You work in environments where lifting sling inspection and safety can mean the difference between a routine day and a catastrophic incident. Sling failures risk lives and disrupt operations, especially when professionals do not follow strict compliance requirements.

Leading international standards, such as IMCA Guidelines in marine, DNV-GL in maritime, and API RP 2D in oil and gas, demand regular inspections and certified equipment.

Standard/Guideline | Industry | Key Compliance Requirements |

|---|---|---|

IMCA Guidelines | Marine | Regular inspections, proper storage, and handling practices |

DNV-GL Standards | Maritime | Certification, safety, and performance criteria |

API RP 2D | Oil & Gas | Regular inspections, rigging practices, and load testing |

ATEX Certification | Oil & Gas | Compliance for explosive atmospheres |

FAA Regulations | Aerospace | Precision, accuracy, and strict safety protocols |

NADCAP Accreditation | Aerospace | Certification for safety and quality standards |

Powerful Machinery stands with you by providing certified lifting solutions trusted worldwide. You depend on reliable products and proven safety to protect your team and your investments.

Use the included checklist and procedures to help ensure compliance and maintain a safe workplace.

Key Takeaways

Regular sling inspections are crucial for safety. Inspect slings before each use to prevent accidents and ensure compliance with safety standards.

Understand the types of slings available. Choose the right sling based on load characteristics and environmental conditions to maximize safety and efficiency.

Follow strict maintenance protocols. Clean and store slings properly to extend their lifespan and prevent damage from environmental factors.

Document all inspections and repairs. Accurate recordkeeping supports compliance and helps track the safety status of your lifting equipment.

Invest in ongoing training for your team. Regular training on sling inspection and safety practices reduces risks and enhances workplace safety.

Why Sling Inspection and Safety Matter?

Risks of Sling Failure

You face many risks when lifting equipment is not properly inspected. Abrasion and surface wear weaken slings when dragged across rough surfaces. Corrosion and chemical exposure in wet or hazardous environments increase the chance of failure.

Kinking, crushing, and bending from improper handling create structural weaknesses. Overloading and poor load distribution can cause sudden breaks. Fatigue and wire strand breaks develop after repeated use. Improper attachment and rigging practices lead to slippage and dangerous situations.

Extreme temperatures also compromise sling performance. These risks threaten both your safety and the integrity of your operations.

Legal and Regulatory Standards

You must follow strict regulations to ensure safe lifting practices and compliance. The table below summarizes key standards for lifting sling inspection and safety:

Regulation/Standard | Description |

|---|---|

PUWER | Equipment must be suitable, maintained, and operators trained. |

LOLER | Requires thorough examinations every 6-12 months by a competent person. |

BS EN 13155 | Sets requirements for non-fixed lifting attachments. |

BS EN 818 | Details specifications for chain slings. |

BS EN 1492 | Outlines textile sling standards for lifting operations. |

Regular inspection and maintenance schedules are essential. You should conduct pre-use checks for visible damage and follow manufacturer guidelines for routine maintenance. Powerful Machinery’s products meet or exceed these international standards, supporting your commitment to safety and compliance.

Prevention vs Consequences

You protect lives and assets when you prioritize sling inspection. Neglecting inspections can result in catastrophic failures, severe injuries, and fatalities. Regular preventive maintenance ensures operational integrity and reduces risk.

Skipping inspections may cause substantial economic losses from equipment damage and legal issues. Routine sling inspection prevents dangerous failures, saves lives, and lowers costs related to accidents. Investing in safe lifting practices and maintenance helps you avoid long-term financial losses.

Prevention is always more effective than dealing with the consequences of neglect.

Tip: Consistent lifting sling inspection and safety practices keep your workplace secure and compliant with regulations.

Types of Lifting Slings

You encounter several types of slings in construction, marine, and industrial settings. Each offers unique benefits for specific lifting tasks. Understanding the differences helps you select the right lifting slings for your operations and maintain workplace safety.

Chain Slings

Chain slings deliver unmatched strength and durability. You use them for lifting steel beams, concrete slabs, and heavy foundry work. Their high-strength steel alloy construction resists cutting and abrasion, making them ideal for harsh environments.

Chain slings can last up to 40 years in service. You benefit from their adjustable configurations and temperature tolerance, which outperform synthetic options. Powerful Machinery’s certified chain slings provide reliable performance for demanding industries.

Tip: Chain slings excel in environments with sharp edges or abrasive surfaces due to their superior strength and resistance.

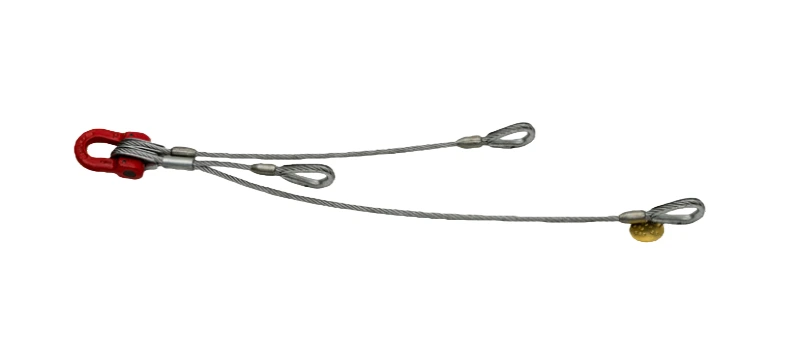

Wire Rope Slings

Wire rope slings offer flexibility and strength for heavy lifting. You rely on them in construction, shipping, and engineering applications. Their intricate woven structure makes them less likely to break and able to endure abrasive wear. Wire rope slings bend without distortion and resist kinking.

You can reuse master links and hooks, which adds value to your operations.

Advantages of Wire Rope Slings | Limitations of Wire Rope Slings |

|---|---|

Lightweight and flexible | Low strength-to-weight ratio |

Endures abrasive wear | Difficult to inspect |

Resistant to kinking | Damaged slings cannot be repaired |

Reusable components | Needs specific lubrication |

Powerful Machinery’s wire rope slings meet international standards and deliver consistent strength for your lifting needs.

Round Webbing Slings

Round webbing slings provide gentle strength for lifting pipes, fragile loads, or irregularly shaped objects. You use them in manufacturing, warehousing, and logistics.

Their polyester construction offers low elongation and high durability. Color-coded labels help you identify load capacity quickly. Powerful Machinery’s round webbing slings comply with EN 1492-1 and EN 1492-2 standards and feature CE certification.

Certification Standard | Label Color | CE Mark |

|---|---|---|

EN 1492-1 | Blue | Yes |

EN 1492-2 | Blue | Yes |

Note: Regular inspection ensures your round webbing slings maintain their strength and safety.

Flat Web Slings

Flat web slings deliver versatile strength for lifting glass panels, prefabricated materials, and light machinery. You benefit from their wide design, which distributes weight evenly and reduces pressure on delicate loads. Flat web slings resist abrasion and UV degradation, making them suitable for outdoor use.

Powerful Machinery’s flat web slings meet ASME B30.9 standards and offer reinforced eyes for added durability.

You use lifting slings in:

Construction projects for steel beams and concrete blocks

Warehousing for pallets and heavy containers

Shipping for hoisting cargo onto vessels

Manufacturing for handling delicate parts

Selecting the right types of slings ensures you maximize strength, safety, and efficiency in every lift.

Lifting Sling Inspection and Safety Requirements

Key Standards (ASME, EN, ISO)

You must follow strict standards to ensure lifting sling inspection and safety in your workplace. These standards set the foundation for compliance and safe operations. The ASME B30.9-2021 standard outlines requirements for fabrication, attachment, use, inspection, testing, and maintenance of slings.

It covers alloy steel chain, wire rope, and synthetic fiber slings. The standard includes new definitions, updated proof test requirements, and guidance on sling protection.

Standard | Description |

|---|---|

ASME B30.9-2021 | Requirements for fabrication, use, inspection, and maintenance of slings for load-handling purposes. |

EN 1492 | European standard for textile slings, including webbing and round slings. |

ISO 9001 | International standard for quality management and compliance in manufacturing processes. |

You rely on Powerful Machinery’s products because they meet or exceed these global standards. Their certified lifting solutions help you maintain compliance and safety in every lift.

Employer and Inspector Responsibilities

You play a critical role in maintaining compliance and safety. Employers must ensure all lifting equipment is in working order. Inspectors conduct initial inspections to verify compliance before use.

You must perform frequent inspections daily or before each shift. If you detect damage, remove the sling from service immediately.

Inspection Type | Responsibility |

|---|---|

Initial Inspection | A qualified person ensures compliance with standards before use. |

Frequent Inspection | User or designated person inspects daily or before each shift. |

Damage Assessment | Remove damaged slings from service and recommend repairs by qualified engineers. |

Carry out checks to confirm equipment is safe.

Complete paperwork according to industry specifications.

Follow health and safety regulations at all times.

Inspection Intervals and Frequency

You must inspect lifting slings before each use. Monthly inspections are required for equipment under severe service conditions. For normal service, conduct yearly inspections.

Severe service demands monthly to quarterly inspections. Special service requires inspections as recommended by a qualified person. OSHA and HSA guidelines mandate periodic inspections every 6 to 12 months.

Inspect slings before each use.

Monthly inspections for severe service.

Yearly inspections for normal service.

Quarterly inspections for equipment exposed to harsh conditions.

Remove any sling from service if you find damage.

Tip: Consistent inspection and compliance with asme standards protect your team and ensure safe lifting operations.

Sling Inspection Procedure and Checklist

You must follow a thorough sling inspection procedure to maintain safety and compliance in your workplace. Use the following sling inspection checklist for each sling type to ensure every lift meets industry standards.

Powerful Machinery’s products feature clear labeling and traceability, making your inspection process more efficient and reliable.

Chain Sling Inspection

A chain sling inspection requires careful attention to detail. You should always start with a pre-use check and follow these steps:

Clean the chain sling before you begin the inspection.

Check the identification tag. Make sure it is legible and matches the working load limit.

Hang the chain sling or lay it flat in a well-lit area. Remove all twists and measure the sling length to confirm it has not stretched.

Inspect each link, master link, load pin, and hook:

Look for overall wear. Discard the sling if wear exceeds 15% of a link diameter.

Check for cuts, nicks, cracks, gouges, burns, or corrosion pits.

Ensure no links are closed up or stretched longer than normal. All links should hinge freely.

Examine hooks. Remove the sling if the hooks have opened more than 15% of the normal throat opening or twisted more than 10 degrees.

Record the manufacturer, type, load limit, and inspection dates in your documentation.

Tip: Powerful Machinery’s chain slings include durable identification tags and traceable serial numbers for easy recordkeeping.

Wire Rope Sling Inspection

Wire rope sling inspection focuses on detecting structural damage and wear. Use this sling inspection checklist before each use:

Look for distortion such as birdcaging, crushing, or kinking.

Check for heat damage. Inspect for fused wires or metallic discoloration.

Examine end attachments for cracks, bends, or broken fittings.

Inspect for corrosion. Replace the sling if you find severe rust.

Watch for pulled eye splices or signs of slippage.

Identify broken wires, abrasion, or any reduction in wire diameter.

Check for damage or displacement of hooks, rings, or links.

Note: Powerful Machinery’s wire rope slings feature robust end fittings and clear labeling to support traceability during inspection.

Synthetic and Web Sling Inspection

Synthetic and web sling inspection requires you to follow a structured sling inspection checklist. Refer to the table below for inspection types and descriptions:

Type of Inspection | Description |

|---|---|

Initial Inspection | Conduct before first use. Check specifications, working load limit, and look for damage. |

Frequent Inspection | Perform a visual inspection before each use. Identify potential damage or defects. |

Periodic Inspection | Have a qualified person inspect annually or as needed based on usage and conditions. |

During each inspection, check for:

Tears, cuts, frayed edges, or broken stitching.

Chemical damage or discoloration.

Illegible or missing identification labels.

UV damage or stiff, brittle areas.

Knots or twists in the sling.

Hardware and attachments for corrosion or deformation.

Tip: Powerful Machinery’s synthetic slings use color-coded labels and reinforced eyes for easy identification and enhanced durability.

Round Sling Inspection

Round sling inspection focuses on both the cover and the core yarns. Use this sling inspection checklist to ensure safety:

Confirm the sling identification label is present and legible.

Inspect for acid or caustic burns.

Look for evidence of heat damage.

Check for holes, tears, cuts, abrasive wear, or snags that expose the core yarns.

Examine for broken or damaged core yarns.

Identify weld splatter or discoloration.

Remove the sling if you find knots, except for core yarns inside the cover.

Inspect fittings for pitting, corrosion, cracks, bends, twists, gouges, or breaks.

Follow ASME B30.10 and B30.26 criteria for hooks and rigging hardware.

Criteria for Removal from Service |

|---|

Missing or illegible sling identification |

Acid or caustic burns |

Evidence of heat damage |

Holes, tears, cuts, abrasive wear, or snags that expose the core yarns |

Broken or damaged core yarns |

Weld splatter that exposes core yarns |

Knots in the round sling (except core yarns inside the cover) |

Fittings that are pitted, corroded, cracked, bent, twisted, gouged, or broken |

Other conditions that cause doubt as to the continued use of the sling |

Note: Powerful Machinery’s round slings feature CE certification and color-coded labels for quick load identification.

Removal and Quarantine Criteria

You must remove and quarantine any sling that fails the sling inspection checklist. Follow these criteria:

Severe corrosion or localized wear (look for shiny worn spots).

One-third reduction in outer wire diameter.

Damage or displacement of end-fittings, including hooks, rings, or links.

Distortion, kinking, birdcaging, or other evidence of damage to the wire rope structure.

Excessive broken wires.

Illegible or missing identification labels.

Holes, tears, cuts, or snags that expose core yarns in synthetic slings.

Acid or caustic burns, heat damage, or weld splatter.

Any condition that causes doubt about the continued safe use of the sling.

Always quarantine damaged slings immediately. Document the removal and notify your supervisor for further action.

A comprehensive lifting sling inspection and safety program depends on your commitment to using a detailed sling inspection checklist for every sling type. Powerful Machinery’s product labeling and traceability features help you maintain accurate records and ensure compliance with international standards.

Common Sling Failure Modes and Safety Actions

Understanding the most frequent failure modes helps you prevent accidents and maintain a safe workplace. Recognizing these signs during sling inspection allows you to take immediate action and avoid costly downtime.

Chain Sling Failure Signs

Chain slings face heavy use in demanding environments. You should watch for these common defects:

Defect Type | Description |

|---|---|

Gouged links | Indentations from heavy loads or impacts |

Heat Damage | Discoloration from high temperatures that weakens the chain |

Worn links | Reduced diameter at bearing points due to excessive use |

Other warning signs include:

Twisted or bent links from improper handling or overloading

Visible cracks or breaks from physical damage

Elongation or corrosion, especially at link connections

If you notice any of these issues, remove the sling from service right away.

Wire Rope Sling Failure Signs

Wire rope slings can fail in several ways. Look for these indicators during inspection:

Sign of Failure | Description |

|---|---|

Broken wires | More than six broken wires in one lay or more than two in standing ropes |

Diameter reduction | Loss of 5% or more in rope diameter |

Advanced corrosion | Visible rust or pitting |

Structural distortion | Birdcaging, kinking, or permanent deformation |

Damaged end terminations | Cracked, bent, or broken fittings |

Shock loading or overload | Evidence of sudden tension spikes |

Internal core failure | Abnormal flexibility or shrinkage |

Replace any wire rope sling showing these signs to ensure safety.

Synthetic and Web Sling Failure Signs

Synthetic and web slings are sensitive to damage. During inspection, check for:

Burns, melting, or charring

Broken or worn stitches in load-bearing areas

Cuts, snags, tears, or punctures

Knots anywhere in the sling

Distorted, cracked, or corroded fittings

Stiff, brittle, or discolored areas

Missing or illegible identification

Remove any sling with these defects from service immediately.

Immediate Safety Actions

If you find any sign of failure during sling inspection, act quickly:

Remove the sling from service without delay

Replace damaged slings with certified, high-quality products

Document the issue and notify your supervisor

Schedule regular inspections to catch hazards early

Using certified slings from Powerful Machinery ensures you meet international safety standards and protect your team on every lift.

Best Practices for Sling Selection and Maintenance

Choosing the Right Sling

You improve safety and efficiency when you focus on the selection of slings for each lifting task. The best sling for the job depends on several factors. Consider the type of sling material, the environment, and the load characteristics. Chain slings work well in rugged environments and withstand high temperatures.

Nylon slings resist petroleum products but do not perform in acidic conditions. Wire rope slings offer durability and cost-effectiveness. Polyester slings handle common acids and lower temperatures. Assess the weight and configuration of the load, the center of gravity, and the presence of sharp edges.

Select the sling type and size that matches the working load limits and lifting angle. This approach ensures load protection and reduces the risk of damage.

Environment and exposure

Load weight and shape

Center of gravity

Sharp edges or irregular shapes

Tip: Powerful Machinery’s versatile product range covers every lifting scenario, offering certified solutions for construction, marine, and industrial applications.

Environmental and Load Considerations

You must evaluate environmental conditions and load characteristics before using any sling. Extreme temperatures require you to follow manufacturer guidance. Remove fiber-core slings from service if temperatures exceed 180°F (82°C).

Chemical exposure can weaken wire rope slings, so consult the manufacturer for compatibility. Mechanical damage often occurs from improper storage, moisture, or kinking. Store slings in clean, dry, and well-ventilated areas to prevent deterioration.

Environmental Condition | Effect on Sling Use |

|---|---|

Extreme Temperatures | Remove fiber-core slings above 180°F (82°C) |

Chemical Exposure | Consult the manufacturer; it can affect the strength of wire rope slings |

Mechanical Damage | Store slings to avoid damage, moisture, and kinking |

You protect your team and equipment when you match sling selection to the environment and load requirements.

Maintenance and Repair Protocols

You extend the life of your lifting equipment by following strict maintenance routines. Clean slings regularly with appropriate methods to prevent material degradation. Store slings in a dry, well-ventilated area away from moisture and temperature extremes.

Avoid exposing slings to harmful chemicals. Implement a sling management system to track sling history and train personnel in proper handling. Choose slings based on material properties and load capacities to enhance durability. Protect slings from sharp edges and ensure proper loading.

Invest in high-quality slings that meet industry standards for better performance. These best practices help you maintain safe operations and reduce downtime.

Regular cleaning

Proper storage

Avoiding chemical exposure

Sling management system

Training for personnel

Protecting from sharp edges

Quality selection

Note: Powerful Machinery’s certified products deliver durability and reliability, supporting your commitment to safety and maintenance excellence.

Workplace Systems for Sling Safety and Compliance

Creating a robust workplace system for sling safety and compliance requires you to implement clear procedures and reliable tools. You protect your team and maintain operational integrity when you use proven methods for tagging, documentation, and ongoing training.

Tagging and Traceability

Proper tagging of lifting equipment is essential for safety and efficiency. You rely on tags as visual indicators that display critical information about each item. Effective tagging practices help you prevent accidents and meet safety standards. Every tag should include:

Manufacturer or last repair entity

Material composition

Rated load for at least one hitch type and the sling angle

Individual identification, such as a serial number

You improve traceability by ensuring each sling has a unique tag. This system allows you to track inspection history and quickly identify equipment status. Powerful Machinery supports your efforts by providing products with durable tags and traceable serial numbers.

Recordkeeping and Documentation

Accurate recordkeeping forms the backbone of compliance. You must maintain written records for every sling, especially after repairs. These records should include:

Date and nature of repairs

Responsible person or organization

Certificate of proof testing for each repaired sling, confirming it was tested to twice its rated capacity

Certificates for welded end attachments, retained for examination

You organize these documents in a secure location for easy access during an audit. Reliable documentation helps you demonstrate compliance and supports workplace safety.

Training and Audits

Ongoing training ensures your team understands equipment, inspection, and maintenance procedures. You provide instruction on load calculations, rigging techniques, and safety protocols. Pre-lift planning and hazard assessment reduce risks and improve coordination.

You document all training sessions to prepare for audits and maintain compliance with OSHA regulations.

Regular audits verify that your procedures align with industry standards. You conduct pre-shift checks, evaluate operators, and review inspection records. These steps help you identify gaps and strengthen your safety program.

Powerful Machinery offers support for training and documentation, helping you build a culture of safety and accountability.

Tip: Consistent training and thorough audits keep your workplace safe and compliant.

Conclusion

You play a vital role in preventing accidents and ensuring compliance through regular lifting sling inspection and safety. Certified, high-quality slings from Powerful Machinery help you reduce risk and improve reliability.

Statistic | Impact |

|---|---|

60% of crane-related fatalities | Due to a rigging failure |

60% of fatalities from falling objects | Caused by failed rigging |

Using certified products lowers workplace risk.

Following inspection guidelines boosts safety and efficiency.

Audit your equipment, schedule professional inspections, and invest in ongoing training. Make lifting sling safety a core value in your workplace.

FAQ

How often should you inspect lifting equipment?

You should inspect lifting equipment before each use. Schedule periodic inspections every 6 to 12 months, depending on service conditions. Follow manufacturer recommendations and industry standards to maintain safety and compliance.

What signs indicate a sling needs replacement?

Look for visible damage, such as cuts, corrosion, broken wires, or missing identification tags. Remove the sling from service if you find any defects or if you doubt its integrity.

Can you repair damaged lifting slings?

You should never repair damaged lifting slings yourself. Replace any sling showing signs of wear or damage. Only use certified products that meet safety standards.

Why is recordkeeping important for sling safety?

Recordkeeping helps you track inspection dates, repairs, and proof testing. Accurate documentation supports compliance and ensures you use safe equipment for every lift.

What training do operators need for safe lifting?

Operators need training in equipment selection, inspection procedures, load calculations, and safe lifting practices. Regular training reduces risks and improves workplace safety.