Understanding sling angles in lifting operations is crucial for ensuring safe lifting and rigging practices. Sling angles have a direct effect on the tension in each sling leg and play a key role in determining the safety margin for every lift. When utilizing lifting slings at various angles, the tension experienced by each leg changes.

For instance, a 60° sling angle with a 2,000 lbs load results in 1,155 lbs of tension per sling leg, whereas a 30° angle generates a full 2,000 lbs of tension. Selecting the correct sling angle is essential for choosing the appropriate lifting slings and rigging equipment.

Powerful Machinery offers certified chain slings, slings & tie downs, round webbing slings, and flat web slings tailored for professional lifting and rigging requirements.

Sling Angle | Load (lbs) | Multiplier | Tension per Sling Leg (lbs) |

|---|---|---|---|

60° | 2,000 | 1.155 | 1,155 |

45° | 2,000 | 1.414 | 1,414 |

30° | 2,000 | 2.0 | 2,000 |

Key Takeaways

Understanding sling angles is vital for safe lifting. Keep angles above 30 degrees to reduce tension and prevent overload.

Calculate sling tension accurately using the formula: Tension per leg = Load ÷ (2 × sin(sling angle)). This ensures you stay within safe limits.

Regularly inspect slings for wear and damage. Always use certified equipment to enhance safety and efficiency during lifts.

Follow industry standards and guidelines from ASME and OSHA. Compliance helps prevent accidents and ensures safe rigging practices.

Utilize tools like digital inclinometers for precise angle measurements. Accurate measurements are crucial for maintaining safety during lifting operations.

Understanding Sling Angles in Lifting Operations

What is Sling Angle?

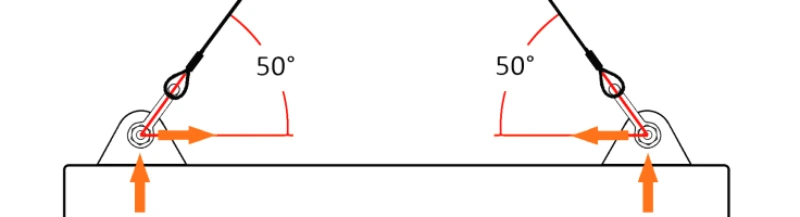

You encounter sling angles in lifting operations every time you attach a sling to a load. The sling angle is the angle formed between the horizontal plane of the load and the sling leg. Industry standards, such as those from ASME and OSHA, define this measurement precisely:

The angle of loading is the inclination of a leg or branch of a sling measured from the horizontal or vertical plane as shown in Fig. N-184-5; provided that an angle of loading of five degrees or less from the vertical may be considered a vertical angle of loading.

You measure the sling angle to determine how the force distributes through each sling leg. Smaller sling angles mean the legs are closer to horizontal, while larger angles bring the legs closer to vertical. This measurement is not just a technical detail—it directly affects the forces acting on your lifting equipment.

Why Sling Angles Matter for Safety?

Sling angles in lifting operations play a critical role in safety. When you decrease the sling angle, the tension in each sling leg increases. This extra tension puts more stress on the sling and can reduce the safety factor. If you use a sling at a low angle, you risk exceeding its rated capacity, which can lead to dangerous failures.

Consider the following table, which shows how sling angles affect tension and load stability:

Sling Angle | Effect on Tension | Effect on Load Stability |

|---|---|---|

Decreasing | Increases tension | Affects stability negatively |

Increasing | Decreases tension | Improves stability |

You should always remember these key points:

Sling angles form between the horizontal plane of the load and the sling.

Smaller angles require more force to lift the load, increasing stress on the sling.

The rated capacity of the sling decreases as the angle decreases.

Incorrect sling angles in lifting operations have led to serious accidents. Data shows that over 30% of rigging-related accidents result from improper sling usage. Investigations reveal that 87% of sling accidents with synthetic slings involve abuse or misuse.

Crane-related incidents, often linked to sling angle errors, have caused hundreds of fatalities in recent years. You must always check the sling angle to maintain a proper safety factor and prevent accidents.

Industry Standards and Powerful Machinery

Industry standards guide you in selecting safe sling angles in lifting operations. The American Society of Mechanical Engineers (ASME) and the Web Sling & Tie Down Association (WSTDA) provide charts and guidelines.

These resources show you how to match sling angles with the correct reduction factors for load capacity. You should keep sling angles above 30 degrees whenever possible to maintain a safe safety factor.

Powerful Machinery supports your commitment to safety. The company’s certified chain slings, slings & tie downs, round webbing slings, and flat web slings meet or exceed international standards. Each sling comes with clear labeling for working load limits and safety instructions.

You can rely on Powerful Machinery’s products to maintain the correct safety factor, even in demanding lifting environments. The brand’s dedication to quality ensures that you have the right tools for safe and effective rigging.

Tip: Always consult the product documentation and safety charts provided by Powerful Machinery. These resources help you select the right sling and maintain the proper sling angle for every lift.

Sling Angle Effects on Tension and Load Limits

Sling Angle and Tension Relationship

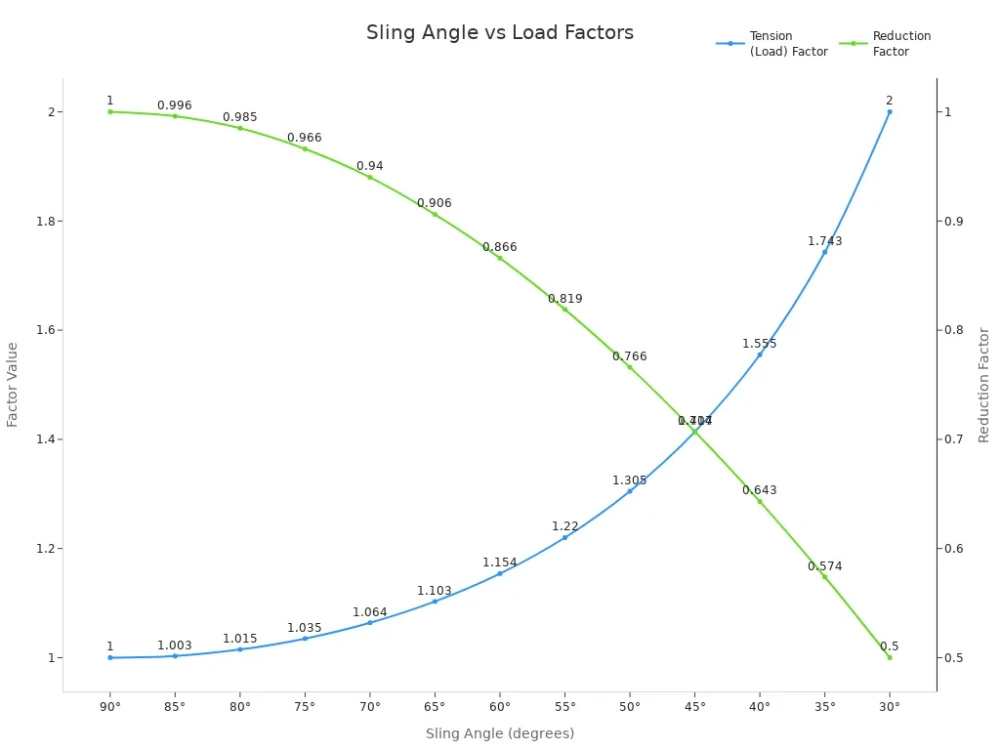

You need to understand how sling angles directly influence the tension in each sling leg. As the sling angle decreases from vertical, the tension in each sling increases. This relationship is critical for safe lifting. Here is what you should know:

The sling angle affects the load factor and the tension in each leg of the sling.

As the sling angle decreases, the tension in the sling increases.

The load factor is a multiplier that quantifies the increased tension due to the angle of the lift.

At a 90° angle, the load factor is 1, so no additional tension is considered.

At a 60° angle, the load factor rises to 1.154, which means greater tension on the sling.

You can see the impact of sling angles on tension in the table below:

Angle (degrees) | Tension Increase |

|---|---|

60 | 15% more |

45 | 41% more |

30 | Doubles |

If you use a sling at a 30° angle, the tension in each leg doubles compared to a vertical lift. This increase can quickly exceed the rated capacity of your sling.

Working Load Limit (WLL) and Reduction Factors

You must always check the working load limit before every lift. The working load limit is the maximum load that a sling can safely handle under specific conditions. As sling angles decrease, you need to apply reduction factors to the rated capacity. This adjustment ensures you do not overload the sling.

For example, a sling with a rated capacity of 2,000 lbs at 90° will have a much lower working load limit at 30°. Always refer to the manufacturer’s charts and documentation to determine the correct working load limits for your sling configuration.

Real-World Examples with Powerful Machinery Slings

Exceeding recommended sling angles can significantly increase stress on your rigging equipment. This stress may lead to load failures, serious injuries, or equipment damage. You can prevent these incidents by following best practices and using certified equipment.

Powerful Machinery slings comply with international standards, including EN 1492, DIN60005, and LOLER. These certifications guarantee that your slings maintain their rated capacity and working load limit, even when you face challenging lifting scenarios.

When you select Powerful Machinery slings, you ensure reliable performance and safety for every lift. Always consider the impact of sling angles on sling capacities and sling load capacity to protect your team and your equipment.

Sling Angle Calculation

Key Formulas and Multipliers

You need to understand the formulas behind sling angles to ensure safe lifting. The most common formula for calculating sling tension in a two-leg sling is:

Tension per sling leg = (Load ÷ (2 × sin(θ)))

where θ is the sling angle from the horizontal. For a more precise calculation, you can use the cosine of the angle:

WLL = 2 × WLL of a single leg × cos(β)

Here, β is the angle between the sling leg and the vertical. The load factor increases as the sling angle decreases, which means the tension in each sling leg rises. Always use the correct multiplier for your sling angle to calculate the tension accurately.

Step-by-Step Calculation Process

Calculating sling angles on site helps you avoid overloading your equipment. Follow these steps for a safe lift:

Measure the length of the sling leg (L) and the height from the load to the lifting point (H).

Calculate the sling angle using θ = arcsin(H/L).

Use a digital inclinometer or angle finder to verify the angle.

Find the load factor for your sling angle from a chart or table.

Multiply the load by the load factor to calculate the tension in each sling leg.

Adjust the working load limit based on the reduction factor for your sling angle.

Tip: Always verify the load weight and center of gravity before lifting. Consult the sling manufacturer’s documentation for specific guidance and ensure compliance with safety standards.

Using Charts and Tools

Charts and digital tools make sling angle calculation easier and more accurate. You can reference tables that show the relationship between sling angles, tension factors, and reduction factors:

Sling Angle | Tension (Load) Factor | Reduction Factor |

|---|---|---|

90° | 1 | 1 |

60° | 1.154 | .866 |

45° | 1.414 | .707 |

30° | 2 | .5 |

Powerful Machinery’s product documentation provides clear tables and design factors for each sling type. For example, a two-leg sling has a design factor of 1.4 for angles between 0-45 degrees and 1.0 for 45-60 degrees. This information helps you calculate sling angles and select the right sling for your load.

Always use these resources to ensure you calculate the tension correctly and maintain safe lifting operations.

Measuring Sling-to-Load Angle on Site

Tools and Techniques for Accurate Measurement

You must measure the sling-to-load angle accurately to ensure safe lifting. Several tools help you achieve precise results. Digital inclinometers provide direct angle readings. Mobile apps, such as Rigging Calculator Tool (iOS) and LEO Rigging Calculator (Android), offer quick calculations for sling tension, length, and angle.

These tools help you verify the sling-to-load angle before every lift.

Tool Name | Platform | Features |

|---|---|---|

Rigging Calculator Tool | iOS | Accurate sling tension, length, and angle calculations |

LEO Rigging Calculator | Android | Quick solutions for everyday rigging calculations |

Sling Load Calculator | Android | Accurate sling tension, length, and angle calculations |

Rigging Calculator | iOS | Calculates basic rigging, weights, and centers of gravity |

2-Axis Ultra Precision Inclinometer | N/A | Provides precise angle measurements with a USB link to PC |

Tip: Always use a calibrated tool to measure sling angles. This practice helps you maintain safety and avoid overloading the sling.

Handling Unequal Sling Lengths

Unequal sling lengths can create unsafe lifting conditions. You should always use slings of identical construction and proper sling length to keep the load balanced. If you cannot match sling lengths, rig an adjustable hitch on the heavy end.

This technique lets you balance the load before lifting. Once the load is applied, the hitch locks in place and keeps the load stable.

Guideline | Description |

|---|---|

Use identical slings | When rigging multiple slings, ensure they are of the same construction and length to maintain balance during lifting. |

Avoid rotation | Single-part hand-spliced slings should not rotate when rigged vertically to prevent splices from unlaying, which can lead to load dropping. |

Technique | Description |

|---|---|

Adjustable hitch | When exact length slings are unavailable, rig an adjustable hitch on the heavy end to balance the load before lifting. Once loaded, the hitch locks in place for the lift. |

Note: Always inspect each sling for wear and confirm the working load limit before use. Powerful Machinery provides detailed product documentation to help you select the right sling for every lift.

Qualified Personnel and Responsibilities

Only qualified personnel should measure sling-to-load angle and verify rigging setups. You need proper training to understand sling angles, load distribution, and safe lifting practices. Training programs, such as Competent Rigger Level 1 and Level 2, cover sling angle calculations and tension analysis.

Qualified Signal Person training ensures you can communicate and direct lifts safely.

Training Program | Duration | Testing Included | Description |

|---|---|---|---|

Competent Rigger Level 1 | 1 Day | Yes | Covers basic to intermediate rigging applications, including sling angle calculations. |

Competent Rigger Level 2 | 2 Days | Yes | Involves advanced rigging applications, including tension calculations based on sling angles. |

Qualified Signal Person | 1 Day | Yes | Training includes a practical exam to satisfy OSHA requirements. |

NCCCO Rigger Level 1 | 2 Days | No | Focuses on basic rigging without testing. |

NCCCO Rigger Level 2 | 2 Days | No | Advanced rigging training without testing. |

NCCCO Signal Person | 1 Day | No | Training without testing, focusing on the signal person’s’s responsibilities. |

Powerful Machinery supports your training needs with technical resources and expert guidance. You can access support materials and product documentation to help you measure sling-to-load angle correctly and maintain safe lifting operations.

Sling Angles and Hitch Types

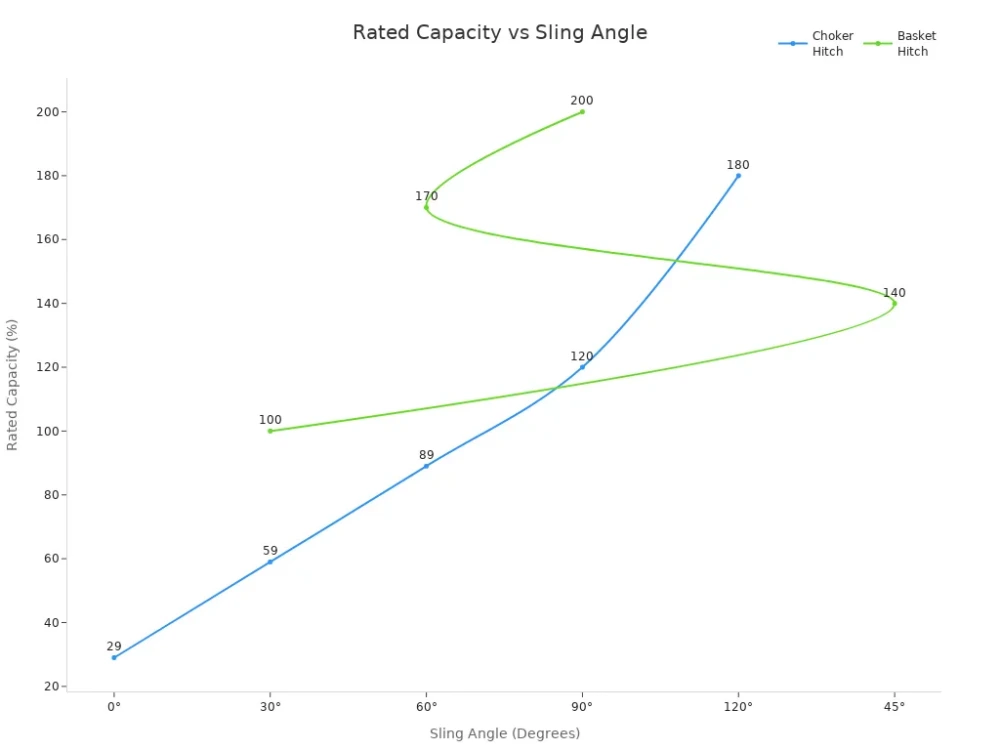

Basket Hitch and Sling Angle

You often use a basket hitch when you need to double the lifting capacity of your sling. This hitch wraps the sling under the load, creating two points of contact. The angle at which you set the sling legs affects the actual lifting capacity.

As the sling angle decreases, the tension in each leg increases, which reduces the effective capacity. For example, a basket hitch at a 90-degree angle can support up to 200% of the sling’s rated capacity.

When the angle drops to 30 degrees, the capacity falls to 100%. You must always check the sling angle before lifting to avoid overloading.

Choker Hitch and Reduction Factors

A choker hitch tightens the sling around the load, making it ideal for securing irregular shapes. However, the sling angle plays a major role in determining how much weight you can safely lift. As the angle decreases, the rated capacity drops sharply.

At 120 degrees, a choker hitch can handle 180% of the sling’s rated capacity. At 30 degrees, it drops to only 59%. The table below shows how different hitch types respond to changes in sling angle:

Hitch Type | Angle (Degrees) | Rated Capacity Percent |

|---|---|---|

Choker Hitch | 120° | 180% |

Choker Hitch | 90° | 120% |

Choker Hitch | 60° | 89% |

Choker Hitch | 30° | 59% |

Choker Hitch | 0° | 29% |

Basket Hitch | 90° | 200% |

Basket Hitch | 60° | 170% |

Basket Hitch | 45° | 140% |

Basket Hitch | 30° | 100% |

Note: Always refer to the sling manufacturer’s charts and documentation to confirm safe working limits for each hitch type.

Multi-Leg and Four-Leg Sling Configurations

Multi-leg and four-leg sling assemblies allow you to lift large or awkward loads with greater stability. The sling angle between each leg and the load directly affects the tension in every sling. As the angle decreases, the tension increases, which can reduce the working load limit.

You should always keep the sling angle above 30 degrees to maintain safety. Powerful Machinery offers chain slings, round webbing slings, and flat web slings designed for multi-leg configurations. Each sling comes with clear labeling and documentation to help you select the right setup for your lift.

Proper sling selection and angle measurement ensure you achieve a safe and efficient rigging operation every time.

Safe Rigging Practices with Powerful Machinery

Maintaining Safe Sling Angles

You must maintain safe sling angles to protect your team and equipment during every lift. Following best practices for lifting slings helps you reduce risks and prevent workplace fatalities. Use these steps to keep sling angles within safe limits:

Inspect your sling before every lift. Remove any sling showing damage.

Never modify or tie knots in a sling. Use only manufacturer-approved configurations.

Keep sling legs straight. Avoid kinks that reduce load-carrying capacity.

Stay within the rated working load limit. Never exceed the sling’s capacity.

Balance the basket hitches to prevent the shifting of the load.

Secure every connection between the sling, load, and lifting hook.

Protect slings from sharp edges using guards or padding.

Clear the lift zone of obstructions.

Keep personnel out of the danger zone under suspended loads.

Use tools, not hands, to position slings.

Lift slowly to avoid shock loads.

Never drag or yank slings. Lift the load fully before removing the sling.

Maintaining proper sling angles is essential for safe lifting practices. You help prevent non-fatal workplace injuries and ensure efficient rigging operations.

Equipment Selection and Inspection

Selecting the right sling and rigging hardware is vital for safety. You must consider the load’s weight, shape, and sling angles. Always verify the working load limits and inspect slings for wear, cuts, or deformation before each use.

Choose slings made from high-strength materials, such as Powerful Machinery’s chain slings, round webbing slings, and flat web slings. These products meet international standards and provide reliable performance for every lift.

Check rigging hardware, including hooks and shackles, for wear and proper rating.

Follow manufacturer guidelines for inspection intervals and sling usage.

Ensure proper sling angles and balanced loads throughout the lift.

Avoiding Common Mistakes

You can avoid common mistakes by staying alert and following safe lifting practices. Improper use of slings, incorrect sling selection, and poor sling angles often lead to accidents. A horizontal sling angle of 30 degrees doubles the tension on the sling, increasing the risk of failure.

Most synthetic sling accidents result from misuse, so proper training and equipment selection are critical.

Always use the correct sling for the load.

Maintain proper sling angles to avoid excessive tension.

Never ignore signs of wear or damage.

Regulatory Compliance and Best Practices

Regulatory standards require you to calculate sling angles accurately and maintain safe rigging practices. The table below shows how the rigging angle affects load tension:

Rigging Angle | Effect on Load Tension |

|---|---|

Decreased | Increases exponentially |

Proper Calculation | Essential for safety |

You must comply with OSHA, ASME, and international standards when using lifting slings. Powerful Machinery’s certified products help you meet these requirements and maintain a safe work environment. Always consult product documentation and safety charts to ensure compliance and protect your team.

Tip: Regular inspection and adherence to standards keep your rigging operations safe and efficient.

Critical Lifts and Advanced Planning

Lifting with Angles Below 30 Degrees

You face unique challenges when performing a lift with sling angles below 30 degrees. The tension in each sling leg can exceed the vertical capacity, which may result in overload. For example, a sling at a 30-degree angle can experience forces up to 10,000 pounds per leg, doubling the risk of failure.

You must conduct an engineering review before attempting these critical lifts. Always follow manufacturer guidelines, as the rated capacity of the sling decreases sharply with lower sling angles. Careful calculations and strict adherence to safety procedures protect your team and equipment during these demanding operations.

Note: Never ignore the impact of sling angles on the rated capacity. You should always consult with a qualified engineer before proceeding with a lift involving extreme angles.

Using Spreader Bars and Alternatives

You can maintain safe sling angles by using spreader bars or similar devices. Spreader bars distribute the weight of heavy loads across multiple points, converting lifting forces into compression.

This design increases stability and prevents damage to both the load and the rigging equipment. You keep slings at or near a 90-degree angle, which helps you handle oversized loads safely.

Spreader bars increase load stability during overhead lifts.

They allow you to manage heavy-duty cargo that might break under a single connection point.

This setup reduces the risk of slings sliding off the load during a lift.

You should consider spreader bars whenever you need to maintain optimal sling angles and protect your rigging hardware.

Documentation and Lift Plan Approval

You must prepare a Critical Lift Plan for any lift involving sling angles below 30 degrees. This plan requires approval from a qualified person, as outlined in ASME B30.9. You need to verify that the rated load of your rigging equipment matches the number of sling legs, the hitch configuration, and the effects of sling angles.

Professional guidance is essential, especially when the full weight of the load is unknown. Improper rigging and unexpected load movement demand a thorough assessment before you begin the lift.

Documentation Step | Requirement |

|---|---|

Critical Lift Plan | Approval by a qualified person |

Equipment Rating | Adequate for sling legs and hitch configuration |

Professional Assessment | Required for unknown load weights |

Rigging Review | Necessary for complex lifts |

Tip: Always document your lift plan and seek expert approval for challenging lifts. Powerful Machinery offers custom-engineered solutions and technical support to help you meet safety standards for every lift.

Conclusion

You improve safe lifting operations by understanding how sling angles affect every sling. When you pay attention to the sling angle, you extend the lifecycle of each sling and maintain the working load limit. You avoid equipment failure by managing the force on every sling and rigging hardware.

Regular inspection and ongoing training help you use each sling efficiently and safely. Powerful Machinery’s certified sling products support your commitment to safe lifting operations. For expert guidance and product support, visit the Powerful Machinery website.

Key takeaways for sling safety:

Sling angle awareness protects employees.

Sling tension management prevents overloading.

Sling selection and inspection enhance job efficiency.

FAQ

What is the safest sling angle for lifting operations?

You should keep sling angles above 30 degrees. Angles below 30 degrees increase tension and risk of overloading the sling. Always check manufacturer guidelines and use certified equipment from Powerful Machinery for safe lifting.

How do I calculate the tension in each sling leg?

Use this formula:

Tension per leg = Load ÷ (2 × sin(sling angle))

You can also reference the sling angle charts provided in Powerful Machinery’s documentation for quick calculations.

Why does the sling angle affect working load limit (WLL)?

A smaller sling angle increases the tension in each leg. This reduces the effective WLL. Always adjust your calculations and select slings rated for the increased tension at lower angles.

Can I use Powerful Machinery slings for multi-leg configurations?

Yes. Powerful Machinery offers chain slings, round webbing slings, and flat web slings designed for single, double, triple, and quadruple leg setups. Each product includes clear labeling and documentation for safe multi-leg rigging.