Looking for the best lifting eye bolt manufacturers? Here are the top eight you should know:

PowerFul Machinery

Crosby Group

RUD Group

YOKE Industrial Corp.

Chicago Hardware & Fixture Company

J.W. Winco

KD Fasteners

Murphy Lift

You want reliable suppliers. Check their safety ratings, certifications, and product quality. Here’s a quick look at what matters most:

Criteria | Why It Matters |

|---|---|

Safety & Standards | Keeps your team safe |

Material Quality | Ensures long-lasting performance |

Manufacturing Innovation | Delivers consistent, strong products |

Global Reach | Guarantees fast and easy delivery |

Key Takeaways

Choose manufacturers with strong safety ratings and certifications to ensure reliable lifting operations.

Inspect lifting eye bolts regularly for wear and damage to maintain safety and performance.

Consider custom solutions from manufacturers to meet specific project needs and enhance efficiency.

Look for manufacturers with a global reach to ensure timely delivery and support for your projects.

Always match the lifting eye bolt’s load rating to your requirements for safe and effective lifting.

1. PowerFul Machinery

Overview

You want a partner who understands your lifting challenges. Powerful Machinery stands out among lifting eye bolt manufacturers with over 20 years of experience. The company focuses on high-performance lifting and mooring solutions for industries like construction, marine, transportation, and cargo handling.

You get direct-from-manufacturer pricing, so you save money without sacrificing quality.

Key Products

When you need reliable lifting hardware, PowerFul Machinery offers a wide range of options. Here are some of their most popular products:

Wire rope fittings

You can also request custom-engineered solutions. The team works with you to design products that fit your exact needs.

Tip: Regularly inspect your lifting eye nuts for wear, corrosion, or damage to keep your operations safe.

Strengths

You benefit from strict quality control at every step. PowerFul Machinery uses advanced production equipment, like automated welding systems and precision forging presses.

This means you get consistent, high-quality products every time. The company also offers one-stop sourcing and industry-leading customer support. You can count on their engineers to help with custom projects from start to finish.

Certifications

You want proof of quality. PowerFul Machinery holds important certifications that show its commitment to safety and manufacturing excellence:

Certification | Description |

|---|---|

ASTM | Indicates adherence to safety and manufacturing standards. |

ISO | Ensures consistency and quality in manufacturing processes. |

Global Reach

You need your orders delivered on time, wherever you are. PowerFul Machinery has a strong global logistics network. Their team handles everything from secure packaging to customs clearance. You get reliable, on-time delivery for your projects, no matter where you work.

2. Crosby Group

Overview

You want a manufacturer with a reputation for safety and innovation. Crosby Group has earned its spot among the top lifting eye bolt manufacturers worldwide. The company has a long history of producing reliable rigging hardware for industries like oil and gas, construction, and transportation.

You get products that meet strict safety standards and perform well in tough environments.

Key Products

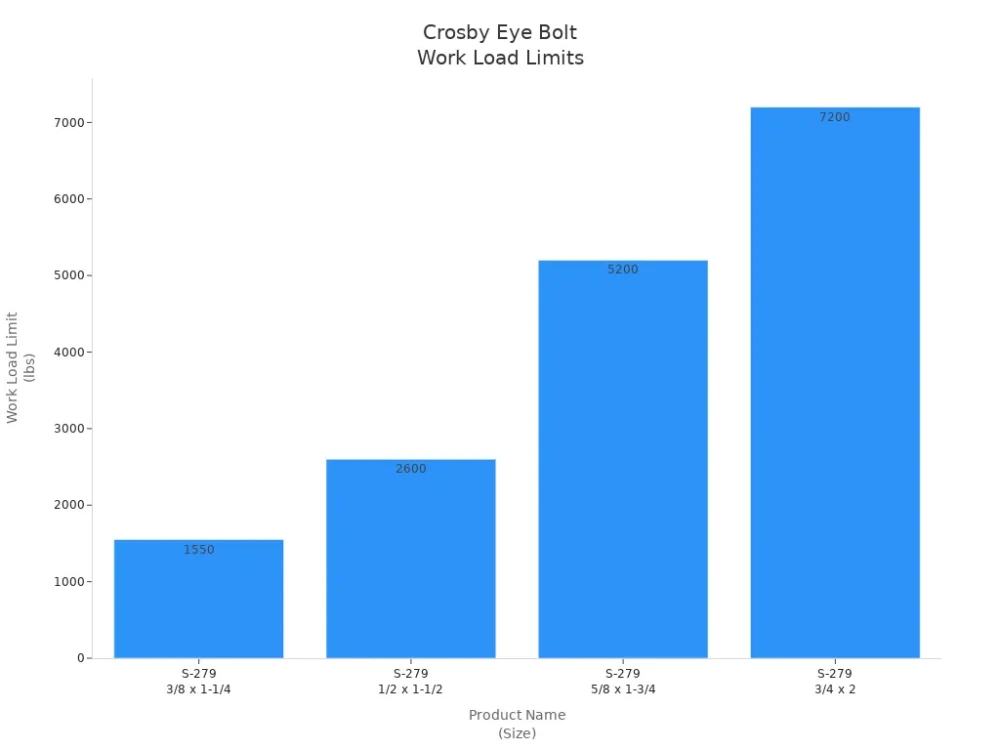

Crosby Group offers a range of lifting eye bolts designed for heavy-duty applications. Their flagship S-279 Forged Machinery Shoulder Nut Eye Bolts stand out for strength and durability. Take a look at the workload limits for their most popular models:

Product Name | Work Load Limit (WLL) | Description |

|---|---|---|

Crosby® S-279 Forged Machinery Shoulder Nut Eye Bolt (3/8 x 1-1/4) | 1,550 lbs | Forged Steel, Quenched and Tempered. Fatigue rated at 1-1/2 times Work Load Limit for 20,000 cycles. |

Crosby® S-279 Forged Machinery Shoulder Nut Eye Bolt (1/2 x 1-1/2) | 2,600 lbs | Forged Steel, Quenched and Tempered. Fatigue rated at 1-1/2 times Work Load Limit for 20,000 cycles. |

Crosby® S-279 Forged Machinery Shoulder Nut Eye Bolt (5/8 x 1-3/4) | 5,200 lbs | Forged Steel, Quenched and Tempered. Fatigue rated at 1-1/2 times Work Load Limit for 20,000 cycles. |

Crosby® S-279 Forged Machinery Shoulder Nut Eye Bolt (3/4 x 2) | 7,200 lbs | Forged Steel, Quenched and Tempered. Fatigue rated at 1-1/2 times Work Load Limit for 20,000 cycles. |

You can also find other popular options:

Crosby® S-279 Machine

Crosby® G-277 Shoulder

Strengths

You get products that are fatigue-rated and tested for thousands of cycles. Crosby Group focuses on safety, so you can trust their hardware for critical lifts. Their engineering team keeps improving designs to meet new industry needs. You benefit from a wide selection and strong technical support.

Note: Always check the workload limit before using any lifting eye bolt. Crosby Group makes it easy to find this information.

Certifications

You want proof that your equipment meets global standards. Crosby Group holds certifications like ISO and ASME, which show their commitment to quality and safety. These certifications help you meet project requirements and pass inspections.

Global Reach

You need fast delivery and support wherever you work. Crosby Group has a worldwide distribution network. You can get their products in North America, Europe, Asia, and beyond. Their team helps with logistics and technical questions, so your projects stay on schedule.

3. RUD Group

Overview

You want a supplier that sets the standard for safety and innovation. RUD Group stands out among lifting eye bolt manufacturers with a reputation for engineering excellence.

The company focuses on heavy-duty lifting solutions for industries like construction, mining, and logistics. You get products that combine German precision with practical design, making your lifting operations safer and easier.

Key Products

RUD Group offers a wide range of lifting points designed for different applications. You can choose from bolt-on, weld-on, and quick-mount options. Each type comes with unique features and impressive load capacities.

Type of Lifting Point | Load Capacity | Features |

|---|---|---|

Bolt-on | Up to 250 tons | 100% crack-tested, ergonomic design, clear WLL markings |

Weld-on | Up to 100 tons | 100% crack-tested, patented wear indicators |

Quick-mount | Varies | High load capacities, visible powder-coated finishes |

You get lifting points that are 100% crack-tested and can handle 4-5 times their rated Working Load Limit. That means you can trust these products for your toughest jobs.

Bolt-on lifting points: Load capacities up to 250 tons.

Weld-on lifting points: Load capacities up to 100 tons.

Quick-mount lifting points: Various load capacities.

All models feature visible safety markings and ergonomic designs.

Strengths

You benefit from RUD Group’s focus on safety and reliability. The company uses patented wear indicators and ergonomic designs to make inspections easy. You can spot potential issues before they become problems.

RUD Group also tests every product to ensure it meets strict standards. You get hardware that performs well in demanding environments.

Tip: Always check the visible safety markings before each lift. This helps you avoid accidents and keeps your team safe.

Certifications

You want proof that your equipment meets global standards. RUD Group holds certifications like ISO 9001 and EN standards. These certifications show the company’s commitment to quality and safety. You can meet project requirements and pass inspections with confidence.

Global Reach

You need fast delivery and support wherever your project takes you. RUD Group has a strong global presence, with distribution centers in Europe, Asia, and North America. You get reliable shipping and technical support, no matter where you work.

4. YOKE Industrial Corp.

Overview

You want a supplier that delivers both innovation and reliability. YOKE Industrial Corp. has earned its place among the top lifting eye bolt manufacturers by focusing on safety, engineering, and global service.

You can count on their products for demanding jobs in construction, mining, oil and gas, and material handling. YOKE’s commitment to quality means you get hardware that stands up to tough conditions and strict safety standards.

Key Products

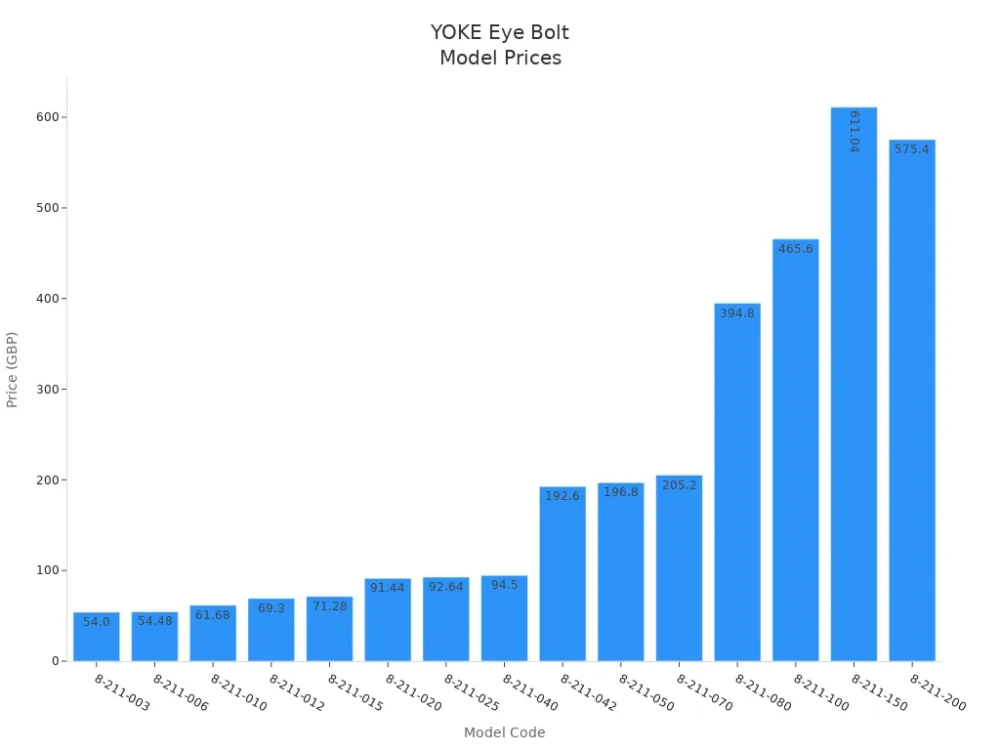

YOKE offers a wide selection of lifting eye bolts, with models designed for different load capacities and applications. If you need a quick comparison, check out some of their best-selling models:

Model Code | Size (mm) | Price (GBP) |

|---|---|---|

8-211-003 | M8 x 1 x 1.25 x 45 | £54.00 |

8-211-006 | M10 x 1.50 x 50 | £54.48 |

8-211-010 | M12 x 1.75 x 60 | £61.68 |

8-211-012 | M14 x 2.00 x 60 | £69.30 |

8-211-015 | M16 x 2.00 x 65 | £71.28 |

8-211-020 | M18 x 2.00 x 75 | £91.44 |

8-211-025 | M20 x 2.50 x 80 | £92.64 |

8-211-040 | M24 x 3.00 x 85 | £94.50 |

8-211-042 | M27 x 3.00 x 110 | £192.60 |

8-211-050 | M30 x 3.50 x 115 | £196.80 |

8-211-070 | M36 x 4.00 x 125 | £205.20 |

8-211-080 | M36 x 4.00 x 140 | £394.80 |

8-211-100 | M42 x 4.50 x 150 | £465.60 |

8-211-150 | M42 x 4.50 x 160 | £611.04 |

8-211-200 | M48 x 5.00 x 170 | £575.40 |

You can see that YOKE covers a wide range of sizes and price points, so you can find the right fit for your project.

Strengths

You benefit from YOKE’s focus on engineering and safety. Their lifting eye bolts are designed for use with Grade 100 chain slings, making them ideal for heavy-duty lifting.

YOKE’s self-locking hooks improve usability and safety for field workers. You get products that are easy to inspect and maintain, which helps you keep your team safe.

Tip: Always match the lifting eye bolt size and grade to your load requirements for the best performance.

Certifications

You want proof that your equipment meets international standards. YOKE holds several key certifications:

Certification Standard |

|---|

ISO 9001-2008 |

API Q1 |

ISO/TS 29001 |

EN 1677-1 |

These certifications show YOKE’s commitment to quality and safety, giving you peace of mind on every lift.

Global Reach

You need a supplier that can deliver anywhere. YOKE works with global channel partners to make their products available worldwide. You can find their lifting eye bolts in industries like construction, mining, and oil and gas. YOKE’s expanded product range means you get solutions for many different applications.

YOKE collaborates with global partners for wide product availability.

Their lifting eye bolts serve construction, mining, oil and gas, and material handling.

Eye Self-Locking Hooks are designed for use with Grade 100 chain slings, making field work easier.

If you want a trusted name among lifting eye bolt manufacturers, YOKE Industrial Corp. delivers quality, safety, and global support.

5. Chicago Hardware & Fixture Company

Overview

You want a supplier with a long history and proven reliability. Chicago Hardware & Fixture Company has been serving customers since 1912. You get products made in the USA, backed by decades of expertise in forging and machining. This company stands out among lifting eye bolt manufacturers for its commitment to quality and safety.

Key Products

You have plenty of choices when you shop here. Chicago Hardware & Fixture Company offers a wide selection of lifting eye bolts. Take a look at some of their most popular options:

Product Name | Description |

|---|---|

Lifting Eyes Self-Colored | Drop forged from C-1035 steel, heat-treated. Available blank or threaded. Standard self-colored finish. |

Machinery Eye Bolts Standard Shank Lengths Plain Pattern | Maximum blank lengths, vertical loads based on a safety factor of 5 to 1. |

Drop Forged Eye Bolts Regular – Machine Thread | Drop forged heat-treated steel eye bolts with hot galvanized finish. Machine thread before galvanizing. |

Drop Forged Eye Bolts Shoulder – Machine Thread | Similar to a regular machine thread but with a shoulder design. |

You can choose from blank or threaded styles, regular or shoulder designs, and finishes like self-colored or hot galvanized. This variety helps you find the right fit for your project.

Strengths

You get products that meet strict safety standards. Chicago Hardware & Fixture Company uses drop forging and heat treatment to make strong, durable eye bolts. Their vertical load ratings use a 5:1 safety factor, so you can trust these bolts for heavy lifting. You also benefit from their experience and attention to detail.

Tip: Always check the load rating before you start your lift. This keeps your team safe and your equipment working longer.

Certifications

You want proof that your hardware meets industry standards. Chicago Hardware & Fixture Company follows ASTM specifications for its lifting eye bolts. This means you get products that pass tough tests for strength and reliability.

Global Reach

You can order from anywhere in the world. Chicago Hardware & Fixture Company ships products across North America and to international customers. Their team helps you with logistics, so your order arrives on time and in good condition.

6. J.W. Winco

Overview

You want a manufacturer that blends innovation with reliability. J.W. Winco stands out among lifting eye bolt manufacturers for its focus on precision engineering and modern design. You get products that work well in industrial, construction, and marine settings.

The company has built a reputation for quality hardware and fast customer service.

Key Products

You have plenty of choices when you look at J.W. Winco’s lineup. Their lifting eye bolts come in a variety of materials and sizes, so you can match the right product to your job. Take a look at some of their most innovative options:

Product Type | Material Options | Thread Sizes | Load Capacity (N) | Eye Diameter (mm) |

|---|---|---|---|---|

Stainless Steel Lifting Eye Bolts | A2 Stainless Steel, A4 Stainless Steel | M8 to M24 | 1,400 to 18,000 | 20 to 50 |

You can choose from different grades of stainless steel, which helps you handle tough environments and resist corrosion.

Safety swivel lifting eye bolts give you extra peace of mind.

You can find these bolts in stainless steel for added durability.

They work well for many lifting applications, from machinery to marine use.

Strengths

You get more than just hardware. J.W. Winco focuses on safety and user-friendly design. Their safety swivel lifting eye bolts help prevent accidents by allowing the bolt to rotate under load.

You can trust their products to hold up under pressure. The company also offers quick delivery and helpful technical support, so you never feel stuck.

Tip: Always check the load capacity and thread size before you start your lift. This keeps your team safe and your equipment working longer.

Certifications

You want proof that your lifting hardware meets strict standards. J.W. Winco products follow international guidelines for quality and safety. You can rely on their hardware to pass inspections and keep your projects on track.

Global Reach

You can order J.W. Winco products from almost anywhere. The company ships worldwide and has a strong presence in North America and Europe. You get fast delivery and support, no matter where your project takes you.

7. KD Fasteners

Overview

You want a supplier that makes ordering simple and delivers strong products. KD Fasteners stands out among lifting eye bolt manufacturers for its wide selection and fast turnaround. You get both bent and forged eye bolts, so you can pick the style that fits your job.

The company has built a reputation for reliable service and flexible manufacturing. If you need something custom, KD Fasteners works with you to create the right solution.

Key Products

You have plenty of choices when you shop with KD Fasteners. Their lifting eye bolts come in different sizes and materials. Take a look at what they offer:

Product Type | Description |

|---|---|

Lifting Eye Bolts | 580 |

You can order off-the-shelf forged eye bolts from ¼” to 1” in diameter. If you need something bigger, custom orders go up to 2-1/2” in diameter. KD Fasteners uses steel, stainless steel, aluminum, and other materials, so you get the right bolt for your environment.

Strengths

You get flexibility and speed. KD Fasteners manufactures eye bolts in many sizes and materials, so you can find what you need fast. Their team helps you with custom orders, making sure your lifting hardware fits your project.

You can count on their products for durability and safety. The company keeps a large inventory, so you rarely wait long for your order.

Tip: Always double-check the diameter and material before you place your order. This helps you avoid delays and keeps your project moving.

Certifications

You want proof that your lifting eye bolts meet industry standards. KD Fasteners follows ASTM guidelines for its products. This means you get hardware that passes tough tests for strength and reliability. You can trust their bolts for heavy lifting and demanding jobs.

Global Reach

You can order from almost anywhere. KD Fasteners ships products across North America and to international customers. Their team helps with logistics, so your order arrives on time. You get support from start to finish, no matter where your project takes you.

8. Murphy Lift

Overview

You want a supplier that puts safety and reliability first. Murphy Lift has built a strong reputation among lifting eye bolt manufacturers. The company focuses on designing hardware that meets the needs of construction, marine, and industrial projects.

You get products that help you lift heavy loads with confidence. Murphy Lift uses modern engineering and listens to customer feedback to improve its designs.

Key Products

You have plenty of choices when you look at Murphy Lift’s product line. The company offers several types of lifting eye bolts for different jobs. Here are some popular options:

Forged steel lifting eye bolts for heavy-duty applications

Stainless steel eye bolts for corrosion resistance

Swivel eye bolts for flexible lifting angles

Custom-sized eye bolts for unique projects

You can pick the right bolt for your job. Murphy Lift also provides accessories like nuts and washers to complete your setup.

Strengths

You benefit from Murphy Lift’s focus on safety and durability. The company tests every product to make sure it meets strict standards. You get hardware that works well in tough environments.

Murphy Lift’s team helps you choose the right products and answers your questions quickly. You can rely on their support from start to finish.

Tip: Always check the load rating and installation instructions before you use any lifting eye bolt. This keeps your team safe and your equipment working longer.

Certifications

You want proof that your lifting hardware meets industry standards. Murphy Lift holds important certifications, including:

Certification | What It Means |

|---|---|

ISO 9001 | Quality management system |

ASTM | Material and safety standards |

These certifications show Murphy Lift’s commitment to quality and safety.

Global Reach

You can order Murphy Lift products from almost anywhere. The company ships worldwide and works with distributors in North America, Europe, and Asia. You get fast delivery and helpful support, no matter where your project takes you. Murphy Lift’s logistics team makes sure your order arrives on time.

Comparison of Lifting Eye Bolt Manufacturers

Features Table

You want a quick way to compare the top lifting eye bolt manufacturers. Here’s a table that shows their main features, certifications, and product range:

Manufacturer | Certifications | Product Range | Unique Selling Points |

|---|---|---|---|

PowerFul Machinery | ASTM, ISO | Chains, hooks, shackles, eye nuts | Direct pricing, custom solutions |

Crosby Group | ISO, ASME | Forged eye bolts, rigging hardware | Fatigue-rated, strong support |

RUD Group | ISO 9001, EN | Bolt-on, weld-on, quick-mount points | Crack-tested, ergonomic design |

YOKE Industrial Corp. | ISO 9001, API Q1, EN | Eye bolts, self-locking hooks | Grade 100 compatibility |

Chicago Hardware & Fixture | ASTM | Forged eye bolts, blank/threaded | Made in USA, 5:1 safety factor |

J.W. Winco | International | Stainless steel, swivel eye bolts | Safety swivel, fast delivery |

KD Fasteners | ASTM | Bent/forged eye bolts, custom sizes | Large inventory, quick turnaround |

Murphy Lift | ISO 9001, ASTM | Forged, stainless, swivel, custom | Safety focus, global shipping |

Strengths Summary

You get different strengths from each manufacturer. PowerFul Machinery gives you direct pricing and custom engineering. Crosby Group offers fatigue-rated products and strong technical support. RUD Group stands out with crack-tested lifting points and ergonomic designs.

YOKE Industrial Corp. delivers Grade 100 compatibility and self-locking hooks. Chicago Hardware & Fixture Company provides American-made bolts with high safety factors.

J.W. Winco brings you safety swivel options and quick delivery. KD Fasteners helps with custom sizes and keeps a large inventory. Murphy Lift focuses on safety and reliable global shipping.

Tip: Choose the manufacturer whose strengths match your project needs. You save time and avoid problems when you pick the right partner.

Locations Overview

You want to know where these companies operate. Powerful Machinery ships worldwide and has a strong export network. Crosby Group has distribution in North America, Europe, and Asia. RUD Group covers Europe, Asia, and North America.

YOKE Industrial Corp. works with global partners for wide availability. Chicago Hardware & Fixture Company ships across North America and internationally. J.W. Winco serves North America and Europe.

KD Fasteners delivers across North America and beyond. Murphy Lift works with distributors in North America, Europe, and Asia.

You can find lifting eye bolt manufacturers almost anywhere. This makes it easier for you to get the products you need, fast.

How to Choose Lifting Eye Bolt Manufacturers?

Quality & Standards

You want lifting eye bolts that keep your team safe and your equipment running smoothly. Start by checking the manufacturer’s quality control process. Look for companies that use advanced production equipment and test every batch.

Reliable lifting eye bolt manufacturers will share details about their materials and safety ratings. If you see clear load limits and safety markings, you know the products meet tough standards.

Inspect product specifications for load ratings.

Ask about the manufacturer’s testing procedures.

Choose companies with a reputation for strong, durable hardware.

Tip: Always match the eye bolt’s load rating to your project needs.

Certifications

Certifications show you which manufacturers take safety seriously. Look for ISO, ASTM, or EN certifications. These prove the company follows strict rules for quality and safety. Certified lifting eye bolt manufacturers help you pass inspections and meet project requirements.

Certification | What It Means |

|---|---|

ISO | Consistent quality |

ASTM | Material safety |

EN | European standards |

Note: Ask for certification documents before you buy.

Customization

Every project is different. You might need custom sizes, materials, or finishes. The best lifting eye bolt manufacturers offer custom engineering and design support. If you need something special, ask if the company can create a solution just for you.

Request custom sizes or materials.

Ask about design support from in-house engineers.

Support & Service

Good support makes your job easier. Choose manufacturers with fast customer service and strong logistics. You want help with technical questions, quick quotes, and reliable shipping. The right partner keeps your project on track.

Look for responsive customer service.

Check delivery times and logistics support.

Ask about after-sales help.

Tip: Reach out to the manufacturer’s support team before placing a big order.

Conclusion

You’ve seen the eight leading lifting eye bolt manufacturers and what makes each one stand out:

Powerful Machinery: Direct pricing, custom solutions

Crosby Group: Fatigue-rated hardware, strong support

RUD Group: Crack-tested, ergonomic design

YOKE Industrial Corp.: Grade 100 compatibility, self-locking hooks

Chicago Hardware & Fixture: Made in the USA, high safety factor

J.W. Winco: Safety swivel, fast delivery

KD Fasteners: Quick turnaround, custom sizes

Murphy Lift: Safety focus, global shipping

Ready to choose? Use the comparison table and tips above. Reach out for quotes or consultations to find the perfect fit for your project.

FAQ

What is a lifting eye bolt used for?

You use a lifting eye bolt to attach ropes, cables, or chains to heavy loads. This helps you lift or move equipment safely. You often see them in construction, shipping, and manufacturing.

How do I choose the right lifting eye bolt size?

Check your load weight first. Match the eye bolt’s rated capacity to your needs. Always read the manufacturer’s chart for size and load limits. If you’re unsure, ask the supplier for help.

Are lifting eye bolts reusable?

Yes, you can reuse lifting eye bolts if they show no signs of wear, corrosion, or damage. Always inspect them before each use. Replace any bolt that looks worn out or bent.

What certifications should I look for?

Look for certifications like ISO, ASTM, or EN. These show the manufacturer follows strict safety and quality standards. Certified products help you meet project requirements and pass inspections.

Can I get custom lifting eye bolts?

Absolutely! Many manufacturers offer custom sizes, materials, or finishes. If you need something special, just ask. Custom options help you get the perfect fit for your project.