You want peace of mind every time you drop anchor. If you notice your anchor chain links look thinner or show rust, it may be time to think about when to replace the anchor chain. Many boaters worry about getting stranded because of a weak chain, so regular inspections matter.

Checking for rust, cracks, or flattened links during seasonal maintenance helps you spot trouble early. Powerful Machinery offers certified, high-quality anchor chains so you can focus on safe boating.

Key Takeaways

Inspect your anchor chain regularly for signs of rust, thinning, or cracks. Early detection prevents potential failures.

Replace your anchor chain if any link is thinner than 88% of its original thickness or shows severe deformation.

Follow a routine for inspections: check before each trip, conduct a detailed monthly review, and schedule professional inspections annually.

Choose high-quality anchor chains, like those from Powerful Machinery, for better durability and corrosion resistance in harsh marine environments.

When to Replace Anchor Chain: Key Signs

Knowing when to replace anchor chain is key to keeping your boat safe. You want to spot problems before they turn into emergencies. Let’s break down the main warning signs you should watch for during your regular checks.

These signs apply to all chains, but you’ll notice that Powerful Machinery anchor chains are built to handle tough conditions and last longer than most.

Corrosion and Rust

Corrosion and rust are the biggest threats to any anchor chain. Saltwater, humidity, and even rain can eat away at metal over time. If you see orange or brown patches, pitting, or flaking, your chain’s condition is at risk. Corrosion weakens the metal, making it less reliable when you need it most.

Corrosion leads to metal deterioration, which can cause the chain to fail.

If you ignore rust, the chain loses strength and may not hold your boat.

Corrosion fatigue happens when the chain faces stress and seawater at the same time. Tiny cracks form and grow, which can cause the chain to snap.

Powerful Machinery chains, especially those made from stainless steel, resist corrosion better than standard chains. Still, you need to check every chain’s condition often, no matter the brand.

Thinning or Worn Links

You should always check the thickness of your anchor chain links. Over time, friction and wear can make the links thinner. If you notice any link that looks smaller than the rest, it’s time to measure.

If the diameter of a link has shrunk by more than 12% from its original size, you need to replace the chain.

Worn links can’t handle the same load and may break under pressure.

Always check anchor pins and the spots where the chain rubs against metal.

Powerful Machinery anchor chains are designed for durability, but even the best chains will wear down with heavy use. Regular checks help you catch thinning links before they become a problem.

Deformation or Cracks

Look for any links that are bent, twisted, or cracked. Deformation changes how the chain handles stress and can make it unpredictable.

Twisted or bent links often happen from sudden pulls or improper handling.

Fatigue cracks usually start at welds or sharp edges and grow over time.

If any link is worn down by more than 10% or shows severe deformation, replace the chain right away.

Chains from Powerful Machinery go through strict quality checks to prevent these issues, but you still need to inspect them after heavy use or rough weather.

Loss of Galvanization

Galvanized chains have a zinc coating that protects them from rust. If you see shiny steel showing through or notice the coating peeling off, the chain’s condition is at risk.

Loss of galvanization exposes the steel to water and air, speeding up rust.

The zinc layer acts as a shield, so once it’s gone, the chain can deteriorate quickly.

Galvanized chains may need re-coating every few years, depending on use.

Powerful Machinery offers both galvanized and stainless steel chains. Stainless steel chains don’t need re-galvanizing and last longer in harsh marine environments.

Chain Age and Usage

Even if your anchor chain looks fine, age and heavy use can weaken it. Chains face stress every time you anchor, especially in rough weather or strong currents.

Here’s a quick look at industry standards for chain grades and their typical uses:

Chain Grade | Material Type | Working Load Limit (WLL) | Safety Factor | Notes |

|---|---|---|---|---|

G30 | Low carbon steel | 7,600 pounds | 4:1 | General-purpose chain, not for windlasses. |

G40 | High carbon steel | 11,600 pounds | 3:1 | Common, less strong than G70. |

G43 | High carbon steel | 11,600 pounds | 3:1 | Used in recreational boating. |

G70 | Heat-treated steel | 11,600 pounds | 4:1 | For windlasses, avoid re-galvanizing. |

G80 | Higher strength steel | N/A | 4:1 | Not common for anchoring, but available. |

G100 | Higher strength steel | N/A | 4:1 | Newer, not widely recommended yet. |

G120 | Higher strength steel | N/A | 4:1 | Very new, limited recommendations. |

If your chain has seen years of heavy use, or if you can’t remember when you last replaced it, you should consider a new one. Powerful Machinery chains are built to outlast industry averages, but every chain has a lifespan.

Tip: If you’re ever unsure about the condition of your anchor chain, it’s safer to replace it. Your safety on the water depends on it.

When you know the signs and keep an eye on your chain’s condition, you’ll always know when to replace the anchor chain. Powerful Machinery’s certified chains give you extra peace of mind, but regular checks are still your best defense against failure.

Inspection and Replacement Frequency

How Often to Inspect

You want your anchor chain to last, so regular inspection is a must. Most boating safety organizations recommend a few simple steps to keep you on track:

Check your anchor chain before every trip. Look for obvious damage or wear.

Do a thorough inspection once a month or at least every three months, depending on how often you use your boat.

Bring in a professional for a detailed inspection once a year or every two years.

Always inspect your chain after any extreme weather, like storms or heavy seas.

These steps help you catch problems early and keep your chain in top shape.

Replacement Intervals

How often should you replace your anchor chain? It depends on how much you use your boat and the conditions you face. For heavy use, plan to replace your chain every 3 to 5 years. If you use your boat less often or want to stay ahead of problems, aim for a preventive replacement every 5 to 7 years.

Powerful Machinery anchor chains are built for durability, but every chain has a limit.

Factors Affecting Lifespan

Many things can affect how long your anchor chain lasts. Here are a few key factors:

Saltwater causes chains to corrode faster than freshwater.

Chains left in damp, salty environments break down more quickly.

Frequent use and rough conditions shorten the chain’s life.

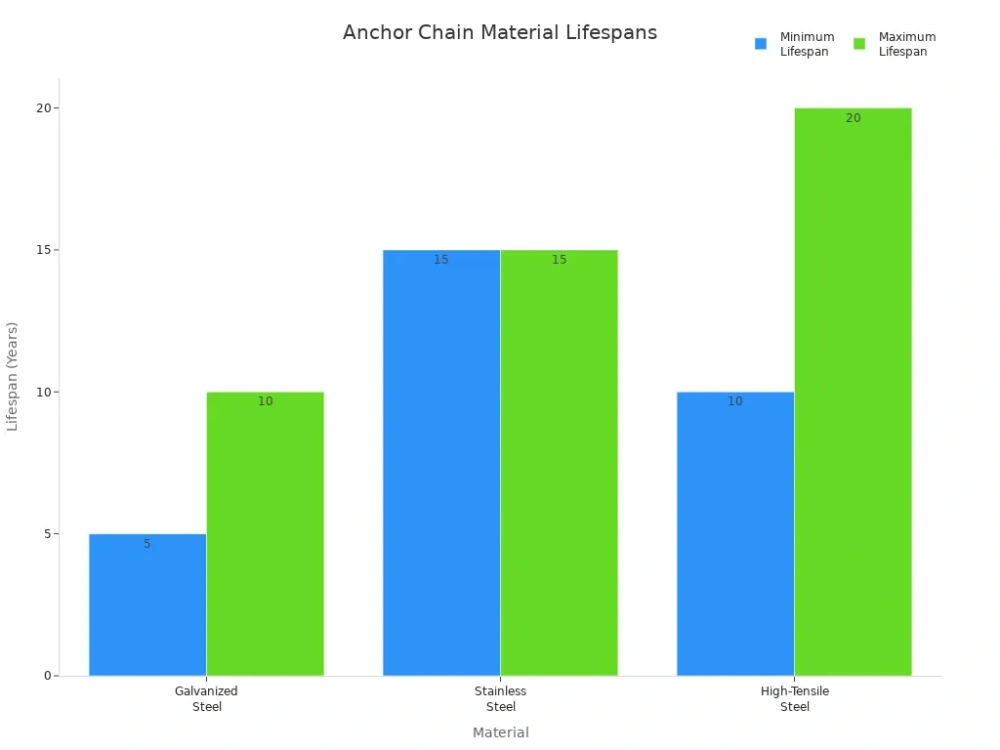

The material you choose also matters. Take a look at how different materials stack up:

Material | Lifespan (Years) | Notes |

|---|---|---|

Galvanized Steel | 5-10 | Can be reduced to 3-5 years in harsh conditions |

Stainless Steel | Up to 15 | Well-maintained chains |

High-Tensile Steel | 10-20 | Depends on usage and maintenance |

If you use a Powerful Machinery studless anchor chain made from stainless steel, you can expect a longer service life, especially with proper care. Always match your chain to your boating environment for the best results.

How to Inspect Anchor Chains?

Keeping your anchor chain in top shape starts with regular inspections. You don’t need to be a marine engineer to spot trouble early. Here’s how you can check your chain, including Powerful Machinery’s studless anchor chain, and know when to call in the pros.

Visual Checks

Start by laying out the entire chain on your deck. Rinse off any mud, salt, or debris. Look for rust, pitting, or flaking. Tap each link with a hammer—if you hear a dull sound instead of a crisp ring, that link might have a crack. Check for bent, twisted, or stretched links.

If you see shiny spots where the galvanization has worn off, pay extra attention there.

Measuring Wear

Grab a caliper or a tape measure. Measure the diameter of several links, especially those that look thinner. Clean the links before measuring to get accurate results. If any link is less than 88% of its original thickness, it’s time to replace the chain.

Don’t forget to measure the length of a few links—if they’ve stretched more than 7-8%, swap them out.

Measure at different points to catch uneven wear.

Avoid measuring links that are obviously misshapen or corroded.

Spotting Weak Points

Focus on the connections. Inspect the anchor line where it meets the chain, and check shackles for tightness and signs of corrosion. Look at the rope-to-chain splice and make sure it’s secure. Pay attention to areas that rub against metal, like hawseholes or chocks. Swap the ends of your chain every year to even out wear.

Tip: Keep your chain clean and dry when not in use. This simple habit can add years to its life.

Professional Inspection

Sometimes, you need an expert. Schedule a professional inspection every year or two, especially if you use your boat often or in tough conditions. Professionals follow strict standards and use tools like ultrasonic testers to find hidden damage.

Always follow the manufacturer’s guidelines for your specific chain. If you’re unsure about any step, reach out to Powerful Machinery for advice.

Maintenance Tips for Longer Life

Cleaning and Storage

You want your anchor chain to last as long as possible. Start by rinsing your chain with fresh water after every trip. Salt and dirt can speed up rust, so wash them away before storing your chain.

Dry the chain completely before you put it in the anchor locker. A clean, dry storage area helps prevent moisture and rust. Here’s a simple routine you can follow:

Inspect your chain for rust or damage after each use.

Rinse with fresh water to remove salt and debris.

Lubricate the links every two weeks to keep them moving smoothly.

Store your chain in a dry, clean locker.

Tip: Fix any broken links right away to keep your chain strong and safe.

Protective Coatings

Protective coatings make a big difference in how long your anchor chain lasts. Hot-dip galvanizing covers the steel with a thick layer of zinc. This zinc layer acts as a shield, taking the hit from saltwater and stopping rust before it reaches the steel.

If you see white rust, that’s the zinc doing its job. Galvanized chains work well in saltwater, but you can also find chains with epoxy or thermal spray coatings for extra protection.

Galvanization protects against corrosion in harsh marine environments.

The zinc layer sacrifices itself first, saving the steel underneath.

Regular Checks

Regular checks keep your anchor chain reliable. Before every trip, look for signs of wear or damage. Once a month, inspect the entire chain for thinning, cracks, or rust. At the start and end of each boating season, do a full inspection. After storms or rough seas, check your chain again. This routine helps you catch problems early.

Pre-trip: Quick check for obvious issues.

Monthly: Detailed inspection of all links.

Seasonal: Full review at the start and end of the season.

After storms: Extra check for hidden damage.

Using Powerful Machinery Chains

Choosing certified anchor chains from Powerful Machinery gives you peace of mind. These chains meet strict safety standards and come with corrosion-resistant features like hot-dip galvanization or stainless steel construction. You get a chain that lasts longer and needs less maintenance. Here’s what sets Powerful Machinery apart:

Feature | Description |

|---|---|

High Performance Anchors | Keeps your crew and vessel safe in all conditions |

Certified by Class Authorities | Recognized for quality and reliability |

Range of Designs | Fits different operations and seabed types |

You can trust Powerful Machinery chains to handle tough marine environments and keep your boat secure.

Conclusion

You want your anchor rode to keep you safe, so pay attention to the warning signs. Look for rust, thinning, or cracks in your anchor rode. Replace it if you see damage or if it’s been in use for years. Regular checks and cleaning help your anchor rode last longer. Certified, high-quality anchor rode reduces the risk of anchor failure.

Companies prove, test, and certify marine chains to prevent anchor failure.

Always ask for proof certificates when buying an anchor rode.

When you maintain your anchor rode, you avoid problems like dragging anchors or running aground. A reliable anchor rode gives you peace of mind every time you’re on the water.

FAQ

How do I know if my anchor chain is still safe to use?

Check for rust, thinning, cracks, or bent links. If you spot any of these, your chain may not be safe. When in doubt, replace it for peace of mind.

Can I use a studless anchor chain in saltwater?

Yes! Powerful Machinery’s studless anchor chains use corrosion-resistant materials like galvanized or stainless steel. These chains work great in saltwater and last longer with regular cleaning.

How do I measure anchor chain wear?

Use a caliper to measure the diameter of several links. If any link is less than 88% of its original thickness, it’s time to replace the chain. Always measure clean, undamaged links for accuracy.

What’s the best way to store my anchor chain?

Rinse your chain with fresh water after each trip. Dry it completely before storing it in a clean, dry locker. This simple habit helps prevent rust and keeps your chain strong.

Why should I choose Powerful Machinery anchor chains?

You get certified quality, corrosion resistance, and custom options. Powerful Machinery chains meet strict safety standards, so you can trust them to keep your boat secure in any marine environment.