You will find several types of chain master links in lifting and rigging applications. Standard master links, welded master links, and forged master links each offer distinct advantages for specific industries. The table below outlines their features and common uses:

Type of Master Link | Description | Applications |

|---|---|---|

Standard Master Links | Most commonly used due to its versatility and ease of use. | Construction, industrial, and marine industries |

Welded Master Links | Designed for heavy-duty applications requiring high strength and durability. | Oil & gas, mining sectors |

Forged Master Links | Known for exceptional strength and wear resistance. | Construction, heavy machinery operations |

Choosing the right shape, such as oblong or pear-shaped, helps distribute stress evenly and reduces the risk of failure. Forged master link manufacturing delivers unmatched strength and durability, supporting safety and efficiency with every lift.

For multi-leg sling setups, master link assemblies play a vital role. You should always consult certified size charts, like those provided by Powerful Machinery, to select the optimal product for your lifting needs.

Key Takeaways

Understand the three main types of master links: standard, welded, and forged. Each type serves different industries and applications.

Always check the working load limit (WLL) of master links to ensure safe lifting. Match the link size and grade to your specific load requirements.

Use pear-shaped links for better load alignment and stability, especially in two-leg sling assemblies. This design helps prevent twisting during lifts.

Select oblong master links for multi-leg sling setups. They provide extra space for attaching multiple sling legs, enhancing load distribution.

Choose certified master links from trusted manufacturers like Powerful Machinery. This ensures compliance with safety standards and reliable performance.

Chain Master Links Overview

Definition

You will encounter chain master links as essential components in lifting systems and rigging hardware. These closed-loop devices create secure connection points in rigging and sling assemblies.

You often see them at the top of multiple-leg sling assemblies, where they gather and connect one to four sling legs. In the industry, you may also hear them called collector rings or links.

Master links serve as the main connection point for multiple sling legs.

Oblong master links, a common type, appear as permanently closed loops at the top of chain assemblies or wire rope bridles.

These links not only collect the legs of a sling assembly but also connect to other rigging equipment.

When you select from the types of chain master links, you ensure that your lifting systems have the right foundation for safe and efficient operation.

Importance of Lifting

Chain master links play a central role in lifting operations. You rely on them to connect multiple hooks and chain links, distributing loads evenly and maintaining stability.

Grade 8 master links, for example, use high-strength alloy steel to deliver exceptional strength and a high working load limit. Intermediate master links connect several chain lengths in a sling assembly, which helps balance the load during lifts.

Choosing certified chain master links from a trusted manufacturer like Powerful Machinery gives you peace of mind. Powerful Machinery’s products meet or exceed international safety standards, including ISO9001, TUV Rheinland, and OSHA.

You benefit from rigorous load capacity testing, material strength, and compliance with strict safety requirements.

Safety Feature | Description |

|---|---|

Load Capacity Testing | Each chain link is tested to confirm its load capacity for reliability. |

Compliance with Safety Standards | Meets ANSI, NACM, ASTM, and OSHA requirements. |

Material Strength | Made from high-strength alloy steel for durability and resistance. |

When you choose the right types of chain master links for your lifting systems, you enhance both safety and efficiency. Powerful Machinery’s expertise and certifications ensure you receive reliable, high-quality products for every rigging challenge.

Types of Master Links

Regular (Oval) Links

Regular, or oval, master links are among the most common types you will encounter in lifting and rigging. Their symmetrical oval shape allows for even load distribution, which helps prevent stress concentrations that could weaken your lifting assembly. You often use these links as the main connection point at the top of single– or multi-leg chain slings.

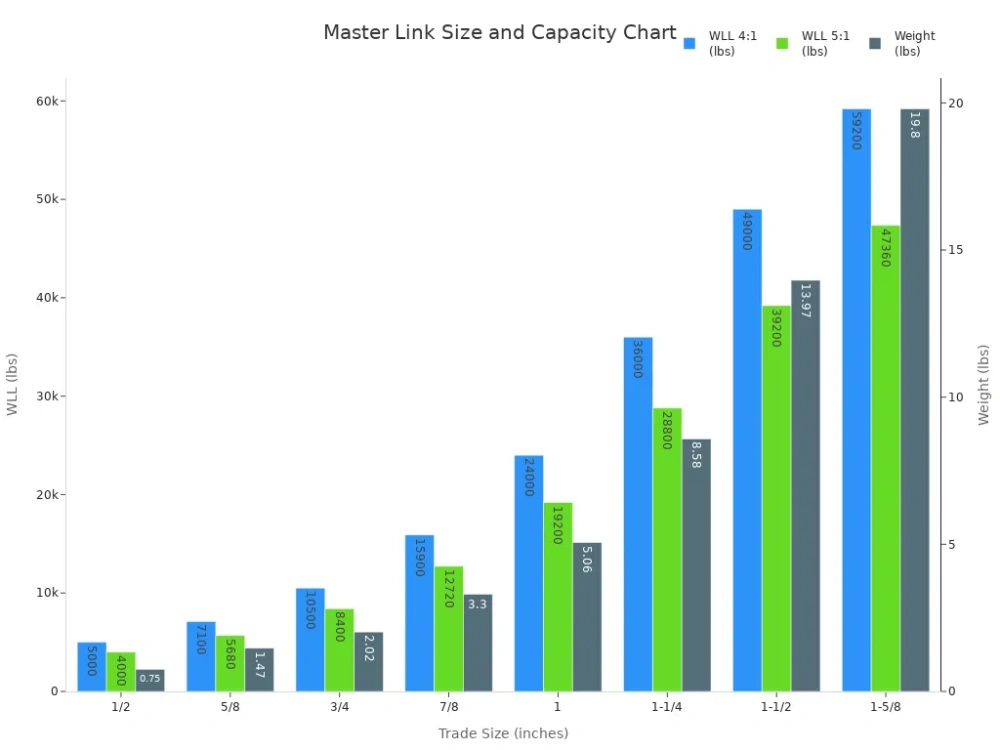

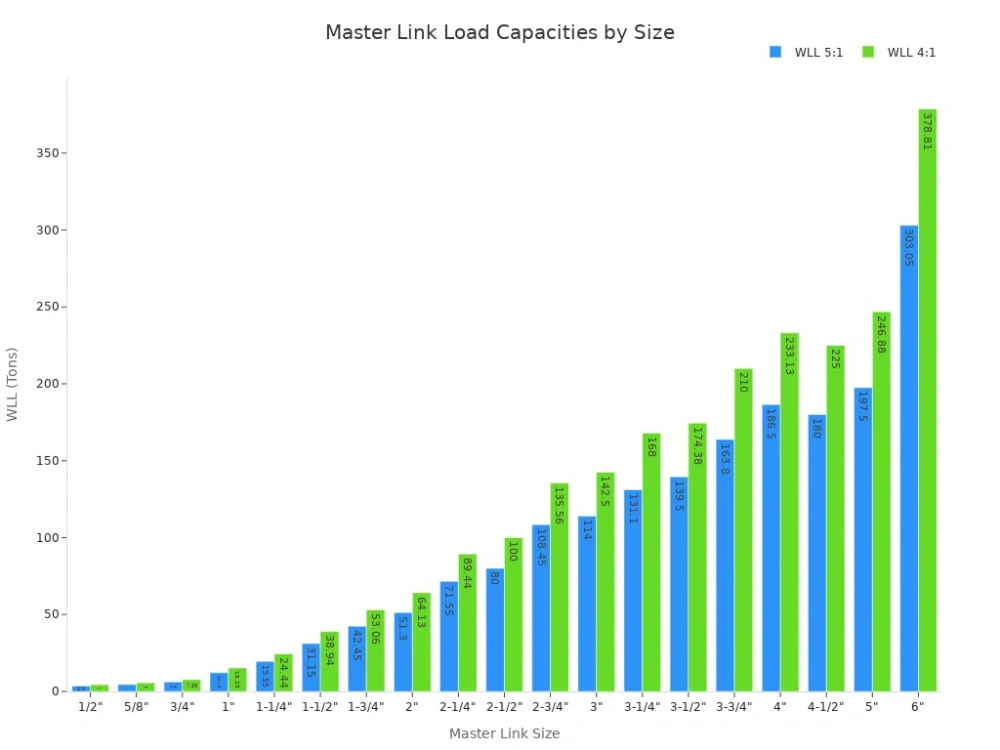

When you select regular master links, you should always consider their working load limit (WLL). The WLL varies by size and safety factor. The table below shows typical load capacities for regular (oval) master links:

Size | WLL 5:1 (TONS) | WLL 4:1 (TONS) |

|---|---|---|

1/2″ | 3.5 | 4.38 |

5/8″ | 4.5 | 5.63 |

3/4″ | 6.15 | 7.69 |

1″ | 12.18 | 15.23 |

1-1/4″ | 19.55 | 24.44 |

1-1/2″ | 31.15 | 38.94 |

1-3/4″ | 42.45 | 53.06 |

2″ | 51.3 | 64.13 |

2-1/4″ | 71.55 | 89.44 |

2-1/2″ | 80 | 100 |

2-3/4″ | 108.45 | 135.56 |

3″ | 114 | 142.5 |

3-1/4″ | 131.1 | 168 |

3-1/2″ | 139.5 | 174.38 |

3-3/4″ | 163.8 | 210 |

4″ | 186.5 | 233.13 |

4-1/2″ | 180 | 225 |

5″ | 197.5 | 246.88 |

6″ | 303.05 | 378.81 |

You can find these links in Powerful Machinery’s G80 Links collection. These products use high-strength alloy steel and advanced heat treatment for maximum durability. When you need a reliable connection for your chain slings, regular master links provide a proven solution.

Tip: Always match the master link size and grade to your sling configuration and load requirements. This ensures safe lifting and extends the life of your rigging equipment.

Pear-Shaped Links

Pear-shaped master links offer a unique profile that tapers at one end. This design helps you align the link with the direction of the load, which can reduce side loading and improve stability. You often use pear-shaped links in two-leg chain sling assemblies or when you need to connect to a hook with a narrow throat.

The tapered end of the pear-shaped link allows for better orientation and helps prevent twisting during lifts. You will find these links especially useful in applications where space is limited or where you need to guide the load in a specific direction.

Powerful Machinery manufactures pear-shaped links as part of its G80 Links range. These links undergo strict quality control and meet international safety standards. When you choose pear-shaped links, you gain flexibility for specialized lifting tasks and ensure compatibility with a wide range of hooks and rigging hardware.

Note: Pear-shaped links are ideal for two-leg chain slings and applications where you need precise load alignment.

Oblong Links

Oblong master links, sometimes called “egg links,” feature an elongated oval shape. This design gives you extra space for attaching multiple sling legs or large hooks. You will often see oblong links at the top of multi-leg chain sling assemblies, where they serve as the main collector for several sling legs.

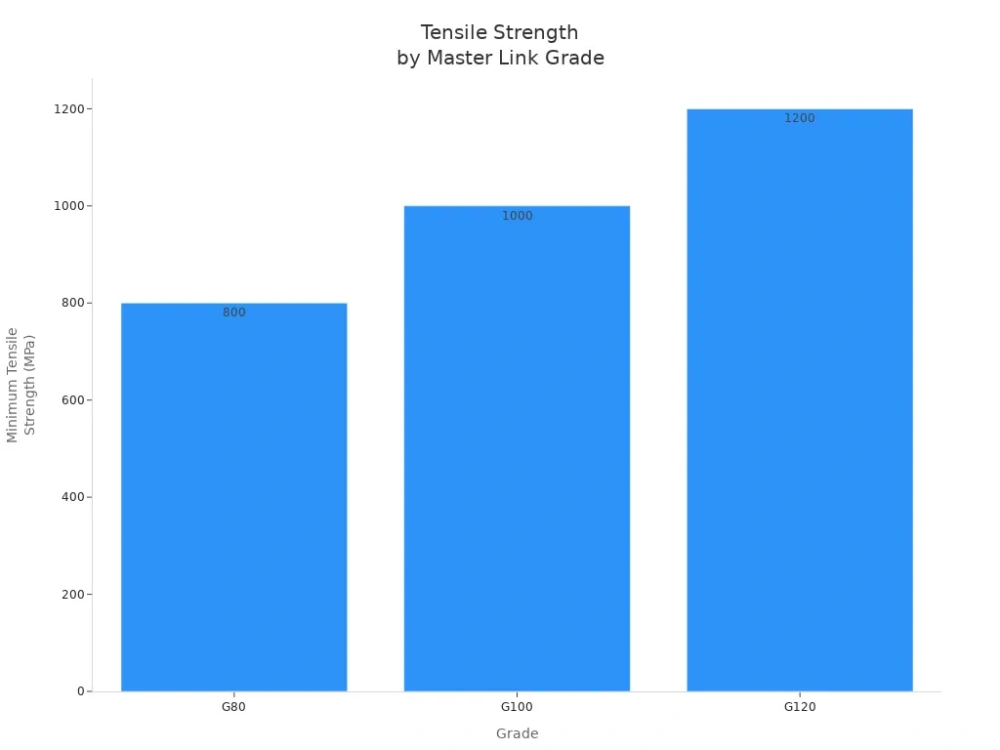

Oblong links come in various grades, including G80, G100, and G120. Each grade offers different tensile strengths and safety factors. For example:

Grade | Minimum Tensile Strength (MPa) | Base Material | Heat Treatment | Key Alloying Elements |

|---|---|---|---|---|

G80 | 800 | Medium-carbon steel | Quenching & Tempering | C (0.25-0.35%), Mn |

G100 | 1,000 | High-strength low-alloy | Controlled quenching | Cr, Mo, V |

G120 | 1,200 | Advanced HSLA steel | Precision tempering | Cr, Ni, Mo, Nb/V |

You can select oblong links with working load limits ranging from 7,400 lbs to 279,000 lbs, depending on the size and grade. Powerful Machinery’s G80 oblong master links meet ASTM A952 and ASME B30.26 specifications, ensuring you receive products that comply with industry standards.

Grade 80 oblong master links: WLL from 7,400 to 279,000 lbs.

G120 oblong master links: Safety factor of 6:1.

G80 oblong master links: Safety factor of 4:1.

When you use oblong links from Powerful Machinery, you benefit from robust construction and precise engineering. These links integrate seamlessly with chain master links and chain slings, giving you confidence in every lift.

Pro Tip: Always verify the grade and working load limit of your oblong master link before use. This step helps you maintain compliance and ensures safe lifting operations.

Powerful Machinery’s G80 Links and Chain Slings provide you with certified, high-performance solutions for every lifting challenge. Whether you need regular, pear-shaped, or oblong master links, you can trust these products to deliver strength, reliability, and safety in demanding environments.

Forged Master Link Manufacturing

Forging Process

When you choose a forged master link for your lifting operations, you select a product shaped by a precise and robust manufacturing process. The forging process begins with heating steel billets to a high temperature.

You then see the metal shaped under intense pressure, which refines the grain structure and aligns it with the link’s final form. This method produces a forged master link with exceptional strength and toughness.

Unlike casting or welding, forging eliminates internal voids and improves the metal’s integrity. You benefit from a component that resists fatigue and performs reliably in demanding environments.

Take a look at how forging compares to other manufacturing methods:

Aspect | Forging Benefits | Other Methods |

|---|---|---|

Strength | Achieves stronger parts due to grain orientation | Often suffers from porosity in welded structures |

Internal Voids | Eliminates internal voids | May retain voids from casting or machining |

Mechanical Properties | Superior impact and stress resistance | Generally, lower performance in critical applications |

You gain increased strength, toughness, and fatigue resistance when you use a forged master link. This makes it ideal for critical lifting applications in construction, marine, and transportation industries.

Safety and Reliability

You rely on forged master link products for consistent performance and safety. Powerful Machinery implements strict quality control measures throughout the forging process.

These include laboratory tests for fracture splittability, dimensional surface inspections of hot forgings, and nondestructive examinations of press components. Temperature measurement best practices ensure each forged master link meets precise specifications.

The company also studies the effects of inclusions on steel alloys to maximize fatigue performance.

Quality Control Measure | Description |

|---|---|

Fracture Splittability Testing | Assesses steel composition and forging process controls |

Dimensional Surface Inspection | Increases machine utilization and reduces scrap |

Nondestructive Examination | Ensures the integrity of forging press components |

Temperature Measurement | Maintains optimal forging conditions |

Inclusion Analysis | Improves fatigue performance of steel alloys |

You can trust Powerful Machinery’s forged master link products because they comply with international standards such as EN1677-4. These standards guarantee reliability for overhead lifting, lashing, and towing.

Powerful Machinery’s commitment to quality and certification means you receive forged master link solutions that meet the highest expectations for safety and durability.

Tip: Always verify that your forged master link carries the proper certification before use. This step helps you maintain compliance and ensures safe lifting operations.

Master Link Assemblies

Multi-Leg Sling Use

You often encounter master link assemblies when you need to lift complex or unbalanced loads. In multi-leg sling applications, you connect two or more sling legs to a single master link at the top.

This configuration allows you to distribute the load evenly across each leg, which increases stability and safety during lifting heavy loads.

A double-leg chain sling uses an oblong master link as a collector ring at the top.

Triple-leg and quadruple-leg chain slings also feature a collector ring, ensuring balanced support for every leg.

The master link or lifting device at the top must be rated for the combined load of all sling legs.

The angle of each sling leg affects the working load limit, so you must adjust your calculations accordingly.

Before every lift, you should inspect your chain slings for wear, damage, and proper markings. Always follow manufacturer instructions and safety guidelines. Proper training in load calculation and sling positioning is essential for safe operation.

Tip: Select the right sling configuration and chain grade for your load. Consider environmental factors such as temperature and moisture to ensure safe lifting.

Industrial Applications

You will find master link assemblies in a wide range of industries. These assemblies connect one to four sling legs made from chain, wire rope, or synthetic materials.

You use them in construction, engineering, clean rooms, the food industry, and maritime operations.

Master links provide a stable connection point for various sling assemblies, making them essential for safe lifting.

Powerful Machinery’s Chain Slings and G80 master link assemblies deliver reliable performance in demanding environments. These products meet ISO, ASTM, and ASME certifications, ensuring you comply with international safety standards.

Certification Type | Description |

|---|---|

ISO Certification | Adheres to rigorous international quality standards for safety in heavy lifting operations. |

ASTM Compliance | Governs material specifications and testing for reliability. |

ASME Compliance | Ensures manufacturing meets industry standards for safety and performance. |

Customers like Ben Carter from Canada and David Müller from Germany trust Powerful Machinery’s forged master link assembly for critical projects. You can rely on these assemblies for consistent results, even in the toughest conditions.

Aspect | Single Master Links | Master Link Assemblies |

|---|---|---|

Load Distribution | Less even distribution | Evenly distributes load across multiple sling legs |

Safety | Potentially less stable | Enhances the stability and safety of the lift |

Selecting the right chain master link ensures safety and efficiency in every lift. You should consider these key factors:

Load weight and capacity

Load shape and size

Environment

Lifting angles

Frequency of use

Compatibility with fittings

Safety standards and compliance

Feature | Benefit |

|---|---|

Weldless Master Links | High strength and durability for lifting safety |

Quality Fittings | Trusted manufacturers enhance reliability |

You can find detailed size charts, product specifications, and safety guidelines on Powerful Machinery’s website. Explore their resources to make informed decisions for your lifting needs.

FAQ

What is the difference between a master link and a master link assembly?

A master link is a single closed loop for connecting sling legs. A master link assembly combines a main link with sublinks, allowing you to attach multiple sling legs for complex lifts.

How do you choose the right master link size?

You should check the working load limit and ensure compatibility with your sling configuration. Always refer to certified size charts and product specifications for safe selection.

Can you use master links with both chain and wire rope slings?

Yes, you can use master links with chain, wire rope, or synthetic slings. Always verify compatibility with your rigging hardware and follow manufacturer guidelines.

Why should you select forged master links for lifting?

Forged master links provide superior strength and durability. You gain better resistance to fatigue and impact, which increases safety in demanding lifting environments.

Where can you find certified master links and assemblies?

You can find certified master links and assemblies at Powerful Machinery’s website. The site offers detailed size charts, product specifications, and safety certifications.