Chain slings play a critical role in lifting and rigging operations across industries. Powerful Machinery delivers certified chain slings trusted for demanding tasks, ensuring you achieve safe and efficient results.

New heat-treated alloys now boost load limits by 20% and cut sling weight by 15%.

Over 20 million chain slings are deployed annually for heavy lifts worldwide.

Modular designs extend sling life by up to 30%, while RFID chips improve compliance.

Lifting Device | Safety Features | Efficiency Features |

|---|---|---|

Chain Slings | High durability, heat resistance, versatile design | Better strength-to-weight ratio, adaptable configurations |

Wire Rope Slings | Moderate strength, flexible but susceptible to damage | Generally less expensive, lighter weight |

Synthetic Slings | Not recommended for high temperatures | Limited to lighter loads, less durable in harsh conditions |

Understanding the types of chain slings and choosing the right chain sling grade helps you match the safest solution to every lift.

Key Takeaways

Chain slings are essential for lifting heavy loads safely in various industries. They offer unmatched durability and flexibility, making them ideal for construction, manufacturing, and marine operations.

Choosing the right type of chain sling, such as single-leg or multi-leg, enhances load stability and safety. Each type serves specific lifting needs, so understanding their applications is crucial.

Regular inspection and maintenance of chain slings prevent accidents and extend their service life. Always check for wear, damage, and compliance with safety standards before use.

Customization options allow you to tailor chain slings to your specific lifting requirements. Select the right grade, length, and attachments to ensure optimal performance.

Using advanced materials and IoT technology in chain slings improves load capacity and safety. These innovations help you monitor and manage lifting operations effectively.

Chain Sling Types Overview

What Are Chain Slings?

You rely on chain slings when you need to lift, move, or position heavy loads in industrial settings. These specialized lifting devices use high-strength steel chains and secure attachments to handle demanding tasks.

Chain slings offer unmatched durability and flexibility, making them essential for construction, manufacturing, marine, and cargo handling operations. Powerful Machinery manufactures chain sling solutions that meet strict international standards, including ISO9001, OSHA, and ASME B30.

You benefit from products that undergo proof testing, visual inspection, and non-destructive testing before reaching your worksite.

Tip: Always check for a certificate of proof test before using any new, repaired, or reconditioned chain sling. This ensures compliance with safety regulations and protects your team.

Certification/Standard | Description |

|---|---|

OSHA | Requires proof testing of alloy steel chain slings before use. |

ASME B30 | Specifies safety standards for rigging equipment, including testing and certification procedures. |

Key Features and Benefits

Chain slings deliver several advantages over other lifting devices. You get superior strength and resistance to heat, abrasion, and harsh environments. Powerful Machinery uses advanced materials like Grade 80 and Grade 100 steel, which provide higher load capacities and longer service life.

Grade 80 is ideal for overhead lifting and towing, while Grade 100 offers even greater strength and abrasion resistance.

High-strength, lightweight materials improve load capacity and extend lifespan.

IoT integration enables real-time monitoring and diagnostics for enhanced safety.

Customization options let you match sling chains to specific operational needs.

You also gain peace of mind knowing that chain slings from Powerful Machinery comply with enhanced safety standards and sustainability innovations. These products withstand environmental challenges, such as extreme heat or chemical exposure, and maintain performance even in tough conditions.

Regular inspection helps you identify wear, stretching, or damage, reducing accident risks and ensuring reliable operation.

Types of Chain Slings

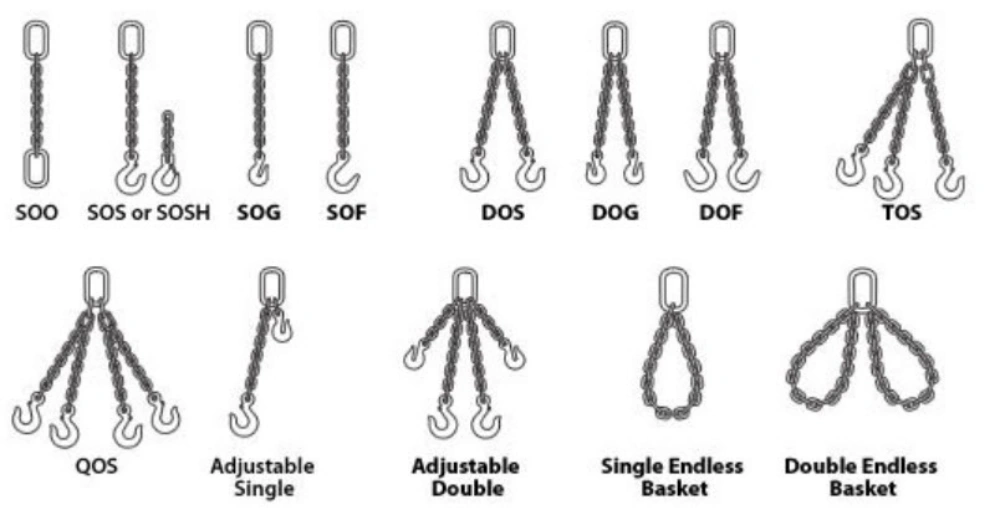

When you select lifting equipment, understanding the types of chain slings helps you match the right solution to your operational needs. Chain slings are classified by the number of legs and their adjustability. Each type offers unique advantages for specific lifting scenarios.

Powerful Machinery provides a full range of certified chain slings, including custom options for demanding projects.

Type | Description | Grade Options |

|---|---|---|

Single-leg | One chain length supporting the load, offering stability and balance. | Grade 80, 100 |

Double-leg | Two separate legs for lifting loads needing support on two corners. | Grade 80, 100 |

Multi-leg | Consists of three or more chains for heavier loads, allowing multiple pickup points. | Grade 80, 100, 120 |

You benefit from chain slings that comply with international standards such as EN 818-2 and ISO 6082. Powerful Machinery offers customization for size, reach, attachments, and grade, ensuring you get the best fit for your lifting requirements.

Single Leg Chain Sling

A single-leg chain sling features one chain length with a hook or attachment at each end. You use this type for vertical lifts where stability and balance are critical. The single-leg chain sling is ideal for lifting loads with a single attachment point, such as steel beams or machinery components.

The global market for single-leg chain slings reached $380 million in 2024 and is projected to grow steadily.

You can choose from Grade 80 or Grade 100 steel for higher working load limits and durability.

Note: Powerful Machinery customizes single-leg chain slings for heavy-duty lifting in construction and warehouses. You can specify the chain size, reach, and attachments to match your project.

2 Leg Chain Sling

A 2-leg chain sling, also called a double-leg sling, uses two chains connected to a master link. You rely on this type for lifting loads that need support at two points, such as large panels or containers. The design provides better weight distribution and stability.

Advantages include improved load balance and reduced risk of tipping.

Double leg chain slings handle up to 14,200 lbs at a 90° angle and 8,094 lbs at 35°, depending on chain grade and diameter.

Sling Type | Working Load Limit at 90° | Working Load Limit at 35° |

|---|---|---|

3/8″ Grade 80 Double | 14,200 lbs | 8,094 lbs |

Tip: Powerful Machinery offers double-leg chain slings in various grades and sizes. You can request custom fittings and master links for specialized lifting tasks.

3 Leg Chain Sling

A 3-leg chain sling, part of the multi-leg chain sling category, consists of three chains attached to a master link. You use this type for lifting irregular or heavy loads that require support at three points. The design increases stability and allows for multiple pickup points.

Chain Diameter | WLL at 0–45° | WLL at 45–60° |

|---|---|---|

6 mm | 2.87 t | 2.34 t |

10 mm | 8.10 t | 6.61 t |

20 mm | 31.9 t | 25.9 t |

You can select chain grades and diameters to match your load requirements. Powerful Machinery provides Grade 80 and Grade 100 options, with working load limits up to 187,800 lbs for the largest sizes.

4 Leg Chain Sling

A 4-leg chain sling uses four chains connected to a master link. You choose this type for lifting very large or complex loads that need support at four points. The design maximizes load stability and reduces the risk of shifting during lifts.

Four-leg chain slings are common in construction, shipyards, and cargo handling.

You can customize the chain grade, diameter, and attachments for specific lifting scenarios.

Note: Powerful Machinery engineers four-leg chain slings for maximum strength and reliability. You can specify custom master links, hooks, and chain lengths to suit your application.

Adjustable Chain Slings

Adjustable chain slings give you unmatched flexibility for complex lifting operations. You can modify the length of each leg using eye-type grab hooks, making these slings ideal for loads with varying heights or irregular shapes.

Adjustable chain slings are essential in dynamic work environments where load sizes change frequently.

You can quickly adapt the sling configuration for confined spaces or unbalanced loads.

This flexibility enhances safety and load stability, especially in challenging rigging scenarios.

Tip: Powerful Machinery offers adjustable chain slings with customizable fittings, sizes, and grades. You can tailor each sling to your exact requirements for maximum efficiency and safety.

Key Customization Options from Powerful Machinery:

Size: Select the chain diameter based on your working load limit.

Reach: Measure from bearing point to bearing point, including all attachments.

Attachments: Choose standard master links or request custom hooks and connectors.

Type: Specify double leg, oblong link, sling hook, or other configurations.

You gain a competitive edge by choosing chain sling types that match your lifting needs. Powerful Machinery’s expertise ensures you receive certified, high-performance products designed for heavy-duty applications.

Applications of Different Types of Chain Slings

Vertical Lifting

You encounter vertical lifting tasks in many industries, including construction, marine, and transportation. Chain sling types play a vital role in these operations. Single-leg chain slings are your go-to choice for straightforward vertical lifts, basket hitches, and choker hitches.

You use them to secure loads such as steel beams or machinery components. Multi-leg chain sling types provide enhanced stability and load distribution, making them suitable for heavier or unbalanced loads. You often select multi-leg slings for taller lifts or when you need to transport loads over significant distances.

Common vertical lifting applications:

Vertical lift of steel beams

Basket hitch for pipes or cylindrical objects

Choker hitch for securing irregular shapes

Powerful Machinery’s chain sling types offer you the flexibility to match the right sling to each lifting scenario. You benefit from certified products that ensure safety and reliability in every vertical lift.

Load Balancing

You must achieve proper load balancing to prevent accidents and ensure efficient lifting. Different chain sling types contribute to load balancing in unique ways. Single-leg slings provide simplicity and versatility, but they may lead to unbalanced lifts due to their single point of contact.

Double-leg chain sling types enhance stability and work best for symmetrical loads, giving you better weight distribution. Multi-leg chain sling types offer superior load-sharing capabilities, which you need for complex lifts involving large machinery or irregularly shaped cargo.

Tip: You can tailor multi-leg chain sling types to match specific load shapes and weights, improving safety and efficiency in your lifting operations.

In construction applications, you rely on these chain sling types to move heavy panels, precast concrete, and structural components. In marine and cargo handling, you use them to lift containers and bulky equipment, ensuring balanced and secure lifts every time.

Heavy and Complex Lifts

You face heavy and complex lifts in industries such as construction and marine. Chain sling types excel in these demanding environments. You should always use trained and qualified personnel for rigging tasks. You inspect all equipment and the environment before starting any lift.

You check the load balance and stability to prevent accidents. You maintain clear communication among team members to ensure safety.

Use trained and qualified personnel for rigging.

Inspect equipment and the environment for safety.

Check load balance and stability before lifting.

Maintain clear communication during lifts.

Chain sling types offer minimal elongation, which helps you maintain constant tension during heavy lifts. Their high-tensile steel construction ensures reliability and strength. You depend on these chain sling types for lifting large machinery, bridge sections, and marine equipment.

Powerful Machinery’s chain sling types provide you with the durability and customization needed for complex lifting scenarios.

Outdoor and Harsh Environments

You often work in outdoor and harsh environments where lifting solutions must withstand extreme conditions. Chain sling types constructed from high-grade alloy steel deliver exceptional durability. You benefit from their resistance to heat, corrosion, and UV exposure.

Unlike synthetic slings, chain sling types maintain their integrity in demanding settings. You can repair individual links, which extends the service life of your chain sling.

Advantages of chain sling types in harsh environments:

High strength and durability

Resistance to heat, corrosion, and UV exposure

Repairable links for extended service life

You rely on chain sling types for repetitive lifting tasks in construction, marine, and cargo handling. Their design factor of 4:1 means you get a breaking strength four times higher than the rated Working Load Limit.

Powerful Machinery’s chain sling types give you confidence in outdoor and challenging environments, where other lifting solutions may fail.

Note: You maximize safety and efficiency by choosing the right chain sling types for your specific applications. Powerful Machinery’s certified products help you meet the toughest demands in construction, marine, transportation, and cargo handling.

Choosing the Right Chain Sling

Factors to Consider

Selecting the right chain sling for your lifting operation requires careful evaluation. You must consider several critical factors to ensure safety and efficiency.

Know the Weight, Strength, and Delicacy of the Load

You need to determine the exact weight and strength of the load. Always check the Working Load Limit (WLL) of the sling. This step prevents overloading and reduces the risk of injuries.Identify the Center of Gravity and Sling Flexibility

You should observe the shape of the object. Understanding the center of gravity helps you achieve balanced lifts. For irregular shapes, flexible chain slings offer better control.Check for Sharp Edges

Sharp edges can damage lifting equipment. You should use chain slings or wire rope slings for loads with abrasive surfaces.

Safety Tip: Over 30% of rigging accidents result from incorrect sling usage. You can avoid catastrophic injuries and financial losses by choosing the proper equipment.

Cause of Failure | Preventative Measure |

|---|---|

Overloading | Use load monitoring systems to stay within rated capacity. |

Wear and Tear | Schedule regular inspections and maintenance. |

Improper Use | Train your team on correct handling and application. |

Inadequate Inspections | Maintain a strict inspection and documentation regime. |

Matching Sling Type to Task

You must match the chain sling type to the specific lifting task for optimal performance.

Load Weight and Size

Select a sling rated above the heaviest load you expect to lift.Load Sensitivity

For delicate surfaces, you should use softer slings. For rugged items, chain or wire rope slings provide superior durability.Environmental Conditions

Metal slings perform best in high-temperature or chemically hazardous areas. Synthetic slings may degrade in UV light or oily environments.Frequency of Use

Durable chain slings suit frequent heavy lifting. Synthetic options work for occasional tasks.Sling Length and Configuration

Choose a sling length that fits your application. Consider the configuration—single, double, triple, or quadruple leg—for proper load support.

Following recognized safety guidance ensures operational excellence and compliance with industry standards. You protect your team and assets by making informed choices.

Conclusion

Selecting the correct chain sling type ensures safe and efficient lifting in every project. You gain peace of mind when you trust Powerful Machinery, a brand that meets ASME and international safety standards. Regular inspection and maintenance keep your equipment reliable and compliant.

Routine checks help you spot twisting, bending, or corrosion early.

Removing damaged slings prevents accidents and extends service life.

Qualified personnel inspect slings before each use and annually.

Service Condition | Inspection Interval |

|---|---|

Normal Service | Yearly |

Severe Service | Monthly to Quarterly |

Special Service | As recommended by a Qualified Person |

You protect your team and investment by following these best practices. Always consult Powerful Machinery for certified, customized chain sling solutions.

FAQ

What are the main types of chain slings you can choose?

You can select single leg, double leg, triple leg, or quadruple leg chain slings. Each type suits different lifting needs. Powerful Machinery offers custom options to match your specific requirements.

How do you determine the right chain sling grade for your job?

You check the working load limit and environment. Grade 80 suits most overhead lifts. Grade 100 provides higher strength for demanding tasks. Powerful Machinery helps you select the best grade for safety and performance.

Can you use chain slings outdoors or in harsh conditions?

You can rely on chain slings in outdoor and harsh environments. High-strength steel resists corrosion, heat, and UV exposure. Powerful Machinery’s certified chain slings maintain durability in extreme conditions.

How often should you inspect your chain slings?

You inspect chain slings before each use and schedule regular checks. Yearly inspections suit normal service. Monthly or quarterly checks fit severe conditions. Qualified personnel ensure your equipment stays safe and reliable.

Can you customize chain slings for unique lifting tasks?

You request custom chain slings from Powerful Machinery. You choose chain length, grade, attachments, and configuration. Customization ensures your sling matches your project’s exact lifting needs.