on racks or storing them in lockers to keep them off the ground. Avoid extreme temperatures and prevent chemical exposure by choosing a climate-controlled area.

Best Practice | Description |

|---|---|

Avoid Sunlight | Store slings in a location that does not receive direct sunlight. |

Keep Clean | Ensure slings are clean before storage. |

Organize Properly | Hang slings on racks or in lockers to keep them off the ground. |

Avoid Extreme Temperatures | Store slings away from hot or cold environments. |

Prevent Chemical Exposure | Do not store slings near chemicals that could degrade the material. |

Powerful Machinery’s guidance emphasizes the importance of proper sling storage to maximize sling life and maintain safety standards.

Preventing Premature Wear

You prevent premature wear by following best practices during use and storage. Inspect slings frequently for signs of wear, damage, or corrosion. Store slings in a clean, dry, and well-ventilated area to avoid rust and deterioration. Handle slings carefully, avoiding dragging them on rough surfaces.

Clean slings regularly to remove contaminants. Apply high-quality lubricant to metal components to reduce friction and protect against rust.

Step | Description |

|---|---|

Inspect | Conduct frequent inspections for wear, damage, or corrosion. |

Store | Keep slings in a clean, dry, and ventilated area. |

Handle | Avoid dragging slings on rough surfaces; use proper lifting techniques. |

Clean | Regularly clean slings to remove contaminants. |

Lubricate | Apply lubricant to metal parts to prevent rust. |

You extend sling life and maintain safety by following these maintenance and storage practices. Powerful Machinery recommends regular inspections and adherence to guidance for all lifting equipment.

Inspection, Repair, and Retirement

When to Inspect and Repair?

You need to inspect lifting slings regularly to maintain safety and prevent unexpected failures. Inspection intervals depend on how often and where you use the equipment. In normal conditions, you should perform a frequent inspection daily or before each shift. In severe conditions, inspect before every use.

Schedule periodic inspections yearly for normal service, but increase the frequency to monthly or quarterly if you work in harsh environments or special applications.

Inspection Type | Frequency of Inspection |

|---|---|

Frequent Inspection | Daily or before each shift in normal conditions; before each use in severe conditions. |

Periodic Inspection | Yearly for normal service; monthly to quarterly for severe service; as recommended for special service. |

If you find minor issues, such as dirt or light surface wear, clean and maintain the sling according to manufacturer guidance. Never attempt to repair major damage yourself. Only qualified professionals should repair lifting slings, and all repairs must follow industry standards.

Powerful Machinery supports you with expert advice and ensures every product meets strict compliance requirements.

Criteria for Sling Disposal

You must know when to retire a sling from service. Remove a sling immediately if you notice any of the following:

Missing or unreadable capacity tags

Cracks, breaks, excessive wear, nicks, or gouges

Stretched, bent, twisted, or deformed chain links or components

Signs of heat damage or weld splatter

Pitting or corrosion

Inability of components to hinge freely

Wear of 13% or more at any point on a link

These criteria help you avoid accidents and keep your workplace safe. Always follow the latest industry guidance and refer to standards like ASME B30.9 for exact values.

Maximizing Sling Lifespan

You can extend the life of your lifting slings by following a few simple steps. Store slings in a clean, dry area away from sunlight and chemicals. Inspect slings before and after every use. Clean them regularly and avoid dragging them on rough surfaces.

Use proper lifting techniques and never exceed the rated capacity. Powerful Machinery provides detailed instructions and ongoing support to help you maximize equipment lifespan and maintain compliance with international standards.

Tip: Regular inspection and proper care not only improve safety but also reduce replacement costs over time.

How Long Do Lifting Slings Last?

Factors Affecting Lifespan

You determine the lifespan of lifting slings by considering several important factors. Material quality plays a major role. High-grade polyester or alloy steel slings from Powerful Machinery offer extended durability, especially when you follow proper guidance.

Environmental conditions also impact longevity. Extreme heat, UV exposure, moisture, and chemicals can weaken fibers or corrode metal components. Maintenance practices matter as well. Routine inspections and immediate removal of damaged slings help you maintain safety and prevent premature failure.

Factor | Description |

|---|---|

Material Quality | Premium materials last longer, especially with regular care. |

Environmental Factors | Heat, sunlight, moisture, and chemicals can shorten lifespan. |

Maintenance Practices | Frequent inspections and prompt replacement of damaged slings are essential. |

Note: Exceeding the rated capacity places stress on sling fibers and shortens their usable life. Always follow the manufacturer’s load guidelines.

Signs for Replacement

You must recognize when to retire a sling to maintain a safe work environment. Look for these warning signs:

Frayed fibers or broken stitching

Cuts, abrasions, or visible damage

Corrosion or rust on metal fittings

Deformation, stretching, or twisted components

Missing or unreadable identification tags

If you notice any of these issues, remove the sling from service immediately. Regular monitoring ensures you do not use compromised equipment.

Best Practices for Longevity

You extend the life of your lifting slings by following industry guidance and best practices:

Inspect slings before each use for damage or wear.

Clean slings using manufacturer-recommended techniques to prevent material degradation.

Store slings in a cool, dry place away from sunlight and moisture.

Always comply with load capacity limits to avoid premature failure.

Powerful Machinery designs slings for maximum durability, using certified materials and advanced manufacturing processes. By following these steps, you maintain safety and get the most value from your equipment.

Conclusion

You protect yourself and your team by following these steps for lifting sling safety: select the right sling, inspect it before use, apply proper rigging, maintain equipment, and store it correctly.

Choose certified products from Powerful Machinery for reliable performance.

Review safety procedures often and consult experts if you have questions.

Remember, consistent safety practices prevent accidents and extend equipment life.

FAQ

How often should you inspect your lifting sling?

You should inspect your lifting sling before every use. Schedule periodic inspections based on usage and environment. Daily checks catch visible damage. Annual inspections by a qualified person ensure compliance and safety.

What should you do if a sling’s identification tag is missing?

Remove the sling from service immediately. You must not use any sling without a clear, legible identification tag. This tag provides essential safety information and traceability.

Can you repair a damaged synthetic sling?

You should never repair a damaged synthetic sling yourself. Only qualified professionals can assess and repair slings. Most industry standards require you to replace damaged synthetic slings rather than repair them.

How do you choose the right sling for your load?

Assess the load’s weight, shape, and environment. Match the sling type and capacity to your task. Always check the working load limit on the tag. Powerful Machinery offers certified options for every lifting need.

Where should you store lifting slings when not in use?

Store lifting slings in a clean, dry, and shaded area. Hang them on racks or place them in lockers. Avoid exposure to sunlight, chemicals, and extreme temperatures to extend sling life.