Regular inspections keep you safe when using lever hoists. You protect yourself and your team by following a lever hoist inspection checklist every time you operate equipment. Powerful Machinery’s lever chain hoist and mini lever hoists meet strict safety standards. These include ASME, ISO, and CE Marking.

Standard | Description |

|---|---|

ASME | Standards like ASME B30.16 for overhead hoists are respected in North America and worldwide. |

ISO | ISO standards set a global framework for quality and manufacturing. |

CE Marking | The CE mark shows a product meets European health, safety, and environmental rules. |

A lever hoist inspection checklist helps you spot issues early. This keeps equipment reliable and extends its life. Use a systematic approach to ensure safety and efficiency each day.

Key Takeaways

Conduct daily inspections of lever hoists to identify issues early and ensure safety.

Follow a systematic checklist that includes checking load blocks, levers, and safety mechanisms.

Document all inspections and repairs to maintain compliance with safety standards.

Use qualified personnel for periodic inspections to ensure thorough checks and operational safety.

Regular training for operators enhances safety and helps prevent accidents.

Lever Hoist Inspection Checklist Overview

Key Steps in the Inspection Checklist

You need to check several important parts when you inspect lever hoists. Each part plays a role in safe lifting. If you miss a step, you risk equipment failure or injury. Here are the main components you should review during every inspection:

Load blocks

Suspension housings

Levers

Attachments

Clevises

Yokes

Suspension bolts

Shafts

Gears

Bearings

Pins

Rollers

Locking and clamping devices

Load sprockets

Idler sprockets

Drums

Sheaves

Brake mechanisms

Supporting structure or trolley

Labels

End connections of load chains, rope, or web strap

The hoist and hoist mounting

You should always follow the manufacturer’s instructions for your specific model. Powerful Machinery’s lever hoists include safety features and clear labels to help you complete each step.

Quick Reference for Daily Inspections

A daily inspection checklist helps you keep your equipment in top shape. You can spot problems early and avoid costly downtime. Here are some quick tips for daily checks:

Make sure all components work correctly before use.

Look for signs of wear, damage, or misalignment.

Check that safety labels are readable and in place.

Test the brake mechanism and locking devices.

Confirm the hoist is mounted securely.

Tip: Regular inspections help you find issues before they cause accidents. You also extend the life of your lever hoists and keep your workplace safe.

By using a clear inspection checklist, you improve safety and efficiency every day.

Why Inspections Matter for Lever Hoists?

Safety and Compliance Benefits

You play a key role in maintaining operational safety when you inspect lever chain hoist equipment. Regular inspections help you spot issues before they become hazards. You protect yourself and your team by following safety standards every time you use lever hoists.

Inspections also support compliance with safety standards, which is essential for legal operation.

Here are the main benefits you gain from routine inspections:

You identify worn-out components that could cause accidents.

You ensure compliance with safety standards set by OSHA and ASME.

You avoid costly fines and legal penalties by meeting regulations.

You reduce the risk of workplace injuries.

Benefit Type | Description |

|---|---|

Safety | Proactively identifies potential risks and hazards, reducing the likelihood of accidents. |

Compliance | Inspections are mandated by governing bodies, ensuring adherence to safety standards. |

Note: Inspections help you maintain a safe work environment and keep your lever chain hoist in top condition.

Preventing Accidents and Equipment Failure

You prevent accidents and equipment failure by inspecting lever hoists before each use. Operational safety depends on your attention to detail. When you check for damage or misalignment, you stop problems before they lead to downtime or injury.

Inspections also help you maintain compliance with safety standards, which protects your business and your team.

You minimize the risk of unexpected equipment breakdowns.

You keep productivity high by avoiding unplanned downtime.

You ensure every lever chain hoist operates reliably.

Operational safety starts with you. By making inspections part of your daily routine, you create a safer workplace and extend the life of your equipment.

Inspection Frequency and Qualified Personnel

Daily, Periodic, and Post-Repair Inspections

You need to follow inspection requirements to keep your lever hoist safe and reliable. International standards like OSHA and ISO recommend different intervals for checking your equipment. You should perform frequent inspections before each use and schedule periodic inspections to catch deeper issues.

Inspection Type | Interval |

|---|---|

Frequent Inspection | Daily to monthly |

Periodic Inspection | 1 to 12-month intervals |

Frequent inspections focus on visible problems such as worn hooks or damaged chains. You can spot these issues quickly and prevent accidents. Periodic inspections go deeper. You check internal parts like brakes and electrical systems. Certified technicians usually handle these checks.

Inspection Type | Frequency | Scope of Inspection | Who Performs |

|---|---|---|---|

Frequent Inspection | Daily or pre-use | Quick checks for visible issues (e.g., hooks, chains) | Operators or foremen |

Periodic Inspection | Monthly/Quarterly/Annually | Comprehensive checks including internal parts (e.g., brakes, electrical systems) | Certified technicians |

Pre-operational inspections are essential for operational safety. You should also inspect your lever hoist after any repairs. This step confirms that the equipment works correctly and meets inspection requirements. Regular maintenance helps you avoid unexpected breakdowns and keeps your workplace safe.

Tip: Always follow the manufacturer’s guidelines and ASME B30.21 recommendations for inspection intervals.

Who Should Perform Inspections?

You must select qualified personnel to carry out lever hoist inspections. Operators can handle frequent inspections, but periodic inspections require certified technicians. The right person ensures operational safety and meets all inspection requirements.

Qualification/Certification | Description |

|---|---|

Field Experience | A significant amount of field experience is required. |

Knowledge of Codes | Must know applicable codes. |

Formal Training | Required formal training in safe operating procedures. |

A crane inspector should have over 2,000 hours of field experience related to maintenance, service, repair, modification, and functional testing of crane components.

Practical knowledge of federal, state, and local codes is essential.

Formal training in safe operating procedures and equipment terminology is necessary.

Comprehensive operator training is strongly recommended by HMI, OSHA, and ASME.

Proper training includes reviewing the hoist’s manual and hands-on use of the hoist.

Regular inspections of powered underhung overhead hoists must be conducted by qualified, trained persons.

Pre-shift hoist inspections are mandated by OSHA and ASME codes.

Visual inspections of hooks and slings used with hoists are covered under ASME B30.10.

Conduct pre-operational inspections to ensure the hoist is safe to use.

Identify and address any abnormalities before using the hoist.

You improve operational safety by choosing inspectors with the right experience and training. You also meet inspection requirements and keep your lever hoist in top condition. Periodic inspections by certified technicians help you find hidden problems and maintain compliance.

Step-by-Step Lever Hoist Inspection Checklist

A systematic inspection process helps you maintain operational safety and meet safety standards every time you use lever hoists.

Powerful Machinery’s lever chain hoist and mini lever hoist models come with CE and ISO certifications, which means you can trust their quality and safety mechanisms. Follow this checklist to ensure your equipment stays reliable and compliant.

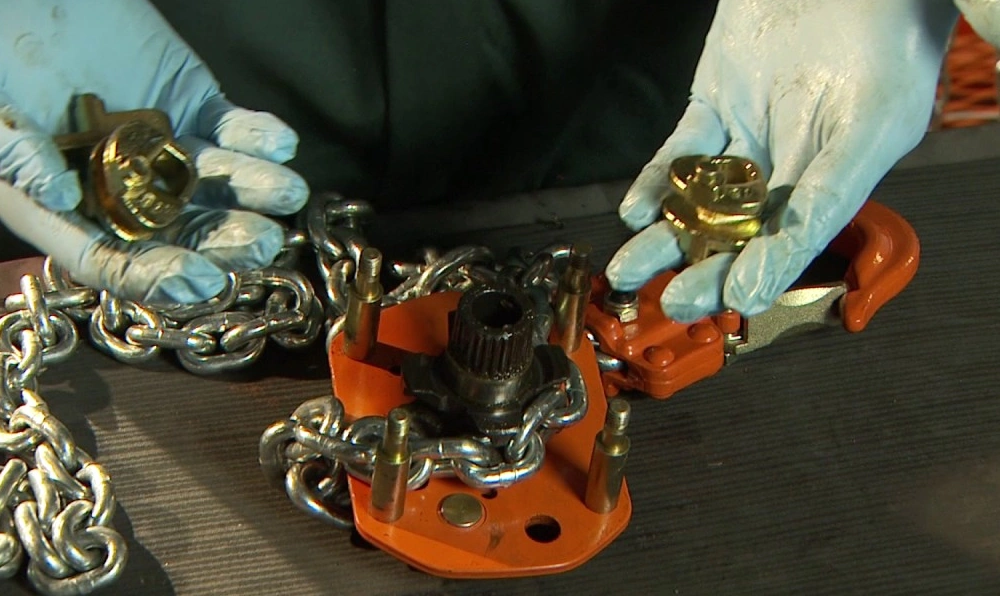

Visual Inspection of Chains, Hooks, and Body

Start your inspection by looking closely at the main components. This step helps you catch visible problems before they become serious hazards. Both the lever chain hoist and mini lever hoist require careful attention to detail.

Examine the hooks for cracks, nicks, gouges, twisting, or any deformation of the throat opening. Replace the hook if you see any of these issues.

Inspect the load chains for nicks, gouges, deformation, flaws, heat damage, bent links, wear, stretch, or corrosion. Make sure the chain has proper lubrication.

Check the hoist body for deformation or corrosion. Confirm that all bolts and nuts are present and secure.

Look for missing or unreadable safety labels. These labels provide important information about safety standards and operational safety.

For Powerful Machinery’s lever chain hoist, pay special attention to the reinforced handle and non-slip safety nut. For the mini lever hoist, check the compact body and rust-resistant finish.

Tip: Always follow the manufacturer’s guidelines for your specific model. This ensures you do not miss any critical inspection points.

Functional Testing and Safety Features

After the visual inspection, test the hoist’s safety mechanisms and controls. This step verifies that your lever hoists operate smoothly and safely.

Confirm that all markings and labels are intact and easy to read.

Test the hoist controls for responsiveness. Controls should be clearly marked and easy to use.

Operate the hoist without a load. Listen for unusual noises and check for smooth movement.

Inspect the hook again for signs of wear, deformation, or cracks.

Examine the chain for excessive wear, twisted links, or other damage.

For Powerful Machinery’s lever chain hoist, test the brake mechanism and ergonomic hand wheel. For the mini lever hoist, check the 360° operation and load-limiting function.

Make sure all safety mechanisms, such as locking devices and non-slip nuts, work as intended.

Note: Functional testing helps you confirm that your lever hoists meet safety standards and are ready for safe operation.

Documentation and Recordkeeping

Proper documentation is a key part of operational safety and compliance. Keeping accurate records helps you track the condition of your lever chain hoist and mini lever hoist over time.

Record every inspection, maintenance, and repair. Include the date, inspector’s name, defects found, and corrective actions taken.

Use a table or logbook to organize your records. This makes it easy to identify recurring issues and prove compliance with safety standards.

Store documentation in a secure place. You may need to show these records during audits or inspections.

Review your records regularly. This helps you spot patterns and schedule preventive maintenance.

Inspection Date | Inspector | Equipment Model | Defects Found | Corrective Action | Next Inspection |

|---|---|---|---|---|---|

2024-06-01 | J. Smith | Lever Chain Hoist 0.5T | None | N/A | 2024-07-01 |

2024-06-01 | A. Lee | Mini Lever Hoist 0.25T | Bent Hook | Replaced Hook | 2024-07-01 |

Keeping detailed records supports your commitment to operational safety and helps you maintain compliance with international safety standards.

By following this step-by-step checklist, you ensure that your lever hoists remain safe, reliable, and ready for use. Powerful Machinery’s certified products make it easier for you to meet safety standards and protect your team.

Common Issues Found During Lever Hoist Inspections

Wear, Damage, and Misalignment

You often find wear, damage, or misalignment when you inspect lever hoists. These problems can affect safety and performance. Regular maintenance, including lubrication and careful inspection, helps prevent issues like load slippage and unusual noise.

Operator training and following load capacities are also important for avoiding damage.

Common problems include:

Load slippage from faulty pawl or ratchet mechanisms or overloading

Noise and vibration caused by loose components or worn bearings

Corrosion from moisture or chemicals

Inaccurate load readings due to calibration or sensor damage

You may also notice worn pawls, damaged ratchet teeth, or stiff operation. Stiff operation often results from poor lubrication or misalignment. If you see these signs, you should address them right away to keep your equipment safe.

Tip: Always check for missing or illegible identification tags, broken wires, corrosion, and deformation of wire ropes. These issues appear frequently in industry reports.

Chain and Hook Problems

Chain and hook problems are common during lever hoist inspections. You might see hooks that have opened or deformed. This usually means the hoist was overloaded. If you find a hook that has changed shape, replace it immediately and inspect the rest of the hoist for other damage.

Other chain and hook issues include:

Bent or stretched chain links

Rust or corrosion on chains

Broken or damaged rigging hardware

You keep your workplace safe by checking these parts before every use.

Non-Compliance Indicators

Non-compliance indicators show that your lever hoist does not meet safety standards. You should look for these signs during every inspection:

Failure to inspect equipment before use

Overloading the hoist beyond its rated capacity

Improper rigging techniques that cause load imbalance

Operators who have not received proper training

If you spot any of these issues, take action right away. You protect yourself and your team by following inspection routines and using the hoist correctly.

Note: Addressing non-compliance helps you avoid accidents and keeps your equipment in top condition.

Actions to Take If Problems Are Found

Reporting and Tagging Procedures

When you find a problem during your lever hoist inspection, you must act quickly. Start by reporting the issue to your supervisor or safety manager. Use clear language to describe what you found. Include details such as the type of defect, the location on the hoist, and the possible risk.

Next, tag the equipment. Attach a visible tag or label to the lever hoist. The tag should say “Do Not Use” or “Out of Service.” This step warns others not to use the hoist until repairs are complete.

Always record the problem in your inspection log. Write down the date, your name, the equipment model, and a short description of the issue.

Tip: Never use a lever hoist that has a warning tag or is waiting for repairs. This keeps everyone safe and prevents accidents.

Repair or Replacement Steps

After you report and tag the faulty hoist, you need to follow a clear process for repair or replacement. Only trained or certified personnel should perform these steps.

Replace any broken or old chains with high-quality certified parts.

Adjust all levers to ensure proper movement and control.

Inspect and replace hooks that show signs of damage, stretching, or wear.

You should also check the following parts in order:

Inspect the shape of the top hook and make sure the safety catch fits well.

Check the hoist body for distortion or missing gear covers.

Examine the hand chain wheel and casing for cracks or other damage.

If you find any part that cannot be repaired, replace it with a certified component from a trusted supplier like Powerful Machinery. Always test the hoist after repairs to confirm it works safely. Record all repairs and replacements in your maintenance log.

Keeping detailed records helps you track equipment history and supports compliance with safety standards.

Maintaining Compliance and Safety with Powerful Machinery Hoists

Training and Manufacturer Guidelines

You play a key role in keeping your workplace safe when you use lever hoists. Powerful Machinery supports you by meeting strict safety standards, including ASME B30.21, OSHA, and ANSI. These standards guide the construction, inspection, and maintenance of lever hoists.

The table below shows how each standard helps you maintain compliance with safety standards:

Safety Standard | Description |

|---|---|

ASME B30.21 | Covers construction, inspection, testing, and maintenance of lever hoists. |

OSHA | Enforces safety standards in the workplace, including hoisting equipment. |

ANSI | Provides consensus standards for lifting devices, ensuring reliability and safety. |

You should always follow the manufacturer’s guidelines for best practices. These guidelines help you use lever hoists safely and keep them in good condition. Regular training for operators and inspectors is important.

Training programs include mobile crane inspector training, overhead crane inspector training, and specialized inspector training for rigging equipment. Comprehensive on-site training programs give you hands-on experience with your equipment.

Tip: Training helps you understand how to inspect, operate, and maintain lever hoists according to safety standards.

Continuous Improvement Practices

You improve safety and compliance with safety standards by making continuous improvement part of your routine. Start by reviewing your inspection records and looking for patterns. If you see repeated issues, update your best practices and share them with your team.

Encourage everyone to report problems and suggest solutions.

Hold regular training sessions to refresh your knowledge.

Use official documentation from Powerful Machinery to guide your inspections.

Stay updated on changes to safety standards and adjust your procedures as needed.

You build a culture of safety by focusing on best practices and ongoing training. This approach reduces the risk of accidents and keeps your lever hoists working reliably. Compliance with safety standards also protects your business from legal penalties and improves your reputation.

Conclusion

You improve workplace safety when you use a lever hoist inspection checklist. Powerful Machinery’s lever hoists offer reliability and meet strict standards. Regular inspections help you prevent accidents, ensure equipment reliability, and maintain compliance.

Benefit | Description |

|---|---|

Preventing accidents | Regular inspections help identify potential issues before they lead to accidents. |

Ensuring equipment reliability | Consistent checks ensure that the hoists function properly and safely. |

Maintaining compliance | Following inspection protocols helps meet industry safety standards. |

You extend the lifespan of lever hoists by catching problems early.

Documenting inspections helps you track equipment condition and schedule repairs.

Ongoing education keeps you and your team vigilant and informed.

Stay proactive. Make lever hoist inspections part of your daily routine for a safer, more efficient workplace.

FAQ

How often should you inspect a lever hoist?

You should inspect your lever hoist before each use. Schedule periodic inspections every month or quarter. Always follow the manufacturer’s recommendations for your specific model.

Tip: Frequent checks help you catch problems early and keep your equipment safe.

What signs show that a lever hoist needs repair?

Look for bent hooks, stretched chains, missing safety labels, or unusual noises. If you see any damage or the hoist does not operate smoothly, stop using it and report the issue.

Problem | Action |

|---|---|

Bent hook | Replace hook |

Stretched chain | Replace chain |

Missing label | Add label |

Who can perform lever hoist inspections?

You can do daily visual checks if you have basic training. Certified technicians should handle periodic and post-repair inspections. Proper training ensures safe and accurate inspections.

Operators: Daily checks

Technicians: Detailed inspections

Why do you need to keep inspection records?

Inspection records help you track equipment condition and prove compliance with safety standards. You can use a logbook or digital file to record dates, findings, and repairs.

Note: Good records support workplace safety and help you plan maintenance.