Every time you operate lifting equipment, you face real risks. Improper lifting chain use leads to over 30% of rigging-related accidents, with workplace injuries reaching 2.6 million cases in 2023.

The financial impact can exceed $43,000 per incident. You can prevent these costly mistakes by making chain sling safety your top priority. Powerful Machinery stands as your trusted partner, delivering certified solutions that support your commitment to safe and compliant lifting operations.

Key Takeaways

Select the right lifting chain sling based on grade, configuration, and certification to ensure safety and efficiency.

Conduct thorough pre-use inspections of chain slings to identify potential hazards and maintain compliance with safety standards.

Follow proper lifting practices, including planning, load assessment, and correct rigging techniques to prevent accidents.

Maintain accurate documentation of inspections and certifications to demonstrate compliance with safety regulations.

Store and clean chain slings properly to extend their lifespan and ensure they remain safe for use.

Chain Sling Selection

Selecting the right lifting chain slings is the first step to safe and efficient lifting. You must consider grade, configuration, and certification to match your job’s demands and meet safety standards.

Grades and Strength

When choosing a chain sling, always check the grade. The grade affects the working load limit and chain capacity.

Grade 30 and 43 chains work well for construction, securement, and agricultural tasks.

Galvanized or stainless-steel chains resist corrosion, making them ideal for marine use.

Grade 70 chains offer higher strength and serve best for transport tie-downs.

For overhead lifting, use only Grade 80 or higher. Grade 100 chains provide about 25% more strength than Grade 80, making them perfect for heavy-duty lifting.

Selecting the right lifting chain means you match the proper size and type to your load. Smaller diameters handle lighter loads, while larger diameters support heavier weights. Powerful Machinery offers a full range of certified chain slings, each proof-tested to ensure safety and reliability.

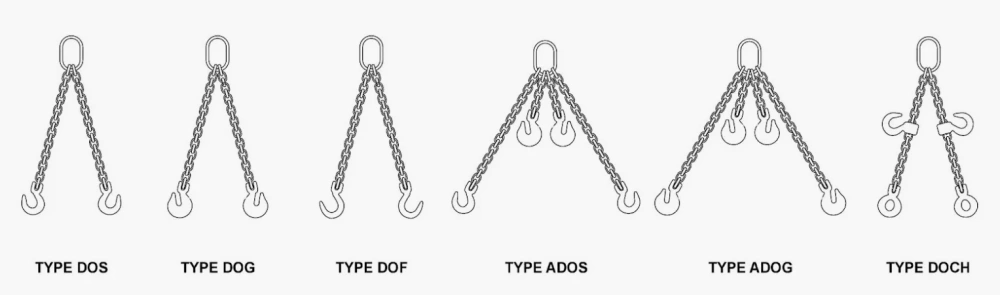

Configurations and Applications

You must choose the correct configuration for your lifting needs. The table below shows common types and their best uses:

Chain Sling Type | Use Case Description |

|---|---|

Single Leg | Best for simple lifts with lighter loads and single attachment points. |

Double Leg | Offers more control and stability for heavy or awkward items. |

Triple Leg | Balances loads from three points, ideal for large machinery. |

Quadruple Leg | Handles very heavy loads, giving maximum stability for tough jobs. |

Powerful Machinery’s chain slings come in all these configurations, so you can always find the right fit for your application.

Certification and Tagging

Always check for proper certification and tagging before use. Certified chain slings from reputable manufacturers like Powerful Machinery reduce risk and improve workflow. Each sling must have:

Specification | Requirement |

|---|---|

Tagging Requirements | Manufacturer’s name, sling diameter, rated load, and hitch type. |

Unique Identification | A unique serial number for traceability. |

Additional Information | Optional details like hitch configuration and date of manufacture. |

These tags ensure you meet international standards such as ISO, ASTM, and OSHA. Certification guarantees that your chain slings are safe, traceable, and ready for demanding jobs.

Pre-Use Inspection

Before every lift, you must perform a thorough pre-use inspection to ensure chain sling safety. This process helps you catch potential hazards early and keeps your operation compliant with industry standards.

Chain Sling Safety Checks

A qualified person should always conduct the inspection. Start by laying out the chain sling and checking each component. Use this checklist to guide your inspection:

Examine every link, master link, load pin, and hook for cracks, breaks, or excessive wear.

Look for missing or unreadable identification tags.

Identify nicks, gouges, or surface damage. Remove the sling from service if you find any cuts, burns, or deep scratches.

Check for stretched or elongated links and components. If you see any, do not use the sling.

Inspect for rust, corrosion, or weld splatter.

Make sure all links move freely and that hooks are not twisted or opened beyond safe limits.

You must never ignore these warning signs. Powerful Machinery designs each chain sling to meet strict quality standards, but regular inspection remains your responsibility.

Cleaning and Measuring

Clean the chain sling before you inspect it. Dirt and grit can hide damage and make it hard to spot problems. Use a wire brush or cloth to remove debris. Hang or stretch the sling to check for twists and measure its length. Use a caliper to measure worn areas.

If the diameter falls below the minimum size, remove the sling from service. Look for signs of wear at link connections and on the outer surface. Oil the chain if you see rust or pitting. Store slings in a clean, dry place to prevent corrosion.

Documentation Review

A qualified person should always verify the legibility of the identification tag. Check that the tag displays the manufacturer’s name, sling diameter, rated load, and unique serial number.

Review inspection records to confirm the sling passed previous checks. If you find missing documentation or unclear markings, remove the sling from service until you resolve the issue. Keeping accurate records supports chain sling safety and helps you meet regulatory requirements.

Tip: Consistent pre-use inspections and documentation help you maintain a safe workplace and extend the life of your lifting equipment.

Lifting Practices Checklist

Planning and Load Assessment

You must start every lifting operation with a clear plan. Written procedures help you avoid confusion and reduce risk. Always select lifting chain assemblies with enough strength for your load.

Position and install your equipment correctly. Never work under suspended loads. Powerful Machinery’s chain slings offer high-tensile strength and certified reliability, supporting safe planning and execution.

Prepare a written plan for each lift.

Choose lifting chain assemblies with adequate strength.

Position equipment for maximum stability.

Install the lifting chain assembly according to the manufacturer’s guidelines.

Keep personnel away from suspended loads.

Tip: Careful planning and load assessment prevent accidents and protect your team.

Rigging and Hook Orientation

Proper rigging ensures safe and efficient lifting operations. You must orient hooks correctly to maintain load stability. Select the right lifting hooks for your lifting chain assemblies. Powerful Machinery provides a range of hooks and attachments designed for secure load control.

Orient hooks to prevent accidental disengagement.

Use a lifting chain assembly with hooks suited for your specific load.

Select lifting hooks that match the configuration of your chain slings.

Avoid side-loading or point-loading hooks.

Note: Correct hook orientation and rigging reduce the risk of failure and improve load control.

Dos and Don’ts

Follow these essential rules to keep your lifting chain assemblies safe and effective. Operators must stay alert and follow best practices at all times.

Visually inspect chain slings before each use.

Know your load and select the proper lifting chain assembly.

Never overload the sling; check the Work Load Limit.

Do not point load hooks; rest the load on the hook’s base.

Ensure the chain is not twisted or kinked.

Do not shorten slings with makeshift devices.

Protect the chain from damage during lifting.

Lift and lower loads smoothly to avoid shock loading.

Keep hands and fingers clear while tightening the sling.

Avoid exposing alloy chain slings to excessive heat.

Protect slings from corrosion during storage.

Store slings properly on an A-Frame.

Alert: Ignoring these dos and don’ts can lead to equipment failure and serious injury.

Adjusting for Corners and Angles

Loads often have sharp edges or uneven surfaces. You must adjust your lifting chain assembly to prevent damage and maintain stability. Powerful Machinery’s chain slings work well with edge protectors and padding, keeping your equipment safe.

Best Practice | Description |

|---|---|

Use Padding or Edge Protectors | Prevents chains from directly contacting sharp edges, reducing damage risk. |

Choose Stable Lifting Points | Ensures the load remains balanced throughout the lift, enhancing stability. |

Tip: Always use padding and select stable lifting points to protect your lifting chain assemblies and ensure a safe lift.

You can rely on Powerful Machinery’s certified chain slings and lifting chain assemblies for every step in your lifting practices checklist. Their products support safe, efficient, and compliant lifting operations.

Inspection & Maintenance

Daily and Periodic Checks

You must inspect your chain slings before every use. This routine helps you catch problems early and keeps your lifting operations safe. Industry standards require different inspection frequencies based on service conditions. Use the table below to guide your schedule:

Service Condition | Inspection Frequency |

|---|---|

Normal Service | Every 12 months |

Severe Service | Every 1 to 3 months |

Special Service | As determined by a qualified person |

Before Use | Always inspect before use and during use if conditions change |

Designated personnel should perform daily checks, while certified inspectors handle periodic reviews. Always keep accurate records of these inspections to comply with OSHA and ASME standards.

What to Inspect?

You need to examine every part of the chain sling for signs of wear or damage. Focus on these components:

Component | Inspection Focus |

|---|---|

Sling and fastenings | Damage or defects |

Alloy steel chain links | Wear, defective welds, deformation, increase in length |

Chain links | Corrosion, nicks, gouges, stretch |

Master link and hooks | Binding or loss of clearance |

Look for cracks, corrosion, or any deformation. Measure worn links and check for elongation. Clean and oil the chain to prevent rust.

Removal from Service

Remove a chain sling from service if you find any of the following:

Criteria for Removal from Service |

|---|

Missing or illegible identification |

Cracks or breaks |

Excessive wear, nicks, or gouges |

Stretched or deformed links or components |

Heat damage or severe corrosion |

Weld splatter or inability to articulate freely |

Any condition causing doubt about safe use |

⚠️ Never use a sling that shows these signs. Powerful Machinery’s chain slings are built for durability, but safety always comes first.

Storage and Protection

Proper storage extends the life of your chain slings. Follow these best practices:

Store slings off the ground and away from vehicles.

Keep them in a cool, dry, and dark place.

Clean slings regularly to remove dust and moisture.

Avoid chemically active environments.

Use edge protection during lifting to prevent wear.

Tip: Good storage habits protect your investment and help you maintain compliance with safety standards.

Compliance & Records

Certification and Documentation

You must keep accurate records to demonstrate compliance with chain sling safety standards. Proper documentation protects your team and your business during audits or inspections. Chain slings require inspection by a trained user before each use.

A competent person must also inspect them at least once a year, with written results. You need to maintain records of the most recent inspections, repairs, and proof tests. These records must be available for examination at any time.

Inspect chain slings before every use.

Document annual inspections by a competent person.

Keep written records of all inspections and repairs.

Retain certificates of proof testing for each sling.

Ensure identification tags remain legible and attached.

Tip: Good documentation supports the certification of lifting chains and helps you meet audit requirements.

Qualified Personnel

You must assign inspection and maintenance tasks to qualified personnel. Only trained users and competent persons can perform these duties. The table below outlines the requirements for each role:

Role | Requirement |

|---|---|

Trained User | Inspect before each use |

Competent Person | Inspect at least once annually |

Proper training ensures that inspections are thorough and that chain slings remain within their work load limit. Regular training also reduces the risk of accidents and equipment failure.

Regulatory Standards

You must follow all applicable regulations to ensure safe lifting operations. The table below highlights key regulations and their requirements:

Regulation | Description |

|---|---|

OSHA 1910.5 (c) (1) | Specific standards take precedence over general standards. |

ASME B30.9-1.10.1 (c) | Never exceed the rated load of the sling. |

OSHA 1910.184 (e) (1) | Identification tags are required for all alloy steel chain slings. |

OSHA 1910.184 (e) (2) (i) | Attachments must match the chain’s rated capacity. |

OSHA 1910.184 (e) (2) (ii) | Makeshift links or fasteners are not allowed. |

You must also ensure proof testing of new, repaired, or reconditioned slings before use. Keep certificates of proof test for every sling. Powerful Machinery meets or exceeds all major international standards, including ASME, ISO, and OSHA.

Rigorous inspection and testing guarantee that every product complies with the latest regulations. The 2021 updates to ASME B30.9 introduced new definitions and requirements for endless slings and sling protection, so you should stay informed about these changes.

Note: Non-compliance can lead to equipment failure, injuries, legal consequences, and unsafe working conditions. Always follow regulations and keep your records up to date.

Conclusion

You can ensure chain sling safety and compliance by following these essential steps:

Select certified chain slings for your application.

Inspect equipment before each use and document findings.

Operate with proper rigging techniques and load control.

Maintain slings through regular cleaning and storage.

Keep accurate records and schedule periodic expert inspections.

Ongoing training and consulting with certified professionals help you stay current with industry standards. Choose Powerful Machinery for reliable, certified lifting solutions that support your commitment to safety.

FAQ

What types of chains are best for lifting heavy loads?

You should select Grade 80 or Grade 100 chains for lifting heavy loads. These chains offer high strength and durability. Powerful Machinery provides certified chains that meet international safety standards for demanding lifting applications.

How often should you inspect lifting chains?

You need to inspect chains before each use and schedule periodic inspections based on service conditions. Daily checks help you spot damage early. Annual inspections by a qualified person ensure chains remain safe and reliable.

Can you use chains in outdoor or corrosive environments?

You can use chains in outdoor or corrosive environments if they have corrosion-resistant finishes. Powerful Machinery offers chains designed to withstand harsh conditions, including marine and construction sites. Always clean and store chains properly after use.

What should you do if you find damage on your chains?

You must remove chains from service immediately if you find cracks, deformation, or excessive wear. Never attempt to repair chains yourself. Contact a qualified professional or your supplier for guidance on safe replacement.

Are chains customizable for specific lifting needs?

You can customize chains for length, configuration, and attachments to fit your lifting requirements. Powerful Machinery offers custom-engineered chains and accessories. Consult with experts to ensure chains match your project specifications.