You must choose the right lifting sling material based on your load, work environment, and specific safety needs. Improper lifting sling selection causes over 30% of rigging-related workplace accidents.

Certified lifting slings from Powerful Machinery improve your operational efficiency by 15%, reduce load handling time by 20%, and decrease equipment downtime by 10%.

Metric | Improvement |

|---|---|

Operational Efficiency Increase | 15% |

Load Handling Time Reduction | 20% |

Equipment Downtime Decrease | 10% |

Powerful Machinery offers certified, high-performance lifting solutions for every application. For complex lifts, consult our experts to ensure safety and reliability.

Key Takeaways

Choose the right lifting sling material based on your load and environment to prevent accidents.

Regularly inspect slings for wear and damage to ensure safety and compliance with industry standards.

Understand the unique properties of each sling type to match them effectively to your lifting needs.

Follow safety regulations and guidelines to create a safer workplace and reduce liability.

Consult experts for complex lifts to ensure you select the best lifting solutions for your operations.

Why Lifting Sling Material Matters?

Safety and Efficiency

You face serious risks when you select the wrong lifting sling material for your operation. Each type of sling has a specific use case, and using the wrong one can lead to accidents or equipment failure.

For example, a synthetic web sling may not withstand sharp edges, high heat, or corrosive environments. You must match the sling material to the load and the conditions to prevent incidents.

Tip: Always check the environment and the load before choosing your sling. This simple step can prevent costly mistakes.

Here is a quick reference for suitable use cases:

Sling Type | Suitable Use Case |

|---|---|

Webbing slings | Light, non-abrasive loads |

Flexible but protected | |

Wire rope slings | Heavy-duty and abrasion-resistant |

High-heat, rugged industrial use |

When you use the correct lifting sling material, you improve safety, reduce downtime, and ensure compliance with industry standards. Powerful Machinery’s products meet strict international certifications, so you can trust their reliability in any environment.

Key Selection Factors

You need to consider several factors when choosing between types of lifting slings:

Weight of the load: Make sure the sling can handle the load safely.

Size and shape of the load: Some slings work better with irregular shapes.

Center of gravity: Proper balance prevents tipping or shifting.

Attachment points: Check how the sling connects to the load.

Environmental conditions: Heat, chemicals, and moisture affect material performance.

Type of lift: Decide if you need a single-leg, multi-leg, or endless configuration.

Sling material: Choose the right material for your application.

International safety standards require you to inspect slings for wear, corrosion, and damage. You must also follow certifications such as ISO 9001, ASME B30.9, OSHA, and TUV Rheinland. Powerful Machinery’s lifting solutions comply with these regulations, giving you peace of mind.

By understanding these key factors, you make informed decisions that protect your team and your investment.

Lifting Sling Material Overview

Types of Sling Materials

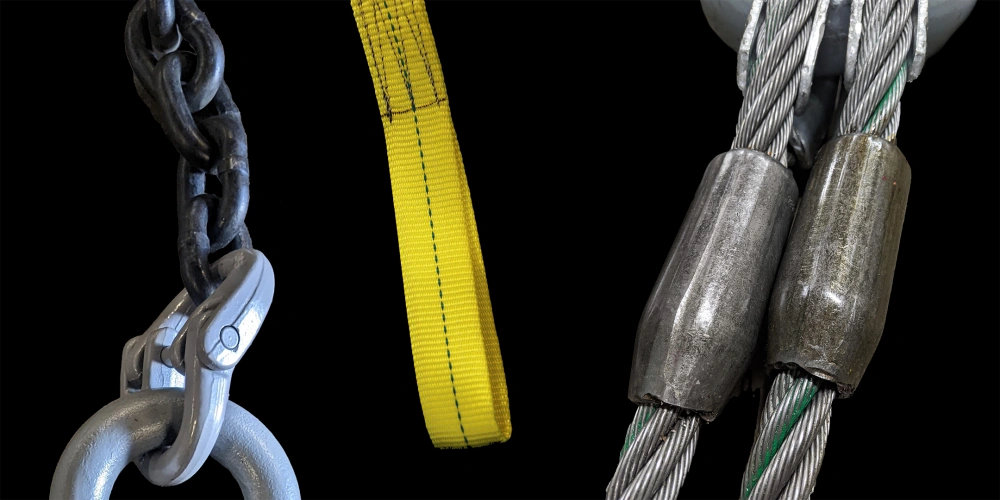

You encounter several types of lifting slings in heavy industry. Each lifting sling material offers unique benefits for different applications. Powerful Machinery provides certified products in all major categories, ensuring you find the right solution for your lifting needs.

Chain slings: You use these for heavy-duty lifting. They are made from high-strength steel, brass, or stainless steel. Chain slings handle rugged environments and high working load limits.

Wire rope slings: These slings consist of steel or nylon wires. You rely on them for industrial lifting tasks that demand resistance to wear and tear.

Webbing slings: You select these when you need flexibility and cost-effectiveness. They are constructed from high-strength polyester or nylon. Webbing slings work well for lighter loads but are not ideal for wet conditions.

Round slings: These slings are light and flexible. They use flat or tubular webbing and suit loads with large surface areas or cylindrical shapes.

Powerful Machinery’s range covers all these materials, meeting strict international standards for safety and performance.

Material Properties

You must understand the properties of each lifting sling material before making your selection. Chain slings feature interlinked metal chains, giving you high strength and durability. Round slings use a continuous loop of synthetic fabric, providing flexibility and adaptability for delicate surfaces.

Wire rope slings offer a higher working load limit than webbing or round slings, and they resist abrasion. Webbing slings deliver excellent flexibility and durability, but you should avoid them in wet environments.

Here is a comparison of key properties:

Property | Chain Slings | Round Slings |

|---|---|---|

Structural Composition | Interlinked metal chains, high-strength steel alloys | Continuous loop of high-strength synthetic material |

Load Capacity and Weight | Handles heavier loads, higher weight-to-load ratio | Lighter alternative, favorable weight-to-load ratio |

Flexibility | Rigid, less adaptable to irregular loads | Highly flexible, conforms to load shape |

Safety | Resistant to cutting and abrasion, ideal for harsh environments | Soft material, safer for delicate surfaces |

Cost Considerations | Higher initial cost, lower total cost over time | Cost-effective upfront, may need more frequent replacements |

You improve safety and efficiency when you match the lifting sling material to your load and environment. Powerful Machinery’s certified products give you confidence in every lifting operation.

Chain Slings

Composition & Grades

You rely on chain slings when you need maximum strength and reliability for heavy-duty applications. Powerful Machinery manufactures chain slings from high-strength steel alloys such as 20Mn2, SCM440, and 23MnNiMoCr5-4.

These materials undergo special heat treatment to deliver exceptional toughness and elongation of over 20%. You can choose between Grade 80 and Grade 100 chain slings, each offering unique mechanical properties for lifting sling material.

Grade | Material | Strength | Weight | Durability | Flexibility |

|---|---|---|---|---|---|

80 | Alloy Steel | Standard | Heavier | Good | Moderate |

100 | Special Alloy Steel | Higher | Lighter | Superior | Excellent |

Grade 100 chain slings provide 25% higher strength compared to Grade 80, allowing you to lift heavier loads with greater safety.

Advantages

You benefit from chain slings in rugged applications because they offer unmatched durability and resistance to harsh environments. Chain slings resist chemicals, UV radiation, and abrasion, making them ideal for heavy loads in extreme conditions.

You can safely use them in environments with dirt, oil, and high temperatures ranging from -40°F to 400°F without reducing their working load limit. Chain slings also have a long service life, which makes them a cost-effective choice for repeated lifting tasks.

Note: Chain slings outperform synthetic slings in high-temperature and chemically aggressive environments.

Applications

You find chain slings widely used in industries that demand reliable lifting solutions. Common applications include:

Construction sites

Shipping yards

Manufacturing plants

Industrial operations

Foundries

Steel mills

You can customize chain slings for specific lifting needs, choosing single, double, triple, or quadruple leg designs. This flexibility ensures you match the right sling to your load and application.

Safety Considerations

You must follow strict safety standards when using chain slings. OSHA 1910.184 and ASME B30.9 outline safe operating practices, product identification, inspection requirements, and use limitations. The Canadian Centre for Occupational Health and Safety also provides guidelines for safe sling use.

Always know the weight of your load and never exceed the rated capacity of your sling. Regular inspection for wear, corrosion, and damage is essential to maintain safety in every lifting operation.

Tip: Adhering to these standards protects your team and ensures reliable performance in heavy-duty applications.

Webbing & Round Slings Selection

Material & Structure

You choose webbing and round slings for their unique construction and adaptability. Powerful Machinery offers slings made from high-strength polyester and nylon, which deliver excellent durability and resistance to abrasion.

Flat woven webbing slings use a strip of synthetic material sewn into a loop, while round slings feature a continuous loop of synthetic fibers inside a protective sleeve. This design gives you options for different lifting needs.

Feature | Flat Woven Webbing Slings | Roundslings |

|---|---|---|

Construction | Made from a flat strip of synthetic webbing material, sewn to form a loop. | Made from a continuous loop of synthetic material in a protective sleeve. |

Flexibility | Less flexible, suitable for even pressure distribution. | Highly flexible, adapts to various load shapes. |

Surface Protection | Gentle on delicate loads due to the wide, flat surface. | Soft design reduces the risk of damage to fragile loads. |

Lifting Points | Reinforced lifting eyes at the ends for secure attachment. | Distributes weight evenly, no rigid lifting of the eyes. |

Wear Resistance | More resistant to cutting and abrasion due to a thicker design. | Generally less resistant to wear compared to webbing slings. |

Stiffness | Stiffer design, maintains load orientation. | Softer and more adaptable to load shapes. |

Benefits

You benefit from webbing and round slings because they offer versatility, safety, and ease of use. Powerful Machinery’s slings use color-coding, which helps you quickly identify the correct sling for your load.

This system reduces the risk of overloading and promotes consistency across different job sites. You also meet safety regulations and industry standards when you follow color codes.

Color coding allows for quick identification of the correct sling for a load, reducing the risk of overloading.

It standardizes lifting operations across various sites and industries, promoting consistency and safety.

Compliance with color codes is often mandated by safety regulations and industry standards.

You find these slings lightweight and easy to handle, which improves efficiency during lifting operations.

Best Uses

You select polyester webbing slings for loads that require gentle handling or have irregular shapes. These slings work well in environments with common acids and where minimum stretch is important. You avoid using them with concentrated sulfuric acid or in highly alkaline conditions.

Characteristics | Suitability for Loads |

|---|---|

Unaffected by common acids | Ideal for loads in acidic environments |

Minimum stretch | Suitable for loads requiring low stretch during lifting |

Unsuitable for concentrated sulfuric acid | Not recommended for loads in highly alkaline conditions |

Round slings provide excellent protection for fragile or painted surfaces. You use them for lifting delicate machinery, finished products, or loads with uneven surfaces.

Safety Tips

You must inspect webbing and round slings before every use to ensure safety. Follow these steps:

Check for loose threads or broken stitches.

Look for signs of chemical damage or deterioration.

Ensure labels are legible and accurate.

Inspect hooks for bending, cracks, and proper latch function.

Untangle knots and make sure slings lie flat without twists.

Look for discoloration, brittleness, mold, or contaminants from UV or environmental exposure.

Keep a log of inspections, findings, and actions taken.

Regular inspection and documentation help you maintain safe lifting operations and extend the life of your equipment.

Wire Rope Slings Guide

Construction

Wire rope slings use high-quality steel wires, such as EIPS or EEIPS, to deliver reliable performance in demanding environments. You will find different construction patterns, like 6 x 19 or 6 x 37, which influence flexibility and abrasion resistance. Some slings include thimbles at connection points to extend service life.

You can choose between independent wire rope cores (IWRC) for higher temperature resistance and load capacity, or fiber cores (FC) for added flexibility. Wire rope slings come in single-leg or multi-leg designs, giving you options for various hoisting and rigging applications.

Strengths

You benefit from wire rope slings because they combine strength and flexibility. These slings handle heavy loads and adapt to different shapes. The lightweight design makes them economical and easy to maneuver. When you compare wire rope slings to chain slings, you notice several differences:

Feature | Wire Rope Slings | Chain Slings |

|---|---|---|

Strength | Strong, suitable for heavy loads | Extremely strong, designed for heavy and bulky loads |

Flexibility | Flexible, but can be damaged by kinking | Flexible design, withstands impact and harsh conditions |

Durability | Durable but susceptible to corrosion and damage | Very durable, repairable, withstands extreme conditions |

Weight | Lightweight, more economical | Heavier can be more expensive |

Inspection | Difficult to inspect, especially around the core | Easy to inspect |

Repairability | Not repairable, should be disposed of if damaged | Repairable, individual links can be replaced |

Temperature Resistance | Not suitable for extreme temperatures | Preferred in high-temperature applications |

You can rely on wire rope slings for lifting tasks that require a high working load limit and adaptability.

Limitations

You must remain aware of the main limitations of wire rope slings. In wet, marine, or chemical environments, corrosion can develop quickly. Rust and chemical damage weaken the wire structure, reducing the working load limit and increasing the risk of sudden failure.

Wire rope slings are also not repairable. If you find damage, you must replace the sling to maintain safety.

Safety Practices

You should always follow strict safety practices when using wire rope slings:

Inspect wire rope slings and accessories before each use and before storage.

Store and handle slings properly to prevent kinks and crushing.

Protect slings from sharp edges and position hooks to face outward from the load.

Never use defective slings or accessories.

Ensure the wire rope is not twisted or knotted.

Do not join slings made from different layers of rope.

Stay within the rated working load limit for every lift.

Balance the load evenly, especially when using basket hitches.

Securely attach the sling to the load with proper rigging hardware.

Regular inspection and correct handling help you avoid accidents and extend the life of your wire rope slings.

Sling Material Comparison

Capacity & Durability

You need to evaluate lifting sling material based on lifting capacity and durability. Chain slings offer the highest lifting capacity, making them ideal for heavy loads in demanding rigging operations.

Wire rope slings provide strong support for industrial lifting, while webbing and round slings excel with lighter loads and delicate surfaces. Durability metrics include abrasion resistance, UV resistance, environmental resistance, chemical resistance, and tensile strength.

For example, Extreema® slings maintain integrity after 5000 abrasion cycles, while polyester slings last for 2500 cycles. You can rely on Powerful Machinery’s products for robust performance and long service life.

Sling Type | Lifting Capacity | Abrasion Resistance | UV Resistance | Chemical Resistance | Tensile Strength |

|---|---|---|---|---|---|

Chain Slings | Very High | Excellent | Excellent | Excellent | Superior |

Wire Rope Slings | High | Good | Good | Good | High |

Webbing Slings | Moderate | Moderate | Good | Good | Moderate |

Round Slings | Moderate | Good | Good | Good | Moderate |

Chain slings and wire rope slings deliver unmatched durability for heavy-duty lifting. Webbing and round slings provide flexibility and protection for sensitive loads.

Environmental Resistance

You must consider environmental resistance when selecting sling materials for rigging. Chain slings withstand extreme temperatures from –40°F to 1,000°F, making them suitable for hot and cold environments.

Wire rope slings perform well between –40°F and 400°F, while synthetic webbing and round slings operate safely from –40°F to 194°F. High ambient heat can degrade synthetic fibers, and chemicals or salt may corrode steel unless properly maintained.

You should always match the sling material to the environment to ensure safety and reliability.

Sling Type | Minimum Temp | Maximum Temp | Notes |

|---|---|---|---|

Alloy Chain | –40°F | 1,000°F | Rated load may decrease at high temps |

Wire Rope (IWRC) | –40°F | 400°F | Fiber core max 180°F |

Synthetic Web/Round Slings | –40°F | 194°F | Vulnerable to heat and chemicals |

Synthetic slings are best for environments free from high heat and corrosive chemicals. Chain and wire rope slings excel in extreme conditions.

Inspection & Maintenance

You protect your team and equipment by following best practices for inspection and maintenance. Always inspect slings before and after each use for wear, damage, or distortion. Clean slings with mild soap and water, and avoid harsh chemicals. Store slings in a dry, clean area away from sunlight and sharp edges.

Lubricate metal components to prevent corrosion. Hang slings properly to avoid kinks, and use edge protectors to prevent cuts. Keep detailed records of inspections and maintenance activities.

Regularly inspect for damage or distortion.

Clean with mild soap and water.

Store in a dry, clean space away from sunlight.

Lubricate metal parts to prevent corrosion.

Hang slings to avoid kinks or bends.

Use edge protectors for added safety.

Maintain inspection and maintenance logs.

Consistent inspection and proper care extend the life of your lifting sling material and ensure safe rigging operations.

Lifting Sling Selection Guide

Matching Sling to Load

You must approach choosing lifting slings with a systematic process to ensure safe and efficient material handling. Start by determining the weight and size of your load. You can find this information in technical specifications or by calculation.

Knowing the center of gravity helps you position the sling correctly and prevents shifting during lifting.

Follow these steps when matching the sling to the load:

Identify the exact weight and dimensions of the load.

Verify the center of gravity for balanced lifting.

Select the sling type based on load shape:

Round slings work best for delicate or cylindrical items.

Web slings suit flat, stable loads.

Chain slings handle rugged, heavy-duty applications.

Wire rope slings support industrial loads with high working load limits.

Check the sling’s material, construction, and rated capacity.

Confirm compatibility with your lifting equipment and rigging hardware.

Tip: Always verify the sling’s working load limit before each lift. This step reduces risk and supports safe material handling.

You improve safety and efficiency by matching the sling to the load’s requirements. Powerful Machinery offers custom-engineered solutions for unique lifting challenges. You can consult their experts for tailored recommendations.

Environmental Factors

Environmental conditions play a critical role in choosing lifting slings for material handling and rigging. You must assess the worksite for temperature extremes, chemical exposure, and other hazards.

Consider these factors:

Extreme heat can evaporate lubricants in wire ropes and reduce tensile strength in synthetic fibers.

Cold temperatures may make synthetic slings stiff and steel brittle, increasing the risk of damage.

Chemicals such as acids and solvents weaken synthetic and wire rope slings. Nylon and polyester are especially vulnerable to chemical degradation.

Sunlight, dirt, and temperature changes accelerate deterioration in web slings. Single ply slings degrade faster than multiple ply slings.

Store web slings in cool, dry, and dark places to maintain their strength against UV exposure.

Note: You should always select sling materials that match the environmental demands of your application. This practice extends the life of your lifting equipment and supports frequent inspections.

You protect your investment and your team by considering these environmental factors. Powerful Machinery provides lifting slings designed to withstand harsh conditions, ensuring reliable performance in any setting.

Regulatory & Safety Needs

You must comply with industry regulations when choosing lifting slings for material handling. Regulatory bodies set standards for safe operation, inspection, and maintenance of lifting equipment.

Here is a summary of key standards:

Regulatory Body | Standards/Guidelines | Description |

|---|---|---|

OSHA | Safety Standards | Establishes guidelines for safe operations, inspection, maintenance, and training for lifting operations. |

ASME | B30 Series | Provides comprehensive guidelines for operating and maintaining lifting machinery. |

ISO | ISO 4309, ISO 16881 | Offers standards for wire rope care, maintenance, and safety recommendations for lifting operations. |

You must follow these standards to ensure safe rigging and material handling. Frequent inspections are required to maintain compliance and prevent accidents. You should keep detailed records of inspections and maintenance activities.

Tip: Consult Powerful Machinery for certified lifting equipment that meets or exceeds international safety standards. Their team can help you navigate regulatory requirements and select the right products for your operation.

You create a safer workplace and reduce liability by adhering to these guidelines. Proper selection and maintenance of lifting slings support efficient material handling and protect your team.

Conclusion

You improve safety and efficiency when you match the sling material to your specific application. Powerful Machinery provides certified, custom lifting solutions designed for your toughest challenges. Regular inspection and maintenance deliver long-term benefits:

You spot minor issues before they become serious accidents.

You reduce hazards and create a safer workplace.

You keep your lifting equipment operating efficiently, which boosts productivity.

Stay committed to safety standards and consult experts for complex lifts.

FAQ

What makes webbing slings suitable for delicate loads?

You choose webbing slings for delicate loads because the wide webbing surface distributes pressure evenly. This design protects painted or fragile surfaces from scratches. You avoid damage during industrial lifting tasks by using webbing slings with soft, flexible webbing.

How do you inspect webbing slings before use?

You inspect webbing slings by checking for cuts, fraying, or broken stitches along the webbing. You look for discoloration or chemical damage. You confirm that the webbing label is readable and the webbing slings show no signs of excessive wear.

Can webbing slings handle outdoor industrial lifting?

You use webbing slings for outdoor industrial lifting when you need lightweight and flexible equipment. The webbing resists UV rays and moisture. You store webbing slings in dry, shaded areas to extend the life of the webbing and maintain safety.

How do you select the right webbing for your application?

You select webbing based on load weight, shape, and environment. You check the webbing slings’ color code for capacity. You choose webbing with reinforced eyes for secure attachment. You match the webbing to the demands of your industrial lifting job.

What are the advantages of webbing slings over other sling types?

You benefit from webbing slings because the webbing is lightweight and easy to handle. You use webbing slings for irregular or fragile loads. The webbing offers flexibility and reduces the risk of surface damage. You rely on webbing for efficient industrial lifting.