You rely on rigging devices to move heavy loads safely and efficiently in industrial environments. These devices include chains, slings, wire ropes, and specialized hardware, all engineered for strength and reliability.

Powerful Machinery, a trusted name in essential rigging equipment, offers a comprehensive range that meets strict international standards.

Using certified, high-performance rigging equipment reduces risks and ensures the safety of both workers and materials.

Type of Rigging | Examples of Devices | Applications |

|---|---|---|

Lifting Rigging | Chain hoists, Wire rope hoists, Lever hoists, Cranes | Vertical load movement in construction and marine |

Horizontal Movement Rigging | Skates, Trolley systems, Winches | Horizontal load movement in installations |

Positioning Rigging | Turnbuckles, Hydraulic positioning systems | Precise load placement and alignment |

If you want to know what the rigging devices are used for, understanding these categories and their functions is critical for safety and efficiency in any operation.

Key Takeaways

Understand the different types of rigging devices, such as slings, chains, and hoists, to choose the right equipment for your lifting needs.

Always inspect rigging hardware before use to ensure safety and prevent accidents. Look for signs of wear or damage.

Select rigging equipment based on the load’s weight and type, ensuring it meets the required working load limit for safe handling.

Follow safety protocols and guidelines, including proper communication and training for all workers involved in rigging operations.

Choose certified rigging equipment from trusted suppliers like Powerful Machinery to enhance safety and efficiency in your operations.

Main Rigging Devices to Move Loads

When you ask what the rigging devices are used to move loads, you need to understand the essential components that make up modern rigging systems. Each device plays a unique role in lifting, securing, and moving heavy materials.

Powerful Machinery offers a full range of rigging hardware and lifting devices designed for safety and reliability in demanding environments.

Slings and Lifting Chains

Slings and lifting chains form the backbone of most rigging systems. You use these rigging devices to connect loads to cranes or hoists. Slings come in several types, including wire rope, chain, and synthetic materials like polyester and nylon. Each material offers different properties for specific lifting applications.

Material | Properties |

|---|---|

Polyester | Strong and durable, commonly used for lifting slings. |

Wire Rope | Offers high strength and is suitable for heavy loads. |

Nylon | Known for strength, flexibility, and abrasion resistance. |

Chain slings, especially those made from Grade 80 and Grade 100 alloy steel, provide exceptional strength and durability. You can select single-leg or multi-leg configurations based on your lifting needs.

Chain Grade | Configuration | Working Load Limit (WLL) in Tonnes |

|---|---|---|

Grade 80 | Single Leg | Varies by size |

Grade 80 | Double Leg | Varies by size |

Grade 100 | Single Leg | Varies by size |

Grade 100 | Double Leg | Varies by size |

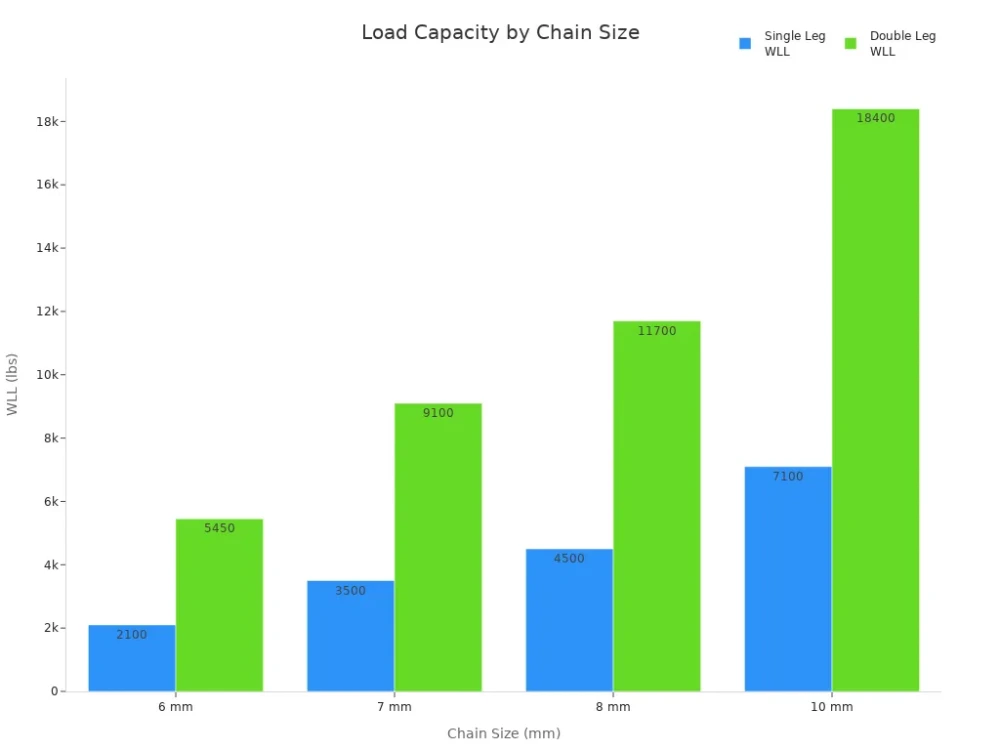

Chain Size (mm) | Single Leg WLL (lbs) | Double Leg WLL (lbs) |

|---|---|---|

6 | 2,100 | 5,450 |

7 | 3,500 | 9,100 |

8 | 4,500 | 11,700 |

10 | 7,100 | 18,400 |

You should always match the sling or chain to the load’s weight and lifting angle. Powerful Machinery manufactures certified slings and lifting chains that meet or exceed international standards, ensuring your rigging gear performs under pressure.

Shackles and Hooks

Shackles and hooks are critical rigging hardware for connecting different parts of your rigging systems. Shackles, such as bow and D-shackles, provide secure connection points between slings, chains, and lifting devices.

Hooks allow for quick attachment and release of loads, with options like self-locking hooks for added safety.

Always inspect shackles and hooks before every use. Never exceed the working load limit, and ensure proper alignment and secure pin placement.

Rule | Description |

|---|---|

1 | Inspect shackles before every use for signs of damage or wear. |

2 | Never exceed the Working Load Limit (WLL) of the shackle. |

3 | Choose the correct type of shackle for the specific application. |

4 | Align loads properly to maximize strength and prevent damage. |

5 | Use the correct pin and ensure it is secured properly. |

6 | Avoid shock loading to prevent catastrophic failure. |

Powerful Machinery supplies a wide selection of shackles and hooks, all tested for strength and reliability. These rigging devices are essential for safe and efficient rigging operations.

Wire Rope and Fittings

Wire rope and its fittings are fundamental in many rigging systems. You use wire rope for its high tensile strength and flexibility, making it ideal for lifting, pulling, and securing heavy loads. The construction of the wire rope determines its balance between strength and flexibility.

Wire Rope Class | Tensile Strength | Flexibility | Best Use Case | Trade-off |

|---|---|---|---|---|

6×19 | High | Low | High surface wear applications | Less flexible, not ideal for multiple bends |

6×26 | Moderate | Moderate | Balanced applications need both | Not as abrasion resistant as 6×19, not as flexible as 6×37 |

6×37 | Moderate | High | Frequent bending applications | Wears faster in abrasive conditions due to smaller wires |

Wire rope fittings, such as sockets, clips, and thimbles, ensure secure connections within your rigging gear. Powerful Machinery offers a complete range of wire rope and fittings, engineered for durability and performance in harsh environments.

Lifting Clamps and Blocks

Lifting clamps and blocks expand your rigging hardware options for specialized lifting tasks. You use lifting clamps to grip and move materials like steel plates, beams, and concrete elements safely. Plate clamps, scissor lifters, and beam clamps each serve specific purposes in construction and manufacturing.

Plate clamps handle flat sheet metal.

Scissor lifters move slabs.

Beam clamps anchor equipment securely.

Lifting blocks, including block and tackle systems, provide mechanical advantage for raising heavy loads. These devices reduce manual effort and enhance safety on job sites. Powerful Machinery’s lifting clamps and blocks are trusted by professionals for their robust construction and reliability.

Hoists, Winches, and Pulleys

Hoists, winches, and pulleys are essential lifting devices in rigging systems. Hoists lift loads vertically, using chains or wire ropes. Winches pull, lift, or tension loads and can be installed at a distance from the load. Pulleys, often used with hoists and winches, provide mechanical advantage and help guide the wire rope or chain.

Feature | Hoist | Winch |

|---|---|---|

Functionality | Only lifts loads | Lifts, pulls, or tension loads |

Positioning | Installed directly above the load | Can be installed at a distance |

Mechanism | Uses chain | Uses cable (steel or synthetic) |

Working Length | 2 to 20 meters | 15 to 120 meters |

You can rely on Powerful Machinery for a full range of hoists, winches, and pulleys, all designed for demanding rigging applications.

Bridle Configurations and Spreaders

Bridle configurations and spreaders help you distribute loads evenly during lifting. Different rigging configurations, such as bridles and basket hitches, offer unique load distribution characteristics. Proper selection of these rigging devices ensures stability, balance, and safety when you move loads.

Bridle configurations use multiple slings or chains to balance the load.

Spreaders keep lifting slings apart, reducing stress and preventing damage.

Understanding these rigging systems is essential for optimizing your lifting operations. Powerful Machinery provides custom-engineered bridle and spreader solutions to fit your specific project needs.

When you consider what the rigging devices are used to move loads, you must evaluate the full range of rigging hardware, lifting devices, and rigging gear available. Powerful Machinery stands as your trusted partner for certified, high-performance rigging equipment that meets the highest safety standards.

Rigging Device Functions and Applications

Lifting and Securing Loads

You depend on rigging to lift and secure heavy materials in many industries. Rigging hardware, such as slings, chains, and wire rope, allows you to move loads vertically and horizontally. You use lifting devices like chain hoists and cranes to raise materials in construction, manufacturing, and maritime operations.

Rigging equipment ensures that you can position loads with precision and keep them stable during movement. The table below shows how different rigging systems function in industrial settings:

Type of Rigging System | Function Description |

|---|---|

Lifting Rigging | Designed to move loads vertically using devices like chain hoists and cranes. |

Horizontal Movement Rigging | Facilitates horizontal movement of loads using skates, rollers, and winches. |

Positioning Rigging | Provides precise control for the final placement of loads with tools like turnbuckles and hydraulic systems. |

You see rigging hardware used every day to lift steel beams, secure machinery, and handle cargo. Powerful Machinery’s certified rigging equipment gives you confidence in high-risk environments.

Connecting and Supporting Components

Rigging hardware connects and supports every part of your rigging system. You use shackles, hooks, and master links to join slings and chains. Wire rope fittings and clamps help you anchor and stabilize loads. In manufacturing, you rely on rigging to move heavy machines and tools.

In construction, rigging hardware supports beams and panels during assembly. In shipyards, you use rigging equipment to lift ship components and secure cargo. Common use cases include:

Construction: Erecting buildings and infrastructure with safe, precise lifting.

Manufacturing: Moving machinery and tools for assembly.

Maritime Operations: Lifting ship parts and handling cargo.

You must select the right rigging hardware for each task to ensure safety and efficiency.

Enhancing Safety and Efficiency

Rigging equipment plays a vital role in keeping your operations safe and efficient. You use wireless lift control systems to manage lifts remotely, reducing risk. Computer-guided rigging equipment gives you real-time data for planning and execution.

High-performance synthetic ropes offer lighter weight and better handling. Adjustable spreader beams help you balance loads. Smart rigging sensors monitor load parameters to prevent accidents. The table below highlights how rigging devices improve safety and efficiency:

Rigging Device | Contribution to Safety and Efficiency |

|---|---|

Wireless lift control systems | Enables remote management, enhancing safety and operational efficiency. |

Computer-guided rigging equipment | Provides real-time data for effective planning and execution of lifts. |

High-performance synthetic ropes | Lighter, improved visibility, reduced snap-back, and better handling. |

Adjustable spreader beams | Modular design for various loads promotes balanced handling. |

Smart rigging sensors | Monitors load parameters in real-time to ensure safe lifting. |

You must follow inspection procedures and safe load handling protocols. Powerful Machinery’s certified rigging hardware meets international standards, giving you reliable performance in demanding environments.

Choosing Rigging Devices for Your Needs

Assessing Load Type and Weight

You must start every rigging project by understanding the load you need to move. The type, weight, and shape of the load determine which rigging hardware and rigging equipment you should use. Each piece of rigging has a specific working load limit.

You must never exceed this limit to ensure safety. The balance and center of gravity of the load also affect your choice of rigging hardware. Use the table below to guide your selection:

Factor | Description |

|---|---|

Load Type and Weight | Know the exact weight and shape. Always match with the correct working load limit. |

Environment | Choose materials that resist corrosion or extreme temperatures if needed. |

Lifting Angle | Check the angle of lift. Angles can increase tension and affect the strength of rigging hardware. |

Match Rigging Equipment Capacity | Evaluate rigging points and the load’s center of gravity to prevent accidents. |

Considering Environment and Standards

Environmental conditions play a big role in your rigging choices. You must consider wind, rain, temperature, and ground stability before you move loads. For example:

Wind can cause loads to swing, so use wind sensors and stop work in high winds.

Rain and moisture increase slippage. Keep rigging hardware dry and markings visible.

Extreme temperatures can make some rigging brittle. Use temperature-rated rigging equipment.

Poor visibility means you need high-visibility gear and extra lighting.

Wet or soft ground can affect stability. Always check the ground before setup.

You must also follow international standards for rigging hardware and lifting. Standards like ISO 4309 and ISO 16881 set rules for wire rope care and safety. The table below shows key standards:

Standard | Focus Area |

|---|---|

ISO 4309 | Wire rope care, maintenance, inspection, and discard procedures |

ISO 16881 | Safety recommendations for steel wire ropes |

Why Choose Powerful Machinery?

You need a partner who understands rigging hardware and lifting challenges. Powerful Machinery offers certified rigging equipment and custom solutions for every industry. Their products meet all major safety standards and deliver reliable performance.

You benefit from expert support and guidance for every project. The table below highlights the advantages:

Advantage | Description |

|---|---|

Commitment to Safety | Reliable solutions that protect your team and assets. |

Compliance with Standards | Products support all safety and quality standards. |

Quality of Products | Certified equipment and custom-engineered rigging hardware. |

You get expert advice for choosing the right rigging hardware.

All products meet international quality standards.

With Powerful Machinery, you can trust your rigging hardware to perform in any environment.

Rigging Safety and Inspection

Pre-Use Checks

You must inspect all rigging hardware before every shift. This step protects you and your team from accidents during lifting. Start by checking slings for damage or wear. Examine shackles, eyebolts, and other rigging hardware for cracks or deformation. Make sure every piece of equipment has a clear capacity tag.

Inspect load securing devices and tag lines for good condition. Confirm that you have the right rigging for the day’s lifting tasks. Always verify the load weight and check slings, ropes, and chains for fraying or cuts. Secure all shackles and hooks. Test hoists and cranes for reliable operation.

Evaluate ground conditions for stability. Assign a trained signal person to manage communication during rigging operations.

Inspect all slings, shackles, and rigging hardware for damage or wear.

Check capacity tags and ensure they are legible.

Confirm load weight and match with the correct rigging.

Assign a trained signal person for clear communication.

Safe Operation Practices

You must follow strict procedures when using rigging hardware for lifting. Begin by knowing the exact weight of each load. Select the correct hitch configuration to keep the load stable. Understand how sling angles affect tension and distribution. Match each sling to the job, considering material, environment, and load shape.

Use standardized hand signals or radios for communication. Assess the area for hazards and set up barricades to keep unauthorized people away. Follow OSHA and industry guidelines for rigging and lifting. Train all riggers to understand manufacturer instructions and safe storage.

Inspect and maintain all rigging hardware regularly. Monitor the entire rigging process to ensure safety and load integrity.

Know the load weight and choose the right hitch.

Use proper communication and secure the work area.

Train all workers and inspect rigging hardware before use.

Follow safety regulations and use correct personal protective equipment.

Monitor the lifting process at all times.

Common Hazards and Prevention

You face several hazards when using rigging hardware for lifting. Improper sling use, worn gear, and load shift can cause accidents. Remove any rigging hardware that shows signs of wear. Distribute loads evenly and secure them to prevent slippage.

Watch for environmental risks like wind or unstable ground. Make sure every operator receives proper training. Maintain control of the load and know its center of gravity. Select the right rigging hardware and consult charts for sling capacities.

According to the U.S. Bureau of Labor Statistics, crane-related incidents often result from equipment failures and improper rigging practices. You can prevent these accidents by following strict inspection routines and using certified rigging hardware.

Powerful Machinery supports your safety by supplying certified rigging hardware that meets ISO, OSHA, and ASME standards. The company provides training resources, inspection checklists, and custom safety programs to help you maintain a safe lifting environment.

Contribution | Description |

|---|---|

Certified Equipment | Supplies products meeting international safety standards. |

Training Resources | Offers inspection checklists and training materials. |

Customized Safety Programs | Develops tailored safety programs with clients. |

Ongoing Education | Promotes skill development and ongoing training. |

Quality and Reliability | Designs products for demanding environments and rigorous testing. |

You rely on rigging devices to move loads safely and efficiently. Choosing certified equipment like Powerful Machinery’s products helps you prevent accidents, comply with regulations, and improve job site efficiency.

Certified rigging reduces risks and ensures proper handling.

Regular inspections—daily, periodic, and after delivery—keep your operations safe and cost-effective.

Inspection Type | Frequency |

|---|---|

Initial Inspection | Upon receiving hardware |

Daily Inspection | Before each shift |

Periodic Inspection | Every 12 months or more often, based on use |

Consult Powerful Machinery for expert advice and custom solutions tailored to your needs.

FAQ

What is the most important factor when choosing a rigging device?

You must consider the load’s weight and type first. Select rigging hardware with a working load limit that matches or exceeds your requirements. Always check certifications for safety and reliability.

How often should you inspect rigging equipment?

You should inspect rigging hardware before each use and perform periodic inspections every 12 months. If you notice damage or wear, replace the equipment immediately.

Tip: Keep a checklist for daily inspections to ensure nothing gets missed.

Can you use the same rigging device for every lifting job?

You should not use the same device for every job. Each lifting task requires specific rigging hardware based on load shape, weight, and environment. Always match the device to the application.

Why choose Powerful Machinery for rigging solutions?

You benefit from certified products, custom-engineered solutions, and expert support. Powerful Machinery meets international safety standards and provides reliable equipment for demanding industries.

Benefit | Description |

|---|---|

Certified Quality | Meets global safety standards |

Custom Solutions | Tailored to your project needs |

Expert Support | Guidance from industry professionals |