You will encounter three main types of slings for lifting tasks: chain, wire rope, and synthetic. Each sling offers unique advantages for heavy lifting in construction and industrial environments. Safety remains critical when choosing slings.

Using certified products, such as those from Powerful Machinery, reduces risk and increases reliability. Consider this: crane-related fatalities due to rigging failure account for 60% of 40 reported cases, and 60% of 42 fatalities result from falling objects caused by failed rigging (CDC, Bureau of Labor Statistics).

Statistic Description | Value | Source |

|---|---|---|

Crane-related fatalities due to rigging failure | 60% of 40 fatalities | CDC |

Fatalities struck by falling objects due to failed rigging | 60% of 42 fatalities | Bureau of Labor Statistics |

By understanding the types of slings available, you can select the best sling for your lifting needs and improve workplace safety.

Key Takeaways

Understand the three main types of slings: chain, wire rope, and synthetic. Each type has unique advantages for different lifting tasks.

Always choose certified slings from reputable manufacturers like Powerful Machinery. This ensures safety and reliability during lifting operations.

Regularly inspect slings before use. Look for visible damage, such as cuts or broken wires, to prevent accidents.

Match the sling type to the load and environment. This improves safety and efficiency in lifting tasks.

Use edge protectors with synthetic slings to prevent damage to delicate loads. This ensures safe handling of fragile items.

Main Types of Slings

When you select equipment for lifting tasks, you will encounter three primary types of slings: chain slings, wire rope slings, and synthetic slings. Each type offers distinct advantages for different environments and load requirements. The table below summarizes their defining characteristics and typical applications:

Sling Type | Defining Characteristics | Typical Applications |

|---|---|---|

Made from strong metal alloy chains, heat-resistant, ideal for rough loads, and adjustable. | Best for high heat environments, lifting heavy loads, and items with sharp edges. | |

Wire Rope Slings | Composed of twisted steel wires, strong, flexible, and abrasion-resistant. | Suitable for general heavy lifting in factories and construction, where some flexibility is needed. |

Synthetic Slings | Made from fibers like nylon or polyester, lightweight, and gentle on loads. | Ideal for lifting delicate items, where a lightweight and non-damaging sling is required. |

Chain Slings by Powerful Machinery

Chain slings stand out as the most robust option among all types of slings. You will find them essential for heavy lifting in construction, manufacturing, shipping, and transportation.

Powerful Machinery produces chain slings using high-strength steel, offering durability and resistance to wear. You can choose from single, double, triple, or quadruple leg designs to match your lifting needs.

Tip: Chain slings excel in environments with extreme temperatures, ranging from -40 °F to 400 °F. You can adjust their length and configuration for complex lifting scenarios.

The advantages of chain slings include:

Durability in stressful climates

Repairable and re-certifiable

High heat resistance

Easy to adjust for different loads

You will benefit from chain slings when handling rough or sharp-edged materials. Powerful Machinery’s chain slings meet or exceed major international safety standards. The table below highlights the certifications that guarantee their reliability:

Certification | Description |

|---|---|

ISO | Global framework for lifting appliances and duty cycles. |

CE | Conformity with health, safety, and environmental protection standards in the European Economic Area. |

TUV | Rigorous testing for safety and quality standards. |

ASTM | Standards for materials and testing methods. |

OSHA | Safe and healthful working conditions enforcement. |

ASME | Rules for design, marking, inspection, and operation of hoists. |

EN | Rigorous safety for equipment sold in the EU. |

You will see Powerful Machinery’s chain slings used in:

Construction

Manufacturing

Shipping

Transportation

Chain slings provide unmatched strength for heavy lifting. You can rely on their performance in demanding environments.

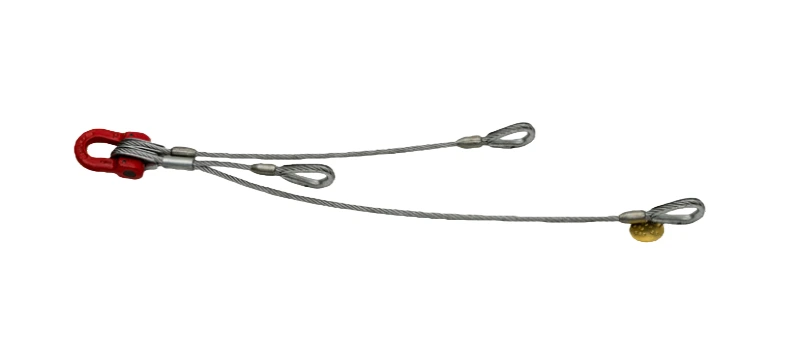

Wire Rope Slings

Wire rope slings offer a balance between strength and flexibility. You will use them for general heavy lifting in factories and construction sites. These slings consist of twisted steel wires, making them abrasion-resistant and strong.

You can wrap wire rope slings around loads more easily than chain slings, which helps when lifting irregular shapes.

Wire rope slings have extremely high load capacity. They are less flexible than synthetic slings but more flexible than chain slings. The table below compares their features:

Feature | Wire Rope Slings | Synthetic Slings |

|---|---|---|

Strength | Extremely high load capacity | Moderate load capacity |

Flexibility | Less flexible, better for heavy-duty use | Highly flexible, better for delicate loads |

For rigging and lifting applications that require abrasion resistance and flexibility, wire rope slings are the best option. You must inspect wire rope slings regularly to maintain safety. Daily visual checks help you spot broken wires, kinks, or severe corrosion. The table below outlines inspection requirements:

Condition Type | Inspection Frequency | Inspection Details |

|---|---|---|

Normal Service | Monthly | Visual checks for surface wear, corrosion, and minor deformities. |

Semi-Annual | Detailed examination by a qualified inspector for internal and external wear. | |

Severe Service | Weekly to Daily | Rigorous inspection focusing on wear, corrosion, deformations, and fatigue signs. |

Quarterly | Comprehensive evaluation by a certified inspector for severe wear or damage. |

You should look for:

Missing or illegible sling identification

Broken wires

Severe abrasion

Kinking or crushing

Heat damage

Damaged end attachments

Severe corrosion

Wire rope slings give you reliable performance for heavy lifting tasks. You can trust their strength and flexibility in most industrial settings.

Synthetic Slings Overview

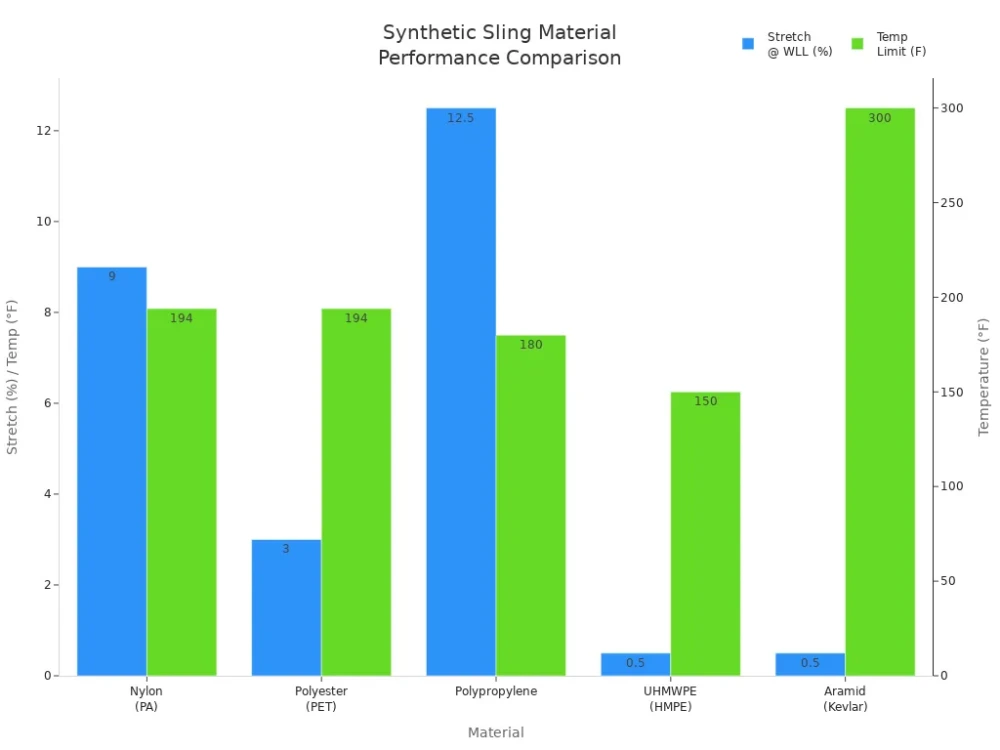

Synthetic slings are made from fibers such as nylon, polyester, polypropylene, UHMWPE, or aramid. You will use synthetic slings when you need lightweight equipment that protects delicate loads. These slings are gentle on surfaces and easy to handle.

The choice of material affects the performance and durability of synthetic slings. The table below compares the main materials:

Material | Stretch @ WLL | Acid Resistance | Alkali Resistance | UV Resistance | Temp Limit (F) | Abrasion Resistance |

|---|---|---|---|---|---|---|

Nylon (PA) | 8-10% (High) | Poor | Excellent | Good | ~194°F | Excellent |

Polyester (PET) | ~3% (Low) | Excellent | Poor | Excellent | ~194°F | Good |

Polypropylene | 10-15% (High) | Excellent | Excellent | Poor | ~180°F | Fair |

UHMWPE (HMPE) | <1% (Very Low) | Excellent | Excellent | Excellent | ~150°F | Excellent |

Aramid (Kevlar) | <1% (Very Low) | Fair | Fair | Poor | >300°F | Fair |

Synthetic slings weigh less than chain or wire rope slings. You will find them cost-effective and easy to transport. The table below shows how synthetic slings compare to other types of slings:

Feature | Chain Slings | Wire Rope Slings | Synthetic Slings |

|---|---|---|---|

Weight | Heavy | Medium | Very light |

Cost (Upfront) | Higher | Medium | Lower |

Safety | Very good resistance to sharp edges | Fair resistance often needs pads | Low resistance, always needs pads |

You should use synthetic slings for lifting fragile or finished goods. You will need to use edge protectors with synthetic slings to prevent damage. Synthetic slings offer flexibility and safety for delicate lifting tasks.

Note: You must always match the type of sling to the load and environment. Choosing the right sling improves safety and efficiency.

You now understand the main types of slings. You can select the best sling for your lifting needs by considering the load, environment, and safety requirements.

Basic Web Sling Types

When you work with slings for lifting, you will often choose between flat web slings and round webbing slings. These basic web sling types offer unique benefits for different lifting tasks. Flat web slings are made from woven synthetic fibers, such as nylon or polyester.

They have a flat, wide design that distributes pressure evenly across the load. Round webbing slings, on the other hand, use a continuous loop of synthetic fibers encased in a protective jacket. This design gives you greater flexibility and allows the sling to conform to the shape of the load.

Feature | Flat Web Slings | Round Webbing Slings |

|---|---|---|

Construction | Made from woven fibers, flat and wide. | Continuous loops of synthetic fibers, encased in a jacket. |

Flexibility | Less flexible, ideal for flat surfaces. | Highly flexible, conforms to load shapes. |

Surface Protection | Distributes pressure over a larger area. | Soft design protects fragile loads. |

Weight | Lightweight and easy to handle. | Lighter than web slings of the same capacity. |

Applications | Suitable for many lifting tasks. | Best for irregularly shaped or delicate loads. |

Flat Web Slings from Powerful Machinery

You will find flat web slings from Powerful Machinery offer outstanding quality and reliability. These slings use advanced manufacturing technology, including fully automatic sewing machines and high-precision looms.

This ensures consistent quality for every sling. Flat web slings meet strict safety standards, such as ASME B30.9, CE, GS, ISO, EN 1492, and OSHA. You can use them for lifting heavy loads in construction, manufacturing, and transportation.

Unique Features of Powerful Machinery Flat Web Slings | Description |

|---|---|

Quality and Reliability | High-quality products that meet safety standards. |

Advanced Manufacturing Technology | Automatic sewing machines and precision looms. |

Comprehensive Range of Products | Many slings and accessories for lifting solutions. |

You can select flat web slings with different load capacities and safety factors. For example, a typical flat web sling offers a vertical working load limit of 3,000 kg, a choker limit of 2,400 kg, and a basket limit of 6,000 kg. Safety factors range from 5:1 to 8:1, giving you confidence in every lift.

Round Webbing Slings

Round webbing slings provide superior flexibility and load protection. You will use these slings for lifting delicate or irregularly shaped items. The continuous loop design allows the sling to wrap around loads without causing damage.

Round slings distribute weight evenly, minimizing stress on fragile materials. The soft synthetic construction reduces the risk of scratches or dents.

Round slings are made from polyester fibers in a continuous loop.

They offer versatility and lightweight handling.

You get excellent load protection for sensitive materials.

Even load distribution prevents damage to delicate loads.

The smooth surface protects fragile objects.

Powerful Machinery’s round webbing slings comply with international safety standards, including EN 1492-2 and ISO 4878. You can identify load capacities easily with color-coded slings. These round lifting slings feature safety factors of 6:1, 7:1, or 8:1, ensuring safe lifting operations.

You benefit from durable synthetic materials that resist abrasion and harsh conditions. Powerful Machinery backs its webbing slings with warranties, giving you peace of mind.

Tip: Always check the sling’s color code and label before lifting. This helps you match the sling to the load and ensures safe operation.

You can rely on basic web sling types from Powerful Machinery for safe, efficient lifting in any industrial setting.

Types of Construction Lifting Slings

Selecting the Right Sling

You face many choices when selecting types of construction lifting slings for lifting and rigging tasks. You must match the sling to the load, environment, and safety requirements. The table below helps you compare criteria for choosing the right sling for construction lifting applications:

Criteria | Description |

|---|---|

Sling Type | Consider the six basic types of slings: chain, wire rope, metal mesh, synthetic rope, web, and roundslings. |

Load Characteristics | Assess the nature, weight, and configuration of the load, such as choker, vertical, or basket hitches. |

Rigging Methods | Understand how you will rig the sling and which hitch you will use. |

Environmental Factors | Evaluate contact and ambient temperatures, and check for chemical exposure. |

Protection Requirements | Decide if the sling needs protection from sharp edges or surfaces. |

User Training | Make sure all users have training in sling selection, inspection, and hazard awareness. |

You need to consider the weight and strength of the load, the flexibility of the sling, and the temperature limits. You must also check the configuration and shape of the load, environmental circumstances, and results of visual examination before each use.

The table below shows recommended applications for common types of construction lifting slings:

Type of Sling | Characteristics | Recommended Applications |

|---|---|---|

Lifting Chains | Durable, versatile, adjustable, and reparable. Can damage delicate items. | Heavy lifting in extreme conditions. |

Wire Rope Slings | Made of steel wires, flexible, and strong. | General lifting tasks require flexibility. |

Flat Webbed Slings | Made of polyester or nylon, resistant to specific chemicals. | Lifting items with potential chemical exposure. |

Round Lifting Slings | Lightweight, high-strength, protected by a jacket. | Lifting items with edges that need protection. |

Powerful Machinery offers a full range of construction lifting slings and lifting equipment, including single, double, triple, and quadruple leg chain slings, custom-engineered solutions, high-tensile Grade 80 and Grade 100 chains, hooks, shackles, and wire rope fittings.

All products meet strict safety requirements and hold certifications such as ISO9001, ISO14001, TUV Rheinland, EURO CERT, EAC, Geprüfte Sicherheit, OSHA, ASTM, China Classification Society, and Korean Register.

Safety and Inspection

You must inspect slings before every lifting and rigging operation. Safety depends on regular checks and compliance with international standards. The table below outlines inspection intervals and procedures for construction lifting slings:

Inspection Type | Frequency/Details |

|---|---|

Daily Visual Inspection | Check for obvious damage like broken wires or severe corrosion. |

Additional Inspections | Based on usage frequency, service conditions, and prior experience, document findings. |

Written Record | Maintain a log of conditions observed and any deterioration noted. |

You should perform initial inspections when you acquire new slings. Frequent or pre-shift inspections are necessary daily, weekly, or before each use. Periodic inspections every 6 to 12 months include functional testing.

Special inspections follow incidents or repairs. You must always check the rated weight capacity and lifting capacity before each use. You protect your team and equipment by following these steps.

Tip: You improve safety and efficiency in lifting operations by using certified construction lifting slings from Powerful Machinery and following inspection guidelines.

Conclusion

You gain the most from slings when you match their strengths to your lifting needs. The table below highlights how wire rope, chain, and synthetic slings differ in performance and safety:

Sling Type | Advantages | Disadvantages |

|---|---|---|

Wire Rope Slings | Strong, flexible, abrasion-resistant | Difficult to inspect |

Chain Slings | Durable, adjustable, repairable | Heavy, expensive |

Synthetic Slings | Lightweight, protects delicate loads | Prone to cuts, not heat-resistant |

Choose certified, high-quality slings from Powerful Machinery to ensure safety and compliance. Inspect slings before each use, replace damaged ones, and store them properly. Consult with manufacturers for custom sling solutions that fit your project. Training and regular inspection help prevent accidents and extend service life.

FAQ

What is the safest way to inspect a lifting sling before use?

You should check for visible damage, such as cuts, abrasions, or broken wires. Always verify the sling’s identification tag and working load limit. Remove any sling from service if you find defects.

How do you choose the right sling for your lifting task?

Consider the load weight, shape, and surface. Match the sling type to the environment and lifting method. Always check the sling’s rated capacity and certifications.

Can you use synthetic slings outdoors?

Yes, you can use synthetic slings outdoors. Polyester slings resist UV rays and moisture. Always inspect for wear or damage before each use.

How often should you replace lifting slings?

Tip: Replace slings immediately if you see damage or if the identification tag is missing.

You should follow manufacturer guidelines and conduct regular inspections. Most slings require replacement after significant wear or at the end of their service life.