Choosing the right turnbuckle material depends on your environment, load requirements, and safety needs. You should always select turnbuckles that meet international standards for safety and performance.

Powerful Machinery supplies certified turnbuckles trusted by professionals worldwide. Your choice affects durability, safety, and cost. Review the table below for key safety standards:

Specification/Standard | Description |

|---|---|

ISO 1491 | International standard for turnbuckle safety |

DIN 1480 | German standard for turnbuckle design/testing |

ASME B16.12 | American standard for turnbuckle fittings |

You can lower the total cost of ownership by considering purchase price, maintenance, and replacement frequency.

Key Takeaways

Choose turnbuckle materials based on your project’s environment and load requirements to ensure safety and durability.

Stainless steel is ideal for marine and outdoor applications due to its superior corrosion resistance; always verify certifications.

Galvanized steel offers a cost-effective solution for moderate environments but may not withstand harsh conditions.

Consider the load capacity and safety factors when selecting turnbuckles; ensure they exceed the expected load for reliability.

Regular inspections and maintenance of turnbuckles are essential to ensure safety and extend their lifespan.

Turnbuckle Material Overview

When you select a turnbuckle material, you need to consider strength, corrosion resistance, and your project’s environment. Each material offers unique benefits for different types of turnbuckles and applications.

Galvanized Steel

Galvanized steel turnbuckles provide a cost-effective solution for many outdoor projects. The zinc coating helps protect against rust, but it can wear off over time, especially in harsh or marine environments. You often see this material used in construction, fencing, and general outdoor tensioning tasks.

Galvanized steel offers a working load limit of around 3,500 lbs and tensile strength between 38,000 and 62,000 PSI. However, it is less resistant to corrosion than stainless steel, so you should use it with caution in wet or salty conditions.

Stainless Steel Turnbuckle

Stainless steel stands out as the top choice for marine, architectural, and outdoor applications. Powerful Machinery’s stainless steel turnbuckle features high-grade material that resists rust, even in saltwater. This turnbuckle material delivers a tensile strength of 100,000 to 150,000 PSI and a working load limit near 3,200 lbs.

The chromium content forms a protective layer, so the turnbuckle remains durable even if scratched. You can choose from jaw-jaw, hook-eye, and eye-eye types of turnbuckles to fit your needs.

Powerful Machinery’s products meet ASME B30.26 and material certifications, ensuring safety and reliability for demanding environments.

Tip: For long-term use in marine or high-moisture areas, always select stainless steel turnbuckles for superior corrosion resistance.

Brass

Brass turnbuckles offer good corrosion resistance and a classic appearance. You might use them in decorative or light-duty indoor settings. Brass can become fragile under heavy loads or stress, so it is not ideal for structural or marine applications.

This turnbuckle material works best where aesthetics matter more than maximum strength.

Aluminum

Aluminum turnbuckles provide a lightweight option with a wide load capacity range, from 2,000 to 10,000 lbs. You often find them in applications where weight matters, such as stage rigging or temporary structures.

Aluminum resists corrosion but may not match the durability of stainless steel in harsh environments. You should use this material when you need easy handling and moderate strength.

Material | Cost | Corrosion Resistance | Ideal Use Cases |

|---|---|---|---|

Galvanized Steel | Cheaper | Less resistant | Outdoor, construction, fencing |

Stainless Steel | Higher | Extremely resistant | Marine, outdoor, architectural |

Brass | Medium | Good | Decorative, light-duty, indoor |

Aluminum | Medium | Good | Lightweight, temporary, stage rigging |

By understanding the strengths and limitations of each turnbuckle material, you can choose the right types of turnbuckles for your project’s safety and longevity.

Factors to Choose the Right Turnbuckle

When you choose the right turnbuckle for your project, you must evaluate several critical factors. These considerations help you match the turnbuckle material and design to your specific needs, ensuring safety, durability, and cost-effectiveness.

Powerful Machinery provides certified products that meet international standards, giving you confidence in every application.

Load Capacity & Strength

You need to assess the load capacity and material considerations before selecting the right turnbuckle. The turnbuckle must support the intended load without exceeding its elastic limit. This ensures the turnbuckle can recover its shape and function after tension is released.

Engineering data shows that turnbuckles perform best when the material remains within the elastic range under tensile forces. For construction and rigging, you should follow recommended safety factors:

Safety Factor Type | Value |

|---|---|

Design Factor | Minimum of 5 |

Proof Load | Minimum of 2 times the rated load |

Always check the rated load and safety factor for each turnbuckle. Powerful Machinery’s products undergo rigorous testing to guarantee reliable performance under demanding conditions.

Environmental Exposure & Corrosion

The environment plays a major role in your choice of turnbuckle material. Outdoor and marine settings expose turnbuckles to humidity, temperature changes, and pollutants. These factors affect corrosion rates and long-term durability.

Galvanized steel corrosion rates depend on humidity, temperature, and pollution.

Stainless steel corrosion rates also vary with atmospheric conditions.

Brass and aluminum turnbuckles show different corrosion behaviors, but specific rates depend on the environment.

Laboratory testing confirms that AISI 316 stainless steel offers high corrosion resistance, making it ideal for saltwater and high-humidity environments. AISI 304 stainless steel provides moderate resistance, while galvanized steel offers good rust protection but is less effective in marine conditions.

Material Type | Corrosion Resistance | Notes |

|---|---|---|

AISI 316 Stainless | High | Marine-grade alloy with superior resistance to chloride corrosion. |

AISI 304 Stainless | Moderate | Commonly used but less resistant to saltwater than AISI 316. |

Galvanized Steel | Moderate | Offers good rust resistance but is not as effective in saltwater. |

You should always match the turnbuckle material to the environment for maximum longevity.

Application Type

Your application determines the best turnbuckle material and configuration. Heavy-duty construction projects require turnbuckles with high strength and certified safety standards. Marine and outdoor uses demand corrosion-resistant materials.

Decorative or light-duty indoor projects may benefit from brass or aluminum for their appearance and ease of handling. Compatibility with ropes, chains, or cables also matters. Powerful Machinery offers a wide range of turnbuckles to suit every application, from industrial lifting to architectural tensioning.

Tip: Always verify the compatibility of your turnbuckle with the ropes or chains used in your project to prevent mismatched connections.

Safety Standards

Safety is essential when you choose the right turnbuckle. International standards ensure that turnbuckles meet strict requirements for identification, proof load, and material quality. You should look for products that comply with recognized standards, such as:

ASME B30.26: This standard outlines identification and proof-load criteria for turnbuckles used in load-bearing applications.

Powerful Machinery’s turnbuckles meet or exceed these standards, providing peace of mind for professionals in construction, marine, and industrial sectors.

Budget

Cost is a key factor in large-scale projects. You must balance upfront expenses with long-term value. The cost of turnbuckle materials varies:

Material | Cost Comparison |

|---|---|

Carbon Steel | Lowest upfront cost |

Stainless Steel | 20–30% premium due to durability |

Brass | Varies, generally higher than steel |

Aluminum | Moderate cost, lightweight |

Stainless steel turnbuckles cost more but offer superior durability and lower maintenance. Galvanized steel provides a budget-friendly option for less demanding environments.

Powerful Machinery helps you optimize your investment by offering certified products that reduce replacement frequency and maintenance costs.

By considering load capacity and material considerations, environmental exposure, application type, safety standards, and budget, you can select the right turnbuckle for your project. Powerful Machinery’s commitment to safety and certified products ensures you receive reliable solutions for every application.

Turnbuckle Material Comparison

Pros & Cons

When you compare turnbuckle materials, you need to weigh their strengths and weaknesses for your specific project. Each option offers unique benefits and limitations. You should focus on durability, corrosion resistance, ease of use, and cost.

Stainless Steel

Advantages: Superior corrosion resistance, excellent heat resistance, sleek appearance, and long-lasting with minimal maintenance.

Disadvantages: Higher upfront cost, heavier, and more difficult to work with.

Powerful Machinery’s stainless steel turnbuckles deliver outstanding performance in marine and outdoor environments. You can rely on their durability and certified safety for demanding applications.

Galvanized Steel

Advantages: Cost-effective, good corrosion resistance in moderate environments, and easier to weld.

Disadvantages: Zinc coating can wear off, is less visually appealing, not as durable in harsh conditions.

You should choose galvanized steel turnbuckles for general outdoor or construction projects where budget matters and exposure is moderate.

Brass

Advantages: Good corrosion resistance, attractive finish, easy to handle.

Disadvantages: Lower strength, not suitable for heavy loads or marine use, can become brittle over time.

Brass turnbuckles work best for decorative or light-duty indoor projects.

Aluminum

Advantages: Lightweight, easy to handle, moderate corrosion resistance, suitable for temporary structures.

Disadvantages: Lower durability in harsh environments, less strength compared to steel.

Aluminum turnbuckles offer a practical solution for stage rigging or lightweight applications.

Quick Reference Guide

You need a clear overview to help you select the right turnbuckle for your project. The following tables and lists summarize key factors, average lifespans, and safety considerations.

Material Strengths and Weaknesses

Material | Strengths | Weaknesses |

|---|---|---|

Stainless Steel | Superior corrosion resistance, long-lasting, minimal maintenance | High cost, heavier, harder to work with |

Galvanized Steel | Cost-effective, good for moderate environments, easy to weld | Zinc coating wears off, less durable in harsh conditions |

Brass | Good corrosion resistance, attractive, easy to handle | Lower strength, brittle, not for heavy loads |

Aluminum | Lightweight, easy to handle, moderate corrosion resistance | Less durable, lower strength |

Average Lifespan by Turnbuckle Type

Turnbuckle Type | Average Lifespan (Years) | Conditions |

|---|---|---|

DIN1480 Turnbuckle | 10 – 15 | Well-maintained, moderate loads |

5 – 10 | Outdoor or harsh settings | |

Light Turnbuckle | 3 – 5 | Normal use |

1 – 2 | Less ideal conditions | |

Commercial Type | 5 – 10 | Normal operating conditions |

2 – 5 | Challenging environments or heavy use |

Note: Stainless steel turnbuckles from Powerful Machinery often exceed average lifespans due to superior material quality and rigorous testing.

Safety and Performance Factors

Factor | Description |

|---|---|

Material Selection | Stainless steel is preferred for marine use; carbon steel is cost-effective but needs maintenance. |

Load Requirements | You must ensure turnbuckles meet working load limits for heavy-duty jobs. |

Certifications | Look for ANSI and ISO compliance for safety and quality assurance. |

Customer Support | Choose manufacturers with responsive support for project management. |

Forged vs Cast Turnbuckles

Attribute | Forged Turnbuckles | Cast Turnbuckles |

|---|---|---|

Strength | Higher tensile power | Lower tensile strength |

Ductility | More ductile, bends before breaking | More brittle, risks snapping |

Impact Resistance | Better shock absorption | May shatter under impact |

Fatigue Life | Longer lifespan under stress cycles | Shorter lifespan under repeated stress |

Tip: For safety-critical projects, always select forged turnbuckles from certified suppliers like Powerful Machinery. You gain higher strength and longer fatigue life.

Decision Checklist

Assess your project’s environment and exposure to moisture or chemicals.

Determine the required load capacity and safety factor.

Verify material certifications and compliance with international standards.

Consider ease of installation and handling.

Review manufacturer support and warranty options.

You can use this quick reference guide to compare turnbuckle material options and make informed decisions. Powerful Machinery provides certified turnbuckles that meet strict safety and quality standards, ensuring reliable performance for every application.

Scenario Recommendations for Choosing the Right Turnbuckle

Marine & Outdoor Use

You need to select a turnbuckle that withstands moisture, salt, and changing weather. Stainless steel, especially grade 316, offers high corrosion resistance and strength for marine environments.

Powerful Machinery’s stainless steel turnbuckles meet ASME B30.26 and ISO standards, ensuring safety and durability. Bronze alloys also resist galvanic corrosion and suit specialized marine tasks. For general outdoor use, galvanized steel provides moderate protection but is less effective in saltwater.

Material | Corrosion Resistance | Strength Characteristics |

|---|---|---|

Stainless Steel | High | Excellent for marine environments, especially grade 316 |

Coated Alloys | Moderate to High | Good for outdoor use, protects against corrosion |

Forged Steel | Moderate | Exceptional impact resistance for heavy-duty applications |

Bronze Alloys | High | Non-magnetic, resistant to galvanic corrosion |

Galvanized Steel | Moderate | Suitable for indoor/outdoor, less effective in marine environments |

Tip: Always verify certifications when choosing a turnbuckle for marine or outdoor use. Reliable suppliers like Powerful Machinery provide documentation for material quality and load capacity.

Construction & Industrial

You must prioritize strength and compliance in construction and industrial settings. Stainless steel and galvanized steel turnbuckles are commonly specified for their durability and rust protection.

Carbon steel offers high strength for heavy-duty applications. Powerful Machinery’s turnbuckles comply with OSHA and ASTM guidelines, supporting safe tensioning and secure fittings.

Stainless steel turnbuckles: Ideal for harsh environments and industrial use.

Galvanized steel turnbuckles: Suitable for construction and outdoor projects.

Carbon steel turnbuckles: Best for heavy-duty, high-stress jobs.

Regular inspections help you identify wear and maintain safety. Adhering to industry standards prevents accidents and ensures structural integrity.

DIY & Home Projects

You want a turnbuckle material that balances ease of use and cost. Steel turnbuckles provide durability and long-term savings, though they require manual assembly. Wood turnbuckles offer low cost and easy handling for light-duty tasks, such as garden structures or temporary bracing.

Material Type | Advantages | Cost-Effectiveness | Ease of Use |

|---|---|---|---|

Steel | Durable, strong | Higher initial cost, long-term savings | Requires manual assembly |

Wood | Low cost, reusable | 1/10 the cost of metal bracing | Easy to work with |

For home improvement, choose a turnbuckle that matches your project’s load and installation needs. Powerful Machinery offers a range of certified options for both DIY and professional use.

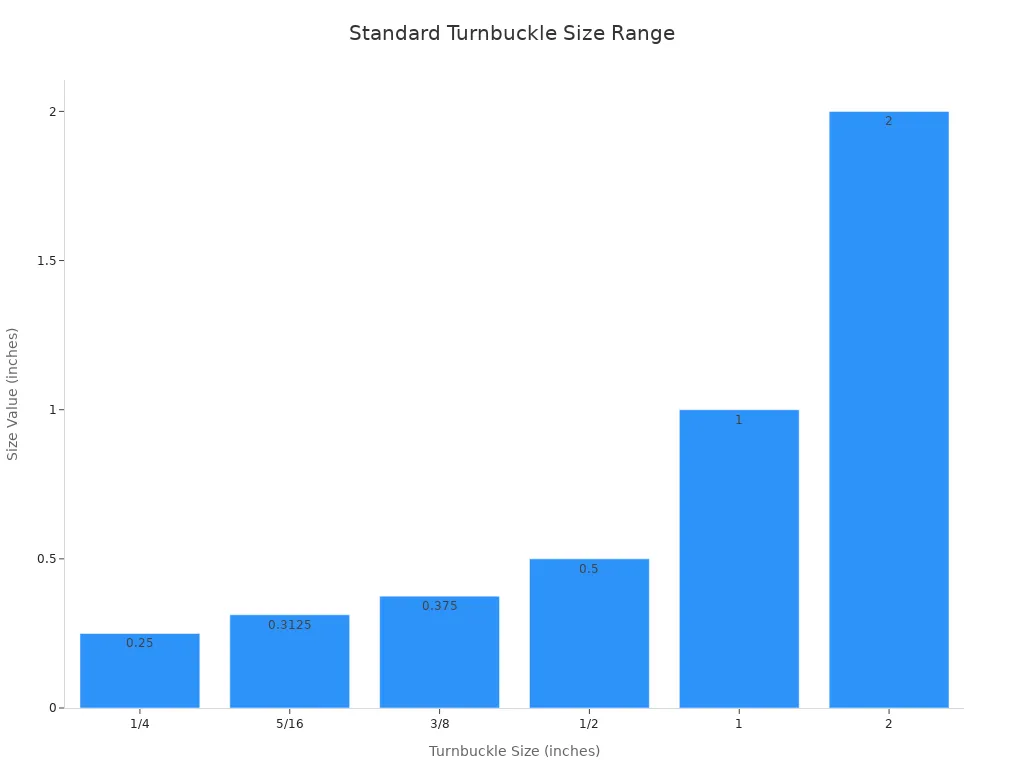

Selecting the Right Turnbuckle Sizes

Sizing Guide

You need to match turnbuckle sizes to your project’s requirements for safety and performance. Start by identifying the application and the forces involved. Calculate the maximum load, including both static and dynamic forces, and add a safety margin of at least two to three times the peak load.

Select the turnbuckle material based on environmental exposure. For saltwater, choose 316 stainless steel. For general outdoor use, hot-dip galvanized steel works well.

Review the working load limit (WLL) for each turnbuckle. Make sure the WLL exceeds your expected load by a safety factor of at least 5:1. Check that the thread size and pitch match the components you plan to connect. Certification matters. Look for turnbuckles that comply with standards like ASME B30.26 or DIN 4132.

The market offers a wide range of turnbuckle sizes. Use the table below to compare standard options:

Turnbuckle Size (inches) | Wire Rope Size (inches) | Improved Plow Steel I.W.R.C. (M.B.S.) | Hooks | Jaws or Eyes |

|---|---|---|---|---|

1/4 | 5,800 | 1/2 | 3/8 | |

5/16 | 9,160 | 5/8 | 1/2 | |

3/8 | 13,120 | 3/4 | 5/8 | |

1/2 | 23,000 | 1 | 3/4 | |

1 | 89,800 | – | 1-1/2 | |

2 | 344,000 | – | 2-3/4 |

Powerful Machinery offers a full range of turnbuckle sizes for every application. You can request custom solutions for unique project needs. These options balance cost and quality, and deliver industrial-grade performance.

Final Checklist

Follow this checklist when choosing the right turnbuckle size and material:

Calculate the working load limit for your application.

Match the turnbuckle size and type to your project’s material, load capacity, and thread type.

Confirm compatibility with all hardware, including thread size and environmental performance.

Verify certifications and safety features.

Choose turnbuckle sizes that allow for easy adjustment and installation.

Tip: Powerful Machinery provides custom Crosby turnbuckle solutions for projects that require special sizes or configurations.

Selecting the right turnbuckle sizes ensures safety and reliability. You protect your investment and meet industry standards by following these steps.

Conclusion

When you select a turnbuckle, always consider the importance of size in turnbuckles and match the turnbuckle material to your environment. Industry guidelines highlight these key points:

Carbon steel and stainless steel are the most common choices.

Galvanized carbon steel turnbuckles resist rust with a zinc coating.

Stainless steel turnbuckles work best in high-moisture or chloride-rich settings.

Powerful Machinery offers certified products that meet international standards, giving you confidence in every project. Use the decision checklist to ensure safety and reliability from start to finish.

FAQ

What is the main difference between stainless steel and galvanized turnbuckles?

You get superior corrosion resistance with stainless steel turnbuckles. Galvanized turnbuckles offer good rust protection for moderate environments. Stainless steel works best for marine or outdoor use, while galvanized steel suits general construction projects.

How do I choose the right turnbuckle hardware for my project?

You should consider load requirements, environment, and safety standards. Select turnbuckle hardware that matches your application and meets international certifications. Powerful Machinery provides a wide range of certified options for every need.

Can I use aluminum turnbuckles outdoors?

You can use aluminum turnbuckles outdoors for lightweight or temporary structures. Aluminum resists corrosion but does not match the durability of stainless steel in harsh conditions. Choose stainless steel for long-term outdoor or marine projects.

What certifications should I look for when buying turnbuckles?

You should look for certifications like ISO, ASME, and DIN. These standards ensure safety, quality, and reliability. Powerful Machinery’s turnbuckles meet or exceed major international certifications for peace of mind.

How often should I inspect turnbuckles in industrial applications?

You should inspect turnbuckles before each use and schedule regular maintenance checks. Look for signs of wear, corrosion, or deformation. Frequent inspections help you maintain safety and extend the lifespan of your equipment.