You rely on chain blocks when you need a dependable lifting and lowering device for heavy materials. These tools play a crucial role in industries where efficient handling matters most. Powerful Machinery stands out as a trusted name, offering certified solutions that support your toughest jobs.

The global market for chain blocks has reached over 3 billion USD in 2024, driven by construction, manufacturing, mining, and oil & gas sectors.

Demand continues to rise due to increased construction activity and advancements in lifting equipment.

Key Takeaways

Chain blocks are essential tools for lifting heavy loads safely in various industries, including construction and manufacturing.

Choose between manual and electric chain blocks based on your lifting needs; manual blocks are portable, while electric blocks offer speed and control.

Always match the chain block‘s lifting capacity and height to your specific task to ensure safety and efficiency.

Look for safety features like overload protection and reliable brakes when selecting a chain block to enhance workplace safety.

Regular maintenance and inspections of your chain block are crucial for safe operation and longevity.

Chain Blocks Overview

What Are Chain Blocks?

You encounter chain blocks in many industrial settings. These devices help you lift and lower heavy loads safely and efficiently. Chain blocks use a manual hand chain to operate, while chain hoists may use electric motors. The main difference lies in their operation and power source.

Chain blocks and chain pulley blocks require no external power, making them ideal for environments where electricity is unavailable or impractical.

Feature | Chain Block | Chain Hoist |

|---|---|---|

Operation | Manual (hand chain) | Manual or powered (electric motor) |

Power Source | None (manual operation) | Electric or battery-powered |

Mechanical Advantage | Uses gears for lifting with less effort | Often faster due to motor assistance |

Usage | Suitable for various environments | Common in factories and warehouses |

Cost | Generally lower cost | Typically higher due to motorization |

Maintenance | Easy maintenance | May require more maintenance |

Working Principle of Lifting

You benefit from the mechanical advantage provided by chain blocks. The gear train multiplies your force, allowing you to lift heavy loads with minimal effort. The lift wheel grips the chain, preventing slippage.

The mechanical brake holds the load securely in place. The grade of the chain determines the strength and efficiency of the lifting operation.

Mechanism | Description |

|---|---|

Gear Train | Multiplies the operator’s force. |

Lift Wheel | Grips the load chain to prevent slippage. |

Mechanical Brake | Holds the load securely in place. |

Mechanical Advantage | Allows a small force to lift a heavy load. |

Load Chain Grade | Determines strength and capacity. |

You gain confidence knowing that chain blocks use proven mechanical principles to make lifting safer and easier.

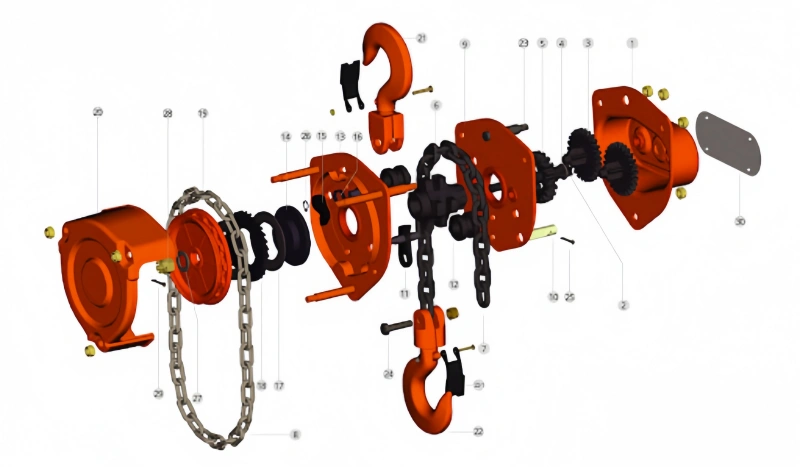

Main Components and Operation

You operate the chain blocks by pulling the hand chain. This action engages the gear system, which amplifies your force. The load chain bears the weight of the object. The hook attaches to the load, and the sprocket ensures smooth movement. The braking system prevents the load from slipping back.

Component | Function |

|---|---|

Hand Chain | Initiates the lifting process. |

Load Chain | Bears the weight of the lifted object. |

Hook | Attaches to the lifting point and the load, and includes safety latches. |

Gear System | Amplifies manual force for heavy lifting. |

Sprocket | Engages with the load chain for smooth operation. |

Braking System | Secures the load during lifting and lowering. |

Powerful Machinery stands as a leading manufacturer of chain blocks. You trust their products because they meet rigorous certifications and standards, including Machinery Directive 2006/42/EC, EN 12100, OSHA, CE Mark, ASME B30.16, ISO 4301, and more.

These certifications ensure you receive reliable, safe, and high-performance lifting solutions for your toughest jobs.

Types of Chain Blocks

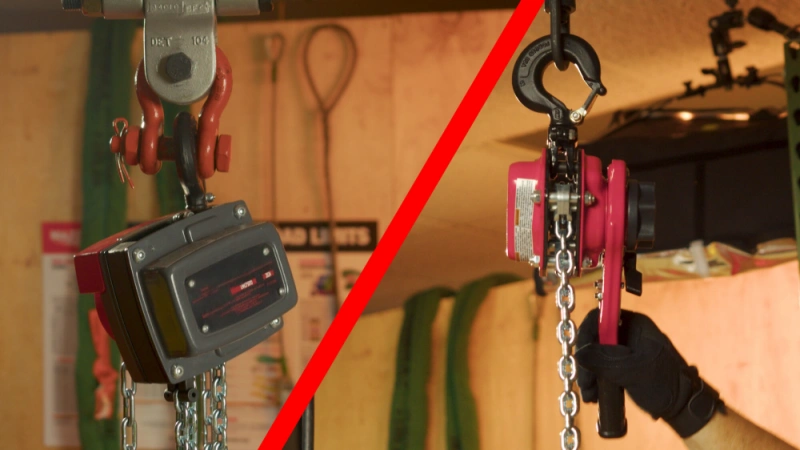

Manual and Electric Chain Blocks

You encounter two main types of chain blocks in the field: manual and electric. Manual chain blocks rely on your physical effort. You pull the hand chain to lift or lower the load.

These devices work well in locations where power is not available or when you need a portable solution. Manual chain block hoists offer simplicity and reliability for everyday lifting tasks.

Electric chain block hoists use a motor to handle the lifting process. You benefit from faster and more controlled movement of heavy loads. These hoists often include advanced safety features, such as limit switches, which help prevent over-travel and protect both the operator and the equipment.

You find electric chain blocks especially useful in environments where you need to lift heavy items frequently or require precise control.

Feature | Manual Chain Blocks | Electric Chain Hoists |

|---|---|---|

Mechanical Design | Operated manually, relying on human strength | Motorized mechanism for faster operations |

Operational Efficiency | Less efficient, slower load movement | More controlled and smoother load traveling |

Safety Features | Basic overload protections | Advanced safety features like limit switches |

Application Suitability | Reliable when power sources are unavailable | Suitable for precise and automated lifting tasks |

You can choose between manual and electric chain blocks based on your work environment, frequency of use, and the level of control you need.

Specialized Types and Industry Uses

You see different types of chain block hoists designed for specific industry needs. Some chain blocks are built for entertainment rigging, where you need silent operation and compact size.

Others are engineered for angled lifting, allowing you to move loads in tight or awkward spaces. You also find corrosion-resistant chain blocks for marine or chemical environments.

Powerful Machinery offers a wide range of chain block hoists to match your application. You can select models with stainless steel chains for harsh conditions or heavy-duty chain block designs for construction and manufacturing.

You benefit from the versatility of these products, which serve industries such as logistics, mining, and transportation.

Tip: You should always match the chain block type to your specific lifting task to maximize safety and efficiency.

Lifting Capacity and Height Options

You must consider both the lifting capacity and the height of lift when choosing a chain block. The lifting capacity tells you the maximum weight the chain block can handle safely. The height of lift refers to how high you can raise the load. Chain blocks come in a wide range of capacities and heights to suit different jobs.

Most chain blocks offer lifting capacities from 1 ton up to 50 tons. Specialized models can handle even heavier loads. You can select the height of lift based on your workspace, with options ranging from a few meters to over 15 meters.

Model | Lift Capacity (tons) | Lift Height (m) |

|---|---|---|

Model A | 5 | 10 |

Model B | 3 | 15 |

Model C | 10 | 8 |

Model D | 7 | 12 |

Model E | 4 | 14 |

Model F | 8 | 9 |

Model G | 6 | 11 |

You can see that Powerful Machinery provides chain block hoists with a variety of lifting capabilities and height options. This flexibility allows you to handle everything from small assembly tasks to large-scale construction projects.

Single vs Multiple Fall Chains

You need to understand the difference between single and multiple fall chains when selecting a chain block. A single fall chain block uses one chain loop to lift the load. This design works well for lighter weights and shorter heights. Multiple fall chain blocks use several chain loops running in parallel.

This setup increases the lifting capacity and allows you to raise heavier loads with less effort.

You should choose a single fall chain block for quick, light-duty lifting. For heavy-duty applications, you benefit from a multiple-fall chain block, which distributes the load across several chains. This design improves safety and extends the life of your equipment.

Note: Always check the manufacturer’s specifications for the correct chain configuration based on your lifting requirements.

You can rely on Powerful Machinery to supply different types of chain block hoists, including both single and multiple fall chain options. These products meet strict international standards, ensuring you get reliable performance and safety for every lifting task.

Key Features of Chain Block

Durability and Safety

You need chain block lifting equipment that stands up to tough jobs and keeps your team safe. Powerful Machinery uses high-strength steel and advanced heat treatment to build chain blocks that resist deformation and wear.

The shell housing shields the hoisting mechanism from dust and impact, while lightweight materials keep the unit easy to handle. You can see how each material adds to durability in the table below:

Material Type | Impact on Durability |

|---|---|

High-strength steel | Excellent strength and resistance to deformation |

Corrosion resistance | Prevents corrosion, extends lifespan in harsh environments |

Heat treatment | Increases hardness, reduces wear, and prevents metal fatigue |

Lightweight housing | Reduces weight, maintains structural integrity |

Safety features matter most in lifting. You get enhanced load stability, reliable braking systems, and overload protection. These features help you avoid accidents and keep your lifting equipment in top condition.

Overload protection stops the chain block if you exceed the safe working load or working load limit. Emergency stop features let you halt lifting instantly if something goes wrong.

Ease of Use and Portability

You want chain blocks that make lifting simple and efficient. Powerful Machinery designs each chain block for smooth operation and easy transport. The compact size and lightweight build let you move the equipment between job sites without hassle.

For example, a 1-ton chain block weighs about 10 kg and stands only 30 cm tall. You can store and carry it with ease, making it perfect for construction, manufacturing, or any environment where flexibility is key.

The compact design fits tight spaces.

Lightweight housing allows quick relocation.

Simple controls make the operation straightforward for any user.

Quality Standards and Certifications

You need confidence in your lifting equipment. Powerful Machinery’s chain blocks meet strict international standards. You find certifications like CE for the EU, OSHA, and ASME B30.16 for the US, and ISO 9001:2015 for quality management.

These certifications show that your chain block lifting equipment delivers reliable performance and safety in every lift.

Always check for these certifications before you buy or use any chain block.

Choosing the Right Chain Block

You must select the right chain block for your lifting task. Start by checking the load capacity and make sure it matches or exceeds your needs. Look for weather-resistant materials and corrosion protection if you work outdoors. Choose a compact design for easy transport.

Make sure your chain block includes safety features like load limiters and reliable brakes. Consider the chain length for your lifting height. Always buy from a trusted manufacturer with a strong reputation.

Factor | Description |

|---|---|

Load Capacity | Match the block to your maximum load, with a safety margin. |

Construction Quality | Select weather-resistant and corrosion-protected materials. |

Portability | Compact design helps with relocation. |

Safety Features | Look for load limiters and braking systems. |

Chain Length | Choose custom lengths for different lifting heights. |

Maintenance | Keep your chain block clean and lubricated. |

Manufacturer | Pick a brand known for quality and reliability. |

Tip: Never exceed the safe working load or working load limit. Always inspect your chain, hooks, and hoisting mechanism before each use to ensure safe operation.

Applications and Alternatives for Lifting

Industry Applications of Chain Blocks

You use chain blocks in many industries where lifting heavy items is part of daily work. On construction sites, you rely on these tools for moving steel beams, generators, and other building materials. In workshops, you lift engines and tools with a 2-ton chain block.

Agriculture workers use chain blocks for tractors and farm equipment. Ports require higher capacity, such as a 3-ton chain block, for shipping containers and cargo. Chain blocks also play a role in entertainment, where you need to rig lighting and stage equipment safely.

Industry | 2 Ton Chain Block | 3 Ton Chain Block |

|---|---|---|

Workshops | Lifting engines, tools | Rarely needed |

Construction | Light materials, small beams | Steel beams, generators |

Agriculture | Tractors, farm equipment | Heavy machinery (combines) |

Ports | Not recommended | Shipping containers, cargo |

You see that each sector has different load requirements. You must select the right chain block for the job to ensure safety and efficiency when transporting big objects.

Alternatives: Electric and Air-Powered Hoists

You may consider other hoist options for your lifting needs. Electric hoists offer fast and smooth operation, making them ideal for manufacturing and warehousing. Air-powered hoists work best in hazardous environments where sparks must be avoided. Manual chain hoists remain the most cost-effective for occasional lifting.

Hoist Type | Upfront Cost | Operating Cost | Service Life | Best For |

|---|---|---|---|---|

Electric hoists | Low | Low | Long | Manufacturing, warehousing |

Air hoists | High | Medium | Long | Hazardous environments |

Manual hoists | Lowest | Lowest | Medium | Occasional lifting |

Motorized chain hoists give you efficiency and reduce physical strain. You can operate them remotely, which improves safety. However, you must perform regular maintenance to prevent equipment failure. Some motorized hoists can be noisy, which may affect your work environment.

Tip: Choose the hoist that matches your lifting frequency, budget, and safety needs.

When to Hire or Buy?

You face a choice between hiring or buying a chain hoist. If you need a hoist for a short-term project or rare lifting tasks, renting makes sense. You save on upfront costs and avoid long-term maintenance. If you use a hoist regularly, buying gives you control and reliability.

You can select the exact chain block or hoist model that fits your requirements. Powerful Machinery offers both purchase and rental options, so you can find the best solution for your business.

You should also consider environmental factors. Manufacturing chain blocks uses energy and resources, but many components can be recycled at the end of their life. Proper disposal and recycling help reduce your environmental impact.

Note: Always inspect your hoist before use and follow safety guidelines to protect your team and equipment.

Conclusion

You improve workplace safety and efficiency when you understand the types and features of chain blocks.

Electric hoists offer advanced safety controls.

Ergonomic designs help prevent accidents.

Smart technology supports predictive maintenance.

Regular inspections keep operations safe.

Energy-efficient models reduce costs.

Choosing certified, reliable products from Powerful Machinery gives you long-term benefits:

Benefit | Description |

|---|---|

Durability | Withstands harsh conditions and heavy use for years. |

Safety | Features like load brakes and overload protection keep your team safe. |

Cost-effectiveness | Low maintenance and no energy costs make these chain blocks a smart investment. |

Assess your lifting needs and select the best option—purchase or rental—for your operation.

FAQ

What is the difference between a chain block and a chain hoist?

You operate a chain block manually, using a hand chain. A chain hoist can be manual or powered by electricity. Chain blocks work well where you do not have power. Chain hoists offer faster lifting and more automation.

How do you maintain a chain block for safe operation?

You should inspect the chain, hooks, and gears before each use. Lubricate moving parts regularly. Store your chain block in a dry place. Replace worn or damaged components immediately to ensure safety.

Can you use a chain block outdoors?

Yes, you can use a chain block outdoors. Choose a model with corrosion-resistant materials for wet or harsh environments. Always check for weatherproof features and proper certifications.

What safety features should you look for in a chain block?

You should look for a secure hook with a safety latch, overload protection, and a reliable braking system. Certifications from organizations like CE or OSHA also indicate strong safety standards.

Tip: Always follow the manufacturer’s guidelines for safe lifting and regular inspections.